Beruflich Dokumente

Kultur Dokumente

2009 03 Fatality Caused by Unloading The Wrong Chemical

Hochgeladen von

Harshad SolankiOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

2009 03 Fatality Caused by Unloading The Wrong Chemical

Hochgeladen von

Harshad SolankiCopyright:

Verfügbare Formate

http://www.aiche.org/CCPS/Publications/Beacon/index.

aspx

Messages for Manufacturing Personnel

Sponsored by CCPS Supporters

March 2009

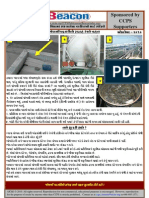

Fatality caused by unloading the wrong chemical into a storage tank!

A truck of sodium hydrosulfide solution arrived at a factory at about 3:30 AM, and was to be unloaded to a storage tank in the area near the top center of the diagram at the right. The truck driver had never been to the plant before, and asked the plant shift supervisor for assistance. The shift supervisor had been told to expect a chemical shipment, and assumed that the chemical would be ferrous sulfate, which is the only chemical that he had ever received on his shift. He directed the truck driver to the unloading station for ferrous sulfate, where the truck is shown in the diagram. The shift supervisor did not verify the identity of the chemical in the truck, although the shipping papers did properly identify the contents as sodium hydrosulfide. The supervisor signed the shipping papers without reading them and left the area. No plant employees remained in the unloading area. The truck driver connected his truck to a hose which was connected to the ferrous sulfate storage tank as shown in the photographs. He began to unload the sodium hydrosulfide solution into the ferrous sulfate tank. Unfortunately, sodium hydrosulfide and ferrous sulfate react to form hydrogen sulfide, a highly toxic gas. Shortly after the unloading began, a plant employee in the basement of the building noticed a pungent odor and lost consciousness. He regained consciousness and made his way outside where he got help from other employees, who called emergency response personnel. They found the truck driver unconscious inside the building, and he was pronounced dead at the scene. He was determined to have been overcome by hydrogen sulfide gas.

What can you do?

ALWAYS positively confirm the identity of any chemical which you add to any vessel. Check the identity of the material, double check it, and then check it again before beginning the chemical transfer! NEVER assume that you know the contents of any truck, railroad car, drum, or other raw material container which arrives at your plant without carefully checking all labels, vehicle placards, and shipping papers. Follow all of your plants procedures for identifying materials, which might include checking shipping papers, letters of analysis, or sampling and testing incoming materials. Ensure that all unloading personnel are trained and understand procedures. If unloading procedures do not exist at your facility, communicate the deficiency to your supervision. Remember that the consequences of accidently mixing incompatible chemicals can be severe including potential for explosion or generation of highly toxic materials. Be aware of potential hazardous reactions between chemicals stored at your facility. Consider use of special fittings and unloading connections to make unloading mistakes more difficult, helping to prevent them. Make sure that all unloading connections and pipes, as well as all storage tanks, are clearly labeled.

Never add any chemical to a vessel without confirming that it is the right material!

AIChE 2009. All rights reserved. Reproduction for non-commercial, educational purposes is encouraged. However, reproduction for the purpose of resale by anyone other than CCPS is strictly prohibited. Contact us at ccps_beacon@aiche.org or 646-495-1371.

The Beacon is usually available in Afrikaans, Arabic, Chinese, Danish, Dutch, English, French, German, Greek, Gujarati, Hebrew, Hindi, Hungarian, Indonesian, Italian, Japanese, Korean, Malay, Marathi, Norwegian, Persian, Portuguese, Russian, Spanish, Swedish, Tamil, Thai, Turkish, and Vietnamese.

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Beacon EnglishDokument1 SeiteBeacon EnglishselvajanarNoch keine Bewertungen

- 2008 11 Laboratory Refrigerator ExplosionsDokument1 Seite2008 11 Laboratory Refrigerator ExplosionsHarshad SolankiNoch keine Bewertungen

- Beacon GujaratiDokument1 SeiteBeacon GujaratiHarshad SolankiNoch keine Bewertungen

- Beacon GujaratiDokument1 SeiteBeacon GujaratiHarshad SolankiNoch keine Bewertungen

- 2008 09 Plant SecurityDokument1 Seite2008 09 Plant SecurityHarshad SolankiNoch keine Bewertungen

- 2009 04 Be PreparedDokument1 Seite2009 04 Be PreparedHarshad SolankiNoch keine Bewertungen

- Beacon EnglishDokument1 SeiteBeacon EnglishHarshad SolankiNoch keine Bewertungen

- Beacon HindiDokument1 SeiteBeacon HindiHarshad SolankiNoch keine Bewertungen

- Beacon GujaratiDokument1 SeiteBeacon GujaratiHarshad SolankiNoch keine Bewertungen

- Spill Containment BeaconDokument1 SeiteSpill Containment BeaconselvajanarNoch keine Bewertungen

- Beacon GujaratiDokument1 SeiteBeacon GujaratiHarshad SolankiNoch keine Bewertungen

- 2008 08 Beacon Measuring Process Safety PerformanceDokument1 Seite2008 08 Beacon Measuring Process Safety PerformanceHarshad SolankiNoch keine Bewertungen

- Beacon GujaratiDokument1 SeiteBeacon GujaratiHarshad SolankiNoch keine Bewertungen

- 2009 05 Mechanical IntegrityDokument1 Seite2009 05 Mechanical IntegrityHarshad SolankiNoch keine Bewertungen

- 2009 01 Fire While Filling Portable ContainerDokument1 Seite2009 01 Fire While Filling Portable ContainerHarshad SolankiNoch keine Bewertungen

- 2008-12-Beacon - Static Electric Discharge Causes Fire - December 2008Dokument1 Seite2008-12-Beacon - Static Electric Discharge Causes Fire - December 2008liveconnectionz282Noch keine Bewertungen

- 2008 04 Gasoline Pipeline Damaged by Construction Causes FireDokument1 Seite2008 04 Gasoline Pipeline Damaged by Construction Causes FireHarshad SolankiNoch keine Bewertungen

- 2008 07 What Is Process SafetyDokument1 Seite2008 07 What Is Process SafetyHarshad SolankiNoch keine Bewertungen

- Dust Explosion 2008 05 BeaconDokument1 SeiteDust Explosion 2008 05 BeaconHaresh PatelNoch keine Bewertungen

- 2008 03 Do Your Shutoff Systems Actually WorkDokument1 Seite2008 03 Do Your Shutoff Systems Actually WorkHarshad SolankiNoch keine Bewertungen

- 2008 10 Ice Ruptures Causes FireDokument1 Seite2008 10 Ice Ruptures Causes FireHarshad SolankiNoch keine Bewertungen

- 2008 06 Halon Cylinder Becomes RocketDokument1 Seite2008 06 Halon Cylinder Becomes RocketHarshad SolankiNoch keine Bewertungen

- 2008 02 How Can You Use The BeaconDokument1 Seite2008 02 How Can You Use The BeaconHarshad SolankiNoch keine Bewertungen

- 2008 01 2007 Beacon Review - Remember The Lessons LearnedDokument1 Seite2008 01 2007 Beacon Review - Remember The Lessons LearnedHarshad SolankiNoch keine Bewertungen

- Oil Tank Fire Caused by Static Discharge: Sponsored by Ccps SupportersDokument1 SeiteOil Tank Fire Caused by Static Discharge: Sponsored by Ccps SupportersNarasimmaraj NagarajanNoch keine Bewertungen

- 2007 11 Cold Embrittlement and Thermal StressDokument1 Seite2007 11 Cold Embrittlement and Thermal StressHarshad SolankiNoch keine Bewertungen

- 2007 10 We Have LiftoffDokument1 Seite2007 10 We Have LiftoffHarshad SolankiNoch keine Bewertungen

- 2007 08 Hazards of Temporary Confined SpacesDokument1 Seite2007 08 Hazards of Temporary Confined SpacesHarshad SolankiNoch keine Bewertungen

- 2007 09 Hot Work PermitsDokument1 Seite2007 09 Hot Work PermitsHarshad SolankiNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Corby AndersonDokument127 SeitenCorby AndersonDouglas Vásquez SandovalNoch keine Bewertungen

- Newton Interviews Bell Copper On KabbaDokument31 SeitenNewton Interviews Bell Copper On KabbaPeter BellNoch keine Bewertungen

- Silver CompoundsDokument26 SeitenSilver Compoundsamalathome8189Noch keine Bewertungen

- Caustic Scrubber Designs For Refinery GasesDokument26 SeitenCaustic Scrubber Designs For Refinery GasesdlmamrNoch keine Bewertungen

- Kinetics of ChalcopyriteDokument6 SeitenKinetics of ChalcopyriteMarcelo Sebastian HerreraNoch keine Bewertungen

- Huntress 1934, Nombre Luminol PDFDokument2 SeitenHuntress 1934, Nombre Luminol PDFfermin.saNoch keine Bewertungen

- Design of Queensland Road Infrastructure For High Risk EnvironmentsDokument7 SeitenDesign of Queensland Road Infrastructure For High Risk EnvironmentsAnonymous fS6Znc9Noch keine Bewertungen

- ACI For WaterproofingDokument7 SeitenACI For WaterproofingGhayas JawedNoch keine Bewertungen

- FCC Wash Water SystemsDokument16 SeitenFCC Wash Water SystemsBehnam RahzaniNoch keine Bewertungen

- Aalco Datasheet ST ST SpecificationsDokument5 SeitenAalco Datasheet ST ST Specificationsorea1Noch keine Bewertungen

- Tasbih Metarial Recovery From Mine Water EffluentDokument17 SeitenTasbih Metarial Recovery From Mine Water EffluentMaruf KhanNoch keine Bewertungen

- 08252016122551manual of ProcedureDokument305 Seiten08252016122551manual of ProcedureSuyog patilNoch keine Bewertungen

- Guidelines for Presulfiding STARS CatalystsDokument14 SeitenGuidelines for Presulfiding STARS CatalystsCarolina Cortes VazquezNoch keine Bewertungen

- Pse 476-6 Kraft Pulping ChemicalsDokument17 SeitenPse 476-6 Kraft Pulping ChemicalsMuhamad Norakmal OmarNoch keine Bewertungen

- Control of Corrosion and ScalingDokument63 SeitenControl of Corrosion and ScalingTalang AkarNoch keine Bewertungen

- Iron Sulfides - Effect On Amine PlantsDokument6 SeitenIron Sulfides - Effect On Amine PlantsHsien Yu100% (1)

- Level 2 - H2S CertificateDokument51 SeitenLevel 2 - H2S CertificateHadi HendizadehNoch keine Bewertungen

- Chemistry of FlotationDokument20 SeitenChemistry of FlotationAnonymous C0lBgO24iNoch keine Bewertungen

- Geoblast Drillhole DatabaseDokument200 SeitenGeoblast Drillhole DatabaseLuis Gustavo Choque BordaNoch keine Bewertungen

- SRB-BART Reaction PatternsDokument1 SeiteSRB-BART Reaction PatternszayedNoch keine Bewertungen

- Chemical SegregationDokument4 SeitenChemical SegregationLudy GiantoNoch keine Bewertungen

- The Life Assessment of API 5L Grade B Geothermal Pipeline in Correlation With Corrosion Under Insulation - JEPEDokument6 SeitenThe Life Assessment of API 5L Grade B Geothermal Pipeline in Correlation With Corrosion Under Insulation - JEPEJaya DiNoch keine Bewertungen

- Preparing Sulfur Prints For Macrostructural ExaminationDokument4 SeitenPreparing Sulfur Prints For Macrostructural Examinationwahyudi100% (1)

- Metals From Ores: 2. Scope of Extractive MetallurgyDokument48 SeitenMetals From Ores: 2. Scope of Extractive MetallurgyAdetiyo Burhanudin HakimNoch keine Bewertungen

- Phosphoric Acid Industry - Problems & SolutionsDokument18 SeitenPhosphoric Acid Industry - Problems & SolutionsRiyasNoch keine Bewertungen

- Zyme Flow Brochure11408Dokument2 SeitenZyme Flow Brochure11408himeshdarshan0% (1)

- Hydrogen Sulfide Treatment in WastewaterDokument9 SeitenHydrogen Sulfide Treatment in WastewaterAri CleciusNoch keine Bewertungen

- Use of Qualitative Chemical Spot Test Kits For Detection of Lead in Dry Paint FilmsDokument5 SeitenUse of Qualitative Chemical Spot Test Kits For Detection of Lead in Dry Paint FilmsEric GozzerNoch keine Bewertungen

- Spent Metal Catalyst 901Dokument16 SeitenSpent Metal Catalyst 901manipalaniusaNoch keine Bewertungen

- Chemical Resistance of Steel 13CrVDokument7 SeitenChemical Resistance of Steel 13CrVgk218Noch keine Bewertungen