Beruflich Dokumente

Kultur Dokumente

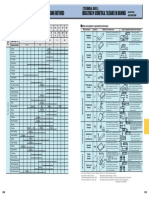

Surface Roughness by Different Processing Methods

Hochgeladen von

api-3848892Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Surface Roughness by Different Processing Methods

Hochgeladen von

api-3848892Copyright:

Verfügbare Formate

プレス

〔Technical Data〕 〔Technical Data〕

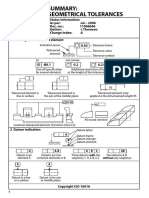

Surface Roughness by Different Processing Methods Indications of Geometrical Tolerance on Drawings Excerpt from

JIS B 0021(1984)

Arithmetical mean Kinds and Symbols of Geometrical Tolerances

0.025 0.05 0.1 0.2 0.4 0.8 1.6 3.2 6.3 12.5 25 50 100

roughness Ra Kind of tolerance Symbol Definition of tolerance zone Examples of diagrammatical indication and its interpretation

Maximum peak Ry 0.1 0.2 0.4 0.8 1.6 3.2 6.3 12.5 25 50 100 200 400 Where symbol φ is attached before the numerical φ0.08 Where a tolerance frame is connected to

Former Rmax. −S −S −S −S −S −S −S −S −S −S −S −S −S

value indicating a tolerance zone, this tolerance the dimension showing the diameter of a

designations Straightness zone is a zone in a cylinder of diameter t. cylinder, the axis of the cylinder shall be

φ

Standard values tolerance contained a cylinder of 0.08mm diameter.

φt

of of standard length 0.25 0.8 2.5 8 25

surface (mm) The tolerance zone is a zone held This surface shall be contained

roughness between two parallel planes a between two parallel planes

Triangular indication ▽▽▽▽ ▽▽▽ ▽▽ ▽ − 0.08

Flatness distance t apart. 0.08mm apart.

Forging Precision tolerance

t

Casting Precision t The tolerance zone in the considered 0.1 The circumference in any section

plane is a zone between two concentric normal to the axis shall be contained

Die casting Circularity circles a distance t apart. between two concentric circles

tolerance 0.1mm apart on the same plane.

Hot rolling Form

tolerance

t

The tolerance zone is a zone The considered surface shall be

Cold rolling contained between two coaxial 0.1 contained between two coaxial

Drawing Cylindricity cylinder surfaces a distance t apart. cylinder surfaces 0.1mm apart.

tolerance

Extruding

The tolerance zone is a zone held In any cross-section parallel to the projection

Tumbling between two lines enveloping circles of 0.04 plane the considered profile shall be contained

t

φ

Profile tolerance diameter t, the centers of between two lines enveloping circles of 0.04mm

Sandblasting

of line which are situated on a theoretically

exact profile line.

in diameter, the centers of which are situated on

a line having the theoretically exact profile.

Rolling

The tolerance zone is a zone held The considered surface shall be contained

between the two surfaces enveloping 0.02 between two surfaces enveloping the

Face cutter grinding Precision

Profile tolerance the spheres of diameter t, the centers spheres of diameter 0.02mm, the centers

Planing of surface t

Sφ of which are situated on a theoretically

exact profile surface.

of which are situated on a surface having

the theoretically exact profile.

Carving

(Slotting) The tolerance zone is a zone held 0.01 A The surface shown by the arrow of the leader

between two parallel planes parallel line shall be contained between two planes

t

Cutter grinding Precision Parallelism to the datum plane and a distance t parallel to the datum plane A and 0.01mm

Precision boring tolerance apart from each other. apart from each other in the direction of the

arrow of the leader line.

A

Filing Precision φt Where symbol φis attached before the numerical φ The axis of the cylinder shown by

φ0.01 A

Orientation value indicating the tolerance, the tolerance zone the arrow of the leader line shall

Round grinding Precision Fine Medium Rough Perpendicularity is a zone within a cylinder of diameter t be contained within a cylinder of

Working tolerance

tolerance perpendicular to the datum plane. diameter 0.01mm perpendicular

method Boring Precision A to the datum plane A.

t The tolerance zone is a zone held between 0.08 A The surface shown by the arrow of the leader line

Drilling two parallel planes inclined at the specified shall be contained between two parallel planes

Angularity

which are inclined at 40°with theoretical exactness

angle to the datum plane and a distance t 40°

Reaming Precision to the datum plane A and which are

α

tolerance apart from each other. 0.08mm apart from each other in the direction

Precision A of the arrow of the leader line.

Broach grinding

The tolerance zone is a zone within a circle or B φ0.03 AB The point shown by the arrow of the leader

Shaving line shall be contained within a circle of

t

sphere of diameter t having its center at the

Positional

0.03mm diameter having its center at the

60

theoretically exact location, hereinafter referred to true location 60mm and 100mm apart,

True

Grinding Precision Fine Medium Rough tolerance location as the“true location”.

100

A

respectively,from the datum straight line

A and from the datum straight line B.

Precision

Hone finishing Coaxiality Where symbol φ is attached before the numerical φ0.01 A The axis shown by the arrow of the

tolerance

A

φt

Super finishing Precision Location value indicating the tolerance, the tolerance zone leader line shall be contained within

or is a zone within a cylinder of diameter t whose a cylinder of 0.01mm diameter

tolerance concentricity axis agrees with the datum axial straight line. whose axis agrees with the

Buffing Precision

tolerance datum axial straight line A.

Paper finishing Precision The tolerance zone is a zone held between

0.08 A

The median surface shown by the arrow of

A

two parallel planes a distance t apart from the leader line shall be contained between

t

Lapping Precision Symmetry each other and arranged symmetrically about two parallel planes 0.08mm apart from

Liquid honing Precision tolerance the datum median plane. each other and arranged symmetrically

about the datum median plane A.

Measuring plane The tolerance is a zone between two concentric 0.1 A−B The run-out in the radial direction of the cylinder

Burnishing circles whose centers agree surface shown by the arrow of the leader line

t

with the datum axial straight line on any

Circular run-out

φ

shall not exceed 0.1mm on any measuring plane

φ

Surface rolling measuring plane normal to the datum axial normal to the datum axial straight line when the

Toleranced straight line and which are a distance t apart

tolerance surface from each other in the radial direction. cylinder is rotated by one rotation about the

Electric discharge carving Run-out A B datum axial straight line A-B.

tolerance The tolerance zone is a zone between two 0.1 A−B The total radial run-out of the cylinder surface

Wire cut electric spark coaxial cylinders having axes agreeing with shown by the arrow of the leader line shall not

Total run-out

φ

the datum axial straight line and a distance exceed 0.1mm at any point on the cylinder

Chemical polishing Precision surface when the cylinder part is rotated about

tolerance t apart from each other in the radial direction.

A B

the datum axial straight line A-B with a relative

movement in the axial direction.

Electrolytic abrasion Precision

Lines used in the drawings in the column of“definition of tolerance zone”indicate the following meanings:

Thick solid line or broken line:Feature Thin alternate long and short dash line:Center line

Thick alternate long and short dash line:Datum Thin alternate long and two short dashes line:Supplementary projection plane or sectional plane

Thin solid line or broken line:Tolerance zone Thick alternate long and two short dashes line:Projection of a feature to supplementary Projection plane or sectional plane

1129 1130

Das könnte Ihnen auch gefallen

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987Von EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonNoch keine Bewertungen

- Geometric Dimensioning & TolerancingDokument47 SeitenGeometric Dimensioning & TolerancingVinoth BalasubramaniyanNoch keine Bewertungen

- Guide to Load Analysis for Durability in Vehicle EngineeringVon EverandGuide to Load Analysis for Durability in Vehicle EngineeringP. JohannessonBewertung: 4 von 5 Sternen4/5 (1)

- Summary-Geometrical Tolerance - I - 07-2006 - Rev ADokument10 SeitenSummary-Geometrical Tolerance - I - 07-2006 - Rev AMhs EngineerNoch keine Bewertungen

- Geometric dimensioning and tolerancing Second EditionVon EverandGeometric dimensioning and tolerancing Second EditionNoch keine Bewertungen

- Geometric Dimensioning and TolerancingDokument6 SeitenGeometric Dimensioning and TolerancingPedro LeosNoch keine Bewertungen

- Latest Report 2Dokument13 SeitenLatest Report 2Piyush BariNoch keine Bewertungen

- Surface RoughnessDokument17 SeitenSurface RoughnessShanmugi VinayagamNoch keine Bewertungen

- Brochure Roundness BookletDokument12 SeitenBrochure Roundness BookletImm Yoon-AhNoch keine Bewertungen

- Is 2102Dokument8 SeitenIs 2102Sowmen Chakroborty100% (1)

- GD&TDokument10 SeitenGD&TShahed FacebookNoch keine Bewertungen

- Geometric Dimensioning and Tolerancing: Procedure / Drafting FNHA-3-B-072.00Dokument69 SeitenGeometric Dimensioning and Tolerancing: Procedure / Drafting FNHA-3-B-072.00003689% (9)

- GDandT Seminar ChennaiDokument89 SeitenGDandT Seminar Chennais ReddyNoch keine Bewertungen

- GD&TDokument70 SeitenGD&TKarthi KeyanNoch keine Bewertungen

- Geometric Dimensioning AND Tolerancing (GD & T) : Prepared by Jignesh PatelDokument13 SeitenGeometric Dimensioning AND Tolerancing (GD & T) : Prepared by Jignesh PatelunendratNoch keine Bewertungen

- ISO Tolerance Part 1 PDFDokument34 SeitenISO Tolerance Part 1 PDFRisira Erantha KannangaraNoch keine Bewertungen

- Geometrical TolerancingDokument12 SeitenGeometrical TolerancingItalo Venegas100% (1)

- Thread TolerancesDokument8 SeitenThread TolerancesLê Xuân HiệpNoch keine Bewertungen

- Gear Drawing PDFDokument12 SeitenGear Drawing PDFpradeep315Noch keine Bewertungen

- 2 Gear BasicsDokument6 Seiten2 Gear BasicsMohamed Adel RizkNoch keine Bewertungen

- General Tolerances For Linear and Angular Dimnsions (Din Iso 2768 t1)Dokument1 SeiteGeneral Tolerances For Linear and Angular Dimnsions (Din Iso 2768 t1)VIVEK UPADHYAYNoch keine Bewertungen

- Broaching PDFDokument7 SeitenBroaching PDFBalaji Karunakaran100% (1)

- Gears - Engineering InformationDokument138 SeitenGears - Engineering InformationGiang T LeNoch keine Bewertungen

- Metrology 1CDokument44 SeitenMetrology 1CRadhaMadhavNoch keine Bewertungen

- Geometrical Dimensioning and TolerenceDokument61 SeitenGeometrical Dimensioning and TolerenceAd Man GeTigNoch keine Bewertungen

- GD&T: Theory To Reality: Mission StatementDokument67 SeitenGD&T: Theory To Reality: Mission StatementCharlie Tej100% (1)

- Fos AsmeDokument41 SeitenFos AsmeMahender Kumar100% (1)

- Gear CorrectionDokument17 SeitenGear CorrectionMurugesanNoch keine Bewertungen

- FastenersDokument28 SeitenFastenersthulasi_krishnaNoch keine Bewertungen

- GD&TDokument33 SeitenGD&TDgreatarunNoch keine Bewertungen

- GDTDokument38 SeitenGDTAntonio CervantesNoch keine Bewertungen

- Tolerance For Press Work PDFDokument1 SeiteTolerance For Press Work PDFmr.nguyenkNoch keine Bewertungen

- SIE1010 Lesson 5.2 - Dimensioning and Tolerancing (Part 2)Dokument56 SeitenSIE1010 Lesson 5.2 - Dimensioning and Tolerancing (Part 2)lightsoul91Noch keine Bewertungen

- GD&TDokument14 SeitenGD&TsrajubasavaNoch keine Bewertungen

- 05 StraightnessMeasurement90Dokument90 Seiten05 StraightnessMeasurement90maddy_scribdNoch keine Bewertungen

- New GD&TDokument3 SeitenNew GD&TvasantNoch keine Bewertungen

- Tolerance AnalysisDokument10 SeitenTolerance Analysisdineshnexus100% (1)

- Lect22 Surface RoughnessDokument16 SeitenLect22 Surface RoughnessAnshul SharmaNoch keine Bewertungen

- Tolerance Stack Up Analysis What Is Stack Up Analysis?Dokument25 SeitenTolerance Stack Up Analysis What Is Stack Up Analysis?Venkadakrishnan ThiagarajanNoch keine Bewertungen

- GD&T QuestionsDokument3 SeitenGD&T Questionsbkattimani0% (1)

- Engineering Metrology and Measurements N.V. Raghavendra L. KrishnamurthyDokument26 SeitenEngineering Metrology and Measurements N.V. Raghavendra L. KrishnamurthyRandøm TalkìêsNoch keine Bewertungen

- Geometric Dimensioning and Tolerancing (GD&T) : Part Production Communication ModelDokument76 SeitenGeometric Dimensioning and Tolerancing (GD&T) : Part Production Communication Modelmariappan128Noch keine Bewertungen

- GD&T Position TolDokument204 SeitenGD&T Position Toldramilt100% (2)

- pr1169 1170 PDFDokument1 Seitepr1169 1170 PDFrahulmuleNoch keine Bewertungen

- Design Data BookDokument1 SeiteDesign Data BookVASIM MANSURINoch keine Bewertungen

- Geometrical Tolerances: Geometrical Tolerances On Drawing Precision Measurement of Geometrical TolerancesDokument30 SeitenGeometrical Tolerances: Geometrical Tolerances On Drawing Precision Measurement of Geometrical Tolerancessohkimfai6340100% (3)

- Specifications: Dimensional TolerancesDokument1 SeiteSpecifications: Dimensional TolerancesIvar KuusikNoch keine Bewertungen

- Surface Roughness JIS B 0601 (1994)Dokument1 SeiteSurface Roughness JIS B 0601 (1994)Tú Nguyễn MinhNoch keine Bewertungen

- Hommel-Etamic Measuring Systems: Geometrical Tolerancing in PracticeDokument1 SeiteHommel-Etamic Measuring Systems: Geometrical Tolerancing in PracticeAlexNoch keine Bewertungen

- Surface Texture SymbolDokument1 SeiteSurface Texture SymbolSrinivas RaoNoch keine Bewertungen

- Surface RoughnessDokument1 SeiteSurface RoughnesswholenumberNoch keine Bewertungen

- Wuolah Free Manufacturing Processes ExercisesDokument70 SeitenWuolah Free Manufacturing Processes ExercisesJaime LopezNoch keine Bewertungen

- Regular Machining Dimension ToleranceDokument1 SeiteRegular Machining Dimension ToleranceSIVA 1010Noch keine Bewertungen

- (Research Reports ESPRIT 4 - Project 322. CAD Interfaces (CAD - 1) ) Richard Schuster, Dietmar Trippner, Michael Endres (Auth.) - CAD - I Drafting Model-Springer-Verlag Berlin Heidelberg (1990)Dokument245 Seiten(Research Reports ESPRIT 4 - Project 322. CAD Interfaces (CAD - 1) ) Richard Schuster, Dietmar Trippner, Michael Endres (Auth.) - CAD - I Drafting Model-Springer-Verlag Berlin Heidelberg (1990)Muscadin MakensonNoch keine Bewertungen

- Surface Roughness Drawing Indications of Surface TextureDokument1 SeiteSurface Roughness Drawing Indications of Surface TextureSIVA 1010Noch keine Bewertungen

- Surface RoughnessDokument1 SeiteSurface Roughnessapi-3848892100% (2)

- Geometric Dimensioning and Tolerancing - WikipediaDokument4 SeitenGeometric Dimensioning and Tolerancing - WikipediaEdryle AtanacioNoch keine Bewertungen

- Socket Head Cap ScrewsDokument1 SeiteSocket Head Cap Screwsapi-3848892100% (5)

- Surface RoughnessDokument1 SeiteSurface Roughnessapi-3848892100% (2)

- Surface RoughnessDokument1 SeiteSurface Roughnessapi-3848892100% (2)

- Calculation of Beam DeflectionDokument1 SeiteCalculation of Beam Deflectionapi-3848892100% (2)

- Claculation of Area, Center of Gravity and Sectional Secondary MomentDokument1 SeiteClaculation of Area, Center of Gravity and Sectional Secondary Momentapi-3848892Noch keine Bewertungen

- Fit Selection BasicDokument1 SeiteFit Selection Basicapi-3848892100% (2)

- Greek Symblos-Atomic SymbolsDokument1 SeiteGreek Symblos-Atomic Symbolsapi-3848892Noch keine Bewertungen

- Solidworks Tutorial 07nov06Dokument13 SeitenSolidworks Tutorial 07nov06Robin SanjayaNoch keine Bewertungen

- Examples of Applicable Steels For Typical ProductsDokument1 SeiteExamples of Applicable Steels For Typical Productsapi-3848892Noch keine Bewertungen

- Solid Works Drawing and DetailingDokument69 SeitenSolid Works Drawing and Detailingapi-3848892100% (1)

- Mastercam Tutorial Surface ModelingDokument4 SeitenMastercam Tutorial Surface Modelingapi-3848892100% (1)

- Calculation of Beam DeflectionDokument1 SeiteCalculation of Beam Deflectionapi-3848892100% (2)

- Greek Symblos-Atomic SymbolsDokument1 SeiteGreek Symblos-Atomic Symbolsapi-3848892Noch keine Bewertungen

- Solid Works AssemblyDokument46 SeitenSolid Works Assemblyapi-3848892Noch keine Bewertungen

- Critical Thinking Skills Success in 20 Minutes A Day - Lauren StarkeyDokument182 SeitenCritical Thinking Skills Success in 20 Minutes A Day - Lauren StarkeyAustin Higgins97% (61)

- Ug Nx3 TutorialDokument235 SeitenUg Nx3 TutorialAJAYKRISHNAA92% (13)

- Prepare For IELTSDokument170 SeitenPrepare For IELTSevilinside_me96% (23)

- Cosmos SWDokument52 SeitenCosmos SWRicardo Vargas GraciaNoch keine Bewertungen

- Surface RoughnessDokument1 SeiteSurface Roughnessapi-3848892100% (2)

- PLC Basic Programme BookDokument45 SeitenPLC Basic Programme Bookapi-384889275% (4)

- Conversion Table of HardnessDokument1 SeiteConversion Table of Hardnessapi-3848892100% (2)

- Surface Roughness by Different Processing MethodsDokument1 SeiteSurface Roughness by Different Processing Methodsapi-3848892100% (1)

- Calculation of Beam DeflectionDokument1 SeiteCalculation of Beam Deflectionapi-3848892100% (2)

- Fit Selection BasicDokument1 SeiteFit Selection Basicapi-3848892100% (2)

- Socket Head Cap ScrewsDokument1 SeiteSocket Head Cap Screwsapi-3848892100% (5)

- SWIFT Chapter11 InheritanceDokument7 SeitenSWIFT Chapter11 InheritanceHien NguyenNoch keine Bewertungen

- DSE Paper CustomDokument24 SeitenDSE Paper CustomGeorge ChanNoch keine Bewertungen

- Liquid Hold UpDokument6 SeitenLiquid Hold UpCatherine ContrerasNoch keine Bewertungen

- Paper IVDokument9 SeitenPaper IVWates SoluNoch keine Bewertungen

- M2 - TOPIC 10 Spherical PolygonsDokument7 SeitenM2 - TOPIC 10 Spherical PolygonsJulia IngallaNoch keine Bewertungen

- Class XI XII Laboratory Manual SolutionDokument106 SeitenClass XI XII Laboratory Manual SolutionRajibul Islam78% (129)

- Surface Area and Volume of A SphereDokument8 SeitenSurface Area and Volume of A SphereAila Elocin PalmasNoch keine Bewertungen

- Maths Class X Sample Paper Test 01 For Board Exam 2024Dokument6 SeitenMaths Class X Sample Paper Test 01 For Board Exam 2024kothandan muthuNoch keine Bewertungen

- Special Functions of Mathematical (Geo-) Physics - GuttingDokument505 SeitenSpecial Functions of Mathematical (Geo-) Physics - GuttingSantiago Alvarez100% (1)

- Maths Class X Sample Test Paper 04 For Board Exam 2020 21 Answers 1Dokument15 SeitenMaths Class X Sample Test Paper 04 For Board Exam 2020 21 Answers 1daksh prajapatiNoch keine Bewertungen

- Math SampleDokument4 SeitenMath SamplejhemakshNoch keine Bewertungen

- Physics Resultant ForceDokument46 SeitenPhysics Resultant ForceTUMICAD, ZAIREN CNoch keine Bewertungen

- The Sindos Priestess - Despoina IgnatiadouDokument25 SeitenThe Sindos Priestess - Despoina IgnatiadouSonjce Marceva100% (2)

- Pace Aits - 5 PDFDokument21 SeitenPace Aits - 5 PDFArihant BansalNoch keine Bewertungen

- Level 1 Modular Quizzes Modules 1-15Dokument40 SeitenLevel 1 Modular Quizzes Modules 1-15Jaimie Del Mundo50% (4)

- MUO Assignment 1 - SolutionDokument2 SeitenMUO Assignment 1 - Solutionpratikxeo3Noch keine Bewertungen

- Differential Calculus 3Dokument26 SeitenDifferential Calculus 3Miranda Paul J.Noch keine Bewertungen

- Stewart Calc ET7Dokument8 SeitenStewart Calc ET7John Paulo SamsonNoch keine Bewertungen

- Physics PracticalsDokument86 SeitenPhysics PracticalsGvns Reddy100% (1)

- Worksheet 3 Plane Solid GeometryDokument10 SeitenWorksheet 3 Plane Solid Geometrybenny bullNoch keine Bewertungen

- Trigonometry QuestionsDokument22 SeitenTrigonometry QuestionsYhardlyn Adina DagdaganNoch keine Bewertungen

- Ece Course DescriptionDokument12 SeitenEce Course DescriptionjimmyboyjrNoch keine Bewertungen

- Parametrized Surfaces: Vector Calculus (MATH-243) Instructor: Dr. Naila AmirDokument12 SeitenParametrized Surfaces: Vector Calculus (MATH-243) Instructor: Dr. Naila AmirRakhmeen GulNoch keine Bewertungen

- Latitude, Longitude, and Great Circle Distances by Chip PearsonDokument4 SeitenLatitude, Longitude, and Great Circle Distances by Chip PearsonSyed Subtain HussainNoch keine Bewertungen

- Geometry and Kinematics of Guided-Rod Sharpening Systems 1.0beta17Dokument100 SeitenGeometry and Kinematics of Guided-Rod Sharpening Systems 1.0beta17Anthony Kang-Ying YanNoch keine Bewertungen

- Sub A Case Study For Substation Lightning Risk EvaluationDokument32 SeitenSub A Case Study For Substation Lightning Risk EvaluationVojaNoch keine Bewertungen

- MULTIPLE CHOICE QUESTIONS in ENGINEERING MATHEMATICS by Venancio I. Besavilla, Jr. VOL1Dokument38 SeitenMULTIPLE CHOICE QUESTIONS in ENGINEERING MATHEMATICS by Venancio I. Besavilla, Jr. VOL1John DelrosarioNoch keine Bewertungen

- General Theory of RelativityDokument45 SeitenGeneral Theory of RelativityPoulami ChakrabortyNoch keine Bewertungen

- SOLIMENDokument3 SeitenSOLIMENKhay NochefrancaNoch keine Bewertungen

- Sarvodaya Physics XIIDokument1 SeiteSarvodaya Physics XIIManavendra Sen ツNoch keine Bewertungen