Beruflich Dokumente

Kultur Dokumente

Molykote Products in India - Email Sales@

Hochgeladen von

Project Sales CorpOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Molykote Products in India - Email Sales@

Hochgeladen von

Project Sales CorpCopyright:

Verfügbare Formate

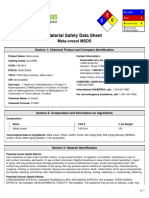

Product Information

Specialty Lubricants MOLYKOTE BG 20

High Performance Grease

FEATURES

Contains no lead or nickel High load carrying capacity Suitable for long-term lubrication by virtue of low oil evaporation and low tendency towards oxidation Wide service temperature range (-45C to 180C; for short periods up to +200C) Suitable for very high rotational speeds (DN value 800,000)

High performance grease for metal/metal combinations involving rapid movements and medium to heavy loadings APPLICATIONS

Suitable for lubrication points with medium to heavy loadings and high to very high speeds, particularly when they are also exposed to high temperatures. Used successfully on clutch release bearings, blower and calender-roller bearings and electric motor bearings.

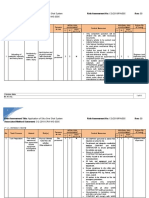

TYPICAL PROPERTIES

Specification writers: These values are not intended for use in preparing specifications. Please contact your local Dow Corning sales representative prior to writing specifications on this product. Standard* Test Color Unit Result Beige mm/10 g/ml mm/s C 240-270 1.01 55 -45 to +180 up to +200 for short periods >295 207x10 130x10 530x10 130x10

COMPOSITION

Ester oil Lithium complex thickener EW/AW-Additive Oxidation inhibitor

Consistency, density, viscosity

ISO 2137 ISO 2811 DIN 51 562 Unworked penetration Density at 20C Base oil viscosity at 40C

Temperature

Service temperature

ISO 2176 Drop point ASTM-D147880 Low temperature torque test at -20C Initial break-away torque Torque after 20 minutes running time ASTM-D147880 Low temperature torque test at -50C Initial break-away torque Torque after 20 minutes running time Four-ball tester (VKA) DIN 51 350 pt.4 Weld load DIN 51 350 pt.5 Wear scar under 800N load Almen-Wieland machine OK load Frictional force with OK load DIN 51 82102A FAG rolling element bearing tested FE9, 1500/6000/160, average value

C Nm Nm Nm Nm

Load-carrying capacity, wear protection, service life

N mm N N h 2400 1.0 20000 2250 662

Speed

DN value mm/min 750000

Corrosion protection

DIN 51 802 SKF-Emcor method Degree of corrosion 1-2

TYPICAL PROPERTIES (continued)

Standard* DIN 51 817 Test Unit % Result 1.2

Oil separation

Standard test 1. DN values are calculated approximations and will vary widely with temperature, load and bearing type. * ASTM: American Society for Testing and Materials ISO: International Standardisation Organisation DIN: Deutsche Industrie Norm

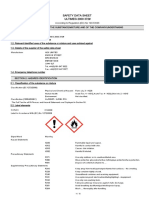

HOW TO USE How to apply

Clean points of contact. Apply in same way as lubricating greases, using brush, spatula, grease-gun or automatic lubricating device. Suitable for delivery by central lubricating system.

HEALTH AND ENVIRONMENTAL INFORMATION

To support customers in their product safety needs, Dow Corning has an extensive Product Stewardship organization and a team of Health, Environment and Regulatory Affairs specialists available in each area. For further information, please consult your local Dow Corning representative.

HANDLING PRECAUTIONS

PRODUCT SAFETY INFORMATION REQUIRED FOR SAFE USE IS NOT INCLUDED. BEFORE HANDLING, READ PRODUCT AND SAFETY DATA SHEETS AND CONTAINER LABELS FOR SAFE USE, PHYSICAL AND HEALTH HAZARD INFORMATION. THE SAFETY DATA SHEET IS AVAILABLE FROM YOUR LOCAL DOW CORNING SALES REPRESENTATIVE.

WARRANTY INFORMATION - PLEASE READ CAREFULLY

The information contained herein is offered in good faith and is believed to be accurate. However, because conditions and methods of use of our products are beyond our control, this information should not be used in substitution for customer's tests to ensure that Dow Corning's products are safe, effective, and fully satisfactory for the intended end use. Dow Corning's sole warranty is that the product will meet the Dow Corning sales specifications in effect at the time of shipment. Your exclusive remedy for breach of such warranty is limited to refund of purchase price or replacement of any product shown to be other than as warranted. Dow Corning specifically disclaims any other express or implied warranty of fitness for a particular purpose or merchantability. Unless Dow Corning provides you with a specific, duly signed endorsement of fitness for use, Dow Corning disclaims liability for any incidental or consequential damages. Suggestions of use shall not be taken as inducements to infringe any patent.

USABLE LIFE AND STORAGE

When stored at or below 20C in the original unopened containers, this product has a usable life of 60 months from the date of production.

PACKAGING

This product is available in different standard container sizes. Detailed container size information should be obtained from your nearest Dow Corning sales office or Dow Corning distributor.

LIMITATIONS

This product is neither tested nor represented as suitable for medical or pharmaceutical uses.

2 Ref. no. 71-0110B-01

23/11/1998 DC 2988

MOLYKOTE is a registered trademark of Dow Corning Corporation. 1997-2001 Dow Corning Corporation. All rights reserved.

Das könnte Ihnen auch gefallen

- Draft - Rig Spares-2Dokument10 SeitenDraft - Rig Spares-2Project Sales CorpNoch keine Bewertungen

- Draft - Rig Spares - Miscellaneous Stock Items-1Dokument65 SeitenDraft - Rig Spares - Miscellaneous Stock Items-1Project Sales CorpNoch keine Bewertungen

- Cameron 700668 From Project Sales Corp, IndiaDokument1 SeiteCameron 700668 From Project Sales Corp, IndiaProject Sales CorpNoch keine Bewertungen

- Nightstick XPR-5592Dokument2 SeitenNightstick XPR-5592Project Sales CorpNoch keine Bewertungen

- Draft - Rig Spares-3Dokument30 SeitenDraft - Rig Spares-3Project Sales CorpNoch keine Bewertungen

- Nightstick XPR-5582-INTEGRITAS-82Dokument2 SeitenNightstick XPR-5582-INTEGRITAS-82Project Sales CorpNoch keine Bewertungen

- Nightstick XPR 5584gmx Integritas 84Dokument2 SeitenNightstick XPR 5584gmx Integritas 84Project Sales CorpNoch keine Bewertungen

- Nightstick XPR 5542gmxDokument2 SeitenNightstick XPR 5542gmxProject Sales CorpNoch keine Bewertungen

- Nightstick XPR 5561gseriesDokument2 SeitenNightstick XPR 5561gseriesProject Sales CorpNoch keine Bewertungen

- PSC Specialty Lubricant 2021Dokument43 SeitenPSC Specialty Lubricant 2021Project Sales CorpNoch keine Bewertungen

- Nightstick XPR 5568 IntrantDokument2 SeitenNightstick XPR 5568 IntrantProject Sales CorpNoch keine Bewertungen

- Nightstick XPR-5562-DICATADokument2 SeitenNightstick XPR-5562-DICATAProject Sales CorpNoch keine Bewertungen

- Magnaseal Plus Lubricant From Project Sales CorpDokument1 SeiteMagnaseal Plus Lubricant From Project Sales CorpProject Sales CorpNoch keine Bewertungen

- Nightstick XPP 5411gxDokument2 SeitenNightstick XPP 5411gxProject Sales CorpNoch keine Bewertungen

- Nightstick XPR 5522gmxDokument2 SeitenNightstick XPR 5522gmxProject Sales CorpNoch keine Bewertungen

- Nightstick XPP 5566 IntrantDokument2 SeitenNightstick XPP 5566 IntrantProject Sales CorpNoch keine Bewertungen

- Nightstick XPP 5465r ForgeDokument2 SeitenNightstick XPP 5465r ForgeProject Sales CorpNoch keine Bewertungen

- Nightstick XPP 5414gx SeriesDokument2 SeitenNightstick XPP 5414gx SeriesProject Sales CorpNoch keine Bewertungen

- Nightstick XPP 5452gDokument2 SeitenNightstick XPP 5452gProject Sales CorpNoch keine Bewertungen

- Nightstick XPP 5450gDokument2 SeitenNightstick XPP 5450gProject Sales CorpNoch keine Bewertungen

- PSC Load-It Load Positioning Safety ToolsDokument13 SeitenPSC Load-It Load Positioning Safety ToolsProject Sales CorpNoch keine Bewertungen

- Rig Spares - Used New Surplus InventoryDokument16 SeitenRig Spares - Used New Surplus InventoryProject Sales CorpNoch keine Bewertungen

- PSC Rescue Sheets For All Weather ProtectionDokument1 SeitePSC Rescue Sheets For All Weather ProtectionProject Sales CorpNoch keine Bewertungen

- KKD Marine Profile 2020Dokument31 SeitenKKD Marine Profile 2020Project Sales CorpNoch keine Bewertungen

- LP250 Anti-Seize From Project Sales CorpDokument1 SeiteLP250 Anti-Seize From Project Sales CorpProject Sales CorpNoch keine Bewertungen

- PSC LoadGuider Datasheet - 2020Dokument1 SeitePSC LoadGuider Datasheet - 2020Project Sales CorpNoch keine Bewertungen

- Magnaseal Plus - MSP-40 MSDS - Project Sales CorpDokument16 SeitenMagnaseal Plus - MSP-40 MSDS - Project Sales CorpProject Sales CorpNoch keine Bewertungen

- PSC Hands-Free Tools Guidebook 2019Dokument18 SeitenPSC Hands-Free Tools Guidebook 2019Project Sales CorpNoch keine Bewertungen

- PSC Magnaseal BOP Valve Lubricants/SealantDokument2 SeitenPSC Magnaseal BOP Valve Lubricants/SealantProject Sales CorpNoch keine Bewertungen

- Workplace Safety Guidebook - DROPPED OBJECT PREVENTIONDokument22 SeitenWorkplace Safety Guidebook - DROPPED OBJECT PREVENTIONProject Sales CorpNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Safety Data Sheet: LDF 260GGDokument8 SeitenSafety Data Sheet: LDF 260GG真幸运Noch keine Bewertungen

- Safety Data Sheet: According To Regulation (EC) No. 1907/2006Dokument9 SeitenSafety Data Sheet: According To Regulation (EC) No. 1907/2006Nicole LoreoNoch keine Bewertungen

- OSHAD-SF-TG-Laboratory Safety - V3.0 - EnglishDokument44 SeitenOSHAD-SF-TG-Laboratory Safety - V3.0 - EnglishNiel Brian Villarazo0% (1)

- Silica GelDokument7 SeitenSilica Gelzedbolete6704Noch keine Bewertungen

- SDS Wash & Walk EcoLabDokument12 SeitenSDS Wash & Walk EcoLabjonathan.gamboaNoch keine Bewertungen

- Msds. 2-EaqDokument6 SeitenMsds. 2-EaqNazuah Ushwatun HassanahNoch keine Bewertungen

- Alsoft V SDS) PDFDokument8 SeitenAlsoft V SDS) PDFMICHEAL KaggwaNoch keine Bewertungen

- MSDS KresolDokument6 SeitenMSDS Kresolshinta sariNoch keine Bewertungen

- Cantesco SolventDokument5 SeitenCantesco Solventmasv792512Noch keine Bewertungen

- Material Safety Data Sheet Diesel Fuel - High Sulfur: Nfpa: Hmis IiiDokument11 SeitenMaterial Safety Data Sheet Diesel Fuel - High Sulfur: Nfpa: Hmis IiiDeshanNoch keine Bewertungen

- Workplace Inspection Checklist: General Yes No NotesDokument4 SeitenWorkplace Inspection Checklist: General Yes No NotesLakshmi BalaNoch keine Bewertungen

- 2007 07 10 Methods Method 351 2Dokument15 Seiten2007 07 10 Methods Method 351 2Yogesh DhekaleNoch keine Bewertungen

- Ni触媒MSDS 英文Dokument4 SeitenNi触媒MSDS 英文dil1717Noch keine Bewertungen

- Farmozine 900 WDG SDS - Feb 2022Dokument6 SeitenFarmozine 900 WDG SDS - Feb 2022JOHNNYNUTSNoch keine Bewertungen

- Risk Assessment For Polyurea Waterproofing WorksDokument11 SeitenRisk Assessment For Polyurea Waterproofing WorksJamsheed Ap Kadangod100% (1)

- Compressed Gas Cylinders and Related SystemsDokument26 SeitenCompressed Gas Cylinders and Related SystemsPassmore DubeNoch keine Bewertungen

- KP20 PDFDokument8 SeitenKP20 PDFAnonymous ad7lmuL7Noch keine Bewertungen

- BT-69 MSDS EngDokument4 SeitenBT-69 MSDS Engmehmet100% (2)

- MSDS Pricebuster Emulsion Paint PDFDokument3 SeitenMSDS Pricebuster Emulsion Paint PDFemeka2012Noch keine Bewertungen

- Fosroc Nitofi LL PU150: Multi-Purpose Hydrophilic Flexible Polyurethane Grout Uses AdvantagesDokument2 SeitenFosroc Nitofi LL PU150: Multi-Purpose Hydrophilic Flexible Polyurethane Grout Uses AdvantagesVaittianathan MahavapillaiNoch keine Bewertungen

- TimemizerDokument2 SeitenTimemizergynugNoch keine Bewertungen

- TIDE CLEAN BREEZE PowderDokument8 SeitenTIDE CLEAN BREEZE PowderWafa MuhammadNoch keine Bewertungen

- Chcs Sds User Guide February 2014Dokument163 SeitenChcs Sds User Guide February 2014Anonymous 9xteZEo46qNoch keine Bewertungen

- Apex Duracast CrossTexDokument2 SeitenApex Duracast CrossTexAsian PaintsNoch keine Bewertungen

- H&S in The Home Care Enviornment - Lap - 301Dokument93 SeitenH&S in The Home Care Enviornment - Lap - 301Jafar KhanNoch keine Bewertungen

- Cummins Prem Blue 15w40 1-18 L Sing Ssv3028m18 Asia-Pacific Purple Book (GHS) - EnglishDokument14 SeitenCummins Prem Blue 15w40 1-18 L Sing Ssv3028m18 Asia-Pacific Purple Book (GHS) - EnglishjosephvanbacNoch keine Bewertungen

- Psguide 2015Dokument83 SeitenPsguide 2015laacostam93Noch keine Bewertungen

- MSDS - Ultimeg 2000-372Dokument6 SeitenMSDS - Ultimeg 2000-372Azka DeliaNoch keine Bewertungen

- TM1553 John Deere 4475, 5575, 6675, 7775 Skid Steer Loaders Technical ManualDokument9 SeitenTM1553 John Deere 4475, 5575, 6675, 7775 Skid Steer Loaders Technical ManualtteelsarsNoch keine Bewertungen

- Sika Boom Cleaner - MSDSDokument9 SeitenSika Boom Cleaner - MSDSEgiya GoldarosaNoch keine Bewertungen