Beruflich Dokumente

Kultur Dokumente

ME1251 Sylabus

Hochgeladen von

azaathmeOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ME1251 Sylabus

Hochgeladen von

azaathmeCopyright:

Verfügbare Formate

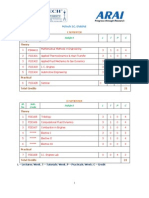

ME1251 HEAT AND MASS TRANSFER LT PC 3 1 0 4 UNIT I CONDUCTION 11 Basic Concepts Mechanism of heat transfer Conduction, convection and

and radiation Fourier law of conduction General differential equation of heat conduction Cartesian and cylindrical coordinates One dimensional steady state heat conduction Conduction through plane wall, cylinders and spherical systems Composite systems Conduction with internal heat generation Extended surfaces Unsteady heat conduction Lumped analysis Use of Heislers chart. UNIT II CONVECTION 10 Basic Concepts Heat transfer coefficients Boundary layer concept Types of convection Forced convection Dimensional analysis External flow Flow over plates, cylinders and spheres Internal flow Laminar and turbulent flow Combined laminar and turbulent Flow over bank of tubes Free convection Dimensional analysis Flow over vertical plate, horizontal plate, inclined plate, cylinders and spheres. UNIT III PHASE CHANGE HEAT TRANSFER AND HEAT EXCHANGERS 9 Nusselts theory of condensation Pool boiling, flow boiling, correlations in boiling and condensation Types of heat exchangers Heat exchanger analysis LMTD Method and NTU Effectiveness Overall heat transfer coefficient Fouling factors. UNIT IV RADIATION 8 Basic concepts Laws of radiation Stefan Boltzman law Kirchoffs law Black body radiation Grey body radiation Shape factor algebra Electrical analogy Radiation Shields Introduction to gas radiation UNIT V MASS TRANSFER 7 Basic concepts Diffusion mass transfer Ficks law of diffusion Steady state molecular diffusion convective mass transfer Momentum, heat and mass transfer analogy Convective mass transfer correlations L: 45 T: 15 Total: 60 TEXT BOOKS 1. Sachdeva, R.C., Fundamentals of Engineering Heat and Mass Transfer, New Age International, 1995. 2. Incropera, F.P. and DeWitt, D.P., Fundamentals of Heat and Mass Transfer, John Wiley and Sons, 1998. REFERENCES 1. Yadav, R., Heat and Mass Transfer Central Publishing House, 1995. 2. Ozisik, M.N., Heat Transfer, McGraw-Hill Book Co., 1994. 3. Kothandaraman, C.P., Fundamentals of Heat and Mass Transfer New Age International

POWER PLANT ENGINEERING LTPC 30 0 3 UNIT I INTRODUCTION TO POWER PLANTS AND BOILERS 9 Layout of steam, hydel, diesel, MHD, nuclear and gas turbine power plants Combined power cycles Comparison and selection Load duration curves Steam boilers and cycles High pressure and super critical boilers Fluidized bed boilers. UNIT II STEAM POWER PLANT 9 Fuel and ash handling Combustion equipment for burning coal Mechanical stokers Pulveriser Electrostatic precipitator Draught Surface condenser types Cooling towers. UNIT III NUCLEAR AND HYDEL POWER PLANTS 9 Nuclear energy Fission Fusion reaction Types of reactors Pressurized water reactor Boiling water reactor Waste disposal and safety. Hydel power plant Essential elements Selection of turbines Governing of turbines Micro hydel developments UNIT IV DIESEL AND GAS TURBINE POWER PLANT 9 Types of diesel plants components Selection of engine type Applications gas turbine power plant Fuels Gas Turbine material Open and closed cycles Reheating Regeneration and intercooling Combined cycle. UNIT V OTHER POWER PLANTS AND ECONOMICS OF POWER PLANTS 9 Geo thermal OTEC Tidel - Pumped storage - Solar thermal central receiver system Cost of Electric energy Fixed and operating costs Energy rates Types of tariffs Economics of load sharing Comparison of economics of various power plants. Total: 45 TEXT BOOKS 1. Arora, S.C. and Domkundwar, S., A Course in Power Plant Engineering, Dhanpatrai, 2001. 2. Nag, P.K., Power Plant Engineering, Tata McGraw-Hill, 1998. REFERENCES 1. Nagpal, G.R., Power Plant Engineering, Hanna Publishers, 1998. 2. Ramalingam, K.K., Power Plant Engineering, Scitech Publications, 2002. 3. Rai, G.D., Introduction to Power Plant Technology, Khanna Publishers, 1995.

CAD/CAM LABORATORY LTPC 0032 LIST OF EXPERIMENTS A) COMPUTER AIDED DESIGN (CAD) 15 1. 3D Part modeling protrusion, cut, sweep, draft, loft, blend, rib 2. Editing Move, Pattern, Mirror, Round, Chamfer 3. Assembly creating assembly from parts assembly constraints 4. Conversion of 3D solid model to 2D drawing - different views, sections, isometric view and Dimensioning 5. Introduction to Surface Modeling and sheet metal. 6. Introduction to File Import, Export DXF, IGES, STL, STEP 7. 3D modeling of machine elements like flanged coupling, screw jack etc. Note: Any one of the 3D MODELING software like Pro/E, IDEAS, CATIA, UNIGRAPHICS, AutoCAD to be used. B) COMPUTER AIDED MANUFACTURING (CAM) 21 1. MANUAL PART PROGRAMMING (Using G and M Codes) in CNC lathe 1.1 Part programming for Linear and Circular interpolation, Chamfering and Grooving 1.2 Part programming using standard canned cycles for Turning, Facing, Taper turning and Thread cutting 2. MANUAL PART PROGRAMMING (using G and M codes) in CNC milling 2.1 Part programming for Linear and Circular interpolation and Contour motions. 2.2 Part programming involving canned cycles for Drilling, Peck drilling, Pocket and Boring. C) SIMULATION AND NC CODE GENERATION 9 NC code generation using CAD / CAM softwares - Post processing for standard CNC Controls like FANUC, Hiedenhain etc. Total: 45 LIST OF EQUIPMENT FOR CAD /CAM LAB (For a batch of 30 students) I . HARDWARES 1. Computer server 1 No. 2. Computer systems (Pentium IV with 1GB Ram) networked to the server 30 Nos. 3. A0 size plotter 2 Nos. 4. Laser Printer 2 Nos. 5. Trainer CNC lathes 2 Nos. 6. Trainer CNC milling 2 Nos II. SOFTWARES 1. CAD/CAM Software 20 licenses (Pro E or IDEAS or Uni-graphics or CATIA) 2. CAM Software 20 licenses (CNC programming and tool path simulation for FANUC, Sinumeric and Heiden controller)

Das könnte Ihnen auch gefallen

- Me6701 Power Plant Engineering L T P CDokument3 SeitenMe6701 Power Plant Engineering L T P CNithyanandmNoch keine Bewertungen

- Thermal Engineering and HMTDokument2 SeitenThermal Engineering and HMTArunkumar MunimathanNoch keine Bewertungen

- Energy Engineering SyllabusDokument49 SeitenEnergy Engineering SyllabusKarthiik88Noch keine Bewertungen

- University departments and course details for M.E. Energy EngineeringDokument44 SeitenUniversity departments and course details for M.E. Energy EngineeringJoswa CaxtonNoch keine Bewertungen

- 191atc401t Applied Thermodynamics and Thermal EngineeringDokument2 Seiten191atc401t Applied Thermodynamics and Thermal EngineeringMohan PushparajNoch keine Bewertungen

- R2015 - Mechanical - JUN-19 CIT 5 Seem SyllabusDokument8 SeitenR2015 - Mechanical - JUN-19 CIT 5 Seem SyllabusAthisayaraj RajNoch keine Bewertungen

- Bput Mtech Thermal 2010Dokument24 SeitenBput Mtech Thermal 2010mani317Noch keine Bewertungen

- Me-311 Transport Phenomenon Unit I Introduction and ConductionDokument5 SeitenMe-311 Transport Phenomenon Unit I Introduction and Conductionmrigank2014Noch keine Bewertungen

- ME8595 Thermal Engineering II FormulasDokument11 SeitenME8595 Thermal Engineering II Formulasmmk.mech59Noch keine Bewertungen

- Power Plant Engineering Course OverviewDokument7 SeitenPower Plant Engineering Course OverviewsumikannuNoch keine Bewertungen

- Applied Thermodynamics and Heat TransferDokument2 SeitenApplied Thermodynamics and Heat TransferJOLYNoch keine Bewertungen

- M.E. Internal Combustion Engineering SyllabusDokument35 SeitenM.E. Internal Combustion Engineering SyllabusJoswa CaxtonNoch keine Bewertungen

- CryogenicDokument23 SeitenCryogenicmgskumar100% (1)

- Be8256 Basic Mechanical Engineering SyllabusDokument1 SeiteBe8256 Basic Mechanical Engineering SyllabusAnonymous dL8dsCncNoch keine Bewertungen

- Me 2403 Syllabus - PpeDokument2 SeitenMe 2403 Syllabus - PpebsamantonyNoch keine Bewertungen

- JNTUK - Academics & Planning - M.tech (Mechanical Engineering) - Thermal Engineerign SyllabusDokument29 SeitenJNTUK - Academics & Planning - M.tech (Mechanical Engineering) - Thermal Engineerign SyllabusRajeswari MachirajuNoch keine Bewertungen

- HTDokument4 SeitenHTIndrajeet ParmarNoch keine Bewertungen

- MECHANICAL ENGINEERING SUBJECTS <40Dokument9 SeitenMECHANICAL ENGINEERING SUBJECTS <40vupputuriNoch keine Bewertungen

- AT6401 Applied Thermodynamics and Heat TransferDokument2 SeitenAT6401 Applied Thermodynamics and Heat Transferkarthikeyan MNoch keine Bewertungen

- Heat Transfer and Renewable Energy FundamentalsDokument2 SeitenHeat Transfer and Renewable Energy FundamentalstagoreboopathyNoch keine Bewertungen

- Advanced Heat Transfer L T P CDokument1 SeiteAdvanced Heat Transfer L T P CKalai VenkatesanNoch keine Bewertungen

- ME6404 Thermal Engineering Gas Power CyclesDokument1 SeiteME6404 Thermal Engineering Gas Power CyclesKani SelvanNoch keine Bewertungen

- Thermodynamics SyllabusDokument1 SeiteThermodynamics SyllabusSrinivasan SNoch keine Bewertungen

- ME6352 Manufacturing Technology LTPC 3 0 0 3 ObjectivesDokument14 SeitenME6352 Manufacturing Technology LTPC 3 0 0 3 ObjectivespugazhNoch keine Bewertungen

- Power PlantDokument1 SeitePower PlantSahi NagarajanNoch keine Bewertungen

- DE - 2012 (1) SDDokument13 SeitenDE - 2012 (1) SDRishabh SinghalNoch keine Bewertungen

- 15 Mechanical EngineeringDokument62 Seiten15 Mechanical Engineeringslv_prasaadNoch keine Bewertungen

- Thermal EnggDokument28 SeitenThermal EnggArun YogaNoch keine Bewertungen

- Psu Syllabus MechanicalDokument2 SeitenPsu Syllabus Mechanicalammu0312Noch keine Bewertungen

- BE8256 r17 Basic Mechanical Engg PDFDokument2 SeitenBE8256 r17 Basic Mechanical Engg PDFkarthik kumarNoch keine Bewertungen

- Cryo First Semester SyllabusDokument17 SeitenCryo First Semester SyllabusRaji PNoch keine Bewertungen

- 1383 - M.tech - ThermalDokument14 Seiten1383 - M.tech - ThermalShri Vignesh KNoch keine Bewertungen

- HMT Lesson PlanDokument6 SeitenHMT Lesson PlanMohan GovindasamyNoch keine Bewertungen

- ME-351 - Applied Thermodynamics II - Course Plan - Rev - 01 PDFDokument4 SeitenME-351 - Applied Thermodynamics II - Course Plan - Rev - 01 PDFVimleshKumarSharmaNoch keine Bewertungen

- Heat ExchangersBasics Design ApplicationsDokument598 SeitenHeat ExchangersBasics Design ApplicationsPujara Manish100% (3)

- Syllabus of Exam: General Ability TestDokument4 SeitenSyllabus of Exam: General Ability TestManvendra SinghNoch keine Bewertungen

- Electrical InstrumentationDokument25 SeitenElectrical InstrumentationAdi WijayaNoch keine Bewertungen

- 376 - ME8595 Thermal Engineering II - Anna University 2017 Regulation SyllabusDokument3 Seiten376 - ME8595 Thermal Engineering II - Anna University 2017 Regulation SyllabusCAD With RaoNoch keine Bewertungen

- Subject Taken NotesDokument3 SeitenSubject Taken NotessuriyasureshNoch keine Bewertungen

- MA1201 Transform and PDEs NotesDokument22 SeitenMA1201 Transform and PDEs NotesAzaath AzuNoch keine Bewertungen

- Thermal - Engg r15 SyllabiDokument14 SeitenThermal - Engg r15 SyllabichrkNoch keine Bewertungen

- Anna University CoimbatoreDokument28 SeitenAnna University CoimbatoreVignesh PvlNoch keine Bewertungen

- ME 216 Mechanical TechnologyDokument3 SeitenME 216 Mechanical Technologynandan144Noch keine Bewertungen

- Watermark Comparison Between IES 2016 and 2017 Syllabus For MechanicalDokument5 SeitenWatermark Comparison Between IES 2016 and 2017 Syllabus For MechanicalShubham Shakya100% (2)

- Use of Approved Data Books Are PermittedDokument3 SeitenUse of Approved Data Books Are PermittedKARTHIKEYANNoch keine Bewertungen

- Smec 216Dokument1 SeiteSmec 216Yashwanth Krishna GampaNoch keine Bewertungen

- PDF 630d990bb1f6aDokument4 SeitenPDF 630d990bb1f6aAgar JaKenduNoch keine Bewertungen

- Thermal EngineeringDokument6 SeitenThermal Engineeringmore_sandeepNoch keine Bewertungen

- SyllabusDokument6 SeitenSyllabusAbhishek KumarNoch keine Bewertungen

- ME6502 Heat and Mass Transfer SyllabusDokument26 SeitenME6502 Heat and Mass Transfer Syllabusamdeva0% (1)

- IC EngineDokument52 SeitenIC EngineShreepal ChilaNoch keine Bewertungen

- Heat Transfer ProDokument7 SeitenHeat Transfer ProBorse RajNoch keine Bewertungen

- Automotive Heat Transfer Modeling and SimulationDokument281 SeitenAutomotive Heat Transfer Modeling and Simulationsardhan.rajender84100% (1)

- Mechanical Engineering Syllabus For UPSC Main ExaminationDokument5 SeitenMechanical Engineering Syllabus For UPSC Main ExaminationtpmuhammadtpNoch keine Bewertungen

- GE2152 - BASIC CIVIL and MECH - Syllabus With Course OutcomeDokument1 SeiteGE2152 - BASIC CIVIL and MECH - Syllabus With Course OutcomerkumaravelanNoch keine Bewertungen

- Flow, Mixing and Heat Transfer in Furnaces: The Science & Applications of Heat and Mass Transfer Reports, Reviews & Computer ProgramsVon EverandFlow, Mixing and Heat Transfer in Furnaces: The Science & Applications of Heat and Mass Transfer Reports, Reviews & Computer ProgramsK. H. KhalilNoch keine Bewertungen

- Mechanical Engineering Science: In SI UnitsVon EverandMechanical Engineering Science: In SI UnitsBewertung: 5 von 5 Sternen5/5 (4)

- Renewable Energy Conversion, Transmission, and StorageVon EverandRenewable Energy Conversion, Transmission, and StorageBewertung: 3 von 5 Sternen3/5 (2)

- Energy Technology: Sources, Systems and Frontier ConversionVon EverandEnergy Technology: Sources, Systems and Frontier ConversionNoch keine Bewertungen

- Heat Transfer and Fluid Flow in Nuclear SystemsVon EverandHeat Transfer and Fluid Flow in Nuclear SystemsHenri FenechNoch keine Bewertungen

- Two Level Factorial Tutorial (Part 1 - The Basics)Dokument28 SeitenTwo Level Factorial Tutorial (Part 1 - The Basics)Pugazhenthi Thananjayan100% (1)

- Aptitude Questions With AnswersDokument43 SeitenAptitude Questions With AnswerscskartheeNoch keine Bewertungen

- Higher Algebra - Hall & KnightDokument593 SeitenHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- CONTENTSDokument1 SeiteCONTENTSazaathmeNoch keine Bewertungen

- Thermal EngineeringDokument118 SeitenThermal EngineeringMukesh Kumar67% (6)

- Ie 305 Metrology Lab 1 Introduction To The Metrology LaboratoryDokument5 SeitenIe 305 Metrology Lab 1 Introduction To The Metrology LaboratoryMargie GardnerNoch keine Bewertungen

- AnsysDokument1 SeiteAnsysazaathmeNoch keine Bewertungen

- Ie 305 Metrology Lab 1 Introduction To The Metrology LaboratoryDokument5 SeitenIe 305 Metrology Lab 1 Introduction To The Metrology LaboratoryMargie GardnerNoch keine Bewertungen

- Inversions of Double Slider Crank Mechanism: Elliptical Trammel. This Is A Device Which Is Used For Generating An EllipticalDokument11 SeitenInversions of Double Slider Crank Mechanism: Elliptical Trammel. This Is A Device Which Is Used For Generating An EllipticalazaathmeNoch keine Bewertungen

- Human To MarsDokument32 SeitenHuman To MarsazaathmeNoch keine Bewertungen

- Aerospace Engineering: Email: Thomas.J.Benson@nasa - GovDokument31 SeitenAerospace Engineering: Email: Thomas.J.Benson@nasa - GovazaathmeNoch keine Bewertungen

- Human SpaceDokument16 SeitenHuman SpaceazaathmeNoch keine Bewertungen

- Machine DesignDokument69 SeitenMachine DesignSushant TiwariNoch keine Bewertungen

- Antenna Specifications Electrical PropertiesDokument2 SeitenAntenna Specifications Electrical PropertiesLuis Adolfo Mazini RodriguesNoch keine Bewertungen

- Inductive Proximity Sensors: Brett Anderson ECE 5230 Assignment #1Dokument27 SeitenInductive Proximity Sensors: Brett Anderson ECE 5230 Assignment #1Rodz Gier JrNoch keine Bewertungen

- Second Mid Term CE 461: Structural Analysis II: Student Name: Student No.: Section: 9 10 11 12Dokument4 SeitenSecond Mid Term CE 461: Structural Analysis II: Student Name: Student No.: Section: 9 10 11 12David Olorato NgwakoNoch keine Bewertungen

- General Physics1 Q2 W8 Module8 ThermodynamicsDokument23 SeitenGeneral Physics1 Q2 W8 Module8 ThermodynamicsRegine Ann ViloriaNoch keine Bewertungen

- Knight Boiler ManualDokument80 SeitenKnight Boiler ManualAnonymous 7xHNgoKE6eNoch keine Bewertungen

- Calculation For Short Circuit Current Calculation Using IEC / IEEE StandardDokument11 SeitenCalculation For Short Circuit Current Calculation Using IEC / IEEE StandardibmmoizNoch keine Bewertungen

- A Git Cheat Sheet (Git Command Reference) - A Git Cheat Sheet and Command ReferenceDokument14 SeitenA Git Cheat Sheet (Git Command Reference) - A Git Cheat Sheet and Command ReferenceMohd AzahariNoch keine Bewertungen

- Is 4410 9 1982 PDFDokument25 SeitenIs 4410 9 1982 PDFSameer Singh PatelNoch keine Bewertungen

- Ductile deformation finite strain analysisDokument27 SeitenDuctile deformation finite strain analysisJorgeBarriosMurielNoch keine Bewertungen

- Molecular Cell Biology Lodish 7th Edition Solutions ManualDokument8 SeitenMolecular Cell Biology Lodish 7th Edition Solutions ManualmarisorbornewwssNoch keine Bewertungen

- Programming structures if, for and while loopsDokument16 SeitenProgramming structures if, for and while loopsFrancisco AristizabalNoch keine Bewertungen

- Product Documentation: Release NotesDokument3 SeitenProduct Documentation: Release NotesArmando CisternasNoch keine Bewertungen

- Z 80 HelptopicsDokument5 SeitenZ 80 HelptopicsEverly NNoch keine Bewertungen

- TCP Operational Overview and The TCP Finite State Machine (FSM)Dokument4 SeitenTCP Operational Overview and The TCP Finite State Machine (FSM)Mayank JaitlyNoch keine Bewertungen

- OptQuest User ManualDokument190 SeitenOptQuest User ManualYamal E Askoul TNoch keine Bewertungen

- Auditing The Usage of Therapeutic Footwear in Diabetic Foot Patients Through Amit Jain's Extended SCC' Classification For Therapeutic FootwearDokument6 SeitenAuditing The Usage of Therapeutic Footwear in Diabetic Foot Patients Through Amit Jain's Extended SCC' Classification For Therapeutic FootwearJosé MorenoNoch keine Bewertungen

- Code - Aster: Multiaxial Criteria of Starting in FatigueDokument44 SeitenCode - Aster: Multiaxial Criteria of Starting in FatigueYoyoNoch keine Bewertungen

- Viscosity Vs ConsistencyDokument6 SeitenViscosity Vs Consistencysontakke manmathNoch keine Bewertungen

- SE 2003&2008 Pattern PDFDokument799 SeitenSE 2003&2008 Pattern PDFBenigno Tique Jonasse100% (1)

- Alkali MetalsDokument12 SeitenAlkali MetalsSaki Sultana LizaNoch keine Bewertungen

- SPCU3C14Dokument20 SeitenSPCU3C14ming tsaoNoch keine Bewertungen

- Forrester Roi StudyDokument30 SeitenForrester Roi StudymcgettsNoch keine Bewertungen

- Effect of Bond Administration On Construction Project DeliveryDokument7 SeitenEffect of Bond Administration On Construction Project DeliveryOlefile Mark MolokoNoch keine Bewertungen

- Chapter 1Dokument11 SeitenChapter 1bekemaNoch keine Bewertungen

- Design and Optimization of Solar Parabolic Trough Collector With Evacuated Absorber by Grey Relational AnalysisDokument9 SeitenDesign and Optimization of Solar Parabolic Trough Collector With Evacuated Absorber by Grey Relational AnalysissatishNoch keine Bewertungen

- TM View Software User - S ManualDokument190 SeitenTM View Software User - S ManualLuis SánchezNoch keine Bewertungen

- Decision Model Using ExcelDokument236 SeitenDecision Model Using Excelসামিউল ইসলাম রাজু100% (3)

- Ef TechnologyDokument2 SeitenEf TechnologyAdarsha SarpangalaNoch keine Bewertungen

- UNIT-1 Introduction To Emi: A Arunkumar GudivadaDokument47 SeitenUNIT-1 Introduction To Emi: A Arunkumar GudivadaBhagya bhagiNoch keine Bewertungen