Beruflich Dokumente

Kultur Dokumente

PNS BAFPS 68 - 2008 - Dried Danggit

Hochgeladen von

dekth1180Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PNS BAFPS 68 - 2008 - Dried Danggit

Hochgeladen von

dekth1180Copyright:

Verfügbare Formate

PHILIPPINE NATIONAL STANDARD

PNS/BAFPS 68:2008 ICS 67.120.30

Dried danggit

BUREAU OF AGRICULTURE AND FISHERIES PRODUCTSTANDARDS

BPI Compound Visayas Avenue, Diliman, Quezon City 1101 Philippines T/ (632) 920.6131 / 455.2856 / 467.9039 TF/ (632) 455.2858 E-mail: bafps@yahoo.com W ebsite: www.bafps.da.gov.ph

DEPARTMENT OF AGRICULTURE

PHILIPPINES

PHILIPPINE NATIONAL STANDARD Foreword

PNS/BAFPS 68: 2008

The Philippine National Standards (PNS) for Dried Danggit was prepared as part of the project of the Bureau of Agriculture and Fisheries Products Standards (BAFPS) with the Bureau of Agricultural Research (BAR) entitled Quality Standardization on Selected Fishery Products . A technical working group (TWG) was created through Special Order Number 100 Series of 2006 identifying members and experts that shall be involved in the formulation the draft standards for fishery products. In collaboration with the industry and the regional offices of the Bureau of Fisheries and Aquatic Resources (BFAR), the TWG presented the draft standards for public consultation in Aklan, Bantayan (Cebu) and General Santos City. The PNS for Dried Danggit aims to provide common understanding on the scope of the standard, product description, classifications, essential composition and quality factors, hygiene and handling, packaging labeling requirements, methods of sampling and analyses, and definition of defectives. A code of practice for the processing and handling of dried fish was also developed for this particular standard.

PHILIPPINE NATIONAL STANDARD Dried danggit 1 Scope

PNS/BAFPS 68: 2008

This standard prescribes quality specifications and safety requirements, and methods for determining these for all commercial dried split danggit (Siganus spp.). 2 References

The titles of the standards publications referred to in this standard are listed on the inside back cover. 3 Definition of terms

For the purpose of this standard, the following terms shall mean: 3.1 artificial drying the process of removing moisture from the fish in an enclosed chamber under controlled temperature, airflow and humidity. 3.2 brine salting the process of soaking fish in salt solution of specific salt concentration for a particular period of time. 3.3 container any form of packaging material, which completely or partially encloses the food (including wrappers). A container may enclose the food as a single item or as several units or types of prepackaged food when such is presented for sale to the consumer. 3.4 contaminants any biological or chemical agent, foreign matter, or other substances that are not intentionally added to food, which may compromise food safety or suitability. 3.5 dry salting the process of mixing fish with salt and stacking the fish into layers one on top of the other. 3.6 dried split fish dried fish prepared by cutting the fish along the dorsal side from the base of the tail to the tip of the head with the internal organs and gills removed prior to salting and drying.

PNS/BAFPS 68: 2008 3.7 food any substance, whether processed or semi-processed or raw which is intended for human consumption and including beverages, chewing gum and any substance, which has been used as an ingredient on the manufacture, preparation or treatment of food. 3.8 food additive any substance not normally consumed as a food by itself and not normally used as a typical ingredient of the food, whether or not it has nutritive value, the intentional addition of which to food for a technological (including sensory evaluation) purpose in the manufacturing, processing, preparation, treatment, packaging, transport or holding of such food results or maybe reasonably expected to result (directly or indirectly) in its or its by product becoming a component of (or otherwise affecting the characteristic of) such food. 3.9 food standard a regulatory guideline that defines the identity of a given food product (i.e. its name and the ingredients used for its preparation) and specifies the minimum quality factors and, when necessary, the required fill of container. It may also include specific labeling requirements other than or in addition to the labeling requirements generally applicable to all prepackaged foods. 3.10 good manufacturing practices (GMP) a quality assurance system aimed at ensuring that products are consistently manufactured, packed, repacked or held to a quality appropriate for the intended use. It is thus concerned with both manufacturing and quality control procedures. 3.11 ingredient any substance including food additive, used as a component in the manufacture or preparation of a food and present in the final product in its original or modified form. 3.12 label includes any tag, brand, mark, pictorial, or other descriptive matter, written printed, marked, embossed or impressed on, or attached to a container of food. 3.13 labeling any written, printed or graphic matter (1) upon any article or any of its container or wrappers or (2) accompanying the packaged food. 3.14 lot food produced during a period of time and under more or less the same manufacturing condition indicated by a specific code.

PNS/BAFPS 68: 2008 3.15 packaging the process of packing that is part of the production cycle applied to a bulk product to obtain the finished product. Any material, including painted material, employed in the packaging of a product including any outer packaging used for transportation of shipment. Packaging materials are referred to as primary or secondary according whether or not they are intended to be in direct contact with the product. 3.16 processed food shall refer to food that has been subjected to some degree of processing (e.g. milling, drying, concentration and canning, etc.), which partially or completely change the physico-chemical and/or sensory characteristics of the raw material. 3.17 sun or solar drying the exposure of fish to open air under the heat of the sun. 3.18 water activity (aW) the ratio of water vapor pressure of the substance to the vapor pressure of pure water at the same temperature. 4 4.1 Description Product definition

The product shall be prepared from fresh fish of the family Siganidae, which have been split, gutted, washed and dried with or without the addition of salt. The heads, bones and tails maybe removed. 4.2 Process definition

The product shall be prepared in one of the salting processes in 4.2.1, if salted and dried by one or a combination of the methods defined in 4.2.2. 4.2.1 Salting methods a) Brine salting is the process of soaking fish in salt solution of specific salt concentration for a particular period of time. Dry salting is the process of mixing fish with salt and stacking the fish into layers one on top of the other.

b)

4.2.2 Drying methods a) b) Sun or solar drying is the exposure of fish to open air under the heat of the sun. Artificial drying is the process of removing moisture from the fish in an enclosed chamber under controlled temperature, airflow and humidity.

PNS/BAFPS 68: 2008 5 5.1 Essential composition and quality factors Ingredients

5.1.1 Fish The fish shall be fresh, and wholesome, fit for human consumption. 5.1.2 Salt Salt shall be of food grade quality and meets the purity requirements of standards for iodized salt as per R.A. No. 8172 An Act Promoting Salt Iodization Nationwide and for Related Purposes. 5.2 Final product

5.2.1 The final product shall conform to the physico-chemical requirements in Table 1. Table 1 Physico-chemical requirements of dried danggit

Characteristic Water activity (aw) maximum at 25C Salt content percent sodium chloride (NaCl), (recommended level) Histamine content (ppm edible portion, maximum)

Requirement 0.75

12.0*

20.0

mg/100g

*salt content may vary provided that the prescribed water activity is not exceeded

5.2.2 The final product shall conform to the following type and size classifications: 5.2.2.1 Type a) b) c) Split, washed and rinsed with fresh water; Split, washed and soaked in sea water; and Split, washed and brined.

PNS/BAFPS 68: 2008 5.2.2.2 Size Classification Table 2 Size of the product as determined by the length of the product (Whole fish) Length 6.1 cm to 7.0 cm 7.1 to 8.0 cm 8.1 to 10 cm

Size designation Small Medium Large 6 Hygiene and handling

6.1 The product shall be prepared in accordance with the Bureau of Food and Drug s AO 153 s. 2004, Revised Guidelines on Current Good Manufacturing Practice in Manufacturing, Packing, Repacking or Holding Food and the Recommended Code of Practice for the processing and handling of dried fish (PNS/BFAD 05: 2006). 6.2 The final product shall conform to the microbiological requirements in Table 3. Table 3 Microbiological specifications for dried danggit n c M M

Analyses Aerobic plate count (cfu/g) Yeasts and molds counts (cfu/g) Total coliforms (MPN/g) Escherichia coli (MPN/g) Staphylococcus aureus (MPN/g)

100,000

500,000

1,000

10,000

10

100

--

11

--

1,000

where: n is the number of samples to be analyzed per volume product; c is the number of samples that may exceed m but not M; m is the maximum count achievable under GMP; and M is the maximum count beyond which product safety / quality may be affected.

PNS/BAFPS 68: 2008 7 7.1 Presentation, packaging and labeling Presentation

7.1.1 The products shall be presented as dried split fish, with or without bones; 7.1.2 The product shall be free from any objectionable odor, color, and flavor; and, any evidence of insect infestation and mold growth; 7.1.3 Individual retail or bulk container shall contain only one species of fish, which are relatively uniform in size; and 7.1.4 The average net weight of the sample unit is not less than the declared net weight provided no individual container shall be less than 95% of the declared net weight. 7.2 Packaging

7.2.1 Retail packaging The product shall be packed in pre-formed bags made of suitable films or laminates and suitable containers. 7.2.2 Bulk packaging The product shall be packed in carton or corrugated boxes or suitable containers lined with plastic films. 7.3 Labeling

7.3.1 Labeling of retail packages/containers Each retail container shall be labeled and marked with the following information in accordance with BFAD Administrative Order Series of 1984. (i) The name of the product. The word dried or dried split shall be followed by the common names in accordance with the customs or practices of the country in which the product is distributed. The species of fish from which the product is derived shall also be declared; The name and the address of the manufacturer, packer, distributor, importer or exporter or vendor of the food; Specify whether the product is salted or unsalted or has low salt content;

(ii)

(iii)

PNS/BAFPS 68: 2008

(iv) The net content by weight in the metric system. Other systems of measurement required by importing countries shall appear in parenthesis after the metric system unit; (v) The words best before followed by the date, month and year indicating end of the period at which the product shall retain its optimum quality attributes at a stated storage condition; Lot identification marked in code identifying product lot; and

(vi)

(vii) The words Product of the Philippines. 7.3.2 Labeling of non-retail containers The name of the product, lot identification and the name and address of the manufacturer or packer shall appear in the container. However, the name and address of the manufacturer may be replaced by identification marks provided that such mark is clearly identified with accompanying documents. 8 8.1 Methods of sampling and analyses Method of sampling

Sampling of lots for physico-chemical examination of the products shall be in accordance with sampling plans provided in Annex E based on FAO/WHO Codex Alimentarius Commission Sampling Plans for Pre-packaged Foods (AQL=6.5) (CAC/RM42 1969). A sample lot (N) shall be the quantity of the product under similar conditions. A sample unit shall be the primary container where the product is in bulk; while the individual fish is the sample unit for retail packaged products. For microbiological analyses, the ICMSF (1978) suggested Case 2, 3-class Sampling Plan is recommended. 8.2 Methods of analyses

8.2.1 Determination of moisture content According to the method of AOAC (1995, 16th Edition) using the Oven Method. 8.2.2 Determination of water activity According to the AOAC (1995, 16th Edition) Methods. 8.2.3 Determination of salt content According to the modified Volhard Method based on AOAC (1995, 16th Edition) Method.

PNS/BAFPS 68: 2008 8.2.4 Determination of histamine content According to the Fluorometric Method or AOAC (1995, 16th Edition) Method. 8.2.5 Determination of aerobic plate count, yeasts and molds According to the USFDA Bacteriological Analytical Manual (1995, 8th Edition) using the Pour Plate Method. 8.2.6 Determination of coliform and Escherichia coli organisms According to the procedure described by ICMSF, 1978. 8.2.7 Determination of Staphylococcus aureus According to the procedure described by ICMSF, 1978. 9 Definitions of defectives

The sample unit shall be considered defective when it exhibits any of the properties defined below. 9.1 Foreign matters

The presence in the sample unit of any matter which has not been derived from the species of fish, does not pose a threat to human health and can be recognized either without magnification or is present at a level determined by any method including magnification that indicates non-compliance with good manufacturing and sanitation practices. 9.2 Appearance

9.2.1 Presence of liver and blood stains, and traces of internal organs; 9.2.2 Excessive cracks, bruises, punctures and crumbling texture; and 9.2.3 Detaching of fish parts (head, tail etc.).

PNS/BAFPS 68: 2008 References The following referenced documents are indispensable for the application of this document. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. BFAD, 2004. Administrative Order No. 153. The Revised Guidelines on the Current Good Manufacturing Practice (cGMP) in Manufacturing, Packing, Repacking or Holding Food. Alabang, Muntinlupa City. Bureau of Food and Drugs FAO/WHO CAC/RCP 1-69, Rev. 3-1997, Amd. (1999). Recommended International Code of Practice: General Principles of Food Hygiene. Rome, Italy. Food and Agriculture Organization/World Health Organization Codex Alimentarius Commission. FAO/WHO CAC/RCP 26-1979. Recommended International Code of Practice for Salted Fish. Rome, Italy. Food and Agriculture Organization/World Health Organization Codex Alimentarius Commission. Product Standard Agency, 1985. PNS 96. Code of Practice in Manufacturing, Processing and Holding Human Food. Philippine National Standard. Republic Act No. 8172. An Act Promoting Salt Iodization Nationwide and for Related Purposes and Its Implementing Rules and Regulations. Published by the National Nutrition Council, 1996. Small Scale Processing of Fish. Technical Memorandum No. 3. International Labor Office. Geneva. 1982. Technology Series

Department of Agriculture Bureau of Agriculture and Fisheries Product Standards Technical Working Group for the Development of Philippine National Standard of Dried Danggit

Chair Director Gilberto F. Layese Bureau of Agriculture and Fisheries Product Standards (BAFPS) Department of Agriculture (DA) Members Ms. Norma C. Borja Bureau of Fisheries and Aquatic Resources (BFAR) Ms. Dolor L. Villaseor Industrial Technology Development Institute (ITDI) Department of Science and Technology (DOST) Ms. Teresita S. Palomares Industrial Technology Development Institute (ITDI) Department of Science and Technology (DOST) Ms. Almueda David Bureau of Food and Drugs (BFAD) Department of Health (DOH) Ms. Charina May Tandas Bureau of Food and Drugs (BFAD) Department of Health (DOH)

Co-chair Ms. Lilia Pelayo Bureau of Fisheries and Aquatic Resources (BFAR) Department of Agriculture (DA)

Experts Involved: Mr. Basilio M. Rodriguez, Jr. Philippine Tilapia Inc. (PTI) Mr. Pete Borja Seaweed Industry Association of the Philippines (SIAP) Mr. Alvin Gimelo Bangus Association of the Philippines (BAPI) Technical Secretariat: Ms. Lara G. Vivas Bureau of Agriculture and Fisheries Product Standards (BAFPS) Ms. Mary Grace Mandigma Bureau of Agriculture and Fisheries Product Standards (BAFPS)

BUREAU OF AGRICUL TURE AND FISHERIES PRODUCT STANDARDS

BPI Compound Visayas Avenue, Diliman, Quezon City 1101 Philippines T/ (632) 920.6131 / 455.2856 / 467.9039 TF/ (632) 455.2858 E-mail: bafps@yahoo.com Website: www.bafps.da.gov.ph

Das könnte Ihnen auch gefallen

- Manual in Fish CanningDokument152 SeitenManual in Fish Canningxtgeronaga100% (1)

- Cottages Bungalows 20140607Dokument148 SeitenCottages Bungalows 20140607Bùi ThắngNoch keine Bewertungen

- PNS BAFS 196 - 2017 - Code of Good Aquaculture Practices For Milkfish and TilapiaDokument15 SeitenPNS BAFS 196 - 2017 - Code of Good Aquaculture Practices For Milkfish and TilapiaMeidior CuetoNoch keine Bewertungen

- Section 2 Microbiology-Answer Key - MicrobiologyDokument80 SeitenSection 2 Microbiology-Answer Key - MicrobiologyKafeel Ahmed100% (2)

- Debate Speech ROTCDokument2 SeitenDebate Speech ROTCdekth118083% (6)

- 2012 27 How To Determine The Shelf Life and Date Marking of FoodDokument33 Seiten2012 27 How To Determine The Shelf Life and Date Marking of FoodPham Thi Cam TuNoch keine Bewertungen

- A Cowboys LifeDokument19 SeitenA Cowboys LifeDucThinhNguyenNoch keine Bewertungen

- GCC Standardization Organization (Gso)Dokument13 SeitenGCC Standardization Organization (Gso)vbnavNoch keine Bewertungen

- Tempeh SummaryDokument9 SeitenTempeh SummaryLovely TinaNoch keine Bewertungen

- PackagingDokument32 SeitenPackagingmelkasewwandi100% (2)

- Gso9 English - 2013Dokument13 SeitenGso9 English - 2013mmammerNoch keine Bewertungen

- Hot Smoked Fish Company HACCP PlanDokument11 SeitenHot Smoked Fish Company HACCP PlanRam Eman OsorioNoch keine Bewertungen

- Food Processing Technology: Principles and PracticeVon EverandFood Processing Technology: Principles and PracticeBewertung: 3.5 von 5 Sternen3.5/5 (7)

- Derek Byerlee, Walter P. Falcon, Rosamond L. Naylor - The Tropical Oil Crop Revolution - Food, Feed, Fuel, and Forests (2016, Oxford University Press)Dokument305 SeitenDerek Byerlee, Walter P. Falcon, Rosamond L. Naylor - The Tropical Oil Crop Revolution - Food, Feed, Fuel, and Forests (2016, Oxford University Press)Dan MuntoiuNoch keine Bewertungen

- PNS-BFAD 01-2005 - Dry Base MixesDokument13 SeitenPNS-BFAD 01-2005 - Dry Base MixesJared Ansaldo0% (1)

- Hot Smoking Fish HACCP ReportDokument16 SeitenHot Smoking Fish HACCP ReportSevim ArslanNoch keine Bewertungen

- Code of Practice for Fish and Fishery ProductsVon EverandCode of Practice for Fish and Fishery ProductsNoch keine Bewertungen

- PNS-BAFPS68-2008 - Dried DanggitDokument12 SeitenPNS-BAFPS68-2008 - Dried DanggitGaily HontiverosNoch keine Bewertungen

- Philippine National Standard For Dried Sea CucumberDokument15 SeitenPhilippine National Standard For Dried Sea CucumberKevin YaptencoNoch keine Bewertungen

- PNS-BFAD 04-2006 - Dried Salted Fish - SpecsDokument17 SeitenPNS-BFAD 04-2006 - Dried Salted Fish - SpecsMuhammad Azharudeen100% (1)

- Pasteurized Crab Meat: Philippine National StandardDokument15 SeitenPasteurized Crab Meat: Philippine National StandardI Kadek Tony Adi SetiawanNoch keine Bewertungen

- Everything You Need to Know About Philippine Dried Anchovies StandardsDokument18 SeitenEverything You Need to Know About Philippine Dried Anchovies StandardsGaily HontiverosNoch keine Bewertungen

- Philippine National Philippine National Philippine National Philippine National Standard Standard Standard StandardDokument15 SeitenPhilippine National Philippine National Philippine National Philippine National Standard Standard Standard StandardldfdNoch keine Bewertungen

- Philippine National Philippine National Philippine National Philippine National Standard Standard Standard StandardDokument14 SeitenPhilippine National Philippine National Philippine National Philippine National Standard Standard Standard StandardGaily HontiverosNoch keine Bewertungen

- RCP Draft Code Bagoong ProcessingDokument30 SeitenRCP Draft Code Bagoong ProcessingRufa Lara Mendez100% (1)

- Philippina National StandardDokument12 SeitenPhilippina National StandardAngelica DuevoNoch keine Bewertungen

- Pembekuan Cepat Ikan FilletDokument8 SeitenPembekuan Cepat Ikan FilletHary DharmaNoch keine Bewertungen

- PNS-BAFPS 67-2008 - Frozen TilapiaDokument14 SeitenPNS-BAFPS 67-2008 - Frozen TilapiaKent BasigaNoch keine Bewertungen

- Codex Standard For Quick Frozen Raw Squid: CODEX STAN 191-1995 Page 1 of 6Dokument6 SeitenCodex Standard For Quick Frozen Raw Squid: CODEX STAN 191-1995 Page 1 of 6gustavosantos01Noch keine Bewertungen

- Codex Standard For Quick Frozen Finfish, Uneviscerated and EvisceratedDokument7 SeitenCodex Standard For Quick Frozen Finfish, Uneviscerated and EvisceratedMet RizalNoch keine Bewertungen

- CXS - 190e Standard For Quick Frozen Fish FilletsDokument6 SeitenCXS - 190e Standard For Quick Frozen Fish FilletsImanNoch keine Bewertungen

- Am Ca FileDokument10 SeitenAm Ca FileNguyen Hien Duc HienNoch keine Bewertungen

- Pembekuan Udang CepatDokument8 SeitenPembekuan Udang CepatHary Prawira DharmaNoch keine Bewertungen

- Code of Hygienic Practice For Fish and Fishery Products Processing EstablishmentDokument16 SeitenCode of Hygienic Practice For Fish and Fishery Products Processing EstablishmentMuhammad Gazali PeluNoch keine Bewertungen

- CXS - 119e Conserva de Peste PDFDokument6 SeitenCXS - 119e Conserva de Peste PDFdorinutza280Noch keine Bewertungen

- Codex Standard For Boiled Dried Salted Anchovies CODEX STAN 236-2003Dokument6 SeitenCodex Standard For Boiled Dried Salted Anchovies CODEX STAN 236-2003henryNoch keine Bewertungen

- CXS - 092e - Codex ShrimpDokument6 SeitenCXS - 092e - Codex ShrimpldfdNoch keine Bewertungen

- Chapter 5 - Fish Quality Assurance: 5.1 Definition of Q.ADokument11 SeitenChapter 5 - Fish Quality Assurance: 5.1 Definition of Q.ADhaval BamaniyaNoch keine Bewertungen

- Food ControlDokument5 SeitenFood ControlpejeNoch keine Bewertungen

- Organic Marine ShrimpDokument27 SeitenOrganic Marine ShrimpRavinder ReddyNoch keine Bewertungen

- Standard For Fish SauceDokument5 SeitenStandard For Fish SauceBassam MalasNoch keine Bewertungen

- 123Dokument6 Seiten123necboowatonNoch keine Bewertungen

- Faculty Science and Techonlogy: Matriculation No: Identity Card No.: Telephone No.: E-Mail: Learning CentreDokument21 SeitenFaculty Science and Techonlogy: Matriculation No: Identity Card No.: Telephone No.: E-Mail: Learning CentreNatasha YusofNoch keine Bewertungen

- CXS - 070e Preparate Din Ton Si Palamida PDFDokument8 SeitenCXS - 070e Preparate Din Ton Si Palamida PDFdorinutza280Noch keine Bewertungen

- A Study About Importance of Biosafety and Biosecurity On Aspect of Good Laboratory Practice (GLP) in A Quality Control (QC) Laboratory of BangladeshDokument11 SeitenA Study About Importance of Biosafety and Biosecurity On Aspect of Good Laboratory Practice (GLP) in A Quality Control (QC) Laboratory of BangladeshPremier PublishersNoch keine Bewertungen

- CXS 119eDokument6 SeitenCXS 119eĐức Thiện ĐỗNoch keine Bewertungen

- BRC Global Standard For Food Safety Issue 7 UK Free PDFDokument5 SeitenBRC Global Standard For Food Safety Issue 7 UK Free PDFMarisa SignarNoch keine Bewertungen

- Codex Stan 92 Rev.1995Dokument8 SeitenCodex Stan 92 Rev.1995Soni SularsoNoch keine Bewertungen

- CODEX STAN 70 1981 Standard For Canned Tuna and BonitoDokument8 SeitenCODEX STAN 70 1981 Standard For Canned Tuna and BonitoHermanaNoch keine Bewertungen

- Standard For Quick Frozen Fish Fillets Codex Stan 190 - 1995Dokument7 SeitenStandard For Quick Frozen Fish Fillets Codex Stan 190 - 1995remyNoch keine Bewertungen

- Foods 12 02657Dokument27 SeitenFoods 12 02657Rahul VashishthNoch keine Bewertungen

- For Public Comment: Draft Malaysian StandardDokument15 SeitenFor Public Comment: Draft Malaysian StandardDukeNoch keine Bewertungen

- Determination of cat food shelf-life at different drying temperaturesDokument12 SeitenDetermination of cat food shelf-life at different drying temperaturesnajmuddin mohdramliNoch keine Bewertungen

- Sous Vide Cooking GuidanceDokument19 SeitenSous Vide Cooking GuidanceJoeNoch keine Bewertungen

- Foods 09 01203Dokument16 SeitenFoods 09 01203Xochitl Ruelas ChaconNoch keine Bewertungen

- Chapter 5 Pasteurized FishDokument13 SeitenChapter 5 Pasteurized FishRizal SiregarNoch keine Bewertungen

- Introducing Improved Small-Scale Smoking Technology For Rohu Fish Smoking, Kale Township, Sagaing Region, MyanmarDokument19 SeitenIntroducing Improved Small-Scale Smoking Technology For Rohu Fish Smoking, Kale Township, Sagaing Region, MyanmarSeyha L. AgriFoodNoch keine Bewertungen

- Codex PDFDokument3 SeitenCodex PDFAnonymous jaiyl8iFhBNoch keine Bewertungen

- CODEX STAN 167-1989 Page 1 of 9Dokument9 SeitenCODEX STAN 167-1989 Page 1 of 9Estephani RojasNoch keine Bewertungen

- 10 3390@foods9091303Dokument12 Seiten10 3390@foods9091303aruna prasadNoch keine Bewertungen

- Packaging Proposal ExampleDokument4 SeitenPackaging Proposal ExampleMa. Jesseca R. RazoNoch keine Bewertungen

- 2017 Code of Good Aquaculture Practices (GAqP)Dokument11 Seiten2017 Code of Good Aquaculture Practices (GAqP)IsabelNoch keine Bewertungen

- Vacuum packaging extends shelf life of smoked milkfishDokument18 SeitenVacuum packaging extends shelf life of smoked milkfishIam Eilsen ObiasNoch keine Bewertungen

- Standards - GMP For Packinghouse of Fresh Fruits and VegetablesDokument18 SeitenStandards - GMP For Packinghouse of Fresh Fruits and VegetableskfyaptencoNoch keine Bewertungen

- Sensory Evaluation Guidelines for Fish and Shellfish LaboratoriesDokument33 SeitenSensory Evaluation Guidelines for Fish and Shellfish LaboratoriesSusantika MurtiniNoch keine Bewertungen

- Handbook of Seafood Quality, Safety and Health ApplicationsVon EverandHandbook of Seafood Quality, Safety and Health ApplicationsCesarettin AlasalvarNoch keine Bewertungen

- Deped Order 51 s2016 Implementation of School Based Feeding Program PDFDokument49 SeitenDeped Order 51 s2016 Implementation of School Based Feeding Program PDFdekth1180100% (1)

- Seating ChartDokument1 SeiteSeating Chartdekth1180Noch keine Bewertungen

- FNRI Lab SchedDokument1 SeiteFNRI Lab Scheddekth1180Noch keine Bewertungen

- E-Class Science Record SheetDokument54 SeitenE-Class Science Record SheetaveheeNoch keine Bewertungen

- Food Safety Audit Report USDokument26 SeitenFood Safety Audit Report USdekth1180Noch keine Bewertungen

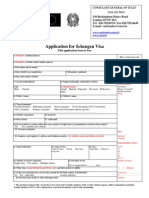

- Visa FormDokument2 SeitenVisa Formumasankar_vknNoch keine Bewertungen

- Agriculture by MohiniDokument12 SeitenAgriculture by MohiniRishabh AroraNoch keine Bewertungen

- CASE-5 Daali Earth FoodsDokument9 SeitenCASE-5 Daali Earth FoodsHashim Ayaz KhanNoch keine Bewertungen

- Thomas Malthus PDFDokument4 SeitenThomas Malthus PDFapi-316446159Noch keine Bewertungen

- Indian Geography UPSC, Banking & SSC ExamsDokument6 SeitenIndian Geography UPSC, Banking & SSC ExamsshivaNoch keine Bewertungen

- University of Cambridge International Examinations General Certificate of Education Ordinary LevelDokument16 SeitenUniversity of Cambridge International Examinations General Certificate of Education Ordinary Levelmstudy123456Noch keine Bewertungen

- Connectors Multiple Exercises AnswersDokument14 SeitenConnectors Multiple Exercises AnswersIrene SánchezNoch keine Bewertungen

- Tugas Parafrase Jurnal MIPKI RevisiDokument2 SeitenTugas Parafrase Jurnal MIPKI RevisiAl-aminNoch keine Bewertungen

- BIOPESTICIDESDokument14 SeitenBIOPESTICIDESnabajyotib054Noch keine Bewertungen

- Local Capacities For Peace 2008 ENDokument72 SeitenLocal Capacities For Peace 2008 ENmaxamed faysalNoch keine Bewertungen

- Phillipine PresidentsDokument15 SeitenPhillipine PresidentsJulius BeraldeNoch keine Bewertungen

- I1B Brick KilnsDokument20 SeitenI1B Brick KilnsmuhammadsuhaibNoch keine Bewertungen

- En M Wikipedia Org Wiki M S SwaminathanDokument16 SeitenEn M Wikipedia Org Wiki M S SwaminathanShiva Kumar100% (1)

- Frolic: Prelude To Marketing Case 1Dokument6 SeitenFrolic: Prelude To Marketing Case 1Abinath StuartNoch keine Bewertungen

- 34-Husk MulchingDokument2 Seiten34-Husk MulchingFrank Dagohoy0% (1)

- Selected Indicator For Agriculture Development Asia Pacific 2011Dokument248 SeitenSelected Indicator For Agriculture Development Asia Pacific 2011Ita SualiaNoch keine Bewertungen

- Mexican Migration to the United States: A History of Economic Drivers and Cultural ImpactsDokument19 SeitenMexican Migration to the United States: A History of Economic Drivers and Cultural ImpactsAngeloCicchettiNoch keine Bewertungen

- ACF Supply and Demand Report - October 18Dokument6 SeitenACF Supply and Demand Report - October 18Ishan SaneNoch keine Bewertungen

- SCP Beer Score SheetDokument1 SeiteSCP Beer Score SheetFamilia Orozco MedinaNoch keine Bewertungen

- The Impact of Human Activities On Coral ReefsDokument19 SeitenThe Impact of Human Activities On Coral ReefsmoniqueNoch keine Bewertungen

- E-Ifc No. 37 June 2014 HR 3.69 MBDokument31 SeitenE-Ifc No. 37 June 2014 HR 3.69 MBqadriranaNoch keine Bewertungen

- Phosphorus Content in FoodsDokument9 SeitenPhosphorus Content in FoodsShane GitterNoch keine Bewertungen

- Activity Sheet Quarter 3 - Week 3: Tvl-Afa - (Agricultural Crops Production Ncii)Dokument7 SeitenActivity Sheet Quarter 3 - Week 3: Tvl-Afa - (Agricultural Crops Production Ncii)Ma Luisa Ancog AngsincoNoch keine Bewertungen

- Passive Voice Sentence StructuresDokument2 SeitenPassive Voice Sentence StructuresHernan Dario Espinosa MartinezNoch keine Bewertungen

- GROUP WORK-Agriculture Biological Asset and Agricultural Produce13-FINALDokument5 SeitenGROUP WORK-Agriculture Biological Asset and Agricultural Produce13-FINALREMBRANDT KEN LEDESMANoch keine Bewertungen

- Brand Book 2019Dokument60 SeitenBrand Book 2019Avinash DekaNoch keine Bewertungen

- Agriculture Grade 11 Unit 1Dokument48 SeitenAgriculture Grade 11 Unit 1tsi92816100% (1)