Beruflich Dokumente

Kultur Dokumente

Abb PLC Ac500-Xc: For Extreme Conditions at Indoor and Outdoor

Hochgeladen von

Marvin VillcaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Abb PLC Ac500-Xc: For Extreme Conditions at Indoor and Outdoor

Hochgeladen von

Marvin VillcaCopyright:

Verfügbare Formate

ABB PLC AC500-XC For extreme conditions at indoor and outdoor

2 2CDC125168B0201

PLC AC500-XC for extreme conditions at indoor and outdoor Ruggedized variants for those fighting with the elements wind, solar, water, pumping, crane, robot, marine, glass

PLC AC500 introduction AC500 is ABBs highly scalable PLC offering lots of different I/O, all major fieldbus interfaces and a wide range of powerful CPU modules. Built-in internet technology allow remote maintenance and remote programming as well and much more. There is always an AC500 configuration which takes care of costs. Anyway, those looking for highest performance as for motion control or closed-loop control via PROFINET find affordable solutions, too. XC stands for extremeconditions ABB expands the AC500 applications from factory automation to renewable energy, waste water treatment and offshore. Many other application benefit from XC as well. Almost any AC500 item is available as XC version. Physical dimensions, basic electrical characteristics and software compatibility correspond with the standard assortment. Extreme conditions details AC500-XC withstands harsh conditions during operations and storage. In many cases, this makes engineering and operations much more cost-efficient. Specification details Extended operating temperature operating temperature -30 C up to +70 C (two couplers, regular mounting, display readable above 0 C) reliable system start at -40 C Extended immunity to vibration 4 g root mean square random vibration up to 500 Hz 2 g sinusoidal vibration up to 500 Hz, including SD-card Extended immunity to hazardous gases and salt mist G3, 3C2 immunity salt mist EN 60068-2-52 / EN 60068-2-11 Hazardous gases from the standard IEC60721-3.3 3C2 mean for example: H 2S SO2/SO3 CL2 NOX Use at high altitudes operating altitude up to 4,000 m above sea level Extended EMC requirements EN 61000-4-5 surge immunity test EN 61000-4-4 transient / burst immunity test

Benefit AC500-XC benefit is cost saving in engineering and operations. Many extras become obsolete: sealing at cable entrances and doors shock absorbers HVAC for the panel cooling fins and cut-outs EMC protection Without HVAC, energy and maintenance costs can be kept at a minimum. So the efforts to design, purchase, install and argue for expensive housings are fully gone. Everybody affected with special cabinets or panels will save time and money thanks to the now possible straight-forward cabinet design. Savings in cable infrastructure Plain components are often placed in buildings for protection, while the I/O port is needed elsewhere. The then required cabling requires relative complex fieldbusses, cables and ducts. The better way can be the robust AC500-XC, placed at the point where the I/O is needed. AC500-XC eliminates the cable hassle. Benefits for design engineers Mechanical dimensions and electrical specifications of connections are the same as for AC500. Panel layouts and wiring harnesses can be re-used. Mechanical design effort is mostly as for plain control gear. Time and complexity are saved. Benefits for operators Investments can be kept at minimum due to smaller engineering efforts. Maintenance and repair efforts are lower than with special expensive cabinets carrying plain components. Product range Please refer to newest AC500 catalog which presents PLC, HMI, highavailability, operations and wireless. Applications Wind turbines, solar trackers, water treatment, sewage, construction equipment, mobile and fixed cranes, robot cell automation, vessels, navigational lights and guidance equipment, beacons, billboard, display, tunnel safety, rail-borne automatic vehicles.

2CDC125168B0201 3

Contact us

www.abb.com/plc www.abb.com/drives

ABB Global Contact Directory The ABB Contact Directory (http://www.abb.com/ contacts/) helps you find local contacts for ABB products in your country. Please select the relevant product group from the dropdown menu to the right or from the page.

We reserve all rights in this document and in the subject matter and illustrations contained therein. Any reproduction, disclosure to third parties or utilization of its contents in whole or in parts is forbidden without prior written consent of ABB AG. Copyright 2011 ABB All rights reserved

Order Number 2CDC 125 168 B0201 printed in Germany (10/11)

ABB Automation Products GmbH Wallstadter Str. 59 68526 Ladenburg, Germany Phone: +49 (0) 6221 701-1444 Fax: +49 (0) 6221 701-1382 Email: plc.sales@de.abb.com

Note: We reserve the right to make technical changes or modify the contents of this document without prior notice. With regard to purchase orders, the agreed particulars shall prevail. ABB AG does not accept any responsibility whatsoever for potential errors or possible lack of information in this document.

Das könnte Ihnen auch gefallen

- ABB SWBD VD4 Brochure PDFDokument6 SeitenABB SWBD VD4 Brochure PDFanand_girgaonkarNoch keine Bewertungen

- VSD ACS 1000 Technical CatalogueDokument106 SeitenVSD ACS 1000 Technical Cataloguedto_otb100% (1)

- Compass: Compact Prefabricated Air Insulated SubstationDokument16 SeitenCompass: Compact Prefabricated Air Insulated Substationcarlose_123Noch keine Bewertungen

- 2CSC400002D0208Dokument751 Seiten2CSC400002D0208Pedro BortotNoch keine Bewertungen

- Apresentação Unisec AbbDokument76 SeitenApresentação Unisec AbbAnd Web100% (1)

- 1.eclipse Datasheet Issue 4-20-51b73d7fe49f9Dokument2 Seiten1.eclipse Datasheet Issue 4-20-51b73d7fe49f9mariomatoNoch keine Bewertungen

- SQD 6152.v2Dokument128 SeitenSQD 6152.v2ttygttNoch keine Bewertungen

- Rcbo (DS201 - DS202C) 2CSC422004B0203Dokument28 SeitenRcbo (DS201 - DS202C) 2CSC422004B0203Oswald NgNoch keine Bewertungen

- Acti9 Communication System CatalogDokument78 SeitenActi9 Communication System CatalogAdiKurniawanNoch keine Bewertungen

- Busbar Differential ProtectionDokument13 SeitenBusbar Differential ProtectionVijay Kumar0% (2)

- The Switchboard That Your Installation Deserves: BloksetDokument12 SeitenThe Switchboard That Your Installation Deserves: Bloksetmumi87Noch keine Bewertungen

- 716 - UniGear ZS2 With VD4 05Dokument6 Seiten716 - UniGear ZS2 With VD4 05srmohapatra5086Noch keine Bewertungen

- Okken Catalogue 2007engDokument318 SeitenOkken Catalogue 2007engLaura Daniela Gavrilas67% (3)

- Integrated GIS 170 H5 Flyer 1HC0104143ACEnDokument2 SeitenIntegrated GIS 170 H5 Flyer 1HC0104143ACEnKing KingNoch keine Bewertungen

- B - BVK-A 2012 EnglDokument10 SeitenB - BVK-A 2012 EnglDamir KrželjNoch keine Bewertungen

- ApparatusDokument85 SeitenApparatusTap ToanNoch keine Bewertungen

- Noticias ABB Breakers y MedicionDokument68 SeitenNoticias ABB Breakers y MedicionRonald Suriaga AuthemanNoch keine Bewertungen

- SENTRON - LV10-PH01 - Complete English 2014Dokument62 SeitenSENTRON - LV10-PH01 - Complete English 2014Patrick MacielNoch keine Bewertungen

- Catalog Okken enDokument26 SeitenCatalog Okken enSaid BelhaimerNoch keine Bewertungen

- Cable Tray InstallationDokument10 SeitenCable Tray Installationalrwin_b2yNoch keine Bewertungen

- Control It: Hardware (Ac800 M/C) & SoftcontrollerDokument74 SeitenControl It: Hardware (Ac800 M/C) & SoftcontrollerDoc_LACNoch keine Bewertungen

- MCCB Ns800n Compact Merlin Gerin - 2Dokument168 SeitenMCCB Ns800n Compact Merlin Gerin - 2Haroon ElahiNoch keine Bewertungen

- Catalogo Sm6 2012Dokument124 SeitenCatalogo Sm6 2012Gilberto Mejía50% (2)

- ABB Surge Protection DevicesDokument18 SeitenABB Surge Protection DevicesPrashanth ChandrashekarNoch keine Bewertungen

- Cathelco ICCP Hull Protection SystemsDokument8 SeitenCathelco ICCP Hull Protection SystemsdalianbouriNoch keine Bewertungen

- REB500Dokument75 SeitenREB500RetratosDeMiVidaNoch keine Bewertungen

- 2 ABB Shift1Dokument22 Seiten2 ABB Shift1Fredrick MuigaiNoch keine Bewertungen

- A9R6C32Dokument148 SeitenA9R6C32Rahul SinganiaNoch keine Bewertungen

- Type of Drawout PDFDokument58 SeitenType of Drawout PDFrantaroNoch keine Bewertungen

- SafeRing SafePlus 12-24kV May 2013 EnglishDokument88 SeitenSafeRing SafePlus 12-24kV May 2013 EnglishDubravko100% (1)

- Abb RmuDokument88 SeitenAbb RmumarkfoyNoch keine Bewertungen

- Siemens SentronDokument62 SeitenSiemens SentronGonzalo PadillaNoch keine Bewertungen

- Sepam 10 Seped307026en Int PDFDokument22 SeitenSepam 10 Seped307026en Int PDFJeffrey Reynaldo RidwanNoch keine Bewertungen

- Sabre Range Brochure WebDokument64 SeitenSabre Range Brochure WebKadirou BigstarNoch keine Bewertungen

- Siemens ALPHA BS Sub and Final Distribution CatalogueDokument40 SeitenSiemens ALPHA BS Sub and Final Distribution CatalogueAl-Usmanu UsmanNoch keine Bewertungen

- Katalog Pretvarača ABB ACS800Dokument60 SeitenKatalog Pretvarača ABB ACS800klozet85Noch keine Bewertungen

- Uncompromising Safety and Comfort (Abb)Dokument18 SeitenUncompromising Safety and Comfort (Abb)abrizal92Noch keine Bewertungen

- 72 - 800 Gas Insulated Switchgear SiemensDokument10 Seiten72 - 800 Gas Insulated Switchgear Siemensamir17012076Noch keine Bewertungen

- SENTRON Residual Current Protective Devices AFDDs Complete English 10 2014 201502111453105536Dokument50 SeitenSENTRON Residual Current Protective Devices AFDDs Complete English 10 2014 201502111453105536Alvaro Coy H.Noch keine Bewertungen

- Easypact Catalouge 10-11-2011 V1Dokument70 SeitenEasypact Catalouge 10-11-2011 V1thiago_gomes7953Noch keine Bewertungen

- Gas Insulated Switchgear For High Voltage Substations SiemensDokument10 SeitenGas Insulated Switchgear For High Voltage Substations SiemenspcelisNoch keine Bewertungen

- Abb Pricelist 2016 16.03.2016Dokument216 SeitenAbb Pricelist 2016 16.03.2016Nasir UddinNoch keine Bewertungen

- ABB CatalogueDokument9 SeitenABB CatalogueSai KiranNoch keine Bewertungen

- Câtlo ABB PDFDokument288 SeitenCâtlo ABB PDFquocthinh_09Noch keine Bewertungen

- ELK-14C 245 1HC0078221AIEnDokument20 SeitenELK-14C 245 1HC0078221AIEnJoel PalomaresNoch keine Bewertungen

- ABB Industrial Drives: ACS800, Single Drives 0.55 To 5600 KW CatalogDokument68 SeitenABB Industrial Drives: ACS800, Single Drives 0.55 To 5600 KW CatalogYaa ShinNoch keine Bewertungen

- Innovative Solid State Circuit Breaker Will Make Ships Safer and More Energy EfficientDokument3 SeitenInnovative Solid State Circuit Breaker Will Make Ships Safer and More Energy EfficientFaryal Gohar Shah 6438-FMS/BBA/F21Noch keine Bewertungen

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsVon Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsBewertung: 4 von 5 Sternen4/5 (1)

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsVon EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNoch keine Bewertungen

- Electrical Energy Efficiency: Technologies and ApplicationsVon EverandElectrical Energy Efficiency: Technologies and ApplicationsNoch keine Bewertungen

- Linear IC Applications: A Designer's HandbookVon EverandLinear IC Applications: A Designer's HandbookBewertung: 4 von 5 Sternen4/5 (1)

- Residual Current Devices: Selection, Operation, and TestingVon EverandResidual Current Devices: Selection, Operation, and TestingNoch keine Bewertungen

- Beginning Digital Electronics through ProjectsVon EverandBeginning Digital Electronics through ProjectsBewertung: 5 von 5 Sternen5/5 (1)

- High-Performance D/A-Converters: Application to Digital TransceiversVon EverandHigh-Performance D/A-Converters: Application to Digital TransceiversNoch keine Bewertungen

- Group 4: Prachi Agarwal, Kriti Sharan, Sumit Naugraiya, Sumit Puri, Vishnu Sharma & Govind DagaDokument53 SeitenGroup 4: Prachi Agarwal, Kriti Sharan, Sumit Naugraiya, Sumit Puri, Vishnu Sharma & Govind DagakritisharanNoch keine Bewertungen

- HWQS Intl System ArchitectureDokument1 SeiteHWQS Intl System Architecturereezqee100% (1)

- Surpac ReportingDokument4 SeitenSurpac ReportingDelfidelfi SatuNoch keine Bewertungen

- Sharmila Podder - Cv.newDokument2 SeitenSharmila Podder - Cv.newMustafa Hussain100% (3)

- State Management in React NativeDokument25 SeitenState Management in React NativeRüstem EleçNoch keine Bewertungen

- Dbms ManualDokument144 SeitenDbms ManualER Jagdeep GurjarNoch keine Bewertungen

- Underwater ROV Control SystemDokument20 SeitenUnderwater ROV Control SystemPhanNamNoch keine Bewertungen

- αξεσουαρ SKODA CITIGO SPORTDokument7 Seitenαξεσουαρ SKODA CITIGO SPORTSkoda Club PeloponnhsouNoch keine Bewertungen

- SystemDesk - EB Tresos Studio Workflow DescriptionsDokument23 SeitenSystemDesk - EB Tresos Studio Workflow DescriptionsAmalkumar V GNoch keine Bewertungen

- Result MBTDokument40 SeitenResult MBTAnkush R KrishnaNoch keine Bewertungen

- Obsolete Product: Descriptio FeaturesDokument8 SeitenObsolete Product: Descriptio FeaturesMaria Das Dores RodriguesNoch keine Bewertungen

- BAY pt3Dokument0 SeitenBAY pt3alsamixersNoch keine Bewertungen

- Doom SourceDokument818 SeitenDoom SourceEvil-Soft.comNoch keine Bewertungen

- 01 - Cisco ISE Profiling Reporting - Part 1Dokument1 Seite01 - Cisco ISE Profiling Reporting - Part 1Nguyen LeNoch keine Bewertungen

- DualityDokument28 SeitenDualitygaascrNoch keine Bewertungen

- B.Sc. Chemistry Honours-2022: 1 ListDokument4 SeitenB.Sc. Chemistry Honours-2022: 1 ListSrijaNoch keine Bewertungen

- Security SY0 501 Study GuideDokument39 SeitenSecurity SY0 501 Study GuidereNoch keine Bewertungen

- Manual ETANK2000Dokument73 SeitenManual ETANK2000Ever BriceñoNoch keine Bewertungen

- ZET 8 Astrology Software: Welcome Astrological Feature ListDokument254 SeitenZET 8 Astrology Software: Welcome Astrological Feature ListLeombruno BlueNoch keine Bewertungen

- FILE Procedures in Obtaining and Carrying Out Work InstructionsDokument3 SeitenFILE Procedures in Obtaining and Carrying Out Work InstructionsEmmerNoch keine Bewertungen

- Trader Manual PDFDokument121 SeitenTrader Manual PDFlorenneth87% (15)

- Grade 9 Math Unit 2 Review AssignmentDokument6 SeitenGrade 9 Math Unit 2 Review AssignmentQurat-Ul-Ain JaferiNoch keine Bewertungen

- 2006-2011 Yaris OEM Cruise Control DIY 20110315Dokument34 Seiten2006-2011 Yaris OEM Cruise Control DIY 20110315juanNoch keine Bewertungen

- Cobol Programming ManualDokument58 SeitenCobol Programming Manualalex_osNoch keine Bewertungen

- GPS and GSM Based Vehicle Tracking SystemDokument16 SeitenGPS and GSM Based Vehicle Tracking SystemShreyas Sridhar0% (2)

- Harvard Apparatus, Model 44 Syringe Pump User ManualDokument56 SeitenHarvard Apparatus, Model 44 Syringe Pump User ManualthynameisraymondNoch keine Bewertungen

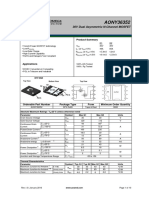

- AONY36352: 30V Dual Asymmetric N-Channel MOSFETDokument10 SeitenAONY36352: 30V Dual Asymmetric N-Channel MOSFETrobertjavi1983Noch keine Bewertungen

- Teachers Voices From Argentine ClassroomsDokument69 SeitenTeachers Voices From Argentine ClassroomsEmanuel AlvarezNoch keine Bewertungen

- JDEtips Article E1PagesCreationDokument20 SeitenJDEtips Article E1PagesCreationValdir AraujoNoch keine Bewertungen

- White Paper On Good GovernanceDokument24 SeitenWhite Paper On Good GovernanceDeekshit KumarNoch keine Bewertungen