Beruflich Dokumente

Kultur Dokumente

Calcul Fatigue Resistance Materiaux

Hochgeladen von

ern_43Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Calcul Fatigue Resistance Materiaux

Hochgeladen von

ern_43Copyright:

Verfügbare Formate

- -- ---- -

I,

ANALYTICAL STRENGTH

ASSESSMENT

5t h Edition

VDMA Verlag

I I

Forschungskuratorium II

Maschinenbau

FKM-Guideline

ANALYTICAL STRENGTH ASSESSMENT

OF COMPONENTS

IN MECHANICAL ENGINEERING

5

th

, revised edition, 2003, English Version

Translation by E. Haibach

Title of the original German Version:

RECHNERISCHER FESTIGKEITSNACHWEIS

FUR MASCHINENBAUTEILE

5., iiberarbeitete Ausgabe, 2003

Editor:

Forschungskuratorium Maschinenbau (FKM)

Postfach 71 0864, D - 60498 Frankfurt / Main

Phone *49 - 69 - 6603 - 1345

(c) 2003

byVDMA Verlag GmbH

Lyoner StraBe 18

60528 Frankfurt am Main

www.vdma-verlag.de

All rights reserved

AIle Rechte, insbesondere das Recht

der Vervielfaltigung und Verbreitung

sowie der Ubersetzung vorbehalten.

Kein Teil des Werkes darfin irgend-

einer Form (Druck, Fotokopie,

Mikrofilm oder anderes Verfahren) ohne

schriftliche Genehmigung des Verlages

reproduziert oder unter Verwendung

elektronischer Systeme gespeichert,

verarbeitet, vervielfaltigt oder

verbreitet werden.

ISBN 3-8163-0425-7

3

This FKM-Guideline was elaborated under contract between

Forschungskuratorium Maschinenbau e. V. (FKM), Frankfurt / Main, and

IMA Materialforschung und Anwendungstechnik Gmhfl, Dresden,

as contractor in charge,

by

Dr.-Ing. Bernd Hanel,

IMA Materialforschung und Anwendungstechnik GmbH, Dresden,

Prof. Dr.-Ing. Erwin Haibach,

Wiesbaden,

Prof. Dr.-Ing. TimID Seeger,

Technische Hochschule Darmstadt, Fachgebiet Werkstoffmechanik,

Dipl.-Ing. Gert Wlrthgen,

IMA Materialforschung und Anwendungstechnik GmbH, Dresden,

Prof. Dr.-Ing. Harald Zenner,

Technische Universitat Clausthal, Institut fur

Maschinelle Anlagentechnik und Betriebsfestigkeit,

and it was discussed among experts from industry and research institutes

in the FKM expert group "Strength of components" .

Financial grants were obtained from the "Bundesministerium fUr Wirtschaft (BMWi, Bonn)" through

the "Arbeitsgemeinschaft industrieller Forschungsvereinigungen 'Otto von Guericke ' e. V. (AiF,

K6ln)" under contract AiF-No. D-156 and B-9434. The "Forschungskuratorium Maschinenbau e.V."

gratefully acknowledges the financial support from BMWi and AiF and the contributions by the experts

involved.

Terms of liability

The FKM-Guideline is intended to conform with the state of the art. It has been

prepared with the necessary care. The user is expected to decide, whether the

guideline meets his particular requirements, and to observe appropriate care in

its application. Neither the publisher nor the editor, the involved experts, or the

translator shall be liable to the purchaser or any other person or entity with

respect to any liability, loss, or damage caused or alleged to have been caused

directly or indirectly by this guideline.

Preface to the English Version of

the 5

th

Edition.

For engineers concerned with construction and

calculation in mechanical engineering or in related fields

of industry the FKM-Guideline for analytical strength

assessment is available since 1994. This guideline was

elaborated by an expert group "Strength of components"

of the "Forschungskuratorium Maschinenbau (FKM),

Frankfurt/Main," with financial support by the

Bundesministerium fur Wirtschaft (BMWi), by the

"Arbeitsgemeinschaft industrieller Forschungsvereini-

gungen 'Otto von Guericke" and by the "Forschungs-

kuratorium Maschinenbau.

Based on former TGL standards and on the former

guideline VDI 2226, and referring to more recent

sources it was developed to the current state of

knowledge.

The FKM-Guideline

- is applicable in mechanical engineering and in related

fields of industry,

- allows the analytical strength assessment for rod-

shaped (lD), for shell-shaped (2D) and for block-shaped

(3D) components under consideration of all relevant

influences,

- describes the assessment of the static strength and of

the fatigue strength, the latter according to an assessment

of the fatigue limit, of the constant amplitude fatigue

strength, or of the variable amplitude fatigue strength

according to the service stress conditions,

- is valid for components from steel, cast steel, or cast

iron materials at temperatures from -40C to 500 C, as

well as for components from aluminum alloys and cast

aluminum alloys at temperatures from -40C to 200 C,

- is applicable for components produced with or without

machining, or by welding,

- allows an assessment in considering nominal stresses as

well as local elastic stresses derived from finite element

or boundary element analyses, from theoretical

mechanics solutions, or from measurements.

A uniformly structured calculation procedure applies to

all of these cases of application. The calculation

procedure is almost completely predetermined. The user

has to make some decisions only.

The FKM-Guideline is a commented algorithm,

consisting of statements, formulae, and tables. Most of

the included figures have an explanatory function only.

4

Textual declarations are given where appropriate to

ensure a reliable application.

Its content complies with the state of knowledge to an

extend that may be presented in a guideline and it

enables quite comprehensive possibilities of calculation.

The employed symbols are adapted to the extended

requirements of notation. The presented calculation

procedure is complemented by explanatory examples.

Practically the described procedure of strength

assessment should be realized by means of a suitable

computer program. Presently available are the PC

computer programs "RIFESTPLUS" (applicable for a

calculation using elastically determined local stresses, in

particular with shell-shaped (2D) or block-shaped (3D)

components) and "WELLE" (applicable for a calculation

using nominal stresses as it is appropriate in the

frequently arising case of axles or shafts with gears etc).

The preceding editions of the FKM-Guideline observed

a remarkably great interest from which the need of an up

to date guideline for analytical strength analyses

becomes apparent. Moreover the interest of users was

confirmed by the well attended VDI conferences on

"Computational Strength Analysis of Metallic

Components", that were organized for presentation of

the FKM-Guideline at Fulda in 1995, 1998 and 2002.

The contents-related changes introduced with the third

edition from 1998 were mainly concerned with the

consideration of stainless steel and of forging steel, with

the technological size factor, with the section factor for

assessing the static strength, with the fatigue limit of

grey cast iron and of malleable cast iron, with additional

fatigue classes of welded structural details and with the

local stress analysis for welded components, with the

specification of an estimated damage sum smaller than

one for the assessment of the variable amplitude fatigue

strength, with the assessment of multiaxial stresses, and

with the experimental determination of component

strength values.

An essential formal change in the third edition was a

new textual structure providing four main chapters, that

describe the assessment of the static strength or of the

fatigue strength with either nominal stresses or local

stresses, respectively. For ease of application each of

these chapters gives a complete description of the

particular calculation procedure, although this results in

repetitions of the same or almost the same parts of text in

the corresponding sections.

The major change in the forth edition from 2002 is the

possibility of considering structural components made

from aluminum alloys or cast aluminum alloys by

applying the same calculation procedure that was

developed for components from steel, cast steel and cast

iron materials so far.

The decisions necessary to include aluminum materials

were derived from literature evaluations. It had to be

recognized, however, that some of the relevant factors of

influence were not yet examined with the desirable

clearness or that available results could not be evaluated

objectively due to large scatter. In these cases the

decision was based on a careful consideration of

substantial relations.

Concerning an analytical strength assessment of

components from aluminum alloys or from cast

aluminum alloys this guideline is delivered to the

technical community by supposing that for the time

being it will be applied with appropriate caution and

with particular reference to existing experience so

far.

The involved research institutes and the "Forschungs-

kuratorium Maschinenbau (FKM)" will appreciate any

reports on practical experience as well as any proposals

for improvement.

Further improvements may also be expected from

ongoing research projects concerning the procedure of

static strength assessment using local elastic stresses,

Chapter 3, and the fatigue assessment of extremely sharp

notches.

Last not least the fifth edition of the FKM-Guideline is a

revision of the forth edition with several necessary,

mainly formal amendments being introduced. It is

presented in both a German version and an English

version with the expectation that it might observesimilar

attention as the preceding editions on a broadened

international basis of application.

5

Notes of the translator

This English translation is intended to keep as close as

possible to the original German version, but by using a

common vocabulary and simple sentences. If the given

translation is different from a literal one, the technical

meaning of the sentence and/or of the paragraph is

maintained, however.

The translation observes an almost identical structure of

the headlines, of the chapters, of the paragraphs and of

the sentences, and even of the numbering of the pages.

Also the tables and the figures as well as their numbering

and headlines are adapted as they are, while only the

verbal terms have been translated.

In particular the original German notation of the

mathematical symbols, indices and formulas, as well

as their numbering, has not been modified in order to

insure identity with the German original in this

respect.

The applier of this guideline is kindly asked to accept

the more or less unusual kind of notation which is

due to the need of clearly distinguishing between a

great number of variables.

In particular the applier is pointed to the speciality,

that a comma ( , ) is used with numerical values

instead of a decimal point ( . ), hence 1,5 equals 1.5

for example. .

For updates and amendments see

www.fkm-guideline.de

6

References

/1/ TGL 19 340 (1983). Ermiidungsfestigkeit, Dauerfestigkeit der Maschinenbauteile.

/2/ TGL 19 341 (1988). Festigkeitsnachweis fiir Bauteile aus Eisengusswerkstoffen.

/3/ TGL 19 333 (1979). Schwingfestigkeit, Zeitfestigkeit von Achsen und Wellen.

/4/ TGL 19 350 (1986). Ermiidungsfestigkeit, Betriebsfestigkeit der Maschinenbauteile.

/5/ TGL 19 352 (Entwurf 1988). Aufstellung und Uberlagerung von Beanspruchungskollektiven.

/6/ Richtlinie VDI 2226 (1965). Empfehlung fiir die Festigkeitsberechnung metallischer Bauteile.

/7/ DIN 18 800 Teil 1 (1990). Stahlbauten, Bemessung und Konstruktion.

/8/ DIN ENV 1993 (1993). Bemessung und Konstruktion von Stahlbauten, Teil1-1:

Allgemeine Bemessungsregeln, ... (Eurocode 3).

/9/ Hobbacher, A.: Fatigue design of welded joints and components. Recommendations of the Joint Working

Group XIII-XV, XIII-1539-96 / XV-845-96. Abbington Publishing, Abbington Hall, Abbington,

Cambridge CB1 6AH, England, 19996

/10/ Haibach, E.: Betriebsfestigkeits - Verfahren und Daten zur Bauteilberechnung, 2.Aufl.

Berlin und Heidelberg, Springer-Verlag, 2002, ISBN 3-540-43142-X.

/11/ Radaj, D.: Ermiidungsfestigkeit. Grundlage fur Leichtbau, Maschinenbau und Stahlbau.

Berlin und Heidelberg: Springer-Verlag, 2003, ISBN 3-540-44063-1.

/12/ FKM-Forschungsheft 241 (1999). Rechnerischer Festigkeitsnachweis fiir Bauteile aus Alumininiumwerkstoff.

/13/ FKM-Forschungsheft 230 (1998). Randschichthartung.

/14/ FKM-Forschungsheft 227 (1997). Lebensdauervorhersage II.

/15/ FKM-Forschungsheft 221-2 (1997). Mehrachsige und zusammengesetzte Beanspruchungen.

/16/ FKM-Forschungsheft 221 (1996). Wechselfestigkeit von Flachproben aus Grauguss.

/17/ FKM-Forschungsheft 183-2 (1994). Rechnerischer Festigkeitsnachweis fur Maschinenbauteile, Richtlinie. *1

/18/ FKM-Forschungsheft 183-1 (1994). Rechnerischer Festigkeitsnachweis fiir Maschinenbauteile, Kommentare.

/19/ FKM-Forschungsheft 180 (1994). Schweillverbindungen II.

/20/ FKM-Forschungsheft 143 (1989). Schweillverbindungen I.

/21/ FKM-Richtlinie Rechnerischer Festigkeitsnachweis fiir Maschinenbauteile,

3., vollstandig iiberarbeitete und erweiterte Ausgabe (1998).

/22/ FKM-Richtlinie Rechnerischer Festigkeitsnachweis fur Maschinenbauteile,

4., erweiterte Ausgabe (2002).

Related Conference Proceedings

Festigkeitsberechnung metallischer Bauteile, Empfehlungen fur Konstrukteure und Entwicklungsingenieure.

VDI Berichte 1227, Diisseldorf, VDI-Verlag, 1995.

Festigkeitsberechnung metallischer Bauteile, Empfehlungen fur Entwicklungsingenieure und Konstrukteure.

VDI Berichte 1442, Diisseldorf, VDI-Verlag, 1998.

Festigkeitsberechnung metallischer Bauteile, Empfehlungen fur Entwicklungsingenieure und Konstrukteure.

VDI Berichte 1698, Dusseldorf, VDI-Verlag, 2002.

Bauteillebensdauer Nachweiskonzepte. DVM-Bericht 800, Deutscher Verband fur Materialsforschung und

-prufung, Berlin 1997.

Betriebsfestigkeit - Neue Entwicklungen bei der Lebensdauerberechnung von Bauteilen. DVM-Bericht 802,

Deutscher Verband fur Materialsforschung und -prufung, Berlin 2003.

1 1'"and 2

nd

Edition ofthe FKM-Guideline

7

Contents

Page

5 Appendices Page

0 General survey

5.1 Material tables. 131

0.1 Scope 9

5.2 Stress concentration factors 178

0.2 Technical background

5.3 Fatigue notch factors 187

0.3 Structure and elements

5.4 Fatigue classes (FAT) for welded

components of structural steel and of

1 Assessment of the static strength

aluminum alloys 195

using nominal stresses

5.5 Comments about the fatigue strength

1.0 General 19

of welded components 209

1.1 Characteristic stress values

5.6 Adjusting the stress ratio of a stress

1.2 Material properties 22

spectrum to agree with that of the S-N curve

1.3 Design parameters 30

and deriving a stepped spectrum 216

1.4 Component strength 33

5.7 Assessment using classes of utilization 218

1.5 Safety factors 34

5.8 Particular strength characteristics of

1.6 Assessment 36

surface hardened components 222

5.9 An improved method for computing the

2 Assessment of the fatigue strength

component fatigue limit in the case of

using nominal stresses

synchronous multiaxial stresses 223

2.0 General 41

5.10 Approximate assessment of the fatigue

2.1 Parameters of the stress spectrum

strength in the case of non-proportional

2.2 Material properties 47

multiaxial stresses 226

2.3 Design Parameters 50

5.11 Experimental determination of

2.4 Component strength 57

component strength values 227

2.5 Safety factors 68

5.12 Stress concentration factor for a substitute

2.6 Assessment 70

structure 230

3 Assessment of the static strength

6 Examples

using local stresses

6.1 Shaft with shoulder 231

3.0 General 73

6.2 Shaft with V-belt drive 236

3.1 Characteristic stress values

6.3 Compressor flange made of grey

3.2 Material properties 76

cast iron 241

3.3 Design parameters 85

6.4 Welded notched component 245

3.4 Component strength 89

6.5 Cantilever subject to two independent loads 250

3.5 Safety factors 90

6.6 Component made of a wrought

3.6 Assessment 93

aluminum alloy 256

4 Assessment of the fatigue strength

7 Symbols and basic formulas

using local stresses

7.1 Abbreviations 259

4.0 General 97

7.2 Indices

4.1 Parameters of the stress spectrum

7.3 Lower case characters

4.2 Material properties 103

7.4 Upper case characters 260

4.3 Design parameters 106

7.5 Greek alphabetic characters 261

4.4 Component strength 113

7.6 Basic formulas 262

4.5 Safety factors 125

4.6 Assessment 127

8 Subject index 263

8

9

oGeneral survey

1 Subject of Chapter 5.11 "Experimental determination of component

strength values" is not the realization of an experimental assessment of

strength, but the question how specific and sufficiently reliable

component strength values suitable for the general procedure of strength

assessment may be derived experimentally.

2 In particular, what critical points of the considered cross-sections or

component.

If an application of the guideline is intended outside the

mentioned field of application additional specifications

are to be agreed upon.

The guideline is not valid if an assessment of strength is

required according to other standards, rules or

guidelines, or if more specific design codes are

applicable, as for example for bolted joints.

The guideline is valid for components produced with or

without machining or by welding of steel, of iron or of

aluminum materials that are intended for use under

normal or elevated temperature conditions, and in detail

- for components with geometrical notches,

for components with welded joints,

for static loading,

- for fatigue loading with more than about 10

4

constant or variable amplitude cycles,

- for milled or forged steel, also stainless steel, cast

iron materials as well as aluminum alloys or cast

aluminum alloys,

- for component temperatures

from- 40C to 500C for steel,

from- 25C to 500C for cast iron materials and

from- 25C to 200C for aluminum materials,

- for a non-corrosive environment.

This guideline is valid for components in mechanical

engineering and in related fields of industry. Its

application has to be agreed between the contracting

parties.

For components subjected to mechanical loadings it

allows an analytical assessment of the static strength

and of the fatigue strength, the latter as an assessment of

the fatigue limit, of the constant amplitude fatigue

strength or of the variable amplitude fatigue strength,

according to the service stress conditions.

Other analytical assessments, for example of safety

against brittle fracture, of stability, or of deformation

under load, as well as an experimental assessment of

strength *

1

, are not subject of this guideline.

It is presupposed, that the components are professionally

produced with regard to construction, material and

workmanship, and that they are faultless in a technical

sense.

12

11

13

14

15

16

13

Page

9

10

Contents

0.3.0 General

0.3.1 Procedure of calculation

0.3.2 Service stresses

0.3.3 Methods of strength assessment

0.3.3.0 General

0.3.3.1 Assessment of the static strength

using nominal stresses, Chapter 1

0.3.3.2 Assessment of the fatigue strength

using nominal stresses, Chapter 2

0.3.3.3 Assessment of the static strength

using local stresses, Chapter 3

0.3.3.4 Assessment of the fatigue strength

using local stresses, Chapter 4

0.3.4 Kinds of components

0.3.4.0 General

0.3.4.1 Rod-shaped (lD) components

0.3.4.2 Shell-shaped (2D) components

0.3.4.3 Block-shaped (3D) components

0.3.5 Uniaxial and multiaxial stresses

0.3.0 General

0.2 Technical Background

3 Usually this probability can hardly be quantified, however.

Basis of the guideline are the references listed on page

7, in particular the former TGL-Standards, the former

Vlrl-Guideline 2226, as well as the- regulations of DIN

18 800, the IIW-Recommendations and Eurocode 3.

Moreover the guideline was developed to the current

state of knowledge by taking into account the results of

more recent investigations.

0.3 Structure and elements

An assessment of the static strength is required prior to

an assessment of the fatigue strength.

Before applying the guideline it has to be decided

- what cross-sections or structural detail of the

2

component shall be assessed * and

what service loadings are to be considered.

The service loadings are to be determined on the safe

side, that is, with a sufficient probability they should be

higher than most of the normally occurring loadings *3.

The strength values are supposed to correspond to an

anticipated probability of 97,5 % (average probability of

survival Po =97,5 %).

lRo2 EN.dog oGeneral survey

0.1 Scope

10

oGeneral survey

0.3.1 Procedure of calculation

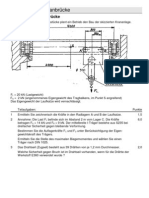

Figure 0.0.2 Procedure of calculation for an assessment

of the fatigue strength.

At the assessment stage (box at bottom of either Figure)

the characteristic values of service stress occurring in

the component (box at top on the left) and the

component strength values derived from the mechanical

material properties and the design parameters (middle

column) are compared by including the required safety

factors (box at bottom on the right). In specifying

component fatigue strength values the mean stress and

the variable amplitude effects are regarded as essential

factors of influence. The assessment of strength is

successful if the degree of utilization is less or equal

1,00, where the degree of utilization is defined by the

ratio of the characteristic service stress to the component

strength value that has been reduced by the safety factor,

Chapter 1.6.

In Figure 0.0.1 and Figure 0.0.2 the arrangements of the

individual boxes from top to bottom illustrate the

sequential procedure of calculation.

0.3.2 Service stresses

For an application of the guideline the stresses resulting

from the service loadings have to be determined for the

so-called reference point of the component, that is the

potential point of fatigue crack initiation at the cross-

section or at the component under consideration. In case

of doubt several reference points are to be considered,

for example in the case of welded joints the toe and the

root of the weld.

There is a need to distinguish the names and subscripts

of the different components or types of stress, that may

act in rod-shaped (lD), in shell-shaped (2D) or in

block-shaped (3D) components, respectively, Chapter

0.3.4.

The stresses are to be determined according to known

principles and techniques: analytically according to

elementary or advanced methods of theoretical

mechanics, numerically after the finite element or the

boundary element method, or experimentally by

measurement.

All stresses, except the stress amplitudes, are combined

with a sign, in particular compressive stresses are

negative.

To perform an assessment it is necessary to decide about

the kind of stress determination for the reference point

considered: The stresses can be determined

as nominal stresses *5 (notation S and T),

as elastically determined local stresses, effective

6

notch stresses or structural (hot spot) stresses *

(notation o and r).

Safety

factors

Safety

factors

--

Sequential

procedure of

caJc.ulation

Sequential

procedure of

calculation

Component

forzeromean stress :

.,

Component

fatigue

strength

i

I

I

J

Component fatigiielimlt

for-the actualmean stress

Characteristic

service

The procedure of calculation for an assessment of the

static strength is presented in Figure 0.0.1, the almost

identical procedure for an assessment of the fatigue

strength in Figure 0.0.2 *4.

Figure 0.0.1 Procedure of calculation for an assessment

of the static strength.

4 A survey on the analytical procedures of assessment based on the

equations of the guideline may be found in Chapter 7.6.

5 Nominal stresses can be computedfor a well defmedcross-section only.

6 The elastic stress at the root of a notch exceeds the nominal stress by a

stress concentration factor. In the case of welded joints effective notch

stresses are applied to the assessment of the fatigue strength only.

Structural stresses, also termed geometrical or hot spot stresses, are

normally in use with welded joints only. For further information see

Chapter 5.5.

11

oGeneral survey

Figure 0.0.3 Organization of the guideline.

7 Accordingto rod-, shell- or block-shaped components, Chapter 0.3.4.

8 The extreme maximum or minimum stresses for the assessment of the

static strength may be different from the maximum and minimum stresses

for the assessment of the fatigue strength, that are determined from the

largest amplitude and the related mean value of a stress spectrum.

0.3.3.1 Assessment of the static strength using

nominal stresses, Chapter 1

Relevant nominal characteristic service stresses are the

extreme maximum and extreme minimum values of the

individual types of stress or stress components, e.g.

nominal values of the axial (or tension-compression)

stress, Szd, of the bending stress, Sb, and so forth *7 *8,

Chapter 1.1.

Relevant material properties are the tensile strength and

the yield strength (yield stress or 0.2 proof stress) as

well as the strength values for shear derived from these.

A technological size effect is taken into account if

appropriate. The influence of an elevated temperature

on the material properties - strength at elevated

temperature and creep strength, yield strength at

elevated temperature and I% creep limit - is allowed for

by means of temperature factors, Chapter 1.2.

Design parameters are the section factors, by which an

experienced partial plasticity of the component is

allowed .according to yield strength, type of loading,

shape of cross-section, and stress concentration factor.

From the section factor and from further parameters an

overall design factor is derived, Chapter 1.3.

The nominal values of the static component strength are

derived from the tensile strength, divided by the

respective overall design factor, Chapter 1.4.

As common in practice the safety factor against the

tensile strength is 2,0. For materials with a yield

strength less than 0,75 times the tensile strength the

safety factor is 1,5 against the yield strength, however.

Under favorable conditions these safety factors may be

reduced, Chapter 1.5.

The assessment is carried out by proving that the degree

of utilization is less or equal 1,00 . The degree of

utilization for an individual stress component or type of

stress is the ratio of its nominal characteristic service

stress value, divided by the allowable nominal static

component strength value, which follows from the

nominal static component strength divided by the safety

factor.

If there are several stress components or types of stress

their individual degrees of utilization are combined to

obtain an entire degree of utilization. The interaction

formula to be applied to that combination allows for the

ductility of the material in question, Chapter 1.6.

For welded components the assessment of the static

strength has to be carried out for the toe section as for

non-welded components, and for the throat section with

I

Fatigue

strength'

assessment

~

Fatii:ue strength

Nominal stresses

. ~ .

Static strength LNoml?al

Nominalstresses ) stresses

;/

Static

strength

aSseSSlllent

~ ~ .

.r" Chapter 3: "<. Chapter 4: -,

( Stade. strength )-. LO.cal. -....ali.ou.estr.c..n..~ t b \

".. IAcalstrcsses/" Stresses \.Li .. .)

. ~ ~ ~

In particular the procedure of calculation is completely

presented in everyone of the four chapters, even if this

results in repetitions of the same or almost the same

parts of text in Chapter I and Chapter 3 or in Chapter 2

and Chapter 4, respectively.

The procedure of calculation using nominal stresses is

to be preferred for simple rod-shaped (lD) and for shell-

shaped (2D) components. The procedure of calculation

using local stresses has to be applied to block-shaped

(3D) components, and moreover in general, if the

stresses are determined by a finite-element or a

boundary-element calculation, if there are no well-

defined cross-sections or no simple cross-section shapes,

if stress concentration factors or fatigue notch factors

are not known, or (concerning the assessment of the

static strength) in the case ofbrittIe materials.

0.3.3 Methods of strength assessment

0.3.3.0 General

In order to present the guideline clearly arranged and

user-friendly, it is organized in four chapters, Figure

0.0.3:

- Assessment of the static strength

using nominal stresses, Chapter I,

Assessment of the fatigue strength

using nominal stresses, Chapter 2,

Assessment of the static strength

using local stresses, Chapter 3,

Assessment of the fatigue strength

using local stresses, Chapter 4.

Correspondingly the component strength values are to

be determined

as nominal strength values or

as local strength values of the elastic local stress, of

the effective notch stress or of the structural stress.

With the procedures of calculation structured uniformly

for both types of stress determination it is intended that

more or less identical results will be obtained from

comparable strength assessments based on either

nominal stresses or local stresses.

an equivalent nominal stress, that is computedfrom the

components of nominal stress acting in the weld seam

*9.

0.3.3.2 Assessment of the fatigue strength using

nominal stresses, Chapter 2

Relevant nominal characteristic service stresses are the

largest stress amplitudes in connection with the

respective stress spectra and the related mean stress

values. They are determined for the individual stress

components or types of stress, e.g. amplitudes and mean

values of the nominal axial (tension-compression)

7 8

stresses, Sa,zd and Sm,zd, and so forth * *, Chapter 2.1.

Relevant material properties are the fatigue limit for

completely reversed axial stress and the fatigue limit for

completely reversed shear stress of the material in

question. A technological size effect is taken into

account where appropriate. The influence of an

elevated temperature is allowed for by means of

temperature factors, Chapter 2.2.

Design parameters to be considered in particular are the

fatigue notch factors, allowing for the design of the

component (shape, size and type of loading), as well as

the roughness factor and the surface treatment factor, by

which the respective surface properties are accounted

for. By specific combination of all these factors a

summary design factor is calculated, Chapter 2.3.

The nominal values of the component fatigue limit for

completely reversed stresses follow from the derived

fatigue limit values of the material, divided by the

respective design factors, Chapter 2.4.1. From these

fatigue limit values the amplitudes of the component

fatigue limit according to the mean stress values (or the

stress ratios) are to be derived, Chapter 2.4.2. The

amplitudes that specify the variable amplitude fatigue

strength of the component are obtained from the fatigue

limit values multiplied by a factor depending on the

parameters of the stress spectrum (total number of

cycles and amplitude frequency distribution), Chapter

2.4.3.

The basic value of the safety factor is 1,5. Under

favorable conditions this safety factor may be reduced,

Chapter 2.5.

The assessment is carried out by proving that the degree

of utilization is less or equal 1,00 . The degree of

utilization for an individual stress component or type of

stress is the ratio of its nominal characteristic service

stress amplitude, divided by the allowable amplitude of

the component fatigue limit or of the component

variable amplitude fatigue strength. The allowable

9 This assessment of the static strength for welded components is

according to DIN 18 800 part 1. As far as conditionally weldable steel,

stainless steel, weldable cast iron materials or weldable aluminum alloys

are concerned, the rules of DIN 18 800 are provisional and may be

applied with caution only.

12

oGeneral survey

amplitude value follows from the nominal amplitude of

the derived component fatigue strength divided by the

safetyfactor.

If there are several stress components or types of stress

their individual degrees of utilization are combined to

obtain the total degree of utilization. The interaction

formula to be applied to that combination allows for the

ductility of the material in question, that is in the same

way as for the assessment of the static strength, Chapter

2.6.

For the assessment of the fatigue strength of welded

components using nominal stresses basic fatigue limit

values for completelyreversed stress are given. They are

independent of the tensile strength of the base material

(which is different to non-welded components). They

are converted by design factors that follow from a

classification scheme of structural weld details. The

combined effect of mean stress and of residual stresses

in welded components is considered by means of a mean

stress factor together with a residual stress factor *10.

0.3.3.3 Assessment of the static strength using local

stresses, Chapter 3

Relevant characteristic local service stresses are the

extreme maximum and extreme minimum stresses of

the individual types of stress or stress components, e.g.

local values of the normal (axial and/or bending) stress,

o, and of the shear (shear and/or torsional) stress *

7

*8,

Chapter 3.1.

Relevant material properties are to be determined as for

nominal stresses, Chapter 3.2.

Design parameters are the section factors, by which an

experienced partial plasticity of the component is

allowed according to yield strength, type of loading, and

shape of the component. The section factors are

calculated on the basis of Neuber's formula, but by

observing individual upper bound values that follows

from the plastic limit load (plastic notch factor). From

the .section factors and from further parameters an

overall design factor is derived, Chapter 3.3 *11.

The local values of the static component strength are

derived from the tensile strength, divided by the

respectiveoverall design factor, Chapter 3.4.

The safety factors are to be determined as for nominal

stresses, Chapter 3.5.

10 The assessment of the fatigue strength for welded components makes

reference to the llW-Recommendations and Eurocode 3. As far as

conditionally weldable steel, stainless steel, weldable cast iron materials

or weldable aluminum alloys are concerned this kind of calculation is

provisional and may be applied with caution only.

11 The assessment ofthe static strength using local stresses on the basis of

Neuber's formula and the plastic limit load is an approximation which has

to be regarded as provisional and is to be applied with caution only.

13

oGeneral survey

12 The indices yand z describe the direction ofthe related vectors ofthe

bending moments My, Mz and ofthe lateral loads Fy, Fz .

nominal stresses by means of a mean stress factor

together with a residual stress factor *10.

Figure 0.0.4 Rod-shaped (ID) component (round

specimen with groove) in bending. Nominal stress S,

and maximum local stress O"m"" at the reference point W.

'z

"0.0...

Calculation using nominal stresses

If the assessment of rod-shaped (ID) components is

carried out by using nominal stresses, Chapter I and 2,

the nominal stresses to be computed at the reference

point are Szd from an axial load, Sb from a bending

moment, T, from a shear load, and/or T

t

from a

torsional moment acting at the respective section.

For the equations given in Chapter 1 and 2 it is

provided, that both the bending stress Sb and the shear

stress T, act in the x-z-plane. Otherwise stress

components Sb,y and Sb,z , Ts,y and Ts,z are to be

considered *12.

0.3.4 Kinds of components

0.3.4.0 General

Rod-shaped (10), shell-shaped (2D) and block-shaped

(3D) components are to be distinguished, as in each case

other stress components or types of stresses, identified

by differing symbols and subscripts, are of concern. The

distinction is only a formal one, however, and the

procedure of calculation is the same in all cases.

Specific particulars apply to welded components.

0.3.4.1 Rod-shaped (ID) components

For rod-shaped (10) components - rod, bar, shaft, or

beam for example - the following system of co-ordinates

is introduced: x-axis is the longitudinal center line of

the component, y- and z-axes are the main axes of the

cross-section that are to be specified so, that for the

moments of inertia I y ~ I

z

is valid, Figure 0.0.4.

0.3.3.4 Assessment of the fatigue strength using local

stresses, Chapter 4

Relevant local characteristic service stresses are the

largest stress amplitudes in connection with the

respective stress spectra and the related mean stress

values. They are determined for the individual stress

components or types of stress, e.g. amplitudes and mean

values of the local normal (axial and/or bending) stress,

0"a and O"m , and so forth *

7

*

8

, Chapter 4.1.

The relevant material properties are determined as for

nominal stresses, Chapter 4.2.

Design parameters to be considered in particular are the

Kt-Kf ratios, allowing for the design of the component

(shape and size), as well as the roughness factor and the

surface treatment factor, by which the respective surface

properties are accounted for. By specific combination of

all these factors a summary design factor is calculated,

Chapter 4.3.

The local values of the component fatigue limit for

completely reversed stresses follow from the derived

fatigue limit values of the material, divided by the

respective design factors, Chapter 4.4.1. The

conversions to the amplitude of the component fatigue

limit and to the amplitude of the component variable

amplitude fatigue strength are as for nominal stresses,

Chapter 4.4.2 to 4.4.3.

The safety factors are to be determined as for nominal

stresses, Chapter 4.5.

The assessment by means of the degree of utilization is

as for nominal stresses, but with the respective local

values of the characteristic stress amplitude and the

value of the component fatigue limit or of the

component variable amplitude fatigue strength, Chapter

4.6.

The assessment is carried out by means of the degree of

utilization as for nominal stresses, but with the

respective local values of the characteristic service stress

and the local component strength values, Chapter 3.6.

For welded components the assessment of the static

strength using local stresses is carried out using

structural stresses (not with notch root stresses), for the

weld toe as for non-welded components, for the root of

the weld using an equivalent structural stress, that is to

be derived from the structural stress components acting

in the weld seam *9.

For the assessment of the fatigue strength of welded

components using structural stresses or effective notch

stresses the same basic fatigue limit values for

completely reversed stresses apply as for nominal

stresses. They hold for effective notch stresses without

conversion, but for structural stresses they have to be

converted by factors given for some typical weld details.

The combined effect of mean stress and of residual

stresses in welded components is to be considered as for

In case of rotationally symmetrical cross-sections with

circumferential notches a resultant bending stress and a

resultant shear stress can be calculated from these stress

components,

s, ' (0.3.1)

T = T

2

+T

2

s s,y S,z

The equations given in Chapter 1 and 2 may be applied

to Sband T;

In the general case of not rotationally symmetrical

cross-sections a calculation using local stresses is

normally to be preferred.

Additional stresses at notches (as for example the

circumferential stress associated with an axial stress of a

shaft with groove) may be included in the stress

concentration factor, otherwise they will be neglected.

Calculation using local stresses

If the calculation of rod-shaped (ID) components is

carried out using local stresses *13, Chapter 3 and 4, the

local normal stresses at the reference point from axial

and from bending loading (in x-direction), azd = a as

well as the local shear stresses "ts = "t from shear and

from torsion (normal to the x-direction) are considered.

If the local stresses are calculated from the nominal

stresses by multiplication with the respective stress

concentration factors, the equations given in Chapter 3

and 4 are applicable.

However, if the calculation yields the complete local

state of stress at the reference point (as for example a

finite-element calculation does), the principle stresses

0"1, 0"2, 0"3 are computed *14 and treated as described for

block-shaped (3D) components.

Rod-shaped (ID) welded components

For rod-shaped (ID) welded components *15 the

notations a and "t apply to structural stresses and the

notation aK and "tK apply to effective notch stresses *16.

13 The assessment of rod-shaped (ID) components should preferably be

carried out using nominal stresses whenever possible.

14 Principle stresses are independent of the chosen coordinate system. In

the special case of a proportional loading the directions of the principle

stresses remain fixed to the coordinates of the component. In the more

general case of non-proportional loading the directions and the amounts

of the three principle stresses will change with time, see Chapter 0.3.5.

14

oGeneral survey

0.3.4.2 Shell-shaped (2D) components Rod-shaped

(ID) welded components

For shell-shaped (2D) components - disk, plate, or shell

for example - the following system of coordinates is

introduced: The x- and y-axis are placed in the surface

at the reference point, the z-axis is normal to the surface

in thickness direction. The normal stress and the shear

stress in thickness direction are supposed to be

negligible, Figure 0.0.5.

Figure O. O. 5 Shell-shaped (2D) component (shell with

cutout detail). Local stresses aa,x at the reference point

W (peak value) and aa,x,ru. at the neighbouring point B.

Calculation using nominal stresses

If the assessment of shell-shaped (2D) components is

carried out using nominal stresses, Chapter 1 and 2, the

nominal stresses at the reference point to be computed

are the normal stresses Szdx = S, and Szdy = S, from

loadings in the x- and y-directions and T, = T from a

shear loading.

Calculation using local stresses

If the assessment of shell-shaped (2D) components is

carried out using local stresses, Chapter 3 and 4, the

local stresses at the reference point azdx = ax and

azdy = ay in the x- and y-directions and the local shear

stress r, = t are considered.

If the local stresses are computed from the nominal

stresses by multiplication with the respective stress

concentration factors, the equations given in Chapter 3

and 4 are applicable.

However, if the calculation yields the complete local

state of stress at the reference point (as for example a

finite-element calculation does), the principle stresses

0"1,0"2,0"3 are computed *14 and treated as described for

block-shaped (3D) components.

15 Rod-shaped (ID) welded components are rolled sections with circular,

tube, 1-, box or other cross-sections connected or joined with butt welds

and/or fillet welds.

15

oGeneral survey

0.3.4.3 Block-shaped (3D) components

In the general case block-shaped (3D) components are

to be calculated using local stresses, Chapter 3 and 4

*17

For block-shaped (3D) components the coordinate

system at the reference point may be of cartesian,

;70.

.. . . ; ( .. cylindrical or spherical type.

- ...

_.

- ..., ... '. .-Sx The calculation is supposed to yield the complete state

/Io-{ (It'd --of local stress at the reference point (as for example a

<;,fI"c-(<lC<{ ,finite-element calculation does). From that the principle

1:---'=--__ nO)'jJIr'rtfl.{ ..... computed *14, and for these the

, degrees of utilization are determined.

If the reference point W is located at a free surface of a

block-shaped (3D) component, Figure 0.0.8, it is

supposed that 0"1 and 0"2 are the principle stresses at the

surface, while the principle stress 0"3 is supposed to point

normally to the surface inwards the component.

In general stress gradients exist for all three principle

stresses, both normal to the surface and in either

direction of the surface. However, only the stress

gradients for 0" 1 and 0"2 normal to the surface can be

considered in the procedure of calculation, while the

stress gradients for 0"1 and 0"2 in any directions of the

surface and the gradients of 0"3 can not.

Block-shaped (3D) components can be calculated as

shell-shaped (2D) components if the stresses O"x , O"y and

't at the load free surface are of concern only. Calculation using effective notch stresses: Maximum stress O"Kx,max

occurring at the weld toe, see Figure 0.0.7.

Calculation using structural stress: Maximum stress O"x,max obtained from

extrapolating the stress distribution towards the weld toe.

Calculation using nominal stresses: Stress Sx .

Top: Joint, Centre: Stress distribution, Bottom: Profile. Relevant is the

stress at the reference point W (at the toe line of the weld).

Figure 0.0.6 Shell-shaped (2D) welded component.

Example: Strap with longitudinal stiffner. After Radaj

/10/.

Shell-shaped (2D) welded components

For shell-shaped (2D) welded components the notations

o"x , O"y and 't apply to structural stresses and the

notations O"Kx , O"Ky and 'tK apply to effective notch

stresses *16 .

Figure 0.0.7 Shell-shaped (2D) welded component.

Example: Cruciform joint and butt weld. After Radaj

/l0/.

Calculation using effective notch stresses: The maximum stress O"Kx,max

occurring at the toe or at the root of the weld has to be computed by

introducing a fictitious effective notch radius r = 1 rom, unless the real

radius is r > 1 rom (the fictitious notch radius is intended for the

assessment of the fatigue strength only).

The fictitious notch radius r = 1 rom applies to welded joints from

structural steel. It is supposed, however, that it is applicable for other

kinds of material as well, although this has to be considered as a

preliminary specification for welded aluminum materials so far.

Figure 0.0.8 Block-shaped (3D) component (flange).

Local longitudinal stress 0"1 and circumferential stress 0"2

at the reference point W (peak values), stresses O"u,s and

at neighboring point B.

F

\/

....... Radius r = 1 mm

/ I \

F

16 Structural stresses can be applied to the assessment of the static

strength and to the assessment of the fatigue strength. Effective notch

stresses can be applied to the assessment of the fatigue strength, but not to

the assessment of the static strength.

17 For block-shaped components the determination of a nominal stress is

not possible since there is no well defmed cross-section.

Block-shaped (3D) welded components

Welds at a load-free surface of block-shaped (3D)

components having no inner defects can be assessed as

shell-shaped (2D) welded components. Then the

notations G

x

, G

y

and 't apply to structural stresses and

the notations O"Kx , O"Ky and 'tK apply to the notch root

stresses at the surface, Figure 0.0.6.

0.3.5 Uniaxial and multiaxial stresses

The stresses occurring in the cross-section or at the

reference point of a component may be caused

by a single load or

- by several loads acting simultaneously.

In both cases

an uniaxial stress or

multi axial stresses

may result at the reference point.

An uniaxial stress occurs under special circumstances

only, as for example in a tension loaded prismatic bar,

or at an unloaded edge of shell-shaped (2D) or block-

shaped (3D) components, the latter even if several loads

act on these components simultaneously, Figure 0.0.9.

In addition an uniaxial stress may be assumed at the

reference point if, by comparison, any further stresses

are small.

In general components are subject to multiaxial stresses,

however. Then two or three normal stresses, or normal

stresses and shear stresses occur at the reference point.

s, t Sy t

"-,-+ T

-"-+T

f

t-':

x

-{Q:Jt..:'

+ - ~

+ ~ a t ..

-

~

~ ~

Figure 0.0.9 Uniaxial and multiaxial stresses.

Nominal stresses Sx- Sy and T.

Left: multiaxial stresses in a sheet section,

Right: uniaxial stress in a sheet section at the edge ofa cutout.

In this guideline a basic principle is defined both for an

assessment of the static strength and of the fatigue

strength in case of multi axial stresses:

the individual degrees of utilization for everyone of

the computed types of stress or stress components

have to be determined and assessed separately in a

first step, and

thereafter these individual degrees of utilization will

be combined by means of an appropriate interaction

formula to obtain the entire degree of utilization for

final assessment.

16

oGeneral survey

Assessment of the static strength

For the assessment of the static strength the most

unfavorable case to be considered is that the extreme

values of all maximum and minimum stresses occur

simultaneously. Accordingly the entire degree of

utilization has to be computed. However, stresses of

different sign that will decrease the entire degree of

utilization are to be included only if they definitely

occur together with the remaining stresses, Chapter 1.6

or 3.6.

Assessment of the fatigue strength

For the assessment of the fatigue strength *18 multiaxial

stresses varying with time have to be distinguished as

follows:

proportional stresses,

synchronous stresses, or

non-proportional stresses.

Proportional stresses

Normally proportional stresses result from a single

loading acting on the component.

Examples of proportional stresses are the

circumferential and the longitudinal stresses of a

cylindrical vessel loaded by internal pressure, or the

bending and torsional stresses of a round cantilever

loaded eccentrically by a single load.

If this single acting loading is varying with time, all

multiaxial stresses are varying proportionally to that

loading and proportionally to each other, which also is

true with regard to their amplitudes and their mean

values. Further, as a consequence, the principle stresses

observe non-changing directions relative to the

component. The amounts of the stresses, also in the

stress amplitude spectra, may be converted by constant

factors. Hence all stress spectra are of similar shape, but

may differ in intensity (amount of their characteristic

maximum stress).

Proportional stresses my also result from several

loadings that act on the component simultaneously and,

for their part, change proportionally with time as well.

Then several stresses of the same kind are to be overlaid

additively.

For proportional multiaxial stresses, the interaction

formulas given in Chapter 2.6 and 4.6 are exactly valid

in the sense of material mechanics, if the related rules of

signs are observed.

18 Both for the assessment ofthe fatigue limit and for the assessment of

the variable amplitude strength.

Synchronous stresses

Synchronous stresses are a simple case of non-

proportional stresses. They are proportional with regard

to their amplitudes, however non-proportional with

regard to their mean values.

Normally synchronous stresses result from a combined

action of a constant loading with a second, different

kind of loading, that is varying with time. Examples are

a shaft with a non-changing torsional loading and a

rotating bending loading. Or a long, lying cylindrical

vessel under pulsating internal pressure, where the

longitudinal stress is non-proportional to the

circumferential stress because of the bending stress from

the dead weight is additively overlaid.

For synchronous multiaxial stresses, the interaction

formulae given in Chapter 2.6 and 4.6 - if observing the

related rules of sign - are valid as a useful

approximation, because they are applied to the stress

amplitudes, which are proportional to each other, and

because the fatigue strength is determined by the stress

amplitudes in the first place. Additional rules for

considering the mean stresses are required, however.

An improved procedure for the assessment of the

component fatigue limit in the case of synchronous

multiaxial stresses is presented in Chapter 5.9.

Non-proportional stresses

Non-proportional stresses result from the action of at

least two loadings that vary non-proportionally with

time in a different manner.

In this most general case of non-proportional loading

different spectra apply to the individual types of stress

that result from the combined loadings. In particular the

amounts and the directions of the principle stresses are

variable with time.

The case of variable directions of the principle stresses

can not be considered with the interaction formulas

given in Chapter 2.6 and 4.6.

Appropriate methods of calculation proposed for the

assessment of the fatigue strength in the case of non-

proportional stresses, that have been developed from a

material mechanics point of view, require much

computing effort and are applicable with computer

programs for short stress sequences only. Their

plausibility is currently subject of investigations.

Therefore only an approximate way of calculation for

the assessment of the fatigue strength in the case of non-

proportional multi-axial stresses can be given, Chapter

5.10: As proportional stresses result from each of the

acting loadings the degrees of utilization of these

individual loadings can be correctly computed and

assessed as described in Chapter 2.6 and 4.6. The so

17

oGeneral survey

determined degrees of utilization for the individual

loadings are then added linearly in order to estimate the

entire degree of utilization. Compared to usual

interaction formulas developed for proportional stresses

the linear addition may be assumed to produce results

on the safe side *19.

A necessary reservation for applying this approximate

way of calculation is, that a thorough stress analysis is

performed in every case and that careful evaluation of

the result is performed finally.

In order to reach an optimum degree of utilization of the

component fatigue strength in the case of non-

proportional multiaxial stresses, an experimental

assessment of the fatigue strength has to be

recommended according to the contemporary state of

the art.

19 For non-proportional multiaxialloadings the reference point may be at

different positions in the case ofthe combined loadings and in the case of

each ofthe individual loadings, respectively. This is because the most

damaging stresses from the combined loadings may occur at positions

different from the positions ofthe maximum stresses from the individual

loadings. By the above mentioned approximation, however, the full

damaging effect of each loading may be assumed to be superimposed at

the reference point in question.

18

oGeneral survey

1.1 Characteristic stress values

19

1 Assessment of the static strength

using nominal stresses

If in those cases it becomes necessary to make best use

of the long-term load bearing capacity of the component

In all other cases of constant or variable loading the

assessment will be more or less on the safe side if the

values Smax,ex,zd , ... and Smin,ex,zd, ... refer to a stress

distribution with a stress gradient, and/or if they refer to

the peak values of a variable stress history, which are of

short duration only, while for the rest of time the stress

is lower.

Elevated temperature

In case of elevated temperature the values Smax,ex,zd, ...

and Smin,ex,zd,... are relevant for a short-term loading

(related to the high temperature strength or high

temperature yield strength).

For a long-termloading (related to the creep strength or

1% creep limit) correct results will only be obtained in

case of a constant (static) tensile stress Smax,ex,zd equally

distributed over the section of concern.

According to this chapter the characteristic service

stress values are to be determined.

Relevant are the extreme maximum and rmmmum

stresses Smax,ex,zd and Smin,ex,zd, ... of the individual stress

components expectedfor the most unfavorable operating

conditions and for special loads according to

specification or due to physical limits *3. Both the

maximum and minimum stresses can be positive or

negative. It is assumed, that all stresses reach their

extreme values simultaneously.

Page

19

20

General

Characteristic stress values

General

Rod-shaped (ID) components

Shell-shaped (2D) components

Contents

1.1.0 General

1.1.0

1.1.1

1.1.1.0

1.1.1.1

1.1.1.2

1.1 Characteristic stress values

Kt,A

~

-__c------- ~ _

. ~ - - + . _ . _ . -- -------'---- .-...-...

F F

For GGG sorts and wrought aluminium alloys with low

elongation, A < 12,5 % , for all sorts GT and GG as

well as for cast aluminium alloys the assessment of the

static strength is to be carried out by using local stresses

according to Chapter 3 *1.

In the case of very high stress concentration factors the

assessment of the static strength is to be carried out by

using local stresses according to Chapter 3 *2.

For block-shaped (3D) components the assessment of

the static strength is to be carried out by using local

stresses according to Chapter 3.

For all other kinds of material (GGG sorts and

wrought aluminium alloys with high elongation,

A'2 12,5 % , GS, milled steel and forging-steel) and for

smaller stress concentration factors of rod-shaped (lD)

and of shell-shaped (2D) components the assessment of

the static strength using nominal stresses is applicable.

Figure 1.0.1 Different sections for a static failure

occurring as a local failure (A) or as a global failure (B).

1.0 General

According to this chapter the assessment of the static

strength using nominal stresses is to be carried out.

It should be observed that not necessarilythe component

static strength is determined by a failure occurring at a

notched section. Likewise a global failure occurring at a

different, unnotched or moderately notched section of

the component may be determining, Figure 1.0.1.

1 Assessment of the static

strength using nominal stresses

IR>11 N.doq

1 Because these materials lack sufficient plasticity.

2 Because extremely high local strains are associated with a very high

stress concentration factor. The stress concentration factor Kt = 3 ofaflat

bar with ahole issuggested asalimit value.

3 In general the values Smax,ex,zd and Smin,ex,zd for the assessment of

the static strength are the extreme values of a stress history. For the

assessment ofthe fatigue strength a stress spectrum is tobe derived from

that history consisting ofstress cycles ofthe amplitudes Sa,zd,i and the

mean values Sm,zd,i , Chapter 2.1.

The largest amplitude ofthis stress spectrum is Sa,zd, 1 , and the related

mean value is Sm,zd,l . The related maximum and minimum values are

Smax,zd,l = Sm,zd,l + Sa,zd,l and Smin,zd,l = Sm,zd,l - Sa,zd,l . The

values Smax,ex,zd and Smin,ex,zd may be different from the values

Smax,zd, 1 and Smin,zd, 1 . This is because extreme, very seldom

occurring events are important only for the assessment of the static

strength, but hardly for the assessment ofthe fatigue strength. In a stress

spectrum which issupposed toapply tonormal service conditions they do

not have tobe considered therefore.

1.1 Characteristic stress values

(because otherwise the assessment cannot be achieved)

an expert stress analysis is recommended to define the

appropriate stress value to be used for the assessment.

Such an analysis is beyond the scope of the present

guideline, however.

Superposition

If several stress components act simultaneously at the

reference point, they are to be overlaid. For the same

type of stress (for example tension and tension

Smax,ex,zd,l, Smax,ex,zd,2 , ... ) the superposition is to be

carried out at this stage, so that in the following a single

stress value (Smax,ex,zd, ...) exists for each type of stress

*4. For different types of stress (for example bending

and torsion, or tension in direction x and tension in

direction y) the superposition is to be carried out at the

assessment stage, Chapter 1.6.

Stress components acting opposed to each other and

which do not or can not occur simultaneously, are not to

be overlaid however.

1.1.1 Characteristic stress values

20

1 Assessment of the static strength

using nominal stresses

Figure 1.1.1 Components of nominal stress SII' Til' SJ.

and TJ. in welds. After DIN 18800, Part 1.

Left: Butt weld, Right: Fi)let weld; the nominal stress istobecomputed

with the throat thickness a.

Rod-shaped (ID) welded components

For rod-shaped (ID) welded components the nominal

stresses are in general to be determined separately for

the toe section and for the throat section *7.

For the toe section the nominal stresses are to be

computed as for non-welded components, Eq. (1.1.1)

.For the throat section equivalent nominal stresses have

to be computed from the nominal stresses resulting from

the particular types of loading, Figure 1.1.1 *8.

The extreme maximum and minimum values of the

equivalent nominal stresses are

1.1.1.0 General

Rod-shaped (lD) and shell-shaped (2D), as well as non-

welded and welded components are to be distinguished.

11.1.1 Rod-shaped (ID) components

Rod-shaped (ID) non-welded components

For rod-shaped (lD) non-welded components an axial

stress Szd , a bending stress Sb, a shear stress T, *5

and/or a torsional stress T

t

are to be considered. The

extreme maximum and minimum stresses are

2 2 2

Swv,zd = S..L,zd +T..L,zd +1j1 ,zd '

S..L,zd Axial stress normal to the weld seam

T..L,zd Shear stress normal to the weld seam,

TII,zd Shear stress parallel to the weld seam.

Swv,b, T WV,s and T wv,t in analogy.

Smax,ex,wv,zd and Smin,ex,wv,zd, ....

(1.1.2)

(1.1.3)

(1.1.1) Smax,ex,zd, Smax,ex,b, Tmax.exs . Tmax,ex,t,

Smin,ex,zd, Smin,ex,b, Tmin.ex,s, Tmin,ex,t .

Stresses of different sign (Smax,ex,zd positive, Smin,ex,zd

negative for instance) are generally to be considered

separately *6. For shear and for torsion the highest

absolute value is relevant.

4 Stress components having different signs may cancel out each other in

part orcompletely.

5 Bending and shear in two planes (components y and z) are to be

considered ifappropriate, see Chapter 0.3.4.1 .

6 Particularly inthe case ofcast iron materials with different tension and

compression strength values aswell asinthe case ofunsymmetrical cross-

sections.

Stresses of different sign (Smax,ex,wv,zd posiuve,

Smin,ex,wv,zd negative for instance) are generally to be

considered separately. For shear and for torsion the

highest absolute value is relevant.

7 For welded components ingeneral anassessment ofthe static strength

istobe carried out for the toe section and for the throat section, because

the cross-sectional areas may be different and because the strength

behavior is evaluated in a different way. The assessment for the toe

section istobecarried out asfor non-welded components. The assessment

for the throat section is to be carried out with the equivalent nominal

stress Swv.zd . ...

8 According to DIN 18 800 part 1, page 36. The nominal stress SII

(normal stress parallel tothe orientation ofthe seam) istobeneglected.

9 Normally Swv,zd will result mainly from S..Lzd. Further types of

loading analogous.

(1.1.4)

1.1 Characteristic stress values

1.1.1.2 Shell-shaped (2D) components

Shell-shaped (2D) non-welded components

For shell-shaped (2D) non-welded components normal

stresses in the x- and y-directions Szd,x = Sx and

Szd,y = Sy as well as a shear stress Ts = T are to be

considered.

The extreme maximum and minimum stresses are

Smax,ex,x , Smax,ex,y , Tmax,ex ,

Smin,ex,x , Smin,ex,y , Tmin,ex .

Tension stresses (positive) or compression stresses

(negative) are generally to be considered separately *10.

For shear the highest absolute value is relevant.

Shell-shaped (2D) welded components

For shell-shaped (2D) welded components, Figure 0.0.6,

the nominal stresses are in general to be determined

separately for the toe section and for the throat

section *7.

For the toe section the nominal stresses are to be

computed as for non-welded components, Eq. (1.1.4),

For the throat section equivalent nominal stresses Swv,x,

Swv,y and Twv have to be computed from the nominal

stresses resulting from the particular types of loading,

Figure 1.1.1, according to Eq (1.1.2). The extreme

maximum and minimum values of the equivalent

stresses are

21

1 Assessment of the static strength

using nominal stresses

Smax,ex,wv,x and Smin,ex,wv,x , .... (1.1.5)

In case of opposing effect Smax,ex,wv,x is to be regarded

as positive and Smin,ex,wv,x as negative. Tension and

compression are generally to be considered separately.

For shear the highest absolute value is relevant.

10 See footnote *6. And moreover because the second normal stress Sy

may reduce the degree ofutilization.

1.2 Material properties

22

1 Assessment of the static strength

using nominal stresses

1.2.3 Anisotropy factor

1.2.4 Compression strength factor and

shear strength factor

1.2.4.0 General

1.2.4.1 Compression strength factor

1.2.4.2 Shear strength factor

11m EN.dog

fIg)

values '.'

liCCj)tding.

to s.tanqai"ds

Component

values -

24

23.

27

26

Page

22

Component values according to standards

General

Component values according to standards

of semi-finished products or test pieces

Component values according to the

drawing

Special case of actual component values

Technological size factor

General

Dependence on the effective diameter

Effective diameter

Contents

1.2.0 General

1.2.1

1.2.1.0

1.2.1.1

1.2 Material properties

1.2.1.3

1.2.2

1.2.2.0

1.2.2.1

1.2.2.2

1.2.1.2

1.2.0 General

According to this chapter the mechanical material

properties like tensile strength R.n, yield strength R, and

further characteristics for non-welded and welded

components are to be determined *1.

All mechanical material properties are those of the

material test specimen. Values according to standards,

component values and component values according to

standards are to be distinguished, Figure 1.2.1.

1.2.5

1.2.5.0

1.2.5.1

1.2.5.2

1.2.5.3

Temperature factors

General

Normal temperature

Low temperature

Elevated temperature

Figure 1.2.1 Values according to standards and com-

ponent values according to standards, Rm and Rp, or

values specified by drawings, R.n.z and Rp,z .

Top: All kinds of material except GG, R

m

=:; Rm,N, Rp =:; Rp,N .

Semi-logarithmic decrease of the mechanical material properties withthe

effectivediameter deft'.

Bottom: GG, Rm =:; or ~ Rm,N . Double-logarithmic decrease of the

mechanicalmaterial propertieswiththe effectivediameter deff.

Specified values according to drawings Rm,zand Rp,z.

Values according to standards

The values according to standards <Rm.N , R.n, Rp,N, Rp)

correspond to an average probability of survival

Po = 97,5 % and depend on the effective diameter cleft'

and on the technological size factor.

Material test specimen

In the context of this guideline the material test

specimen is an unnotched polished round specimen of

do = 7,5 mID diameter *2..

Component values

The component values <Rm , R.n.z , R, , Rp,z ) are valid

for the effective diameter cleft' of the component, they

may correspond to different probabilities of survival Po ,

however.

1 If in this chapter values are given for GT, GG or cast aluminum

alloys, they are needed for the assessment of the fatigue strength

only, Chapter 2, but not for the assessment of the static strength,

which is to be carried out using local stresses for these materials,

Chapter 3.

2 This definition is the basis of the presented calculation, although

specimens for tensile tests may usually have diameters different from

7,5mm.

Special case of actual component values

If specific values for a component <Rm.r , Rp,v have been

determined experimentally, they normally apply to a

probability of survival Po = 50 % ,. and therefore they

1.2 Material properties

23

1 Assessment of the static strength

using nominal stresses

are valid only for the particular component, but not for

the entirety of all those components. They may be used,

for instance, fora subsequent assessment of the strength

of the particular component in case of a service failure,

if for that purpose all safety factors are set to 1,00 in

addition.

product *4 , in the case of cast iron or cast aluminum it

is the value from the test piece defined by the material

standard.

The yield strength, Rp,N , is the guaranteed minimum

value specified for the smallest size of the semi-finished

product *4 or for the test piece defined by the material

standard *5.

4 If different dimensions of that semi-finished product are given by

the standard.

1.2.1.2 Component values according to the drawing

The component value of the tensile strength, RID, is

(1.2.2)

(1.2.3)

Rm = 0,94 . Rm,z .

The component value according to the drawing Rm,z is

the tensile strength of the material specified on the

drawing. As the value Rm,z is normally verified by

random inspection of small samples only *6, it is

assumed to have a probability of survival less than P

u

=

97,5 % . Eq. (1.2.2) converts the value Rm,z to a

component value R; that is expected to conform with

the probability of survival of P

u

= 97,5 %.

The yield strength R, corresponding to the tensile

strength Rm is *7 .

Rp= Kd,p . Rp,N . Rm,

Kd,m Rm,N

technological size factors, Chapter 1.2.2,

values of the semi-finished product or

of a test piece defined by standards,

Chapter 5.1 .

5 A probability of survival Po = 97,5 % is assumed for the component

according to standards Rm,N ' Rp,N . This probability of

survival should also applyto the values R

m

' R

p

calculated therefrom.

6 The value R

m

Z is checked by three hardness measurements

(n=3) for where every test has to reach or to exceed the

required value. The probability of survival of the lowest ofn=3 tests

may be estimated to 75 % (= 1 - 1/(n+l) = 1 - 11(3+1) = 0,75), and

may be assigned to Rm,Z . With a likely coefficient of variation of

4% the conversion to Po= 97,5 % follows from Eq. (1.2.2).

7 A conversion proportional to R

p

N I R

m

N would not be correct

since the technological size effect is more pronounced for the yield

strength than for the tensile strength.

Moreover there are to be considered: for compressive

stresses the compression strength factor f, , Chapter

1.2.4, for shear stresses the shear strength factor :4 ,