Beruflich Dokumente

Kultur Dokumente

Modeling and Performance Analysis of A Small Scale Direct Driven PMSG Based Wind Energy Conversion Systems

Hochgeladen von

iisteOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Modeling and Performance Analysis of A Small Scale Direct Driven PMSG Based Wind Energy Conversion Systems

Hochgeladen von

iisteCopyright:

Verfügbare Formate

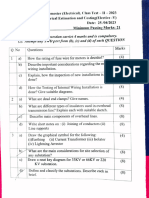

Journal of Energy Technologies and Policy ISSN 2224-3232 (Paper) ISSN 2225-0573 (Online) Vol.1, No.

1, 2011

www.iiste.org

Modeling and performance analysis of a small scale direct driven PMSG based wind energy conversion systems

C.Janani1* K.Rajambal2 1. Dept of electrical and electronics engineering, Pondicherry engg college, Pondicherry 2. Dept of electrical and electronics engineering, Pondicherry engg college, Pondicherry *jchandramohan2@gmail.com Abstract This paper proposes a small scale wind energy conversion system comprising a direct driven PMSG connected to the grid through a power electronic interface. The variable voltage variable frequency output from the wind generator is rectified, boosted and converted in to a fixed voltage fixed frequency output. The boost chopper maintains a constant DC at the inverter terminals. The modulation index of the inverter is adjusted to extract maximum power from the wind. The system components such as wind turbine, PMSG, power electronic interface are modeled in MATLAB/SIMULINK .The power flow analysis of the entire system is carried out for various wind velocities and the effect of duty ratio and modulation index is studied and optimum duty ratio for maximum power extraction at different wind speeds is found out and the simulation results are presented Keywords: wind energy conversion systems, permanent magnet synchronous generator, direct drive.

1. Introduction In the recent years, Wind energy conversion systems (WECS) have become a focal point in the research of renewable energy sources. This is due to the rapid advances in the size of wind generators as well as the development of power electronics and their applicability in wind energy extraction. The high installed capacity of todays wind turbines and decreasing plant costs have shown that wind power can be competitive with conventional, more heavily polluting fossil fuels in the long term. The higher target is to achieve 12% of the worlds electricity from wind power by 2020[1]. . The induction generators are commonly used for low and medium power generations; in such generation schemes it is found that 25% of overall turbine downtime is due to gear box failures; further the gearbox requires frequent maintenance and it also increases the weight of the nacelle which in turn increases the cost [2].The above drawbacks can be overcome in the direct driven wind energy conversion systems (WECS) by replacing mechanical gearbox systems with power electronic converters[3].By eliminating the need for a gearbox between the turbine and generator, these systems are less expensive and also require less maintenance. Nowadays Permanent Magnet Synchronous Generators (PMSGs) are more attractive for direct driven wind energy schemes [5], [7] because of its improved performance and decreasing cost. Further the PMSG has several advantages such as Higher efficiency and energy yield. Additional power supply is not needed for the magnet field excitation.

Improvement in the thermal characteristics of the PM machine due to the absence of the field losses. Higher reliability due to the absence of mechanical components such as slip rings. The voltage of the direct driven PMSG is variable due to the intermittent nature of the wind energy. Fluctuating voltage and power is of major concern in converter based grid connected wind 8|P a ge www.iiste.org

Journal of Energy Technologies and Policy ISSN 2224-3232 (Paper) ISSN 2225-0573 (Online) Vol.1, No.1, 2011

www.iiste.org

generation systems. These variable speed generators necessitate AC-DC-AC conversion systems [4]. In this paper, a study of small-scale direct driven PMSG suitable for household and community level power generation is considered. A dynamic model of the wind energy conversion scheme is developed in MATLAB/SIMULINK. The effect of variation in the duty ratio of the chopper and the modulation index of the inverter on the power output of the generator are analyzed for different wind speeds. The grid integration of the Wind Generator and the study of Active power export and RKVAR requirement under various wind velocities are carried out. A reactive VAR compensator for the improvement of reactive power is designed and incorporated in the system 2. Modeling of system components In the scheme shown in fig 1, the output of the generator varies with wind velocity and the maximum power occurs at a particular rotational speed for a given wind velocity. The optimum speed is achieved by varying the duty ratio of the chopper and the maximum power is fed to the grid at required voltage and frequency using an inverter. 2.1 Wind turbine model The power, pwind in the air flow is expressed as [8] Pwind = 1/2 av3 Where, A = area swept by the blades [m2] = air density [kg/m2] V = wind velocity [m/s] The mechanical power captured by the wind turbine is Written as Pt = 0.5 a cp (, ) v3 The tip speed ratio is defined as = r*r/v Where, R=rotor radius[m] r = angular velocity [rad/s] Cp=coefficient of power conversion The power coefficient is a nonlinear function of the tip speed ratio and the blade pitch angle (in degrees). If the swept area of the blade and the air density are constant, the value of cp is a function of and it is maximum at the particular opt. Hence, to fully utilize the wind energy, should be maintained at opt , which is determined from the blade design. Then Pturbine = 0.5 A cpmaxv3 2.2 PMSG model Dynamic modeling of PMSG can be described in d-q reference system as follows [9], [10],[11]: Vg q = - (R g + p Lq) iq e Ld id + e f Vg d = -(R g + p Ld) id e Lq iq (5) (6) (4) (3) (2) (1)

9|P a ge www.iiste.org

Journal of Energy Technologies and Policy ISSN 2224-3232 (Paper) ISSN 2225-0573 (Online) Vol.1, No.1, 2011

www.iiste.org

Where, R g is the stator resistance, Lq and Ld are the inductances of the generator on the d and q axis, f is the permanent magnetic flux and e is the electrical rotating speed of the generator, defined by r r = pn (7) m Where, pn is the number of pole pairs of the generator and m is the mechanical angular speed. In order to complete the mathematical model of the PMSG, the expression for the electromagnetic torque can be described as [10] Te = 3/2 Pn[(Ld Lq) id iq - f iq] Te = - 3/2 pn f iq 2.3 Power conditioning system The overall function of the power conditioning system (PCS) is to convert the variable amplitude and variable frequency three-phase output voltage from the generator to a fixed amplitude and fixed frequency single-phase ac voltage. The power conditioning system used for connecting the individual WTG to the distribution grid requires the flexible, efficient and reliable generation of high quality electric power. The PCS consists of a diode bridge rectifier, a boost chopper and a single phase inverter. Figure 2 shows the circuit diagram of the power conditioning system . The output from the PMSG is rectified using a three-phase rectifier whose output voltage Vrec is given by Vrec =1.65Vm (10) If ignore the losses of diodes, diode rectifier does not change the power. It only uses to convert AC to DC. The output from the diode bridge rectifier is fed to the boost chopper. Figure 3 shows the circuit diagram of the boost converter used in the PCS. The standard unidirectional topologies of the DC-DC boost converter or chopper in Figure. 3.a consist of a switching-mode power device containing basically two semiconductor switches (a rectifier diode and a power transistor with its corresponding anti-parallel diode) and two energy storage devices (an inductor and a smoothing capacitor) for producing an output DC voltage at a level greater than its input DC voltage. This converter acts as an interface between the full-wave rectifier bridge and the Voltage Source Inverter, by employing pulse-width modulation (PWM) control techniques. Figure 3.b shows control diagram of the boost chopper. The input to the boost converter is the variable DC voltage output from the PMSG / rectifier circuit. The boost converter controls its output voltage to a fixed dc voltage range as required by the inverter stage. Note that the input voltage used is dictated by the voltage range expected from the generator / rectifier circuit..The power generated by a wind turbine typically varies in Proportion to the cube of its rotational speed. Both the voltage vs. Speed characteristic of the Generator and power vs. Speed characteristic of the turbine are considered when specifying the component values in the boost converter circuit. The boost converter is widely used and has been designed to operate in continuous conduction mode, which results in a simple relationship between the input and output Voltage: Vout = Vin/(1-duty ratio) (11) This equation neglects the resistance of the inductor, and the small voltage drop across the diode and switch, but demonstrates the relationship between the duty ratio and output voltage as the input voltage varies. The boost converter is also used to implement another important function ,the ability to track the maximum power operating point of the turbine in given wind conditions [12],[13]. This is achieved by adjusting the duty ratio of the boost converter using a perturbation .the effect of duty cycle for various input voltages is shown in the figure 4. From the figure the optimum duty ratio for various input voltages can be found out. The method is based on the observed system power output only with no external measurement of wind speed necessary. If the duty ratio adjustment leads to an increase in output 10 | P a g e www.iiste.org (8) (9) If id = 0, the electromagnetic torque is expressed as:

Journal of Energy Technologies and Policy ISSN 2224-3232 (Paper) ISSN 2225-0573 (Online) Vol.1, No.1, 2011

www.iiste.org

power, then the duty ratio is again adjusted in the same direction (provided the output voltage remains within a pre-specified range). If it leads to a decrease in output power, the duty ratio is adjusted in the opposite direction. Stand alone systems will normally have the fixed dc bus rigidly fixed by the presence of batteries. However, grid connected systems will generally have no battery storage, thus the fixed dc bus can vary as the duty cycle is altered. The inverter circuit must compensate for this variation to ensure that the ac voltage output remains at a fixed amplitude and frequency. Therefore the input to the inverter must be maintained constant irrespective of changes in the input voltage of the boost chopper. So a PI controller is incorporated with this boost chopper circuit to maintain its output constant by tuning it[6]. The values of proportional gain (kp) and integral gain (ki) used in the pi controller are: Kp=0.01 Ki=1. The constant output of the boost chopper is fed to a single phase Voltage Source Inverter (VSI). In a VSI the input source is a voltage which is stored in DC link capacitor. This inverter chops the input DC voltage and generates an AC voltage with desired magnitude and frequency with respect to pulse patterns and modulation techniques different current and voltage control techniques have been proposed to generate a high voltage high current rectangular waveform based on reference waveforms characteristics[15] 3. Simulation results and discussions The performance of the proposed method was firstly evaluated by MATLAB/SIMULINK simulation. The wind turbine power characteristics are drawn for various wind velocities and it is found that at the wind velocity of 8 m/s maximum power is extracted by the wind turbine which is shown in figure 5. Under rated conditions the output voltage , current and torque of the generator are recorded and shown in the figures 7 and 8. It is found that at the rated speed of 400rpm, the out put phase voltage of the generator is 99V , the output current is 15A. 3.1 Dynamic results The dynamic results of the PCS at different output voltages of the generator are recorded and shown in figures 9, 10, 11. It is found that with the varying wind velocity the output voltage of the generator varies which in turn varies the output voltage of the rectifier,chopper and inverter. But the input voltage of the inverter must be maintained constant so as to send constant voltage to the grid, hence to maintain constant voltage at the input of the inverter a PI controller is incorporated in the boost chopper which maintains constant chopper output voltage irrespective of changes in wind velocity. The dynamic results of the PCS without PI controller and with PI controller are shown in figure 12 and figure 13, it is inferred from the waveform that the PI controller maintains constant chopper output tvoltage even if the wind velocity varies and hence ensures constant power flow to the grid irrespective of variations in wind velocity 3.2 Power flow analysis The power flow analysis for the entire system is carried out and a switched capacitor compensator is designed for reactive power compensation, since most loads are inductive and consumes lagging reactive power, the compensation required is usually supplied by leading reactive power. The most common form of leading reactive power compensation is by connecting shunt capacitors to the line. The active and reactive power transport at various wind velocities is carried out and the results are presented in the figures 14 and figure 15. 1 2 4. Conclusion

In this paper the dynamic model of a grid connected direct driven PMSG based wind electric generator is presented. A power electronic interface comprising an AC-DC-AC converter is used to maintain the DC bus voltage constant for different wind velocities and to extract maximum power from the wind. The 11 | P a g e www.iiste.org

Journal of Energy Technologies and Policy ISSN 2224-3232 (Paper) ISSN 2225-0573 (Online) Vol.1, No.1, 2011

www.iiste.org

simulation results are presented for various wind velocities and the effect of variations in duty ratio of the chopper is investigated. The optimum duty ratio for various wind velocities is identified and the results are discussed. The power flow analysis for the entire system is carried out and a switched capacitor compensator is designed for the improvement of reactive power.

APPENDIX Parameters of the turbine

PARAMETERS RATINGS

Rated power Rated wind speed Air density No of blades Blade diameter Gear ratio 3 4

PARAMETERS

2KW 8m/s 1.2kg/m3 3 2m 1

Parameters of the generator:

RATINGS

Rated power Rated speed No of poles Rated voltage Rated current 5 References

2KW 400rpm 18 99V 15A

6 Kajogbola R. Ajao & Modupe R. Mahamood Wind Energy Conversion System: The Past, The Present And The Prospect Journal of American Science 2009;5(6):17-22 7 Rajveer Mittal, K.S.Sandu, D.K.Jain ,Isolated Operation of Variable Speed Driven PMSG for Wind Energy Conversion System IACSIT International Journal of Engineering and Technology Vol. 1, No.3, August, 2009 ISSN: 1793-8236 J. Darbyshire and C. V. Nayar, Modelling, simulation, and testing of grid connected small scale wind systems, in Proc. Australasian Univ. Power Eng. Conf. (AUPEC), Dec. 2007, pp. 16 Haining Wang, Chem Nayar, Control and Interfacing of a Grid-Connected Small-Scale Wind Turbine Generator Senior Member, IEEE, Jianhui Su, and Ming Ding IEEE TRANSACTIONS ON ENERGY CONVERSION, VOL. 26, NO. 2, JUNE 2011 Ming Y., Gengyin L., Ming Z., Chengyong Z., Modeling of the Wind Turbine with a Permanent Magnet Synchronous Generator for Integration, Proc. of IEEE Power Engineering Society General Meeting, June 2007. 12 | P a g e www.iiste.org

Journal of Energy Technologies and Policy ISSN 2224-3232 (Paper) ISSN 2225-0573 (Online) Vol.1, No.1, 2011

www.iiste.org

A. Macready and C. Coates, Low cost wind turbine controller, in Proc. Australasian Univ. Power Eng. Conf.(AUPEC), Dec. 2007, pp. 15. H. Sharma, S. Islam, T. Pryor, and C. V. Nayar, Power quality issues in a wind turbine driven induction generator and diesel hybrid autonomous grid, J. Elect. Electron. Eng., vol. 21, no. 1, pp. 1925, 2001. Gautam Poddar, Aby Joseph, and A.K.Unnikrishnan ,Sensorless Variable-Speed Wind Power Generator With Unity-Power-Factor Operation, IEEE Trans.Ind. Electron, vol. 50, pp. 1007-1015 , Oct 2003. Ming Yin, Gengyin Li, Ming Zhou and Chengyong Zhao, Modelling of the Wind Turbine with a Permanent Magnet Synchronous Generator for Integrat, Power Engineering Society Genera Meeting, 2007. IEEE, pp. 1-6, June 2007. Yao Weizheng, Kinglon Woo, Zhao Ruijie, Guo Wei, and Wang Yue, Analyze of current control strategy based on vector Control for Permanent-Magnet Synchronous Generator in Wind Power System, Power Electronics and Motion Control Conference, 2009. IPEMC '09.IEEE 6th International, pp. 2209-2212, May 2009. De Broe, S. Drouilhet, and V. Gevorgian, A Peak Power Tracker for Small Wind Turbines in Battery Charing Applications, IEEE Transactions on Energy Conversion, vol. 14, pp, 1630-1635, 1999. Barote, L.; Marinescu, C.; Georgescu, M.: VRB modeling for storage in stand-alone wind energy systems, Proc. of the PowerTech09 IEEE Conference, Bucharest, Romania, June/July 2009.Engineering Society General Meeting, June 2007. Power electronics circuits, devices and applications by Muhammad Rashid , third edition. Table 1 Supply voltage in volts 70 80 90 100 110 120 Optimum duty ratio Output voltage of chopper with PI controller

0.6 0.45 0.35 0.3 0.25 0.2

300 300.7 300.4 300.8 300 300

Figure.1. Wind turbine generator with grid

13 | P a g e www.iiste.org

Journal of Energy Technologies and Policy ISSN 2224-3232 (Paper) ISSN 2225-0573 (Online) Vol.1, No.1, 2011

www.iiste.org

Figure.2.Circuit diagram of the power conditioning system

Figure.3.a. Switching-mode power device Figure3.b Control diagram of the boost chopper.

Voltage (V)

Duty ratio Figure.4.Effect of duty ratio and optimum duty ratio

14 | P a g e www.iiste.org

Journal of Energy Technologies and Policy ISSN 2224-3232 (Paper) ISSN 2225-0573 (Online) Vol.1, No.1, 2011

www.iiste.org

Power (W)

Speeed in rpm Figure.5.Power characteristics of the wind turbine

Torque (N.m)

Power (W)

Time in sec Figure.6. speed and torque of the generator at 400 rpm

Torque (N.m) Time in sec Figure.7. speed and torque of the generator at 400 rpm 15 | P a g e www.iiste.org

Speed (Rad/sec)

Journal of Energy Technologies and Policy ISSN 2224-3232 (Paper) ISSN 2225-0573 (Online) Vol.1, No.1, 2011

www.iiste.org

Current (A)

Voltage (V)

Time in sec Figure.8. Output voltage and current of the generator at 400 rpm

Voltage (V) Time in sec Figure.9. Output voltage of the rectifier for various generator voltages Voltage (V) Time in sec Figure.10. Output voltage of the chopper for various generator voltages 16 | P a g e www.iiste.org

Journal of Energy Technologies and Policy ISSN 2224-3232 (Paper) ISSN 2225-0573 (Online) Vol.1, No.1, 2011

www.iiste.org

Voltage (V)

Time in sec Figure.11. Output voltage of the inverter for various generator voltages

Time in sec Figure 12.Output voltage of the rectifier; boost chopper and inverter for variations in the output voltage of the generator without PI controller

17 | P a g e www.iiste.org

Journal of Energy Technologies and Policy ISSN 2224-3232 (Paper) ISSN 2225-0573 (Online) Vol.1, No.1, 2011

www.iiste.org

Time in sec Figure 13.Output voltage of the rectifier, boost chopper and inverter and output current of the inverter for variations in the output voltage of the generator with PI controller

Current (A)

Voltage (V)

Time in sec Figure 14.output voltage and current of the grid

18 | P a g e www.iiste.org

Journal of Energy Technologies and Policy ISSN 2224-3232 (Paper) ISSN 2225-0573 (Online) Vol.1, No.1, 2011

www.iiste.org

19 | P a g e www.iiste.org

Reactive power (w) Time in sec Figure 15. real and reative power of the grid with switched capacitor compensator

Real power (W)

Das könnte Ihnen auch gefallen

- 4.. (26-36) Signal Strength Based Congestion Control in MANETDokument11 Seiten4.. (26-36) Signal Strength Based Congestion Control in MANETiisteNoch keine Bewertungen

- (1-10) Conversion of Invasive Grasses Into Hand Made Paper For Artistic CreationsDokument10 Seiten(1-10) Conversion of Invasive Grasses Into Hand Made Paper For Artistic CreationsiisteNoch keine Bewertungen

- (39-47) Consumerism A Pillar of Social Welfare Indian PerspectiveDokument9 Seiten(39-47) Consumerism A Pillar of Social Welfare Indian PerspectiveiisteNoch keine Bewertungen

- (21-27) Role of Right To Information Act 2005 in The Human DevelopmentDokument7 Seiten(21-27) Role of Right To Information Act 2005 in The Human DevelopmentiisteNoch keine Bewertungen

- 861 2048 1 SMDokument9 Seiten861 2048 1 SMkhaliddarwish1962Noch keine Bewertungen

- (6-14) Community Based Irrigation Water Management SystemsDokument9 Seiten(6-14) Community Based Irrigation Water Management SystemsiisteNoch keine Bewertungen

- (15-25) Modeling of Flexural Waves in A Homogeneous Isotropic Rotating Cylindrical PanelDokument11 Seiten(15-25) Modeling of Flexural Waves in A Homogeneous Isotropic Rotating Cylindrical PaneliisteNoch keine Bewertungen

- 3 (25-29) .Tender Leaf Fall Vipul SomaniDokument5 Seiten3 (25-29) .Tender Leaf Fall Vipul SomaniiisteNoch keine Bewertungen

- (24-38) Sarbapriya Ray - Final PaperDokument15 Seiten(24-38) Sarbapriya Ray - Final PaperiisteNoch keine Bewertungen

- (4-10) Importance of Brand Personality To Customer LoyaltyDokument7 Seiten(4-10) Importance of Brand Personality To Customer LoyaltyiisteNoch keine Bewertungen

- (16-23) Corporate Social Respnsibility and Compliance With Regulations in NigeriaDokument8 Seiten(16-23) Corporate Social Respnsibility and Compliance With Regulations in NigeriaiisteNoch keine Bewertungen

- (1-5) Thermally Induced Vibration of Non-Homogeneous Visco-Elastic Plate of Variable ThicknessDokument5 Seiten(1-5) Thermally Induced Vibration of Non-Homogeneous Visco-Elastic Plate of Variable ThicknessiisteNoch keine Bewertungen

- (11-20) Public Service Broadcasting by Radio - Challenges AheadDokument10 Seiten(11-20) Public Service Broadcasting by Radio - Challenges AheadiisteNoch keine Bewertungen

- (14-24) Impact of Education On Fish Farming in West Bengal - A Study ReportDokument11 Seiten(14-24) Impact of Education On Fish Farming in West Bengal - A Study ReportiisteNoch keine Bewertungen

- (10-15) A Relationship Between Emotional Intelligence and Self EsteemDokument6 Seiten(10-15) A Relationship Between Emotional Intelligence and Self Esteemiiste100% (1)

- (1-15) Study of BRIC Countries in The Financial TurnmoilDokument15 Seiten(1-15) Study of BRIC Countries in The Financial TurnmoiliisteNoch keine Bewertungen

- The Case of HIV and AIDS Awareness Campaign in NigeriaDokument14 SeitenThe Case of HIV and AIDS Awareness Campaign in NigeriaiisteNoch keine Bewertungen

- (1-13) Distribution and Eco Toxicological Risk Assessment of Persistent Organic Pollutants (POPs) in River Sediments From Delhi, IndiaDokument13 Seiten(1-13) Distribution and Eco Toxicological Risk Assessment of Persistent Organic Pollutants (POPs) in River Sediments From Delhi, IndiaiisteNoch keine Bewertungen

- Technical Efficiency of Cowpea Production in Osun State, NigeriaDokument6 SeitenTechnical Efficiency of Cowpea Production in Osun State, NigeriaiisteNoch keine Bewertungen

- Texture Feature Based Analysis of Segmenting Soft Tissues From Brain CT Images Using BAM Type Artificial Neural NetworkDokument10 SeitenTexture Feature Based Analysis of Segmenting Soft Tissues From Brain CT Images Using BAM Type Artificial Neural NetworkiisteNoch keine Bewertungen

- (1-9) Online Banner Ad CorrectedDokument9 Seiten(1-9) Online Banner Ad CorrectediisteNoch keine Bewertungen

- (1-3) A Study On Global Communication in English LanguageDokument3 Seiten(1-3) A Study On Global Communication in English LanguageiisteNoch keine Bewertungen

- The Impact of Macro Economic Policies and Programs On Poverty ProblemsDokument11 SeitenThe Impact of Macro Economic Policies and Programs On Poverty ProblemsiisteNoch keine Bewertungen

- Sustainable Resource Productivity in Small Scale Farming in Kwara State, NigeriaDokument7 SeitenSustainable Resource Productivity in Small Scale Farming in Kwara State, NigeriaiisteNoch keine Bewertungen

- Super Critical Fluid Technology in Biodiesel ProductionDokument6 SeitenSuper Critical Fluid Technology in Biodiesel ProductioniisteNoch keine Bewertungen

- Surface Roughness Effect On The Performance of A Magnetic Fluid Based Porous Secant Shaped Slider BearingDokument14 SeitenSurface Roughness Effect On The Performance of A Magnetic Fluid Based Porous Secant Shaped Slider BearingiisteNoch keine Bewertungen

- Study The Rheological and Mechanical Properties of PVADokument7 SeitenStudy The Rheological and Mechanical Properties of PVAiisteNoch keine Bewertungen

- Study of Load Balanced Routing Protocols in Mobile Ad Hoc NetworksDokument7 SeitenStudy of Load Balanced Routing Protocols in Mobile Ad Hoc NetworksiisteNoch keine Bewertungen

- Study of Statistical Models For Route Prediction Algorithms in VANETDokument6 SeitenStudy of Statistical Models For Route Prediction Algorithms in VANETiisteNoch keine Bewertungen

- Study of Ground Water in Perungudi Area of ChennaiDokument9 SeitenStudy of Ground Water in Perungudi Area of ChennaiiisteNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- SION Vacuum Circuit Breaker 3AE5: Medium-Voltage EquipmentDokument70 SeitenSION Vacuum Circuit Breaker 3AE5: Medium-Voltage EquipmentAndrewNoch keine Bewertungen

- Preventing a Power Grid CollapseDokument15 SeitenPreventing a Power Grid CollapseMadhusmita Mohanty100% (1)

- POWER FACTOR CAPACITOR BANK MAINTENANCE SOPDokument7 SeitenPOWER FACTOR CAPACITOR BANK MAINTENANCE SOPnovaNoch keine Bewertungen

- RENR2344RENR2344 - SIS Peec Emcp 2 +Dokument4 SeitenRENR2344RENR2344 - SIS Peec Emcp 2 +Sayed Younis SadaatNoch keine Bewertungen

- HP5424 enDokument3 SeitenHP5424 enBogdan VasileNoch keine Bewertungen

- CB Testing SCOPE Compatibility ModeDokument58 SeitenCB Testing SCOPE Compatibility ModeVepty whoops100% (1)

- IEC Codes and StandardDokument4 SeitenIEC Codes and StandardAnand SinhaNoch keine Bewertungen

- Difference Between ICCB, MCCB and MCBDokument8 SeitenDifference Between ICCB, MCCB and MCBAbdulyunus AmirNoch keine Bewertungen

- Service Code in Electrical System (Short-Circuiting in Swing Holding Brake Solenoid) E203Dokument4 SeitenService Code in Electrical System (Short-Circuiting in Swing Holding Brake Solenoid) E203ariy yuli styawan100% (1)

- Sizing Conductors and Selecting Protection Devices: Power Guide 2009 / Book 04Dokument71 SeitenSizing Conductors and Selecting Protection Devices: Power Guide 2009 / Book 04AdrianaChavezNoch keine Bewertungen

- RSB 2020 ADDC RegulationDokument1 SeiteRSB 2020 ADDC RegulationFun TonNoch keine Bewertungen

- D.C. SYSTEM (Battery Chargers & Battery)Dokument5 SeitenD.C. SYSTEM (Battery Chargers & Battery)totochakrabortyNoch keine Bewertungen

- NIA Project Registration and PEA DocumentDokument6 SeitenNIA Project Registration and PEA DocumentkotiniNoch keine Bewertungen

- 1152 RevA PDFDokument49 Seiten1152 RevA PDFDaniel Germán RomeroNoch keine Bewertungen

- Decal, Schematic SD / 60 HZ Intellisys 22182356 LDokument2 SeitenDecal, Schematic SD / 60 HZ Intellisys 22182356 LJose Marie AsuncionNoch keine Bewertungen

- Electrical Safety Inspection Checklist-FDokument2 SeitenElectrical Safety Inspection Checklist-FGyanendra Narayan Nayak88% (8)

- Growth Demand Jawa Madura BaliDokument9 SeitenGrowth Demand Jawa Madura BalikiaNoch keine Bewertungen

- 3AV1 Comparatie Vid Cu SF6Dokument1 Seite3AV1 Comparatie Vid Cu SF6Pintea Ioan FlorinNoch keine Bewertungen

- CSEBDokument18 SeitenCSEBRahul Ranjan100% (1)

- SolaX Power Troubleshooting X1MINI&AIR&BOOST PDFDokument10 SeitenSolaX Power Troubleshooting X1MINI&AIR&BOOST PDFmarketingsunfix sunfix100% (1)

- CT Question PapersDokument6 SeitenCT Question PapersdevNoch keine Bewertungen

- MEP Preliminary Program R00 - Local Authority MatrixDokument2 SeitenMEP Preliminary Program R00 - Local Authority MatrixVarun AryaNoch keine Bewertungen

- MV Substation DesignDokument12 SeitenMV Substation DesignPEC E&I-2Noch keine Bewertungen

- Miniature Circuit Breaker - SB200 DC - 2P - C - 10 AmpereDokument3 SeitenMiniature Circuit Breaker - SB200 DC - 2P - C - 10 AmperechinnathambijNoch keine Bewertungen

- Electrical Engineering Portal - Com Commissioning of Electrical EquipmentDokument8 SeitenElectrical Engineering Portal - Com Commissioning of Electrical EquipmentSethu RatnamNoch keine Bewertungen

- High Voltage Switchgear DistributionDokument3 SeitenHigh Voltage Switchgear DistributionMuruganNoch keine Bewertungen

- Air Circuit Breaker (ACB) 121023.044007Dokument7 SeitenAir Circuit Breaker (ACB) 121023.044007TheULTRANoch keine Bewertungen

- Description: Power Distribution Module eQ38XXDokument4 SeitenDescription: Power Distribution Module eQ38XXusamakhan20567% (3)

- Transformer Protection Relay GRE160 Brochure 12027-1 0Dokument22 SeitenTransformer Protection Relay GRE160 Brochure 12027-1 0tanujaayerNoch keine Bewertungen

- Master Panel Wiring DiagramDokument2 SeitenMaster Panel Wiring DiagramShakik AhammodNoch keine Bewertungen