Beruflich Dokumente

Kultur Dokumente

BEMO Plate Englisch

Hochgeladen von

Vele BogoevskiOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

BEMO Plate Englisch

Hochgeladen von

Vele BogoevskiCopyright:

Verfügbare Formate

BEMO - Pl a t e

Using the sun in a simple and sensible way: Solar thermal systems for innovative solutions.

The solar roofing system for large and industrial roofs. Use your roof for power generation.

BEMO-PLATE

BEMO PLATE The flexible solar system for large and industrial roofs. BEMO PLATE is a solar roofing system which is used primarily in industry, agriculture and other buildings with large roof surfaces because of its size. The system consists of foil laminates of the American producer Unisolar including the state-to-the-art triple junction technology. The foil laminates are stuck to coated metal sheets - quality from BIOHAUS. The laying of the solar Powerplates is rather simple: Depending on the requirements, they are fixed or stuck parallel onto the roof elements. This way, the existing outer shell of the roof is used as substructure. This simple way of laying makes the system ideal for the use in large projects.

BIOHAUS is looking back at an experience in the solar sector of more than 20 years. A special topic is installing solar modules in an esthetically attractive way. Numerous reference buildings show that the combination of ecological generation of electricity and attractive construction can be realized. BIOHAUS relies on thin layer technology. The latest thin layer system BEMO PLATE offers far reaching possibilities for the use in industry, agriculture and trade.

Innovation with great effect Every roof and every facade is an advertisement for the architect and the owner of the building. The name BEMO SYSTEMS has stood for all-round planning, precision prefabrication and versatile application possibilities since 1982. BEMO SYSTEMS makes possible the creation of high-quality and out-of-the-ordinary roofing and wall cladding solutions in aluminium, copper, inc, steel and stainless steel. An optimized standing seam system, industrially pre-fabricated and easy to work, makes the range of architectural options for buildings almost unlimited.

What is photovoltaic? The hunger for energy of the worlds population is steadily increasing. A society is impossible without sufficient energy supply. As fossil energy sources bring along many dangers, renewable energies become a more and more important alternative. Especially the use of solar energy has constantly increased within the last years, not only because of the attractive remuneration for feeding power into the public network based on the law concerning renewable energies. Solar cells are mostly made of silicon. If the sun shines on the cells, a direct voltage is created between the top side and the bottom. This energy is converted into alternating current by a power inverter and fed into to public power supply system. A photovoltaic plant with a top performance of 1 kW provides you with 800 kWh electrical power per year and saves the environment for 500 kg of carbon dioxide and other pollutants every year. With a photovoltaic system you generate clean power!

blue cell green cell red cell reflective metal layer

transparent contact layer

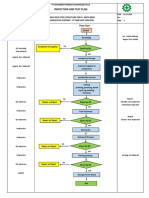

How does BEMO PLATE work? BEMO PLATE modules are mounted this way depending on the kind of outer shell (trapezoidal, corrugated or standing seem profile). With the standing seam profile the installation is effected without penetrating the roof skin. No expensive holding clips or welding is necessary.

total thickness of a Triplejunction cell < 1 m

flexible substrate (stainless steel) < 127 m

The technology BEMO PLATE consists of thin layer cells. The basis is the so-called triple-junction technology: i.e. 3 layers of solar cells lie one over the other. Every single layer is sensitive for another spectral range of light which leads to a better exploitation of energy - especially at diffuse light. Thin layer cells can utilize diffuse radiation better than crystal cells. The revenue is respectively higher. Even with an unfavorable orientation of the roof (e.g. to the east or west) or flat slopes of the roof, you can achieve a higher annual revenue using thin layer cells. By the use of bypass diodes, the system is insensitive to partial shading. At higher temperatures the decline in performance is lower. It is fact that the technology of thin layer cells causes an increase of the annual electricity revenue of up to 20 %, i.e.20 % more payment and faster amortization. Furthermore the production of thin layer cells is more ecological because of the low use of resources and energy during the production. The advantages speak in favor of themselves!

BEMO-PLATE

BEMO-PLATE the combination of ecology and esthetics with BEMO PLATE an optically representative and esthetically attractive look is created. Using Powerplates, architecturally outstanding buildings can be designed. According to the customers wishes the system can be integrated discreetly in the building - a harmonic total look is created. The Powerplates can be integrated much more unobtrusive as, e.g. solar modules on special constructions. Therefore you can kill two birds with one stone: You generate power in an environmental-friendly way and give your house a special accent. BEMO PLATE offers solutions for all kinds of operation fields, be it in commercial areas, industry or agriculture. Numerous reference objects in Germany and abroad are attractive on account of their excellent look - convince yourself!

Foto: Heinz u. Hans-Georg Roelle GmbH

Advantages of BEMO PLATE BEMO PLATE is a solar roofing system for all large roof surfaces and especially suit the BEMO roof system BEMO PLATE with its triple junction technology leads to very good revenues even at diffuse light, unfavorable roof orientation (to the east or west) or flat roof slopes BEMO PLATE can be laid out simply and quickly - the solar Powerplates are versatile BEMO PLATE can be extended and refitted any time BEMO PLATE adapts to the roof form BEMO PLATE does not need any additional standing construction BEMO PLATE can use the entire roof surface.

electrical variables* module class rated burden (PMMP), +/- 5% voltage (UMMP) electric current (IMPP) off-load voltage (UOC) short circuit current (ISC) capacity coefficient ( MPP,T) voltage coefficient ( UMPP,T) electric current coefficient ( IMPP,T) voltage coefficient ( UOC,T) electric current coefficient ( ISC,T)

136 136 33 4,1 46,2 5,1 -0,29 -102 4,1 -176 5,1

Wp V A V A W mV mA mV mA

* under standard test conditions STC (1.000 W/m, spectrum AM 1.5, cell temperature 25 C). During the first 8-10 weeks time of operation are going to appear the following max. variations: capacity PMPP +15%, voltage Uoc +11%, electric current Isc +4%.

Dimensions and weight system application length, ( L -0/+2 mm) width , ( L -0/+2 mm) weight

BEMO Plate 5600 mm 416 mm 21 kg

quality characteristics capacity tolerance capacity guarantee product guarantee max. system voltage1.000 V

5% 20 Jahre auf 80 % Leistung 5 Jahre

constructive characteristics cells buildup front side back side socket connecting cable

amorphous silicon Triple-junction cells, United Solar film laminate at coated steel plate TEFZEL, clear-transparent Flourpolymer coated steel plate two, protection class IP65, integrated Bypassdiodes per cell 1 x 0,5 m, MultiContact MC 3 pin-and-socket connector system per socket

Source: SOLARPRAXIS

Average annual volume of global radiation in Germany in kWh/m2

CREATIVE SECTIONAL DESIGN.

MAAS Profile GmbH & Co. KG Friedrich-List-Strae 25 D -74532 Ilshofen-Eckartshausen Tel.: +49 (0) 79 04-9714- 250 Fax: +49 (0) 79 04-9714-151 e-mail: info@maasprofile.de www.maasprof ile.de ww w. bem o. c om

Prospekt Nr. 510- 11-1/ 1/2007

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Dr. Berg's Favorite HEALTHY JUNK FOODS & Other AlternativesDokument23 SeitenDr. Berg's Favorite HEALTHY JUNK FOODS & Other Alternativesprashant_padte100% (8)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- 4-Week Weight Loss ChallengeDokument6 Seiten4-Week Weight Loss ChallengeTammy JacksonNoch keine Bewertungen

- HBSE-Mock ExamDokument3 SeitenHBSE-Mock ExamAnneNoch keine Bewertungen

- Ups Installation Method StatementDokument197 SeitenUps Installation Method StatementehteshamNoch keine Bewertungen

- Target ListDokument9 SeitenTarget ListChaitali DegavkarNoch keine Bewertungen

- Break Free - Nathaniel BrandenDokument16 SeitenBreak Free - Nathaniel Brandennbckudxtkudkuf50% (2)

- 01 Slug CatchersDokument23 Seiten01 Slug CatchersMohamed Sahnoun100% (2)

- Inspection and Test Plan: Flow Chart Start IncomingDokument1 SeiteInspection and Test Plan: Flow Chart Start IncomingSinden AyuNoch keine Bewertungen

- Terminal Tractors and Trailers 6.1Dokument7 SeitenTerminal Tractors and Trailers 6.1lephuongdongNoch keine Bewertungen

- Presentation On Data Integrity in PharmaDokument80 SeitenPresentation On Data Integrity in Pharmaskvemula67% (3)

- DNV Rules For Electrical Instal at IonsDokument80 SeitenDNV Rules For Electrical Instal at Ionsnzjohn100% (3)

- AnxietyDokument5 SeitenAnxietydrmadankumarbnysNoch keine Bewertungen

- Darnell's Father Goes StrictDokument2 SeitenDarnell's Father Goes StrictDavid Theodore Richardson IIINoch keine Bewertungen

- Informática Ejercicios IDokument10 SeitenInformática Ejercicios IAlejandroMendezNoch keine Bewertungen

- Final Project Report 2Dokument8 SeitenFinal Project Report 2Mallesh MaranurNoch keine Bewertungen

- Delta C200 Series AC Drives PDFDokument5 SeitenDelta C200 Series AC Drives PDFspNoch keine Bewertungen

- Notes Lecture No 3 Cell Injury and MechanismDokument5 SeitenNotes Lecture No 3 Cell Injury and MechanismDr-Rukhshanda RamzanNoch keine Bewertungen

- GDCR Final PDFDokument311 SeitenGDCR Final PDFHrushikesh PatelNoch keine Bewertungen

- DSUSJRC01161350 Corail ST-Total Hip SystemDokument20 SeitenDSUSJRC01161350 Corail ST-Total Hip SystemXeniaNoch keine Bewertungen

- NTS - Candidate (Portal)Dokument1 SeiteNTS - Candidate (Portal)Noureen FatimaNoch keine Bewertungen

- Cement Evaluation CAST-CBL HalliburtonDokument36 SeitenCement Evaluation CAST-CBL HalliburtonrezaNoch keine Bewertungen

- Group 17-Solid State NMR - Questions-AnswersDokument5 SeitenGroup 17-Solid State NMR - Questions-AnswersOmkar AkulwarNoch keine Bewertungen

- PTA Resolution for Donation to School WashroomDokument2 SeitenPTA Resolution for Donation to School WashroomMara Ciela CajalneNoch keine Bewertungen

- Final TLE9 Nail Care9 Q1 Module 3Dokument20 SeitenFinal TLE9 Nail Care9 Q1 Module 3Ma. Andrea LagmanNoch keine Bewertungen

- Jaimin PatelDokument3 SeitenJaimin PatelSanjay SinghNoch keine Bewertungen

- The Role of Play Therapists in Children's Transitions: From Residential Care To Foster CareDokument11 SeitenThe Role of Play Therapists in Children's Transitions: From Residential Care To Foster Caresherry_hoang_1Noch keine Bewertungen

- Limetas Maximos ResidualesDokument27 SeitenLimetas Maximos ResidualesXjoelx Olaya GonzalesNoch keine Bewertungen

- Otology Fellowships 2019Dokument5 SeitenOtology Fellowships 2019Sandra SandrinaNoch keine Bewertungen

- Partial Defoliation of Vitis Vinifera L. Cv. Cabernet SauvignonDokument9 SeitenPartial Defoliation of Vitis Vinifera L. Cv. Cabernet Sauvignon1ab4cNoch keine Bewertungen

- Recombinant DNA TechnologyDokument14 SeitenRecombinant DNA TechnologyAnshika SinghNoch keine Bewertungen