Beruflich Dokumente

Kultur Dokumente

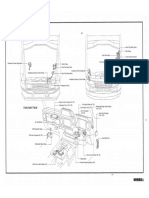

Toyota Inputs & Sensors

Hochgeladen von

fasdomingoCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Toyota Inputs & Sensors

Hochgeladen von

fasdomingoCopyright:

Verfügbare Formate

Components - Engine Inputs

MAF Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . MAP Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . IAT Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ECT Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Throttle Position Sensor . . . . . . . . . . . . . . . . . . . Knock Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . Camshaft Position Sensor . . . . . . . . . . . . . . . . . Crankshaft Position Sensor . . . . . . . . . . . . . . . . Vehicle Speed Sensor . . . . . . . . . . . . . . . . . . . . . ECM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ce1 Ce3 Ce6 Ce8 Ce13 Ce15 Ce17 Ce19 Ce20 Ce21

Ce-1

Components - Engine Inputs

MAF Sensor

Mass Airflow (MAF) Sensor

MONITOR DESCRIPTION

The MAF sensor monitors the amount of air flowing through the throttle valve. The engine control module (ECM) uses this information to determine the fuel injection time and provide a proper air/fuel ratio. Inside the MAF sensor, there is a heated platinum wire exposed to the flow of intake air. By applying a specific current to the wire, the ECM heats this wire to a given temperature. The flow of incoming air cools the wire and an internal thermistor, changing their resistance. To maintain a constant current value, the ECM varies the voltage applied to these components in the MAF sensor. The voltage level is proportional to the airflow through the sensor and the ECM interprets this voltage as the intake air amount. If there is a defect in the sensor or an open or short circuit, the voltage level will deviate outside the normal operating range. The ECM interprets this deviation as a defect in the MAF sensor and sets a DTC.

MONITOR STRATEGY

Related DTCs Required sensors/Components R i d /C t Frequency of operation Duration MIL operation ti Sequence of operation Continuous Within 10 sec. Immediate 2 driving cycles None Engine RPM is less than 4,000 rpm Engine RPM is 4,000 rpm or more P0100 Main Sub MAF sensor is open/shorted MAF sensor Crankshaft position sensor

TYPICAL ENABLING CONDITIONS

The monitor will run whenever the following DTCs are not present See page In4

TYPICAL MALFUNCTION THRESHOLDS

Detection Criteria MAF sensor voltage lt Less than 0.2 V More than 4.9 V Threshold

COMPONENT OPERATING RANGE

Parameter MAF sensor voltage Between 0.5 V and 4.5 V Standard Value

Information developed by Toyota. Used with permission.

Ce-1

Ce-2

Components - Engine Inputs

Mass Airflow (MAF) Sensor Range/Performance Problem

MONITOR DESCRIPTION

The MAF sensor measures the amount of air flowing through the throttle valve. The engine control module (ECM) uses this information to determine the fuel injection time and provide a proper air/fuel ratio. Inside the MAF sensor, there is a heated platinum wire exposed to the flow of intake air. By applying a specific current to the wire, the ECM heats this wire to a given temperature. The flow of incoming air cools the wire and an internal thermistor, changing their resistance. To maintain a constant current value, the ECM varies the voltage applied to these components in the MAF sensor. The voltage level is proportional to the airflow through the sensor and the ECM interprets this voltage as the intake air amount. In order to confirm that the output voltage of MAF sensor corresponds to the actual intake air amount, the ECM checks the output voltage of the MAF sensor under the following conditions: During idle (small intake air volume) S While driving under a high load condition (large intake air volume) S If the ECM detects that the output voltage of the MAF sensor is high while the engine is idling or the output voltage is low while driving under a high load condition, the ECM interprets this as a malfunction in the MAF sensor and sets a DTC.

MONITOR STRATEGY

Related DTCs Required sensors/Components R i d /C t Frequency of operation Duration MIL operation Sequence of operation Continuous Within 10 sec. 2 driving cycles None P0101 Main Sub MAF sensor malfunction MAF sensor Crankshaft position sensor, Throttle position sensor and ECT sensor

TYPICAL ENABLING CONDITIONS

The monitor will run whenever the following DTCs are not present Included in the Typical Malfunction Thresholds See page In4

TYPICAL MALFUNCTION THRESHOLDS

Detection Criteria More than 2.2 V MAF sensor voltage lt Less than 1.0 V Threshold Typical Enabling Condition S Idling S ECT is 70C (158F) or more S Engine RPM is 2000 rpm or more S Throttle valve open

COMPONENT OPERATING RANGE

Parameter MAF sensor voltage Between 0.5 V and 4.5 V Standard Value

Information developed by Toyota. Used with permission.

Ce-2

Ce-3

Components - Engine Inputs

MAP Sensor

Manifold Air Pressure (MAP) Sensor

MONITOR DESCRIPTION

Sensor Specification

Volt (V) (3.96) Output Voltage 3.6 2.4 1.2 150 20 450 60 750 100 840 mmHg (112) kPa

Intake Manifold Absolute Pressure

A20390

The MAP sensor detects the air pressure in the intake manifold. The ECM uses this sensor to calculate the engine load. Engine load is one of the factors the ECM uses to determine the fuel injector ON time, i.e. the fuel injection quantity. The sensor always indicates a pressure in the intake manifold as a complete vacuum is interpreted as zero pressure. Manifold pressures vary from a low values during idle or deceleration conditions to atmospheric pressure at wideopen throttle. Supercharged or turbocharged engines will achieve pressure above atmospheric pressure. The ECM supplies a regulated 5 V referencevoltage to the MAP sensor. The MAP sensor varies its outputs signal voltage between 1.2 V and 3.96 V in response to the pressure variations in the intake manifold. When the pressure in the intake manifold is low, the output voltage of the MAP sensor is low. When the pressure is high, the output voltage is high. If the ECM detects a MAP sensor output voltage that is out of the specified range, the ECM interprets this as a malfunction in the MAP sensor and sets a DTC.

MONITOR STRATEGY

Related DTCs Required sensors/Components R i d /C t Frequency of operation Duration MIL operation Sequence of operation Continuous Within 10 sec. Immediate None P0105 Main Sub MAP sensor circuit is open/shorted MAP sensor None

TYPICAL ENABLING CONDITIONS

The monitor will run whenever the following DTCs are not present See page In4

TYPICAL MALFUNCTION THRESHOLDS

Detection Criteria MAP sensor voltage Threshold Less than 0.5 V or more than 4.5 V

COMPONENT OPERATING RANGE

Parameter MAP sensor voltage Standard Value Between 1.2 V (at 80 kPa) and 3.96 V (at 12 kPa)

Information developed by Toyota. Used with permission.

Ce-3

Ce-4

Components - Engine Inputs

Manifold Air Pressure (MAP) Sensor Range/Performance Problem

MONITOR DESCRIPTION

Sensor Specification

Volt (V) (3.96) Output Voltage 3.6 2.4 1.2 150 20 450 60 750 100 840 mmHg (112) kPa

Intake Manifold Absolute Pressure

A20390

The MAP sensor detects the air pressure (vacuum) in the intake manifold. The ECM uses this sensor to calculate the engine load. Engine load is one of the factors the ECM uses to determine the fuel injector ON time, i.e. the fuel injection quantity. The sensor always indicates a pressure in the intake manifold as a complete vacuum is interpreted as zero pressure. Manifold pressures vary from a low value during idle or a deceleration condition to higher value at wideopen throttle (atmospheric pressure level). Supercharged or turbocharged engines will achieve pressure above atmospheric pressures. The ECM supplies a regulated 5V referencevoltage to the MAP sensor. The MAP sensor varies its outputs signal voltage between 1.2 V and 3.96 V in response to the pressure variations in the intake manifold. When the pressure in the intake manifold is low, the output voltage of the MAP sensor is low. When the pressure is high, the output voltage is high. To confirm that the output voltage of the MAP sensor corresponds to the actual pressure in the intake manifold, the ECM checks the MAP sensor output voltage in the following conditions: While idling (low intake manifold pressure) S While the engine is in a highload condition (high intake S manifold pressure) If the ECM detects a high output voltage from the MAP sensor while the engine is idling or a low output voltage when the engine is highly loaded, the ECM interprets this as a malfunction in the MAP sensor and sets a DTC.

MONITOR STRATEGY

Related DTCs Required sensors/Components R i d /C t Frequency of operation Duration MIL operation Sequence of operation Continuous Within 10 sec. 2 driving cycles None P0106 Main Sub MAP sensor malfunction MAP sensor Crankshaft position sensor, Throttle position sensor and ECT sensor

TYPICAL ENABLING CONDITIONS

The monitor will run whenever the following DTCs are not present Included in the Typical Malfunction Thresholds See page In4

Information developed by Toyota. Used with permission.

Ce-4

Ce-5

Components - Engine Inputs

TYPICAL MALFUNCTION THRESHOLDS

Detection Criteria Threshold More than 3.0 V MAP sensor voltage lt Less than 1.0 V Typical Enabling Condition S Idling S ECT is 70C (158F) or more S Engine RPM is less than 2,500 rpm S Throttle valve open

COMPONENT OPERATING RANGE

Parameter MAP sensor voltage Standard Value Between 1.2 V (at 20 kPa) and 3.96 V (at 112 kPa)

Information developed by Toyota. Used with permission.

CE-5

Ce-6

Components - Engine Inputs

IAT Sensor

Intake Air Temperature (IAT) Sensor

MONITOR DESCRIPTION

Sensor Specification

30 20

10

Acceptable

0.1 20 ( 4) 0 (32) 20 (68) 40 60 80 100 (104) (140) (176) (212)

The IAT sensor mounted on the mass airflow (MAF) sensor*, monitors temperature of the intake air. The IAT sensor has a thermistor that varies its resistance depending on the temperature of the intake air. When the air temperature is low, the resistance in the thermistor increases. When the temperature is high, the resistance drops. The variations in resistance are reflected in the voltage output from the sensor. The ECM monitors the sensor voltage and uses this value to calculate the intake air temperature. When the sensor output voltage deviates from the normal operating range, the ECM interprets this as a malfunction in the IAT sensor and sets a DTC. * When the engine uses a manifold air pressure (MAP) sensor instead of a MAF sensor, the IAT sensor is mounted on the air cleaner box.

Resistance k

Temperature C (F)

A15475

MONITOR STRATEGY

Related DTCs Required sensors/Components R i d /C t Frequency of operation Duration MIL operation Sequence of operation Continuous Within 10 sec. Immediate None P0110 Main Sub IAT sensor circuit is open/shorted IAT sensor None

TYPICAL ENABLING CONDITIONS

The monitor will run whenever the following DTCs are not present See page In4

TYPICAL MALFUNCTION THRESHOLDS

Detection Criteria IAT sensor circuit is shorted: IAT sensor resistance (temperature of intake air) IAT sensor circuit is open: IAT sensor resistance (temperature of intake air) More than 156 k (less than 40C [40F]) Less than 98.5 (more than 140C [284F]) Threshold

Information developed by Toyota. Used with permission.

Ce-6

Ce-7

Components - Engine Inputs

COMPONENT OPERATING RANGE

Parameter IAT sensor resistance i t Standard Value Between 2.0 k and 3.0 k at 20C (68F) Between 0.3 k and 0.4 k at 80C (176F)

Information developed by Toyota. Used with permission.

Ce-7

Ce-8

Components - Engine Inputs

ECT Sensor

Engine Coolant Temperature (ECT) Sensor

MONITOR DESCRIPTION

Sensor Specification

30 20

Resistance k

10

Acceptable

The ECT sensor is used to monitor temperature of engine coolant. The ECT sensor has a thermistor that varies its resistance depending on the temperature of the engine coolant. When the temperature is low the resistance in the thermistor increases. When the temperature is high the resistance drops. The variations in resistance are reflected in the voltage output from the sensor. The ECM monitors the sensor voltage and uses this value to calculate the engine coolant temperature. If the ECM detects that the resistance of the ECT sensor is out of the normal range, the ECM interprets this as a malfunction in the ECT sensor and sets a DTC.

0.1 20 ( 4) 0 (32) 20 (68) 40 60 80 100 (104) (140) (176) (212)

Temp. C (F)

A15475

MONITOR STRATEGY

Related DTCs Required sensors/Components R i d /C t Frequency of operation Duration MIL operation Sequence of operation Continuous Within 10 sec. Immediate None P0115 Main Sub ECT sensor circuit is open/short ECT sensor None

TYPICAL ENABLING CONDITIONS

The monitor will run whenever the following DTCs are not present See page In4

TYPICAL MALFUNCTION THRESHOLDS

Detection Criteria ECT sensor resistance (temperature of engine coolant) i t (t t f i l t) Threshold Less than 79 (more than 140C [284F]) More than 156 k (less than 40C [40F])

Information developed by Toyota. Used with permission.

Ce-8

Ce-9

Components - Engine Inputs

COMPONENT OPERATING RANGE

Parameter ECT sensor resistance i t Standard Value Between 2.0 k and 3.0 k at 20C (68F) Between 0.2 k and 0.4 k at 80C (176F)

Information developed by Toyota. Used with permission.

Ce-9

Ce-10

Components - Engine Inputs

Engine Coolant Temperature (ECT) Sensor Range/Performance

MONITOR DESCRIPTION

Fig. 1 Sensor Specification

30 20

10

Acceptable

0.1 20 ( 4) 0 (32) 20 (68) 40 60 80 100 (104) (140) (176) (212)

Temperature C (F)

A15475

The ECT sensor is used to monitor temperature of engine coolant. The ECT sensor has a thermistor that varies its resistance depending on the temperature of the engine coolant. When the temperature is low the resistance in the thermistor increases. When the temperature is high the resistance drops. The variations in resistance are reflected in the voltage output from the sensor. The ECM monitors the sensor voltage and uses this value to calculate the engine coolant temperature. When the sensor output voltage is outside the normal opS erating range, the ECM interprets this as a malfunction of the ECT sensor and a DTC is set. If the ECT is too low to permit Closed Loop operation S even through enough time has elapsed for the engine to partially warm up, the ECM interprets this as a malfunction of the ECT sensor or cooling system and a DTC is set. If the ECT output does not vary even though the vehicle S is repeatedly accelerated and slowed, the ECM interprets this as a malfunction of the ECT sensor or cooling system and a DTC is set.

MONITOR STRATEGY

Related DTCs P0116 Main Required sensors/Components Frequency of operation Duration D ti Sub Once per driving cycle 250 sec. or more Within 1,200 sec. 6 driving cycles 2 driving cycles None ECT sensor malfunction Insufficient ECT for Closed Loop ECT sensor malfunction when ECT is fixed at 60C (140F) or more Others S ECT sensor malfunction S Insufficient ECT for Closed Loop ECT sensor IAT sensor, MAF sensor (or MAP sensor), Radiator fan, Thermostat and Vehicle speed sensor

Resistance k

MIL operation ti Sequence of operation

Information developed by Toyota. Used with permission.

Ce-10

Ce-11

Components - Engine Inputs

TYPICAL ENABLING CONDITION

Item It The monitor will run whenever the following DTCs are not present Specification Minimum See page In4 Maximum

Case 11: ECT sensor malfunction (ECT is fixed at less than 60C/140F) ECT at engine start IAT at engine start Vehicle speed change by 30 km/h (19 mph) or more 35C (95F) 6.7C (20F) 10 times 60C (140F)

Case 12: ECT sensor malfunction (ECT is fixed at 60C/140F or more) ECT at engine start IAT at engine start Stop and Go* condition (refer to the following chart) Steady Run and Stop* condition (refer to the following chart) Case 2: Insufficient ECT for Closed Loop Throttle valve Intake air amount Fuel cut Open (idle OFF) 0.1 g/sec. Not operating 60C (140F) 6.7C (20F) Once Once 104.4C (220F)

* Stop and Go and Steady Run and Stop condition:

Stop and Go condition

Vehicle stops for 20 sec. or more and accelerates to more than 70 km/h (43 mph) within 40 sec. Vehicle Speed km/h (mph) 70 (43)

Steady Run and Stop condition

Vehicle runs between 65 km/h (40 mph) and 70 km/h (43 mph) or more for more than 30 sec. and stops within 35 sec. Vehicle Speed km/h (mph) 70 (43) 65 (40)

3 (2) Time (sec.)

3 (2) > 20 < 40 > 30 < 35 Time (sec.)

A19563

Information developed by Toyota. Used with permission.

Ce-11

Ce-12

Components - Engine Inputs

TYPICAL MALFUNCTION THRESHOLDS

Detection Criteria Case 11: ECT sensor malfunction (ECT is fixed at less than 60C/140F) Change value of ECT Less than 3C (5.4F) Threshold

Case 12: ECT sensor malfunction (ECT is fixed at 60C/140F or more) Change value of ECT Case 2: Insufficient ECT for Closed Loop Time until ECT reaches Closed Loop temperature* (ECT at engine start 1,200 sec. is less than 6.7C/20F) Time until ECT reaches Closed Loop temperature* (ECT at engine start 300 sec. is between 6.7C/20F and 10C/50F) Time until ECT reaches Closed Loop temperature* (ECT at engine start 120 sec. is 10C/50F or more) 1C (1.8F) or less

COMPONENT OPERATING RANGE

Refer to Fig. 1.

Information developed by Toyota. Used with permission.

Ce-12

Ce-13

Components - Engine Inputs

Throttle Position Sensor Throttle Position Sensor

MONITOR DESCRIPTION

The throttle position sensor varies its resistance with the angle of the throttle valve. The ECM applies a regulated reference voltage to the throttle position sensor + terminal and calculates the angle of the throttle valve based on the voltage present at the throttle position sensor signal terminal. When the throttle valve is near the fully closed position, the output voltage of the throttle position sensor is low. When it is near the fully open position, the output voltage is high. If the ECM detects that the output voltage of the throttle position sensor is out of the normal range, the ECM interprets this as a malfunction of the throttle position sensor. The ECM illuminates the MIL and a DTC is set.

MONITOR STRATEGY

Related DTCs Required sensors/Components R i d /C t Frequency of operation Duration MIL operation Sequence of operation Continuous Within 10 sec. Immediate None P0120 Main Sub Throttle position sensor circuit is open/shorted Throttle position sensor None

TYPICAL ENABLING CONDITIONS

The monitor will run whenever the following DTCs are not present See page In4

TYPICAL MALFUNCTION THRESHOLDS

Detection Criteria Throttle Th ttl position sensor voltage iti lt Threshold Less than 0.1 V (Throttle valve open) More than 4.9 V

COMPONENT OPERATING RANGE

Parameter Throttle position sensor voltage Between 0.5 V and 4.5 V Standard Value

Information developed by Toyota. Used with permission.

Ce-13

Ce-14

Components - Engine Inputs

Throttle Position Sensor Range/Performance Problem

MONITOR DESCRIPTION

The throttle position sensor varies its resistance with the angle of the throttle valve. The ECM applies a regulated reference voltage to the throttle position sensor + terminal and calculates the angle of the throttle valve based on the voltage present at the throttle position sensor signal terminal. When the throttle valve is near the fully closed position, the output voltage of the throttle position sensor is low. When it is near the fully open position, the output voltage is high. The ECM checks the indicated angle of the throttle valve during stop and go conditions. If the indicated angle (or voltage) in the closed throttle position is out of the specified range, the ECM interprets this as a malfunction in the throttle position sensor and sets a DTC.

MONITOR STRATEGY

Related DTCs Required sensors/Components R i d /C t Frequency of operation Duration MIL operation Sequence of operation Continuous Within 10 sec. 2 driving cycles None P0121 Main Sub Throttle position sensor malfunction Throttle position sensor Idle switch

TYPICAL ENABLING CONDITIONS

Item It The monitor will run whenever the following DTCs are not present Throttle position Specification Minimum See page In4 Closed throttle position (idle switch ON) Maximum

TYPICAL MALFUNCTION THRESHOLDS

Detection Criteria Throttle Th ttl angle at closed throttle position l t l d th ttl iti 22 or more Less than 5 Threshold

COMPONENT OPERATING RANGE

Parameter Throttle angle at closed throttle position Between 7.5 and 21 Standard Value

Information developed by Toyota. Used with permission.

Ce-14

Ce-15

Components - Engine Inputs

Knock Sensor

Knock Sensor

MONITOR DESCRIPTION

The knock sensor, located on the cylinder block, detects spark knock. When spark knock occurs, the sensor picksup vibrates in a specific frequency range. When the ECM detects voltage in this frequency range, it retards the ignition timing to suppress the spark knock. The ECM also senses background engine noise with the knock sensor and uses this noise to check for faults in the sensor. If the knock sensor signal level is too low for more than 10 seconds, the ECM interprets this as a fault in the knock sensor and sets a DTC. When the flat type knock sensor is used, the ECM supplies 5 V to the knock sensor and measures this voltage to monitor if knock sensor circuit is open or shorted. If this voltage is out of the specified range, the ECM interprets this as a fault in the knock sensor and sets a DTC. Engines that flat type knock sensor equipped: 2003 1ZZFE (2WD) and 2003 2ZZGE

MONITOR STRATEGY

Related DTCs P0325 Main Sub Continuous 10 sec. 1 sec. Immediate None Knock sensor signal level is too low Knock sensor circuit is open/shorted S Knock sensor signal level is too low S Knock sensor circuit is open/shorted (Flat type knock sensor only) Knock sensor Crankshaft position sensor, ECT sensor and MAF sensor (or MAP sensor)

Required sensors/Components R i d /C t Frequency of operation Duration D ti MIL operation Sequence of operation

TYPICAL ENABLING CONDITIONS

Item It The monitor will run whenever the following DTCs are not present Case 1: Knock sensor signal level is too low Battery voltage ECT Engine RPM (4AFE and 7AFE engine) Engine RPM (1ZZFE and 2ZZGE engine) Throttle valve Intake air amount Time after engine start 10 V 60C (140F) 1,600 2,000 Open (Idle switch OFF) 0.3 g/rev. 5 sec. 5,500 Specification Minimum See page In4 Maximum

Case 2: Knock sensor circuit is open/shorted (Knock sensor voltage is low/high) Battery voltage Time after engine start 10.5 V 5 sec.

Information developed by Toyota. Used with permission.

Ce-15

Ce-16

Components - Engine Inputs

TYPICAL MALFUNCTION THRESHOLDS

Detection Criteria Case 1: Knock sensor signal level is too low Knock sensor signal Case 2: Knock sensor circuit is open/shorted Knock sensor voltage K k lt Less than 0.5 V More than 4.5 V Signal level is too low Threshold

Information developed by Toyota. Used with permission.

Ce-16

Ce-17

Components - Engine Inputs

Camshaft Position Sensor

Camshaft Position Sensor

MONITOR DESCRIPTION

The camshaft position sensor consists of a magnet, an iron core and a pickup coil. This sensor monitors a timing rotor located on the camshaft and is used by the engine control module (ECM) to detect the camshaft angle. The camshaft rotation synchronizes with the crankshaft rotation, and this sensor communicates the rotation of the camshaft timing rotor as a pulse signal to the ECM. Based on the signal, the ECM controls fuel injection time and ignition timing. If there is no signal from the camshaft position sensor even though the engine is turning or the rotation of the camshaft and the crankshaft is not synchronized, the ECM interprets this as a malfunction in the sensor and sets a DTC.

MONITOR STRATEGY

Related DTCs P0340 Main Sub Continuous Within 10 sec. 2 driving cycles MIL operation Immediate None No camshaft position signal when starter operates S No camshaft position signal S Camshaft and crankshaft position signal misalignment S Camshaft signal is abnormal S No camshaft position signal S Camshaft and crankshaft position signal misalignment S Camshaft signal is abnormal Camshaft position sensor Crankshaft position sensor

Required sensors/Components R i d /C t Frequency of operation Duration

Sequence of operation

TYPICAL ENABLING CONDITIONS

The monitor will run whenever the following DTCs are not present See page In4

TYPICAL MALFUNCTION THRESHOLDS

Detection Criteria Case 1: No camshaft position signal Camshaft position signal when starter operates Camshaft position signal when engine RPM is 600 rpm or more Case 2: Camshaft and crankshaft position signal misalignment Camshaft and crankshaft position signal alignment Case 3: Camshaft signal is abnormal Camshaft position signal per 2 revolutions crankshaft 12 or more signals Misaligned No signal No signal Threshold

Information developed by Toyota. Used with permission.

Ce-17

Ce-18

Components - Engine Inputs

COMPONENT OPERATING RANGE

Parameter Camshaft position sensor signal Standard Value S Crankshaft position sensor voltage fluctuates when intake camshaft rotates S 3 signals per 2 revolutions crankshaft

Information developed by Toyota. Used with permission.

Ce-18

Ce-19

Components - Engine Inputs

Crankshaft Position Sensor

Crankshaft Position Sensor

MONITOR DESCRIPTION

The ECM detects engine RPM with the crankshaft position sensor. The crankshaft position sensor consists of a magnet and a pickup coil. Also, a plate with teeth is installed in the crankshaft. Whenever the teeth on the revolving crankshaft pass the magnet in the crankshaft position sensor, a voltage is generated in the pickup coil. The crankshaft position sensor detects the number of revolutions of the crankshaft based on the voltage generated in the pickup coil and then transmits a signal to the ECM. If there is no signal from the crankshaft position sensor even though the engine turning, the ECM interprets this as a malfunction in the sensor and sets a DTC.

MONITOR STRATEGY

Related DTCs Required sensors/Components R i d /C t Frequency of operation Duration MIL operation Sequence of operation Continuous 4.7 sec. 2 driving cycles None P0335 Main Sub No crankshaft position signal Crankshaft position sensor Camshaft position sensor

TYPICAL ENABLING CONDITIONS

The monitor will run whenever the following DTCs are not present Included in the Typical Malfunction Thresholds See page In4

TYPICAL MALFUNCTION THRESHOLDS

Detection Criteria Crankshaft position signal Threshold No signal for 4.7 sec. or more No signal for 0.5 sec. or more Typical Enabling Condition Starter operating S Engine RPM is 600 rpm or more S 3 sec. or more after starter switched to OFF

COMPONENT OPERATING RANGE

Parameter Crankshaft position signal Standard Value S Crankshaft position sensor voltage fluctuates when engine rotates S 34 signals per 1 revolution crankshaft

Information developed by Toyota. Used with permission.

Ce-19

Ce-20

Components - Engine Inputs

Vehicle Speed Sensor

Vehicle Speed Sensor

MONITOR DESCRIPTION

The engine control module (ECM) detects vehicle speeds as pulse signals using a vehicle speed sensor. There are 2 detection methods and the signal travels to the ECM differently depending on the vehicle model. (a) A vehicle speed sensor built into each wheel detects vehicle speed signals (pulse signals). These signals are sent to the ECM via the skid control ECU and the combination meter. (b) The transmission output shaft speed (NC) sensor built into the transmission detects vehicle speed signals (pulse signals). These signals are sent to the ECM via the combination meter. If the ECM does not detect any vehicle speed signals while vehicle is being driven, the ECM interprets it as a malfunction in the vehicle speed sensor circuit and set a DTC.

MONITOR STRATEGY

Related DTCs Required sensors/Components Frequency of operation Duration MIL operation Sequence of operation Continuous Within 10 sec. 2 driving cycles None P0500 Main Sub Vehicle speed sensor circuit malfunction Vehicle speed sensor (or NC sensor), Skid control ECU and Combination meter Crankshaft position sensor, MAF sensor (or MAP sensor), PNP switch

TYPICAL ENABLING CONDITIONS

Item The monitor will run whenever the following DTCs are not present See page In4 S M/T models: Determined by the volume of intake air and engine RPM after the engine warmed up S A/T models: Determined by the throttle angle, PNP switch, engine RPM Specification

Vehicle running

TYPICAL MALFUNCTION THRESHOLDS

Detection Criteria Vehicle speed sensor signal while vehicle is underway: No signal Threshold

Information developed by Toyota. Used with permission.

Ce-20

Ce-21

Components - Engine Inputs

ECM

Power Supply for ECM

MONITOR DESCRIPTION

The battery supplies electricity to the engine control module (ECM) even when the ignition switch is OFF. This electricity allows the ECM store data such as DTC history, freezeframe data, fuel trim values, and other data. If the battery voltage falls below a minimum level, the ECM will conclude that there is a fault in the power supply circuit. At the next engine start, the ECM will turn on the MIL and a DTC will be set.

MONITOR STRATEGY

Related DTCs Required sensors/Components R i d /C t Frequency of operation Duration MIL operation Sequence of operation Continuous 3 sec. Immediate None P1600 Main Sub Battery voltage to ECM is low ECM None

TYPICAL ENABLING CONDITIONS

The monitor will run whenever the following DTCs are not present See page In4

TYPICAL MALFUNCTION THRESHOLDS

Detection Criteria Battery voltage to ECM Less than 3.5 V Threshold

Information developed by Toyota. Used with permission.

Ce-21

Das könnte Ihnen auch gefallen

- ECM Input OutputDokument17 SeitenECM Input OutputFlorin BodroghinăNoch keine Bewertungen

- Tccs Toyota Computer Controlled SystemDokument5 SeitenTccs Toyota Computer Controlled SystemĐức HòangNoch keine Bewertungen

- Navara qr25deBCSDokument20 SeitenNavara qr25deBCSAhmedNoch keine Bewertungen

- AE101 4AGE 20 Valve Pins 2019Dokument5 SeitenAE101 4AGE 20 Valve Pins 2019jorgeNoch keine Bewertungen

- Toyota Celica GT4 ST165 ECU Pin Out and Wiring DiagramDokument3 SeitenToyota Celica GT4 ST165 ECU Pin Out and Wiring DiagramSirleh SalehNoch keine Bewertungen

- 1Nz-Fe Engine Mechanical: Service DataDokument3 Seiten1Nz-Fe Engine Mechanical: Service Dataalbert phiriNoch keine Bewertungen

- Electrochemi Toyota Land Cruiser Prado 2004 DemoDokument15 SeitenElectrochemi Toyota Land Cruiser Prado 2004 DemoVinsensius Agus Priyono100% (1)

- d2fee44ce3373b7c092a008235dbd2f5Dokument153 Seitend2fee44ce3373b7c092a008235dbd2f5Ovvc100% (2)

- Toyota Training - FUEL SYSTEM DIAGNOSIS (L-TR-QL-811A-D)Dokument12 SeitenToyota Training - FUEL SYSTEM DIAGNOSIS (L-TR-QL-811A-D)John BacsikNoch keine Bewertungen

- DTC Check ClearDokument2 SeitenDTC Check ClearDaniel Mamani ParedezNoch keine Bewertungen

- Toyota OBD CodesDokument2 SeitenToyota OBD Codesnanorutamilan100% (1)

- Ignition PDFDokument16 SeitenIgnition PDFDoDuyBacNoch keine Bewertungen

- Ignition PDFDokument17 SeitenIgnition PDFtavi2meNoch keine Bewertungen

- 10-6620 For EMS - 30-6620Dokument14 Seiten10-6620 For EMS - 30-6620Michael AliNoch keine Bewertungen

- 4afe O2sensor TestDokument3 Seiten4afe O2sensor Testkkg4782Noch keine Bewertungen

- Technical Service Bulletin: - DescriptionDokument4 SeitenTechnical Service Bulletin: - Description08088338Noch keine Bewertungen

- 1mz Ecu Wiring DiagramDokument7 Seiten1mz Ecu Wiring Diagram12volt bayNoch keine Bewertungen

- Immob Overview All Models 2005Dokument30 SeitenImmob Overview All Models 2005BYU OTOVLOGNoch keine Bewertungen

- DTC P0130 Oxygen Sensor Circuit Malfunction (Bank 1 Sensor 1)Dokument4 SeitenDTC P0130 Oxygen Sensor Circuit Malfunction (Bank 1 Sensor 1)williamNoch keine Bewertungen

- 1nz-Fe and 2nz-Fe EnginesDokument18 Seiten1nz-Fe and 2nz-Fe EnginesJose Manuel Reyna LlamacuriNoch keine Bewertungen

- 2AZ-FE ToyotaDokument11 Seiten2AZ-FE ToyotaCesar50% (2)

- MITSUBISHI - WiringDiagram - 4M50 (2005 - 2007)Dokument11 SeitenMITSUBISHI - WiringDiagram - 4M50 (2005 - 2007)indecar764100% (1)

- Toyota Rav4 Ecu Recall Euc Problem PDFDokument4 SeitenToyota Rav4 Ecu Recall Euc Problem PDFرشيد الحربيNoch keine Bewertungen

- 2az-Fe Engine Control System Sfi SystemDokument6 Seiten2az-Fe Engine Control System Sfi SystemMarcelo DecimaNoch keine Bewertungen

- Alarm System AlphardDokument10 SeitenAlarm System AlphardAiman HafidzNoch keine Bewertungen

- ABS (Anti-Lock Brake System)Dokument34 SeitenABS (Anti-Lock Brake System)LiviaChirtopNoch keine Bewertungen

- Automatic Transmission PDFDokument334 SeitenAutomatic Transmission PDFAriel MercochaNoch keine Bewertungen

- Ta1248 PDFDokument38 SeitenTa1248 PDFbad_boyz1989Noch keine Bewertungen

- EWD of Zace DR077W (VN)Dokument41 SeitenEWD of Zace DR077W (VN)Binh Binh100% (1)

- List of Automotive AbbreviationsDokument5 SeitenList of Automotive Abbreviationsiman1tt100% (1)

- Starting & ChargingDokument33 SeitenStarting & ChargingMusat Catalin-Marian100% (1)

- 3S-GE Codes ListDokument6 Seiten3S-GE Codes ListGiancarlo CostantiniNoch keine Bewertungen

- w58 RebuildDokument49 Seitenw58 RebuildtfphoenixNoch keine Bewertungen

- Ecs 1azfseDokument1 SeiteEcs 1azfseanon_894803981Noch keine Bewertungen

- Toyota Altezza Ecu Side Terminal (TP5-7Base) Refer The Following For Special Setting When Modifying The Wiring, EtcDokument9 SeitenToyota Altezza Ecu Side Terminal (TP5-7Base) Refer The Following For Special Setting When Modifying The Wiring, EtcAlifNoch keine Bewertungen

- Mazda 5 EngineDokument143 SeitenMazda 5 EngineAngel CastNoch keine Bewertungen

- DTC P1128 Throttle Control Motor Lock Malfunction: Circuit DescriptionDokument1 SeiteDTC P1128 Throttle Control Motor Lock Malfunction: Circuit DescriptionWillian Jane100% (1)

- Body Electrical Echo/yaris 2002Dokument117 SeitenBody Electrical Echo/yaris 2002Tomas Dominguez100% (1)

- 1az-Fse Avensis PDFDokument5 Seiten1az-Fse Avensis PDFfrank mutaleNoch keine Bewertungen

- A32 at PDFDokument293 SeitenA32 at PDFOmar RodriguezNoch keine Bewertungen

- Identification: Avalon (1999), Camry 3.0L, Camry Solara 3.0L & SiennaDokument54 SeitenIdentification: Avalon (1999), Camry 3.0L, Camry Solara 3.0L & SiennaJuan Carlos Martinez NuñezNoch keine Bewertungen

- '90-'92 70-Series Wiring ManualDokument82 Seiten'90-'92 70-Series Wiring ManuallukasNoch keine Bewertungen

- Sequential Fuel Injection SystemDokument66 SeitenSequential Fuel Injection SystemCậu TúNoch keine Bewertungen

- 4 AfeDokument36 Seiten4 AfeJuan ContrerasNoch keine Bewertungen

- Terminals of Ecm: E17 E16 E15 E14Dokument5 SeitenTerminals of Ecm: E17 E16 E15 E14Martin ChilbetNoch keine Bewertungen

- 031 - Engine - Igniter Circuit Malfunction (No. 1)Dokument6 Seiten031 - Engine - Igniter Circuit Malfunction (No. 1)Ayun AhmNoch keine Bewertungen

- 1kr Fe ChargingDokument92 Seiten1kr Fe Chargingfguij33% (3)

- AEM Undocumented Settings v1Dokument13 SeitenAEM Undocumented Settings v1Franklyn RamirezNoch keine Bewertungen

- Biante SKYACTIV: Dimension & Weight Seating & TrimDokument4 SeitenBiante SKYACTIV: Dimension & Weight Seating & Trimyusransyah100% (1)

- A32 EcDokument476 SeitenA32 EcLevin Tan Ht100% (1)

- LACETTI Engine (71-100) - 1.8DDokument30 SeitenLACETTI Engine (71-100) - 1.8DDangLuyenNoch keine Bewertungen

- Electronically Controlled Transmission Communication CircuitDokument3 SeitenElectronically Controlled Transmission Communication CircuitErln Lima100% (1)

- Toyota 4a Fe Engine Reference PDFDokument57 SeitenToyota 4a Fe Engine Reference PDFeviton luisNoch keine Bewertungen

- 1 ZzfeDokument8 Seiten1 ZzfeScuderia Redin100% (1)

- This Tutorial Will Help To Test The Throttle Position Sensor On Your 1989 To 1997 1Dokument7 SeitenThis Tutorial Will Help To Test The Throttle Position Sensor On Your 1989 To 1997 1HERBERT SITORUS100% (1)

- Vehicle Sensors WiringDokument8 SeitenVehicle Sensors WiringAudrick RussellNoch keine Bewertungen

- E Theory OperationDokument7 SeitenE Theory Operationdguruge8Noch keine Bewertungen

- E C M InputsDokument12 SeitenE C M InputsMario RaafatNoch keine Bewertungen

- 15 Diagnóstico de Componentes IntegralesDokument18 Seiten15 Diagnóstico de Componentes IntegralesmongongoNoch keine Bewertungen

- Group 9 Self-Diagnostic System: OutlineDokument8 SeitenGroup 9 Self-Diagnostic System: OutlineDenNoch keine Bewertungen

- Ford Ranger XLT Fault CodesDokument6 SeitenFord Ranger XLT Fault CodesDavisson9Noch keine Bewertungen

- CAV DPA Pump Rebuild ManualDokument21 SeitenCAV DPA Pump Rebuild ManualHERMAWAN97% (32)

- TCM F Series Service Manual PDFDokument145 SeitenTCM F Series Service Manual PDFAmc Forklift Elektrik100% (7)

- Engine Control Unit (ECU) Circuit Theory of OperationDokument2 SeitenEngine Control Unit (ECU) Circuit Theory of OperationPepe AlNoch keine Bewertungen

- 8Dokument33 Seiten8brunosamaeianNoch keine Bewertungen

- Asitosh 23 Final SeminarDokument18 SeitenAsitosh 23 Final Seminarmech mech1Noch keine Bewertungen

- Realistic Airplane Manual by Inkompetent (2018!05!30)Dokument93 SeitenRealistic Airplane Manual by Inkompetent (2018!05!30)Paul Vortex0% (1)

- Subaru Eh Engines Eh36 Eh41 PartsDokument28 SeitenSubaru Eh Engines Eh36 Eh41 PartsMutu DanielNoch keine Bewertungen

- 3784A KXX K4J K4M Clio Motor ManualDokument32 Seiten3784A KXX K4J K4M Clio Motor ManualDavid NebainNoch keine Bewertungen

- Manual Yamaha Outboard Diagnostics (YDIS-Ver2.00)Dokument247 SeitenManual Yamaha Outboard Diagnostics (YDIS-Ver2.00)evangalos92% (13)

- Pinout de La Ecu Del Kia Picanto 2015Dokument7 SeitenPinout de La Ecu Del Kia Picanto 2015Eitan VAN Muller100% (2)

- HybridDokument157 SeitenHybridKusworo Muh100% (3)

- Arburetors: Arburetor Eference AnualDokument60 SeitenArburetors: Arburetor Eference AnualmichaelNoch keine Bewertungen

- 120K ElectricoDokument17 Seiten120K ElectricoMbahdiro Kolenx100% (5)

- 2 SH130-5 Electric Ver Eng (Revised) PDFDokument81 Seiten2 SH130-5 Electric Ver Eng (Revised) PDFFirman andika80% (5)

- Automotive - GM SuperchargerManualDokument15 SeitenAutomotive - GM SuperchargerManualazrim02Noch keine Bewertungen

- Victa Lawnmower Assembly and Owner's Manual: Assembly - Operating K6 Final - QXD 8/12/04 1:33 PM Page 1Dokument28 SeitenVicta Lawnmower Assembly and Owner's Manual: Assembly - Operating K6 Final - QXD 8/12/04 1:33 PM Page 1johnNoch keine Bewertungen

- Cat C18 ACERT Spec Sheets - Commercial PDFDokument28 SeitenCat C18 ACERT Spec Sheets - Commercial PDFpom technical100% (2)

- C20 25 30 33 35L PDFDokument374 SeitenC20 25 30 33 35L PDFVanessa RodriguesNoch keine Bewertungen

- مقترح الميزانية والاحتياجاتDokument16 Seitenمقترح الميزانية والاحتياجاتMohamed SameerNoch keine Bewertungen

- EMISSION CONTROL SYSTEM (2AZ FE) CamryDokument30 SeitenEMISSION CONTROL SYSTEM (2AZ FE) CamryRahmat HidayatNoch keine Bewertungen

- 912E EFI ManualDokument28 Seiten912E EFI Manualelimeir80Noch keine Bewertungen

- X500 - 250 Cap 01 (Info Generali) PDFDokument44 SeitenX500 - 250 Cap 01 (Info Generali) PDFKosta DragicevicNoch keine Bewertungen

- APC200 ECM-ECI VFS Booster Error Codes Ver3 3Dokument17 SeitenAPC200 ECM-ECI VFS Booster Error Codes Ver3 3SioneNoch keine Bewertungen

- Trouble Shooting EngineDokument188 SeitenTrouble Shooting EngineDedy setiawanNoch keine Bewertungen

- 6P2 28197 3H 11 PDFDokument377 Seiten6P2 28197 3H 11 PDFAlex Vdbussche100% (2)

- 1994 Suzuki Sidekick 1.6L TBI Code DiagnoseDokument25 Seiten1994 Suzuki Sidekick 1.6L TBI Code DiagnoseRedVitara100% (1)

- Carburetor and Fuel Injection SystemDokument33 SeitenCarburetor and Fuel Injection SystemPrabesh PoudelNoch keine Bewertungen