Beruflich Dokumente

Kultur Dokumente

Materials Guide

Hochgeladen von

ggudayakumarOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Materials Guide

Hochgeladen von

ggudayakumarCopyright:

Verfügbare Formate

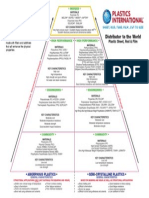

material selection guide

THERMOPLASTICS TRIANGLE

AMORPHOUS HIGH PERFORMANCE MATERIALS

High Service Temperatures High Strength Hot Water and Steam Resistance Thermoformability Structural

HIGH STRENGTH HIGH TEMPERATURE HIGH COST

IMIDIZED MATERIALS

Best Physical Properties Above 400F Best Temperature Resistance High Temperature, High Load Bearing and Wearing Capabilities Good Chemical Resistance Maintains Strength and Sti ness

I MA MIDIZE TER D IAL S

F 5ap0ro0imately p x

VESPEL TECATOR

H ENG IGH P INE ERF ERI ORM NG PLA ANCE STIC S

RADEL R ULTEM POLYSULFONE

PEEK PPS PTFE PVDF (KYNAR)

SEMI-CRYSTALLINE HIGH PERFORMANCE MATERIALS

High Service Temperature Excellent Chemical Resistance High Purity

P. TEM ES RIS

F 3p0ro0imately x ap

INE PLA ERING STIC S

AMORPHOUS ENGINEERING PLASTICS

General Purpose Structural Parts Moderate Strength Moderate Temperature Good Dimensional Stability Good Izod Impact Easily Fabricated Low Temperature Low Strength Good Bondability Good Machinabilty Good Formability Low Cost

POLYCARBONATE NORYL PPO

ENG

PET PBT NYLON ACETAL

SEMI-CRYSTALLINE ENGINEERING PLASTICS

General Purpose Bearing and Wear or Structural Parts Moderate Strength and Sti ness Good Chemical Resistance Moderate Temperature

P. 20oximat TEM ES appr RIS

0Fely

COM M PLA ODITY STIC S

AMORPHOUS COMMODITY PLASTICS

POLYSTYRENE NORYL PPO

POLYPROPYLENE POLYETHYLENE (HDPE, LDPE, UHMW-PE)

SEMI-CRYSTALLINE COMMODITY PLASTICS

Low Temperature Low Strength Good Chemical Resistance Low Moisture Absorbtion Low Cost

GENERAL CHARACTERISTICS

Softens Over a Wide Temperature Range Good Formability Transparent Poor Chemical Resistance Bonds Well Using Adhesives or Solvents Prone to Stress Cracking Poor Fatigue Resistance Structural Applications Only

(not suitable for bearing and wear)

AMORPHOUS PLASTICS

Sharp Melting Point Poor Formability Opaque Good Chemical Resistance Di cult to Bond Using Adhesives or Solvents Resistant to Stress Cracking Good Fatigue Resistance Good for Bearing and Wear

(as well as structural applications)

SEMI-CRYSTALLINE PLASTICS

materials

POLYAMIDE-IMIDE POLYIMIDE

P. 1 0 0imately TEM ES approx RIS

GENERAL CHARACTERISTICS

(Continuously Processed)

POLYCARBONATE

POLYSULFONE

POLYSTYRENE

KYDEX 100

VESPEL SP-211

POLYIMIDE

(Canvas Phenolic)

(Semicrystalline)

VESPEL SP-21

POLYIMIDE

(Homopolymer)

POLYIMIDE

VESPEL SP-22

POLYIMIDE

(Modi ed PPO)

RADEL R

(Paper Phenolic)

(Linen Phenolic)

(Homopolymer)

VESPEL SP-1

UHMW-PE

VESPEL SP-3

(High Impact)

AMORPHOUS THERMOPLASTICS

SEMICRYSTALLINE THERMOPLASTICS

IMIDIZED MATERIALS

THERMOSET COMPOSITES

demanding applications require demanding materials

(Glass Silicone)

(6/6 Extruded)

ACRYLIC

ULTEM

(Glass Epoxy)

NORYL

(Copolymer)

(Copolymer)

ACETAL

ACETAL

LDPE NYLON

NYLON

PETG

HDPE

(6 Cast)

PVDF

(Rigid)

PEEK PET

ABS

PVC

FR-4

PTFE

PBT

PPS

PP

PP

G7

XX

CE

LE

Das könnte Ihnen auch gefallen

- Amorphous and Semi-Crystalline Engineering Thermoplastics: Materials, Properties and ApplicationsDokument30 SeitenAmorphous and Semi-Crystalline Engineering Thermoplastics: Materials, Properties and Applicationsjesus MaldonadoNoch keine Bewertungen

- Ens TecDokument28 SeitenEns TecBorja CanalsNoch keine Bewertungen

- UNIT-IV-Non MetallicDokument112 SeitenUNIT-IV-Non MetallicSethu ramNoch keine Bewertungen

- Chemical Compatibility Table DebemDokument49 SeitenChemical Compatibility Table DebemTrung Thật LêNoch keine Bewertungen

- Matrices: Dr. J. Ramkumar Professor Dept of Mechanical & Design Program IIT Kanpur, IndiaDokument27 SeitenMatrices: Dr. J. Ramkumar Professor Dept of Mechanical & Design Program IIT Kanpur, IndiaMahesh RajaNoch keine Bewertungen

- Universal Techno Piping Corporation: BY: Amina L. MubarikDokument26 SeitenUniversal Techno Piping Corporation: BY: Amina L. MubarikengrsyotiNoch keine Bewertungen

- Amorphous and Semi-Crystalline PlasticsDokument29 SeitenAmorphous and Semi-Crystalline PlasticsFranzMigNoch keine Bewertungen

- Plastics Material For DPT Iv SemDokument49 SeitenPlastics Material For DPT Iv SemMohsin Alam100% (2)

- Polymers in Civil EngineeringDokument33 SeitenPolymers in Civil EngineeringMayank MishraNoch keine Bewertungen

- Coal Tar Epoxy 4: DescriptionDokument2 SeitenCoal Tar Epoxy 4: DescriptionAbhisheK MishrANoch keine Bewertungen

- Thermoplastics Selection GuideDokument1 SeiteThermoplastics Selection GuidelokomundoNoch keine Bewertungen

- Materials For Automobiles Lec 17: Plastics Adhesives Material CostsDokument50 SeitenMaterials For Automobiles Lec 17: Plastics Adhesives Material CostsFaber AndreiNoch keine Bewertungen

- Technical Yarns: Nahida Akter Ela Assistant Professor, AUSTDokument30 SeitenTechnical Yarns: Nahida Akter Ela Assistant Professor, AUSTimranNoch keine Bewertungen

- ClwydDokument32 SeitenClwydmaNoch keine Bewertungen

- R HPP Chemical Processing EN PDFDokument36 SeitenR HPP Chemical Processing EN PDFKumar SaravanaNoch keine Bewertungen

- 2 Engineering Plastics - PPTDokument28 Seiten2 Engineering Plastics - PPTApoorva MNNoch keine Bewertungen

- Thermoplastics: by Kenneth Chaw (A13KM0053)Dokument7 SeitenThermoplastics: by Kenneth Chaw (A13KM0053)Kenneth ChawNoch keine Bewertungen

- Commodity ThermoplasticsDokument55 SeitenCommodity ThermoplasticsBernard GanzwaNoch keine Bewertungen

- Matrices: Dr. J. Ramkumar Professor Dept of Mechanical & Design Program IIT Kanpur, IndiaDokument27 SeitenMatrices: Dr. J. Ramkumar Professor Dept of Mechanical & Design Program IIT Kanpur, Indiadavid josephNoch keine Bewertungen

- Polymer MemsDokument21 SeitenPolymer Memsbaks007Noch keine Bewertungen

- CORROSION PROTECTION Rubber Lining and Coating SystemsDokument16 SeitenCORROSION PROTECTION Rubber Lining and Coating SystemsAnonymous YzSzB0rpNKNoch keine Bewertungen

- Polyacetal Copolymer POM-C Engineering ThermoplasticsDokument9 SeitenPolyacetal Copolymer POM-C Engineering Thermoplasticshudi_leksonoNoch keine Bewertungen

- Week-10 PolymersDokument40 SeitenWeek-10 PolymersMoey RenNoch keine Bewertungen

- Technological Institute of The Philippines: 363 P. Casal, Quiapo, ManilaDokument6 SeitenTechnological Institute of The Philippines: 363 P. Casal, Quiapo, ManilaMichelle MendozaNoch keine Bewertungen

- Polyplastics General Plastics InfoDokument56 SeitenPolyplastics General Plastics InfoSARAI MARINNoch keine Bewertungen

- Specifying Concrete Floor Coatings and Treatments ProceduresDokument49 SeitenSpecifying Concrete Floor Coatings and Treatments Proceduresmuhamadrafie1975100% (1)

- HDPEDokument13 SeitenHDPETos ArchitectureNoch keine Bewertungen

- POLYMERSDokument17 SeitenPOLYMERSNur Nabila HudaNoch keine Bewertungen

- Vistalon Bimodal Rubber - Nov 18th 2010Dokument24 SeitenVistalon Bimodal Rubber - Nov 18th 2010Aryan ShahNoch keine Bewertungen

- Thermoplastics: Submitted By:)Dokument15 SeitenThermoplastics: Submitted By:)Nikhil SharmaNoch keine Bewertungen

- Polymer in Civil EngineeringDokument33 SeitenPolymer in Civil Engineeringlimbong budimanNoch keine Bewertungen

- Polymers Ref DEC 24Dokument40 SeitenPolymers Ref DEC 24Gowtham Kae KaeNoch keine Bewertungen

- Elastomers For Energy, Oil & Gas SealingDokument2 SeitenElastomers For Energy, Oil & Gas SealingDanialNoch keine Bewertungen

- Tarea 2Dokument2 SeitenTarea 2Eirick Wayne Zuñigga De-ItzelNoch keine Bewertungen

- 12 PAPYEX Flexible Graphite Mersen - 09 PDFDokument14 Seiten12 PAPYEX Flexible Graphite Mersen - 09 PDFarizagameroNoch keine Bewertungen

- Hyperdesmo 815Dokument5 SeitenHyperdesmo 815Roger DaoudNoch keine Bewertungen

- Presentation 2Dokument63 SeitenPresentation 2Karma TsheringNoch keine Bewertungen

- PEXa, PEXb, PERT - Advantages - ProcessDokument2 SeitenPEXa, PEXb, PERT - Advantages - ProcessMidhun Mohan MNoch keine Bewertungen

- Allseals Web LowDokument6 SeitenAllseals Web LowjmartinezmoNoch keine Bewertungen

- Polymers in Civil EngineeringDokument34 SeitenPolymers in Civil EngineeringSiriluck NevestNoch keine Bewertungen

- Plastic Material SelectionDokument7 SeitenPlastic Material Selectionkbasher_psgim100% (1)

- Tds-Cpd-Sikalastic 601 BC-usDokument5 SeitenTds-Cpd-Sikalastic 601 BC-usgamini pereraNoch keine Bewertungen

- TDS - Concresive ERLDokument2 SeitenTDS - Concresive ERLVenkata RaoNoch keine Bewertungen

- PPO SlideDokument29 SeitenPPO SlideRadhashyam GiriNoch keine Bewertungen

- Materials - Viton, Nitrile, Silicone, Polyurethane, EPDM, Fluorosilicone, Teflon, PTFE Filled, PEEK, Nylon, AcetalDokument14 SeitenMaterials - Viton, Nitrile, Silicone, Polyurethane, EPDM, Fluorosilicone, Teflon, PTFE Filled, PEEK, Nylon, Acetalpankaj_pawar89Noch keine Bewertungen

- CE336 12 Polymer CompositesDokument34 SeitenCE336 12 Polymer CompositesAmit karNoch keine Bewertungen

- Filtros de Mangas para DespoeiramentoDokument3 SeitenFiltros de Mangas para DespoeiramentoEder PereiraNoch keine Bewertungen

- High Performance Polymers: Unit 1Dokument57 SeitenHigh Performance Polymers: Unit 1AdityaNoch keine Bewertungen

- Epoxy Coating Comparison ChartDokument2 SeitenEpoxy Coating Comparison Chartrezafarbod1Noch keine Bewertungen

- Advanced Technology in Field Applied Thermoplastics For Corrosion Protection Superior To Thermoset Coating SystemsDokument6 SeitenAdvanced Technology in Field Applied Thermoplastics For Corrosion Protection Superior To Thermoset Coating SystemsIan HsuNoch keine Bewertungen

- High Performance Plastics Materials Guide: Craftech Industries'Dokument20 SeitenHigh Performance Plastics Materials Guide: Craftech Industries'akirloskarNoch keine Bewertungen

- El Hyperdesmo-ClassicDokument4 SeitenEl Hyperdesmo-ClassicΙοαννης ΡενκοNoch keine Bewertungen

- 01 PlasticsDokument17 Seiten01 PlasticsVenkatesh BNoch keine Bewertungen

- CompositeDokument78 SeitenCompositefethi.sahiner72Noch keine Bewertungen

- Property Test Method Units Polypropylene CopolymerDokument1 SeiteProperty Test Method Units Polypropylene Copolymerमनोज चौधरीNoch keine Bewertungen

- Impregnating Resins and Varnishes Edition 2013 PDFDokument8 SeitenImpregnating Resins and Varnishes Edition 2013 PDFshambhoiNoch keine Bewertungen

- Plastic Engineering Properties: Abrasion ResistanceDokument3 SeitenPlastic Engineering Properties: Abrasion ResistanceLesterLanosMagbutongNoch keine Bewertungen

- Hostaform® POM Processing: Automotive IndustryDokument1 SeiteHostaform® POM Processing: Automotive Industrylavius_mNoch keine Bewertungen

- Thermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesVon EverandThermal Insulation Handbook for the Oil, Gas, and Petrochemical IndustriesBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsVon EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsBewertung: 5 von 5 Sternen5/5 (1)

- Handbook of Deposition Technologies For Films and CoatingsDokument885 SeitenHandbook of Deposition Technologies For Films and CoatingsTânia Frade CostaNoch keine Bewertungen

- 2011 PVOH 1100 PVOH For Specialty Coatings PDFDokument2 Seiten2011 PVOH 1100 PVOH For Specialty Coatings PDFggudayakumarNoch keine Bewertungen

- Crosslinker CX-100 Pds PDFDokument2 SeitenCrosslinker CX-100 Pds PDFggudayakumarNoch keine Bewertungen

- PVOH Coating PDFDokument14 SeitenPVOH Coating PDFggudayakumarNoch keine Bewertungen

- 2011 PVOH 1100 PVOH For Specialty Coatings PDFDokument2 Seiten2011 PVOH 1100 PVOH For Specialty Coatings PDFggudayakumarNoch keine Bewertungen

- Flexible Packaging: Changing Dynamics of Indian Packaging MarketDokument24 SeitenFlexible Packaging: Changing Dynamics of Indian Packaging Marketggudayakumar100% (1)

- Pattinathar PaadalgalDokument25 SeitenPattinathar Paadalgalapi-3715058100% (4)

- From Polymers To Plastics Van Der Vegt Ak VSSD 2002Dokument240 SeitenFrom Polymers To Plastics Van Der Vegt Ak VSSD 2002ggudayakumar100% (1)

- Aramid Fiber: Monabbir Rafsan Fahim Textile Engineering Management, ButexDokument10 SeitenAramid Fiber: Monabbir Rafsan Fahim Textile Engineering Management, ButexRafsan FahimNoch keine Bewertungen

- Technical Data Sheet TECHSTRAP 2020Dokument1 SeiteTechnical Data Sheet TECHSTRAP 2020BalrajNoch keine Bewertungen

- The Automotive Chassis - Engineering PrinciplesDokument50 SeitenThe Automotive Chassis - Engineering PrinciplesSimplice KengneNoch keine Bewertungen

- Bulk Fabric Consumption: Garmentspart Wise Booking SummaryDokument1 SeiteBulk Fabric Consumption: Garmentspart Wise Booking SummaryPallab MandalNoch keine Bewertungen

- Thermoplastic Composites - Best Practice GuideDokument49 SeitenThermoplastic Composites - Best Practice GuidemanikandapriyaNoch keine Bewertungen

- 13 High Performance Plastics Used in The Automotive IndustryDokument4 Seiten13 High Performance Plastics Used in The Automotive IndustryBhushanNoch keine Bewertungen

- Aircraft Composite Materials - Lecture 03Dokument80 SeitenAircraft Composite Materials - Lecture 03Kaushika Rajapaksha PereraNoch keine Bewertungen

- Plastic Identification CodeDokument1 SeitePlastic Identification Codeapi-241592033Noch keine Bewertungen

- Polymers PostDokument42 SeitenPolymers Postapi-3767370Noch keine Bewertungen

- Final Exam 2010 SolnDokument7 SeitenFinal Exam 2010 SolnSimon AlmeidaNoch keine Bewertungen

- 2 0096 Table 5parts Diagram PGo 16 - 9Dokument8 Seiten2 0096 Table 5parts Diagram PGo 16 - 9Yahya Happy MandalaNoch keine Bewertungen

- Polymers Ref DEC 24Dokument40 SeitenPolymers Ref DEC 24Gowtham Kae KaeNoch keine Bewertungen

- Mil HDBK 793 PDFDokument50 SeitenMil HDBK 793 PDFАндрей ПятыгинNoch keine Bewertungen

- Characteristics, Applications & Processing of Polymers: Issues To Address..Dokument28 SeitenCharacteristics, Applications & Processing of Polymers: Issues To Address..Yudiman HidayatNoch keine Bewertungen

- Plastic - Wikipedia, The Free EncyclopediaDokument6 SeitenPlastic - Wikipedia, The Free Encyclopediadidodido_67Noch keine Bewertungen

- PPS 39 Circular 1Dokument2 SeitenPPS 39 Circular 1Dahiana HaureNoch keine Bewertungen

- Best SpeakersDokument14 SeitenBest SpeakersOros FeliciaNoch keine Bewertungen

- BOSS Hydraulic Valve O-Ring Sizing Chart: InchesDokument1 SeiteBOSS Hydraulic Valve O-Ring Sizing Chart: InchesssinokrotNoch keine Bewertungen

- Kim-Gland PackingDokument5 SeitenKim-Gland PackingIT KenzioTechNoch keine Bewertungen

- Polymers PDFDokument39 SeitenPolymers PDFAngelo Luis RosNoch keine Bewertungen

- Wells Plastics Additives For Polyethylene ExtrusionDokument4 SeitenWells Plastics Additives For Polyethylene ExtrusionmohammedNoch keine Bewertungen

- Din en 15860 2008-09Dokument49 SeitenDin en 15860 2008-09luis_may22Noch keine Bewertungen

- Technical Textile-2 PDFDokument14 SeitenTechnical Textile-2 PDFMd. Rafiqul Islam ManikNoch keine Bewertungen

- JPCL Pipeline Ebook1 PDFDokument27 SeitenJPCL Pipeline Ebook1 PDFDorje Phagmo100% (1)

- Sejarah Serat DuniaDokument24 SeitenSejarah Serat DuniaAditya DisNoch keine Bewertungen

- Fabricating and Machining UHMWPEDokument30 SeitenFabricating and Machining UHMWPEganeshNoch keine Bewertungen

- Yarn BrochureDokument21 SeitenYarn Brochuresivasankari11Noch keine Bewertungen

- Mechanical Properties of Woven Jute-Glass Hybrid-Reinforced Epoxy CompositeDokument13 SeitenMechanical Properties of Woven Jute-Glass Hybrid-Reinforced Epoxy CompositenaziraNoch keine Bewertungen

- Chem181-M15 Expt. No. 6 Final Report - MendozaDokument9 SeitenChem181-M15 Expt. No. 6 Final Report - MendozaAdrian MendozaNoch keine Bewertungen

- Introduction To ElastomerDokument32 SeitenIntroduction To ElastomerAnand DubeyNoch keine Bewertungen