Beruflich Dokumente

Kultur Dokumente

Corus Case Study

Hochgeladen von

Gaurav GargOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Corus Case Study

Hochgeladen von

Gaurav GargCopyright:

Verfügbare Formate

jThe steel manufacturing company Corus focuses on meeting the needs of its worldwide customers and providing innovative

solutions. It manufactures, processes and distributes steel and aluminium products worldwide. Corus is a subsidiary of Tata Steel, part of the giant Indian conglomerate. Tata Group includes businesses in many industries - for example, chemicals, automotive, telecommunications, leisure and consumer goods (such as Tetley Tea). Tata Steel acquired Corus in 2007 as part of a strategy of international expansion. Steel is everywhere in our homes and all around us. Corus Construction & Industrial (CCI), a business unit of Corus, has steel manufacturing facilities in Scunthorpe, Teesside, Scotland and France. The key markets for CCI include construction, energy and renewables, engineering and machinery, mining and earthmoving equipment, shipbuilding, fastenings and rail. The principle manufacturing site at Scunthorpe covers 2,000 acres and employs 5,500 people. The site consumes 6.5 million tonnes of iron ore and 2 million tonnes of coal each year to produce 4.3 million tonnes of steel products.

CORUS

CCIs business strategy is to produce quality steel to satisfy customer requirements, focusing on delivering products at the right time in order to secure profitable business. A key challenge is to meet the increasing demands for more steel, at increasing levels of quality and to comply with more demanding delivery requirements. It would be straightforward to meet these challenges using brand-new facilities. However, a new greenfield site steel mill could cost more than 300 million to build. CCI therefore needs to make process efficiencies and quality and delivery improvements with its existing manufacturing plant. This presents challenges when older facilities are not well structured to use modern manufacturing techniques and processes. This case study focuses on the process of Continuous Improvement (CI) at the CCI steel plate manufacturing mill at Scunthorpe. It will show how Corus is finding new ways of achieving its objectives from existing resources.

Continuous Improvement

Continuous Improvement is often referred to by the Japanese word Kaizen. Kaizen means change for the better and covers all processes in an organisation. These include engineering, IT, financial, commercial and customer service processes, as well as manufacturing. CI involves making continual small improvements to a process rather than big changes at irregular intervals. This requires close monitoring and control, changes to the uses of manpower, machinery, methods, materials and money to improve business efficiency. Continuous Improvement starts with management and under their leadership works down through the organisation. The underlying theme is that everyone is responsible and has a part to play in making improvements. All employees must work together to identify the steps needed to improve working practices. Planning meetings help teams to focus on satisfying customer needs. Visual management techniques, such as flow charts and wall charts make clear what resources are necessary and who is responsible for each part in the process. Everyone has the opportunity to eliminate waste. This is any activity or process that does not add value. A key question to define waste is would a customer pay for that process? There are seven main areas of waste for any business: transportation moving materials or products about inventory keeping too much or the wrong stock motion people moving or travelling excessively waiting times allowing products to wait for processing overproduction making too much over processing doing too many processes during manufacture defects errors or flaws in the product causing rework or needing to be scrapped. Production processes that minimise waste are referred to as lean production. In these processes, the aim is to use less of everything, for example, space, materials or time. CCI in Scunthorpe is looking to reduce waste in its plate manufacturing process. It has adopted the concept of flow. This means that the products are pulled through the process according to customer demand. All parts of the production process, from the supply of raw

steel (slab) to the finished steel plate, are carefully planned. Scheduling for each element of the process ensures that bottlenecks are kept to a minimum. Each process is paced (known as takt time) to control the amount of product in each stage of the process. This ensures that processes operate smoothly without overload or delay and keep the desired output and quality. Tonnage was the traditional key measure of productivity for CCI. For employees to work to a smooth paced process needed a significant culture change.

Target setting

CI working requires everyone to think differently about the way they work. It was recognised that people might be resistant and cling on to old ways of working. The key was getting all workers to see change as their responsibility. The CI coaches support the teams and individuals and promote or champion new ways of working. Over time, the team and individuals are empowered to take responsibility and make decisions for themselves.

Conclusion

Corus is transforming production at its Scunthorpe plate mill through Continuous Improvement. This way of working encourages all employees to behave as team members to identify and support work improvement opportunities. Increasingly employees at every level are making improvement their responsibility, which provides employee job satisfaction. Continuous Improvement helps Corus to provide quality products and services for customers with on time delivery. CI supports Corus aim to achieve satisfied customers and secure repeat sales and longer term orders. It is part of a long term strategy based on service to develop the business. It aims to improve operational demands to fulfil customer expectations and out-perform competitors.

Das könnte Ihnen auch gefallen

- WARBURTONS CASE STUDY KDokument6 SeitenWARBURTONS CASE STUDY KAdorablé PerezNoch keine Bewertungen

- Oscar Mayer - Case Write UpDokument4 SeitenOscar Mayer - Case Write UpShivankit KumarNoch keine Bewertungen

- Kitkat Case StudyDokument3 SeitenKitkat Case StudySatnam Bhatia100% (1)

- Case Study Resolute Marine Energy - Power in WavesDokument3 SeitenCase Study Resolute Marine Energy - Power in WavesPratiksha GaikwadNoch keine Bewertungen

- Guidelines in Research Proposal WritingDokument19 SeitenGuidelines in Research Proposal WritingMark RelloresNoch keine Bewertungen

- Statistics For Absolute Beginners (Second Edition) (Oliver TheobaldDokument144 SeitenStatistics For Absolute Beginners (Second Edition) (Oliver Theobaldcispas2000Noch keine Bewertungen

- Market Basket Final Paper (Group 1)Dokument13 SeitenMarket Basket Final Paper (Group 1)josef paolo ReyesNoch keine Bewertungen

- Apple Sustainability PerformanceDokument6 SeitenApple Sustainability PerformanceCHI-SQUARED STATISTICSNoch keine Bewertungen

- Greenwich SWOT AnalysisDokument1 SeiteGreenwich SWOT AnalysisConackry GuineaNoch keine Bewertungen

- Business Customs in Global MarketingDokument4 SeitenBusiness Customs in Global MarketingKrishnan Srinivasan0% (1)

- Starbucks Delivering Customer Service Case Solution PDFDokument2 SeitenStarbucks Delivering Customer Service Case Solution PDFRavia SharmaNoch keine Bewertungen

- Debt RestructuringDokument4 SeitenDebt Restructuringjano_art21Noch keine Bewertungen

- Discussion Questions TemsaDokument5 SeitenDiscussion Questions Temsafirinaluvina100% (1)

- Philippines Country PulseDokument64 SeitenPhilippines Country PulseellochocoNoch keine Bewertungen

- Imm Case StudyDokument23 SeitenImm Case StudyNandeesh BadamiNoch keine Bewertungen

- Probability Concepts and Applications: To AccompanyDokument98 SeitenProbability Concepts and Applications: To AccompanyChincel G. ANINoch keine Bewertungen

- The Dabbawalas of Mumbai 08Dokument8 SeitenThe Dabbawalas of Mumbai 08ajabrao100% (2)

- Big Bazaar CapstoneDokument84 SeitenBig Bazaar CapstoneNehul KawaNoch keine Bewertungen

- Introduction To Mang Inasal SaveDokument11 SeitenIntroduction To Mang Inasal SaveElla GeraldezNoch keine Bewertungen

- Business Plan FOR: Grass Wood Furniture and Cane Crafting FacilityDokument9 SeitenBusiness Plan FOR: Grass Wood Furniture and Cane Crafting FacilitygjorzeousNoch keine Bewertungen

- Swot AnalysisDokument2 SeitenSwot Analysismarichu apiladoNoch keine Bewertungen

- Just in TimeDokument7 SeitenJust in Timewaqas08Noch keine Bewertungen

- Innovative and Sustainable Business Models inDokument12 SeitenInnovative and Sustainable Business Models inVíctor Alex Ortiz100% (1)

- Minute Burger 2Dokument8 SeitenMinute Burger 2eavanreaNoch keine Bewertungen

- JFC Tows Analysis XXXDDDokument7 SeitenJFC Tows Analysis XXXDDChristian Terens AblangNoch keine Bewertungen

- Case StudyDokument13 SeitenCase StudyRhiki CourdhovaNoch keine Bewertungen

- Case 4 - Pakistani Soccerball (Autosaved)Dokument12 SeitenCase 4 - Pakistani Soccerball (Autosaved)sumesh balakrishnanNoch keine Bewertungen

- Strategic Leadership at AppleDokument16 SeitenStrategic Leadership at AppleYMCA Trinidad and Tobago100% (1)

- Business Plan Assignment 1Dokument7 SeitenBusiness Plan Assignment 1samdeking100% (1)

- ACCO 20293 - Module 1 - Intro To Management AcctgDokument9 SeitenACCO 20293 - Module 1 - Intro To Management AcctgAeram Justine PeñaflorNoch keine Bewertungen

- Advantages and DisadvantagesDokument4 SeitenAdvantages and DisadvantagesCharmaigne SeringNoch keine Bewertungen

- Executive SummaryDokument5 SeitenExecutive SummaryMariah Blez BognotNoch keine Bewertungen

- Balaji TelefilmsDokument11 SeitenBalaji TelefilmsVedant KumarNoch keine Bewertungen

- THE HOUSE OF NUTS FEASIB Revision Part 1Dokument49 SeitenTHE HOUSE OF NUTS FEASIB Revision Part 1Jean Diane JoveloNoch keine Bewertungen

- Factors Affecting Job Satisfaction of Employees in A Public InstitutionDokument145 SeitenFactors Affecting Job Satisfaction of Employees in A Public InstitutionJunedyn TurdilNoch keine Bewertungen

- Philippine Christian University: Senior High School Department Dasmariñas CampusDokument15 SeitenPhilippine Christian University: Senior High School Department Dasmariñas Campusrehina lopez100% (1)

- Chapter 09 NotesDokument5 SeitenChapter 09 NotesNik Nur MunirahNoch keine Bewertungen

- Case Study 2Dokument1 SeiteCase Study 2Mohammad Haroon0% (1)

- Case StudyDokument2 SeitenCase StudyСветлана Дирко100% (1)

- Chapter 2 In-Class ExercisesDokument22 SeitenChapter 2 In-Class ExercisesErwin Bantilan80% (15)

- IBS Course PDFDokument16 SeitenIBS Course PDFSanat MohantyNoch keine Bewertungen

- Assessment 3 - Reflective and Analytic Report - KODAKDokument16 SeitenAssessment 3 - Reflective and Analytic Report - KODAKSheraz KhanNoch keine Bewertungen

- Business Proposal For Setting Up of A Jacket 2003Dokument37 SeitenBusiness Proposal For Setting Up of A Jacket 2003Abhinav Akash SinghNoch keine Bewertungen

- DiversificationDokument18 SeitenDiversificationsalimalmaqbaliNoch keine Bewertungen

- Term Paper On SCM of UnileverDokument19 SeitenTerm Paper On SCM of UnileverMd Nasimul HossainNoch keine Bewertungen

- PDF 1 PDFDokument28 SeitenPDF 1 PDFAkash MohataNoch keine Bewertungen

- Difference Between Goods and ServicesDokument4 SeitenDifference Between Goods and ServicesKapil Dosi0% (1)

- Collaborator AnalysisDokument15 SeitenCollaborator AnalysisDianElizz Zea SantanaNoch keine Bewertungen

- Case Study AnalysesDokument10 SeitenCase Study AnalysesCindy VillaromanNoch keine Bewertungen

- Case Study JollibeeDokument15 SeitenCase Study JollibeeDboyJuabanNoch keine Bewertungen

- Nouns: Activity, Service, Materials, Operation, Production, Opportunities, SystemDokument2 SeitenNouns: Activity, Service, Materials, Operation, Production, Opportunities, SystemPaulius KnezevičiusNoch keine Bewertungen

- The A's Corner Food Truck (Marketing Plan)Dokument11 SeitenThe A's Corner Food Truck (Marketing Plan)Charlie WhiskeyNoch keine Bewertungen

- MIS Case StudiesDokument8 SeitenMIS Case StudiesanupujariNoch keine Bewertungen

- Coordinated Product and Supply Chain DesignDokument4 SeitenCoordinated Product and Supply Chain DesignBao Tran100% (1)

- Mini Project 2 HyperloopDokument26 SeitenMini Project 2 HyperloopSushil SrivastavaNoch keine Bewertungen

- Porter Analysis of CCDDokument4 SeitenPorter Analysis of CCDvidhu devadharNoch keine Bewertungen

- WWF PDFDokument9 SeitenWWF PDFRiya Dutta100% (1)

- Marketing PlanDokument19 SeitenMarketing PlanDiane Elizabeth MuldongNoch keine Bewertungen

- Assignment: SWOT Analysis: Name: Geronimo, Christhian Jhoseph G. Course & Sec: BSTM 211BDokument2 SeitenAssignment: SWOT Analysis: Name: Geronimo, Christhian Jhoseph G. Course & Sec: BSTM 211BChristhian Jhoseph GeronimoNoch keine Bewertungen

- Philippines Food Processing DecDokument15 SeitenPhilippines Food Processing Dectopandy100% (1)

- Supply Chain Management: Presentation byDokument8 SeitenSupply Chain Management: Presentation byHarsh LalNoch keine Bewertungen

- Krajewski - Om12 - 08Dokument74 SeitenKrajewski - Om12 - 08Nuevo IntegranteNoch keine Bewertungen

- Corus 13 FullDokument4 SeitenCorus 13 FullVarun PrasherNoch keine Bewertungen

- Assignment 9 TQM POLIDARIO PDFDokument9 SeitenAssignment 9 TQM POLIDARIO PDFALIAHDAYNE POLIDARIONoch keine Bewertungen

- Maneesh Misra CV - 1Dokument3 SeitenManeesh Misra CV - 1Rohit KarhadeNoch keine Bewertungen

- A Thermoelectric Scanning Facility For The Study of Elemental Thermocouples Robin E Bentley - Meas. Sci. Technol. 11 (2000) 538-546Dokument10 SeitenA Thermoelectric Scanning Facility For The Study of Elemental Thermocouples Robin E Bentley - Meas. Sci. Technol. 11 (2000) 538-546Ver OnischNoch keine Bewertungen

- IT 118 - SIA - Module 1Dokument9 SeitenIT 118 - SIA - Module 1Kim Zyrene DominoNoch keine Bewertungen

- Stanley Commercial Hardware 2014 Price BookDokument124 SeitenStanley Commercial Hardware 2014 Price BookSecurity Lock DistributorsNoch keine Bewertungen

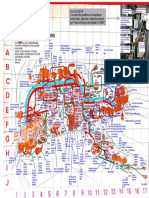

- 164 Dashboard Annotated Ver 2a W-InsertDokument1 Seite164 Dashboard Annotated Ver 2a W-Insertoleg164Noch keine Bewertungen

- Final - Far Capital - Infopack Diana V3 PDFDokument79 SeitenFinal - Far Capital - Infopack Diana V3 PDFjoekaledaNoch keine Bewertungen

- Polaris Ranger 500 ManualDokument105 SeitenPolaris Ranger 500 ManualDennis aNoch keine Bewertungen

- 1LG4253-4AA60 Datasheet enDokument1 Seite1LG4253-4AA60 Datasheet enanm bNoch keine Bewertungen

- Agricultural Extension System in Sudan FinalDokument52 SeitenAgricultural Extension System in Sudan FinalMohamed Saad AliNoch keine Bewertungen

- General Milling Corp Vs CA (DIGEST)Dokument2 SeitenGeneral Milling Corp Vs CA (DIGEST)Raima Marjian Sucor100% (1)

- BOOK2Dokument201 SeitenBOOK2Chetan Satish PadoleNoch keine Bewertungen

- 1580823068890043Dokument6 Seiten1580823068890043Cristopher Dave CabañasNoch keine Bewertungen

- Programa de Formacion: English Dot Works 2Dokument4 SeitenPrograma de Formacion: English Dot Works 2Juan GuerreroNoch keine Bewertungen

- Labour Bureau: Ministry of Labour and Employment, Government of IndiaDokument1 SeiteLabour Bureau: Ministry of Labour and Employment, Government of IndiavinodNoch keine Bewertungen

- Shalina Healthcare JD - Business AnalyticsDokument2 SeitenShalina Healthcare JD - Business AnalyticsMeow bunNoch keine Bewertungen

- DACReq 016Dokument19 SeitenDACReq 016jillianixNoch keine Bewertungen

- CBL 2022 2023Dokument41 SeitenCBL 2022 2023Roy SaberdoNoch keine Bewertungen

- Repair of Small Household Appliances and Power ToolsDokument315 SeitenRepair of Small Household Appliances and Power ToolsahmadnawazjaswalNoch keine Bewertungen

- Ec8691 MPMC Question BankDokument41 SeitenEc8691 MPMC Question BankManimegalaiNoch keine Bewertungen

- Urban Jungle 8Dokument3 SeitenUrban Jungle 8Angel Medez GonzalezNoch keine Bewertungen

- MCQ Criminal Law 1Dokument18 SeitenMCQ Criminal Law 1Clark Vincent Ponla0% (1)

- DEED OF ADJUDICATION WITH ABSOLUTE SALE - VigillaDokument3 SeitenDEED OF ADJUDICATION WITH ABSOLUTE SALE - VigillaAlfred AglipayNoch keine Bewertungen

- Profitability Analysis (Sapphire Fibres Limited)Dokument5 SeitenProfitability Analysis (Sapphire Fibres Limited)Aqsa MoizNoch keine Bewertungen

- NF en 1317-5 In2Dokument23 SeitenNF en 1317-5 In2ArunNoch keine Bewertungen

- Sajjad Ali: API Mechanical Tank Inspector, QCI Welding (Aramco Approved)Dokument5 SeitenSajjad Ali: API Mechanical Tank Inspector, QCI Welding (Aramco Approved)Owais MalikNoch keine Bewertungen