Beruflich Dokumente

Kultur Dokumente

Equipment Design

Hochgeladen von

nirmal_subudhiOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Equipment Design

Hochgeladen von

nirmal_subudhiCopyright:

Verfügbare Formate

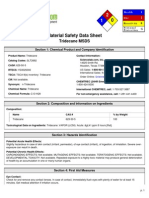

EQUIPMENT DESIGN : DEBUTANIZER

Distillation is probably the most widely used separation process in the chemical and allied industries; its application ranging from the rectification of alcohol, which has been practiced since antiquity to the fractionation of crude oil. DISTILLATION COLUMN DESIGN 1. The design of a distillation column can be divided into the following steps,specify the degree of separation required: set product specification. 2. Select the operating conditions: batch or continuous; operating pressure 3. Select the type of contenting device: plates or packing. 4. Determine the stage and reflux requirements: the number of equilibrium stages. 5. Size the column: diameter, number of real stages 6. Design the column internals: plates, distributors, packing supports. 7. Mechanical design: vessel and internal fittings The principal step will be to determine the stage and reflux requirements. This is a relatively simple procedure when the feed is a binary mixture, but a complex and difficult task when the feed is a binary mixture, but a complex and difficult task when the feed contains more than two components (multicomponent systems). CONTINUOUS DISTILLATION PROCESS DESCRIPTION: The separation of liquid mixtures by distillation depends on differences in volatility between the components. The greater the relative volatilities, the easier the separation. Vapors flows up the column and liquid counter-currently down the column. The vapors and liquid are brought into contact on plates, or packing. Part of the condensate from the condenser is returned to the top of the column to provide liquid

flow above the feed point (reflux), and part of the liquid from the base of the column is vaporized in the re-boiler and returned to provide the vapors flow. In the section below the feed, the more volatile components are stripped from the liquid and this is known as the stripping section. Above the feed, the concentration of the more volatile components is increased and this is called the enrichment, or more commonly, the rectifying section. If the process requirement is to strip a volatile component from a relatively nonvolatile solvent, the rectifying section may be omitted, and the column would then be called a stripping column. In some operations, where the top product is required as a vapor, only sufficient liquid is condensed to provide the reflux flow to the column, and the condenser is referred to as a partial condenser. When the liquid is totally condensed, the liquid returned to the column will have the same composition as the top product. In a partial condenser the reflux will be in in equilibrium with the vapor leaving the condenser. Virtually pure top and bottom products can be obtained in a single column from a binary feed, but where the feed contains more than two components, only a single "pure" product can he produced, either from the top or bottom of the column. Several columns will be needed to separate a multicomponent feed into its constituent parts. APROXIMATE COLUMN SIZING An approximate estimate of the overall column size can be made once the number of real stages required for the separation is known. This is often needed to make a rough estimate of the capital cost for project evaluation. PLATE SPACING The overall height of the column will depend on the plate spacing. Plate spacings from 0.15m (6 in.) to I m (36 in.) arc normally used. The spacing chosen will depend on the column diameter and operating conditions. Close spacing is used with small-

diameter columns, and where head room is restricted; as it will a column is installed in a building. For columns above I m diameter, plate spacing to 0.6 m will normally be used, and 0.5 m (18 in.) can be taken as an initial estimate. This would be revised. as necessary, when the detailed plate design is made. A larger spacing will be needed between certain plates to accommodate feed and side-streams arrangements, and for man-ways. COLUMN DIAMETER The principal factor that determines the column diameter is the vapor flow-rate. The vapour velocity must be below that which would cause excessive liquid entrainment or a high pressure drop. VALVE PLATES (FLOATING CAP PLATES) Valve plates are are proprietary designs. They are essentially sieve plates with largediameter holes covered covered by movable flaps, which lift as the vapor flow increases. As the area for vapor flow varies with the flow-rate, valve plates can operate efficiently at lower flow-rates than sieve plates; the valves closing as low vapor rates. SELECTION OF PLATE Sieve plates are the cheapest and are satisfactory for most applications. Valve plates should be considered if the specified turn-down ratio cannot cannot be rnet with sieve plates. Bubble-caps should only be used where very low vapor (gas) rates have to be handled and a positive liquid seal is essential at all flow-rates.

DISTILLATION COLUMN DESIGN (Gas Concentration Unit)

Temperature = T avg = 130C = 726 R

Pressure = Pavg = 12.143 atm P = 0.345 atm Moleculer wt. (avg) = 52.7 kg/kg.mole Specific gravity of liquid = 0.58 Density of gas at standard conditions G = G = 1.24 lb/ft3 VM = Kv = 30 inches (for tray spacing) Kv = 0.35 (from plant design by Timmerhaus) Vm = Vm = 1.89 ft/sec A = 29.78 ft 2 Dia of tower = = A D = 1.65 ft No. of trays = 40 Space below the bottom plate and above the top plate = 8ft Tray spacing = 30 in = 2.5 ft

Total height = 2.5 x (40+8) = 108 ft Height = 33 m Reflux ratio = Ln/D =5 Plate Design DC = column diameter = 6.15 ft AC = Area of column = 29.78 ft2 AD = Down comer area = 0.11 x 29.78 = 3.276 ft 2 AN = Net area = Ac Ad = 26.5 Ft2 Active Area = Aa = AC 2Ad = 29.78 (2x 3.276) = 23.23 ft 2 Hole area = Ah =10% Aa =0.1 x 23.23 = 2.32ft2 At (Ad/AC) = 3.276 / 29.78 = 0.11 (From fig. 11.31 coulson vol. 6) Iw / Dc = 0.74 Iw = 0.74 x 6.15 Iw = 4.551 ft Assuming weir height = lw =5mm Hole diameter = 5mm Plate thickness = 5 mm No. of units :

Active area = Aa = 23.23 ft2 = 2.13 m2 For atandard we have 150 units /m2 No. of units = 150 x 2.13 = 320 No. of units = 320

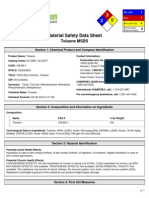

DEBUTANIZER OVERHEAD REFLUX DRUM DESIGN:

FEED = 100122 Kg/hr = 220568.7 lb/ hr Specific gravity = 0.55 Density = 34.32 lb / ft3 Vol. Flow rate = 22.568.7 lb/hr x ft3/34.32 lb = 6426.82 ft3/ hr Assuming holdup time = 5 min (mostly) For 1 hr operation the drum handel: For 5 min drum handle = = 535.56 ft3 Assuming separator is half filled with liquid Total vol. of drum = 535.56 x 2 = 1071.12 ft3

Giving 20% allowance for variation in liquid rate Allowance = 1071.12 0.2 = 214.22 ft3

Actual vol. of drum = 1071.12 +214.22 = 1285.34 ft3 Volume = Area Length Volume = L Volume = 3D (L = 3D) Vol. = D3 x 0.75 D= D= Dia of drum = 8.17 ft L=3xD L = 24.5 ft Length of drum = 24.5 ft

Thickness of wall

Pressure = 11.11 Kg/cm2 P = 158 Psi Radius = R = 49.02 inch Material of construction = KCS

Tensile strength = = 13750 Psi Efficiency of Joint = EJ = 0.85 Corrosion allowance = Cc = 0.125 in t= t= t = 0.66 inch

Page 141

Das könnte Ihnen auch gefallen

- Separator Vessel: Ms. Shreya SahajpalDokument6 SeitenSeparator Vessel: Ms. Shreya SahajpalShreya Sahajpal KaushalNoch keine Bewertungen

- Chap3 Seperators and Seperation TechniquesDokument37 SeitenChap3 Seperators and Seperation TechniquestahaNoch keine Bewertungen

- Vessel DesignDokument43 SeitenVessel Designhomiez99Noch keine Bewertungen

- Steam CondenserDokument2 SeitenSteam CondenserAlphaEcc EngineeringTeamNoch keine Bewertungen

- Separator Sizing and DesignDokument44 SeitenSeparator Sizing and DesignKay EenNoch keine Bewertungen

- Dowtherm Vent CondenserDokument1 SeiteDowtherm Vent Condensersushant_jhawerNoch keine Bewertungen

- Pressure Vessel Design - ProceduresDokument62 SeitenPressure Vessel Design - ProceduresLê Phạm HoàngNoch keine Bewertungen

- Separator SizingDokument3 SeitenSeparator SizingMaryJane Ayisha Sado-ObahNoch keine Bewertungen

- PSV Sizing (Steam)Dokument2 SeitenPSV Sizing (Steam)Saeid Rahimi Mofrad100% (1)

- Welding of Pressure VesselsDokument2 SeitenWelding of Pressure VesselsDvida PleasureNoch keine Bewertungen

- Heat Exchanger Specification Sheet: Shell Side Tube Side Performance of One UnitDokument2 SeitenHeat Exchanger Specification Sheet: Shell Side Tube Side Performance of One UnitMuthuKumar ArunachalamNoch keine Bewertungen

- Features/Benefits: Production Testing Solutions Three-Phase Test SeparatorDokument1 SeiteFeatures/Benefits: Production Testing Solutions Three-Phase Test SeparatorJayesh SanganiNoch keine Bewertungen

- Design of 3 Phase Production SeparatorDokument8 SeitenDesign of 3 Phase Production Separatormyself_riteshNoch keine Bewertungen

- SeparatorDokument9 SeitenSeparatorGelorawan AditNoch keine Bewertungen

- 1289-Hari Prastowo-#2 Pipes Class & Thickness (Rev) Hand-OutDokument17 Seiten1289-Hari Prastowo-#2 Pipes Class & Thickness (Rev) Hand-OutSupriadi TansiNoch keine Bewertungen

- Mechanical Design For Pressure VesselDokument26 SeitenMechanical Design For Pressure VesselibicengNoch keine Bewertungen

- 16 - Blending and AgitationDokument20 Seiten16 - Blending and AgitationRafael ReyesNoch keine Bewertungen

- Separator Design: Rev Description Date Prepared by Client ApprovalDokument18 SeitenSeparator Design: Rev Description Date Prepared by Client ApprovalUsɱâñ Måâñ100% (1)

- 09 SpargerDokument17 Seiten09 SpargerWeb LogueandoNoch keine Bewertungen

- Volumes 2Dokument1 SeiteVolumes 2Rafael ReyesNoch keine Bewertungen

- Nozzle CriteriaDokument2 SeitenNozzle CriteriaKhalil LasferNoch keine Bewertungen

- Test Separator WT 16Dokument4 SeitenTest Separator WT 16jairaso2950Noch keine Bewertungen

- Sample Problem StatementDokument2 SeitenSample Problem Statementsunildubey02Noch keine Bewertungen

- What Is Design Interpretation?Dokument17 SeitenWhat Is Design Interpretation?Qaisir MehmoodNoch keine Bewertungen

- PWS2014 Rawlins DesanderStudyRDokument10 SeitenPWS2014 Rawlins DesanderStudyRJhon Henry Segundo LlaguentoNoch keine Bewertungen

- What Are Oil and Gas SeparatorsDokument15 SeitenWhat Are Oil and Gas SeparatorsFriday IjokgwungNoch keine Bewertungen

- Calculos DemisterDokument2 SeitenCalculos DemistermoviedohNoch keine Bewertungen

- Selection of Separator With BootDokument2 SeitenSelection of Separator With BootMaryJane Ayisha Sado-ObahNoch keine Bewertungen

- SWT PreSolidsSeparation H011840 A4Dokument2 SeitenSWT PreSolidsSeparation H011840 A4slbclqrkNoch keine Bewertungen

- Three Phase Separator Sizing - Bucket & PipeDokument2 SeitenThree Phase Separator Sizing - Bucket & PipeSaeid Rahimi MofradNoch keine Bewertungen

- L028 Me Dat 01 00122 001 00Dokument8 SeitenL028 Me Dat 01 00122 001 00sivasan10006098Noch keine Bewertungen

- Principles of Separation: Production and Test SeparatorsDokument28 SeitenPrinciples of Separation: Production and Test SeparatorsهانيزايدNoch keine Bewertungen

- Compressor Data SheetDokument2 SeitenCompressor Data SheetgoharmahmoodkhokharNoch keine Bewertungen

- 10inch Inlet DiffuserDokument1 Seite10inch Inlet DiffuserJulian Vega DiazNoch keine Bewertungen

- 2.0 AasasDokument41 Seiten2.0 AasasMinimac Pune - HONoch keine Bewertungen

- 1 Process VesselsDokument4 Seiten1 Process VesselsARIANA NICOLE RELIGIOSONoch keine Bewertungen

- Colum Specification SheetDokument6 SeitenColum Specification SheetEddy RainNoch keine Bewertungen

- 03 Metal Packing Support PlatesDokument3 Seiten03 Metal Packing Support PlatesypatelsNoch keine Bewertungen

- Summary of Pressure Vessel: By. Mohamed Bassuoni Mechanical Consultant Engineer Senior Technical InstructorDokument41 SeitenSummary of Pressure Vessel: By. Mohamed Bassuoni Mechanical Consultant Engineer Senior Technical InstructorDHAVAL PANCHALNoch keine Bewertungen

- JT Assembly English A4Dokument2 SeitenJT Assembly English A4HectorNoch keine Bewertungen

- Calcs 4Dokument19 SeitenCalcs 4Syariful Maliki NejstaršíNoch keine Bewertungen

- ES-20.14 Waste Heat PTT Public Co., LTD Recovery Units Engineering Standard REV: 02Dokument10 SeitenES-20.14 Waste Heat PTT Public Co., LTD Recovery Units Engineering Standard REV: 02Nikki RobertsNoch keine Bewertungen

- Glycol Dehydration Unit English LetterDokument4 SeitenGlycol Dehydration Unit English LetterRaulCamachoNoch keine Bewertungen

- Heat HXerDokument2 SeitenHeat HXerGade JyNoch keine Bewertungen

- HP Boiler Blowdown Hex - OPERATINGDokument1 SeiteHP Boiler Blowdown Hex - OPERATINGMuthuKumar ArunachalamNoch keine Bewertungen

- Quiz For Heat Exchanger Selection and Design: T E C H N O L O G YDokument10 SeitenQuiz For Heat Exchanger Selection and Design: T E C H N O L O G Yrvkumar61Noch keine Bewertungen

- Training Manual For PVelite Basic LevelDokument41 SeitenTraining Manual For PVelite Basic LevelsudokuNoch keine Bewertungen

- VGS Vane Separators Are Recommended ForDokument1 SeiteVGS Vane Separators Are Recommended ForSanthu PeelaNoch keine Bewertungen

- HeatExchanger ReportDokument5 SeitenHeatExchanger ReportNur Izzati KamrulnizamNoch keine Bewertungen

- Oil and Gas SeparatorsDokument23 SeitenOil and Gas SeparatorsSofea Hanom NordinNoch keine Bewertungen

- Cvts - Tag No. Mpt-tv-4161Dokument2 SeitenCvts - Tag No. Mpt-tv-4161biswasdipankar05Noch keine Bewertungen

- Process Flow Diagram: Fig: Process Flow Sheet Made With Help of ASPENDokument42 SeitenProcess Flow Diagram: Fig: Process Flow Sheet Made With Help of ASPENSwarnim RajNoch keine Bewertungen

- Equi - Design DistillationDokument22 SeitenEqui - Design Distillationjoker princeNoch keine Bewertungen

- (8.3) Distillation ColumnDokument21 Seiten(8.3) Distillation ColumnAsad SaeedNoch keine Bewertungen

- Flare KO Drum-3Dokument35 SeitenFlare KO Drum-3nghiemta1892% (13)

- BN-EG-UE109 Guide For Vessel SizingDokument28 SeitenBN-EG-UE109 Guide For Vessel Sizingeulalio_méndezNoch keine Bewertungen

- Vertical SeparatorDokument38 SeitenVertical SeparatorSaidFerdjallahNoch keine Bewertungen

- BN Eg UE109 Vessel SizingDokument40 SeitenBN Eg UE109 Vessel Sizingbadelitamarius100% (1)

- Chapter 3-Two-Phase Oil and Gas SeparationDokument56 SeitenChapter 3-Two-Phase Oil and Gas SeparationIvan Zvonar75% (4)

- BN-EG-UE109 Guide For Vessel SizingDokument29 SeitenBN-EG-UE109 Guide For Vessel SizingSachin ChavanNoch keine Bewertungen

- Class 6-1Dokument1 SeiteClass 6-1nirmal_subudhiNoch keine Bewertungen

- Compressor Dynamics 5Dokument1 SeiteCompressor Dynamics 5nirmal_subudhiNoch keine Bewertungen

- Compressor Dynamics 2Dokument1 SeiteCompressor Dynamics 2nirmal_subudhiNoch keine Bewertungen

- Compressor Dynamics 4Dokument1 SeiteCompressor Dynamics 4nirmal_subudhiNoch keine Bewertungen

- Compressor Dynamics 3Dokument1 SeiteCompressor Dynamics 3nirmal_subudhiNoch keine Bewertungen

- ADokument5 SeitenAnirmal_subudhiNoch keine Bewertungen

- Class 6-10Dokument1 SeiteClass 6-10nirmal_subudhiNoch keine Bewertungen

- Compressor Dynamics 1Dokument1 SeiteCompressor Dynamics 1nirmal_subudhiNoch keine Bewertungen

- NoteDokument1 SeiteNotenirmal_subudhiNoch keine Bewertungen

- Dispersion Model 2: Dr. AA Department of Chemical Engineering University Teknology MalaysiaDokument44 SeitenDispersion Model 2: Dr. AA Department of Chemical Engineering University Teknology Malaysianirmal_subudhi100% (1)

- Pviewtutme IntroDokument6 SeitenPviewtutme Intronirmal_subudhiNoch keine Bewertungen

- Hydrocarbon Processing: Deep Water FLNGDokument1 SeiteHydrocarbon Processing: Deep Water FLNGnirmal_subudhiNoch keine Bewertungen

- Process View VBA Tutorial: User'S ManualDokument1 SeiteProcess View VBA Tutorial: User'S Manualnirmal_subudhiNoch keine Bewertungen

- 3888 6839 1 PBDokument8 Seiten3888 6839 1 PBnirmal_subudhiNoch keine Bewertungen

- HeneicosaneDokument3 SeitenHeneicosanenirmal_subudhiNoch keine Bewertungen

- Basic Prog For FlowmeterDokument1 SeiteBasic Prog For Flowmeternirmal_subudhiNoch keine Bewertungen

- Need For Bypass During Positive Displacement PumpDokument2 SeitenNeed For Bypass During Positive Displacement Pumpnirmal_subudhiNoch keine Bewertungen

- SilicaDokument4 SeitenSilicaTgk HM Kinglie Nya'OenoeNoch keine Bewertungen

- Msds HeptadecaneDokument5 SeitenMsds Heptadecanenirmal_subudhiNoch keine Bewertungen

- LaricinaDokument15 SeitenLaricinanirmal_subudhiNoch keine Bewertungen

- Msds Benzena PDFDokument6 SeitenMsds Benzena PDFIrianto Rizaldi FaturrahmanNoch keine Bewertungen

- M MercaptanDokument7 SeitenM Mercaptannirmal_subudhiNoch keine Bewertungen

- E MercaptanDokument8 SeitenE Mercaptannirmal_subudhiNoch keine Bewertungen

- Msds DodecaneDokument6 SeitenMsds Dodecanenirmal_subudhiNoch keine Bewertungen

- Msds UndecaneDokument5 SeitenMsds Undecanenirmal_subudhiNoch keine Bewertungen

- Material Safety Data Sheet: 1. Chemical Product and Company IdentificationDokument7 SeitenMaterial Safety Data Sheet: 1. Chemical Product and Company Identificationnirmal_subudhiNoch keine Bewertungen

- MSDS N EicosaneDokument3 SeitenMSDS N Eicosanenirmal_subudhiNoch keine Bewertungen

- Msds HexadecaneDokument5 SeitenMsds Hexadecanenirmal_subudhiNoch keine Bewertungen

- Msds TridecaneDokument5 SeitenMsds Tridecanenirmal_subudhiNoch keine Bewertungen

- Msds TolueneDokument6 SeitenMsds Toluenenirmal_subudhi100% (1)

- NGSS & Common Core 5E Lesson Plan: Crosscutting Concepts, and Core IdeasDokument5 SeitenNGSS & Common Core 5E Lesson Plan: Crosscutting Concepts, and Core Ideasapi-300263583Noch keine Bewertungen

- Katalogas enDokument20 SeitenKatalogas enEman AdelNoch keine Bewertungen

- Man - Maxthermo - Mc49 - EngDokument8 SeitenMan - Maxthermo - Mc49 - EngCsaba VargaNoch keine Bewertungen

- Cam Price List (Philips)Dokument36 SeitenCam Price List (Philips)dave6522Noch keine Bewertungen

- Moot Proposition.8th Anand Swaroop Gupta Memorial International Moot Court Competition 24Dokument5 SeitenMoot Proposition.8th Anand Swaroop Gupta Memorial International Moot Court Competition 24pranavdubey2018Noch keine Bewertungen

- Long Quiz PhyscieDokument1 SeiteLong Quiz PhyscieFroilan VillanuevaNoch keine Bewertungen

- Register of Licences and Permits For Electric Power Undertakings PDFDokument20 SeitenRegister of Licences and Permits For Electric Power Undertakings PDFNyasclemNoch keine Bewertungen

- Universal Gold 3Dokument2 SeitenUniversal Gold 3Torero02Noch keine Bewertungen

- Gang SawDokument55 SeitenGang SawAstri NgentNoch keine Bewertungen

- 01 PA EngineDokument49 Seiten01 PA EngineDay MinhNoch keine Bewertungen

- Semester II Shivaji University Kolhapur S. E. Electrical II Power ElectronicsDokument2 SeitenSemester II Shivaji University Kolhapur S. E. Electrical II Power ElectronicsAnonymous q6cOT5XgXANoch keine Bewertungen

- Boiler Water ConditioningDokument3 SeitenBoiler Water ConditioningShahin AfrozNoch keine Bewertungen

- Industrial Investment Promotion Policy: 2005-2010 Andhra PradeshDokument31 SeitenIndustrial Investment Promotion Policy: 2005-2010 Andhra PradeshVenkatesh KarnatiNoch keine Bewertungen

- Electrical Machine - 2 Lab ManualDokument50 SeitenElectrical Machine - 2 Lab ManualMohit ChetiwalNoch keine Bewertungen

- Module 6 Temperature SensorsDokument20 SeitenModule 6 Temperature SensorsJyothi SamanthulaNoch keine Bewertungen

- PC1 532Dokument147 SeitenPC1 532bharatsehgal00@gmail.comNoch keine Bewertungen

- Automatic Drainage Cleaning Machine Run Through Solar PowerDokument8 SeitenAutomatic Drainage Cleaning Machine Run Through Solar Powervikalpsharma96Noch keine Bewertungen

- Mopar Accessories Jeep RamDokument38 SeitenMopar Accessories Jeep RamlinseysabrinaNoch keine Bewertungen

- 4016TAG2A 1500 RPM ElectropaK PN2181Dokument5 Seiten4016TAG2A 1500 RPM ElectropaK PN2181Mohammed HamzaNoch keine Bewertungen

- ENGINEERING PHYSICS Problem Set 1 - MidtermDokument2 SeitenENGINEERING PHYSICS Problem Set 1 - MidtermShieNoch keine Bewertungen

- The Influence of Steel Chemistry & Surface Coatings On Resistance Spot Weld Strength and Failure MechanismsDokument14 SeitenThe Influence of Steel Chemistry & Surface Coatings On Resistance Spot Weld Strength and Failure MechanismsDolfredNoch keine Bewertungen

- Complete Solar Panel Installation DesignDokument7 SeitenComplete Solar Panel Installation DesignAnietie Udofia100% (2)

- Cameroon: CrowfundingDokument36 SeitenCameroon: Crowfundingabass nchareNoch keine Bewertungen

- Building Services Module 5 NotesDokument28 SeitenBuilding Services Module 5 NotesTrishul IsNoch keine Bewertungen

- SMA FLX InstallationGuide-XXDokument248 SeitenSMA FLX InstallationGuide-XXAnonymous smdEgZN2IeNoch keine Bewertungen

- Tune Up Spark Plug GappingDokument26 SeitenTune Up Spark Plug GappingSelazinap LptNoch keine Bewertungen

- Checklist For Engineer On DutyDokument14 SeitenChecklist For Engineer On DutyEzhil AnNoch keine Bewertungen

- Tài liệu bồi dưỡng HSG tiếng Anh lớp 11Dokument14 SeitenTài liệu bồi dưỡng HSG tiếng Anh lớp 11xuannghiatandaNoch keine Bewertungen

- Series 219 SMT DIP: Surface Mount DIP Switch - Auto PlaceableDokument2 SeitenSeries 219 SMT DIP: Surface Mount DIP Switch - Auto Placeablejagadees21Noch keine Bewertungen

- Hero Found: The Greatest POW Escape of the Vietnam WarVon EverandHero Found: The Greatest POW Escape of the Vietnam WarBewertung: 4 von 5 Sternen4/5 (19)

- The Fabric of Civilization: How Textiles Made the WorldVon EverandThe Fabric of Civilization: How Textiles Made the WorldBewertung: 4.5 von 5 Sternen4.5/5 (58)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestVon EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestBewertung: 4 von 5 Sternen4/5 (28)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaVon EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaNoch keine Bewertungen

- The End of Craving: Recovering the Lost Wisdom of Eating WellVon EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellBewertung: 4.5 von 5 Sternen4.5/5 (81)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindVon EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNoch keine Bewertungen

- Sully: The Untold Story Behind the Miracle on the HudsonVon EverandSully: The Untold Story Behind the Miracle on the HudsonBewertung: 4 von 5 Sternen4/5 (103)

- Highest Duty: My Search for What Really MattersVon EverandHighest Duty: My Search for What Really MattersNoch keine Bewertungen

- Pale Blue Dot: A Vision of the Human Future in SpaceVon EverandPale Blue Dot: A Vision of the Human Future in SpaceBewertung: 4.5 von 5 Sternen4.5/5 (588)

- System Error: Where Big Tech Went Wrong and How We Can RebootVon EverandSystem Error: Where Big Tech Went Wrong and How We Can RebootNoch keine Bewertungen

- The Technology Trap: Capital, Labor, and Power in the Age of AutomationVon EverandThe Technology Trap: Capital, Labor, and Power in the Age of AutomationBewertung: 4.5 von 5 Sternen4.5/5 (46)

- A Place of My Own: The Architecture of DaydreamsVon EverandA Place of My Own: The Architecture of DaydreamsBewertung: 4 von 5 Sternen4/5 (242)

- Reality+: Virtual Worlds and the Problems of PhilosophyVon EverandReality+: Virtual Worlds and the Problems of PhilosophyBewertung: 4 von 5 Sternen4/5 (24)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerVon EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerBewertung: 4.5 von 5 Sternen4.5/5 (122)

- The Future of Geography: How the Competition in Space Will Change Our WorldVon EverandThe Future of Geography: How the Competition in Space Will Change Our WorldBewertung: 4 von 5 Sternen4/5 (5)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyVon EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyNoch keine Bewertungen

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterVon EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterNoch keine Bewertungen

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansVon EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNoch keine Bewertungen

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerVon EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerBewertung: 4.5 von 5 Sternen4.5/5 (54)

- Transformed: Moving to the Product Operating ModelVon EverandTransformed: Moving to the Product Operating ModelBewertung: 4 von 5 Sternen4/5 (1)

- The Weather Machine: A Journey Inside the ForecastVon EverandThe Weather Machine: A Journey Inside the ForecastBewertung: 3.5 von 5 Sternen3.5/5 (31)

- Mini Farming: Self-Sufficiency on 1/4 AcreVon EverandMini Farming: Self-Sufficiency on 1/4 AcreBewertung: 4 von 5 Sternen4/5 (76)

- Packing for Mars: The Curious Science of Life in the VoidVon EverandPacking for Mars: The Curious Science of Life in the VoidBewertung: 4 von 5 Sternen4/5 (1395)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureVon EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureBewertung: 5 von 5 Sternen5/5 (125)

- When the Heavens Went on Sale: The Misfits and Geniuses Racing to Put Space Within ReachVon EverandWhen the Heavens Went on Sale: The Misfits and Geniuses Racing to Put Space Within ReachBewertung: 4.5 von 5 Sternen4.5/5 (27)