Beruflich Dokumente

Kultur Dokumente

Yanmar Mechnical Pump

Hochgeladen von

송성훈Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Yanmar Mechnical Pump

Hochgeladen von

송성훈Copyright:

Verfügbare Formate

EP-1

Diesel Fuel Injection Pump

A- type Fuel Injection Pump

1. Valve holder 2. Delivery valve 3. Pump barrel 4. Pump plunger 5. Control rack 6. Control sleeve 7. Plunger return spring 8. Spring seat 9. Roller tappet 10. Camshaft

RBSI/ASA

Strictly confidential | Department | 04/18/2005 | Filing note | Robert Bosch GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties.

EP-1

Diesel Fuel Injection Pump

Plunger Operation

1. Pump Barrel 2. Inlet Port 3. Pump plunger 4. Helix 5. Control rack Zero Delivery Partial Delivery Maximum Delivery

1. Plunger Helix 2. Upper and Lower Helix 3. Starting Groove 4. Leakage return slot

RBSI/ASA

Strictly confidential | Department | 04/18/2005 | Filing note | Robert Bosch GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties.

EP-1

Diesel Fuel Injection Pump

Plunger Phases

BDC Prestroke Retraction Lift Effective Stroke Residual Stroke Plunger Stroke

Fuel Intake Start of Delivery End of intake

Delivery End of Delivery

Fuel Discharge

TDC

RBSI/ASA

Strictly confidential | Department | 04/18/2005 | Filing note | Robert Bosch GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties.

EP-1

Diesel Fuel Injection Pump

Delivery Valve

1. Delivery valve holder 2. Delivery valve spring 3. Delivery valve 4. Valve seat 5. Valve holder

1. Valve seat 2. Retraction piston 3. Ring-shaped groove 4. Valve stem 5. Vertical slot

What is the purpose of the delivery valves ? 1. To interrupt the high pressure circuit between fuel injection lines and pump plunger 2. To relieve pressure lines and nozzle space which causes the nozzle to close rapidly thus preventing undesirable fuel dribble. What is the purpose of the retraction piston ? To separate the pipe line against element chamber, maintaining certain volume depending on the length of pipe.

RBSI/ASA

Strictly confidential | Department | 04/18/2005 | Filing note | Robert Bosch GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties.

EP-1

Diesel Fuel Injection Pump

RDV Valve

What is the purpose of the RDV valve ? 1. Faster peak pressure and filling of high pressure pipe, opened through bore. 2. Maintains feed pressure of 3-3.5 bar in the element chamber and pipes when engine is not running.

RBSI/ASA

Strictly confidential | Department | 04/18/2005 | Filing note | Robert Bosch GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties.

EP-1

Diesel Fuel Injection Pump

GDV Constant Pressure Valve

1. Ball 2. Spring seat 3. Compression spring 4. Filler piece 5. Valve holder 6. Valve element 7. Valve spring

When are these constant pressure valves used ? What are the advantages for this type of valves ?

For high pressure fuel injection pumps which develop Pressures above 800 bar and high speed DI engines. It avoids cavitation in the fuel pressure lines and Improves hydraulic stability.

RBSI/ASA

Strictly confidential | Department | 04/18/2005 | Filing note | Robert Bosch GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties.

EP-1

Diesel Fuel Injection Pump

P Type Pump

How long is the plunger stroke ? 10 mm How high is the peak injection Pressure ? Approximately 800 bars

Delivery valve Fuel gallery Plunger barrel

How is the injection pump lubricated ? From the engine lubrication system How far does the control rod travel ? Approximately 21 mm Where are these pumps fitted ?

Control rod Control sleeve Plunger return spring

Roller tappet

Camshaft Commercial vehicles, stationary engines How is the prestroke adjusted ? Prestroke discs beneath the barrel and valve assembly Cam lobe

RBSI/ASA

Strictly confidential | Department | 04/18/2005 | Filing note | Robert Bosch GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties.

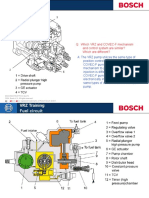

EP-1

Diesel Fuel Injection Pump

MW Type Pump

Delivery valve holder Filler piece Delivery valve spring Plunger flange assy Delivery valve Inlet bore Plunger helix Upper spring seat Control sleeve Plunger Plunger return spring Lower spring seat Roller tappet

Cam lobe

RBSI/ASA

Strictly confidential | Department | 04/18/2005 | Filing note | Robert Bosch GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties.

EP-1

Diesel Fuel Injection Pump

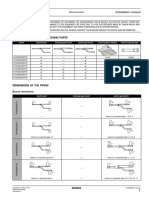

A Type Pump

1. 2. 3. 4. 5. 6. Delivery Valve Pump barrel Pump Plunger Control rack Control sleeve Plunger return spring Adjusting screw Roller tappet Camshaft Cam lobe How is the injection pump lubricated ? From the engine lubrication system How far does the control rack travel ? Approximately 21 mm 7. 8. 9. 10. Where are these pumps fitted ? Commercial vehicles and stationary engines How is the prestroke adjusted ? At the tappet screw How long is the plunger stroke ? 8 mm How high is the peak injection pressure ? Approximately 440 bar

RBSI/ASA

Strictly confidential | Department | 04/18/2005 | Filing note | Robert Bosch GmbH reserves all rights even in the event of industrial property rights. We reserve all rights of disposal such as copying and passing on to third parties.

SHIN DAE-A ENGINEERING

SHIN DAE-A ENGINEERING

SHIN DAE-A ENGINEERING

SHIN DAE-A ENGINEERING

SHIN DAE-A ENGINEERING

SHIN DAE-A ENGINEERING

SHIN DAE-A ENGINEERING

INJECTION PUMP ,

PUMP ** . YANMAR 6RAL, NIIGATA 6L16XC (Coupling) . - . - ENGINE 2CYCLE, 4CYCLE , 4CYCLE ENGINE INJECTION PUMP . . () PUMP TEST . , . (! TEST .) ENGINE , 6 , 8 (PUMP ) 1 - 5 - 3 - 6 - 2 - 4 1 - 4 - 2 - 6 - 3 - 5, 1 - 3 - 5 - 6 - 4 - 2, 1 - 2 - 7 - 3 - 4 - 5 - 6 - 8 1 - 8 - 4 - 3 - 6 - 5 - 7 - 2 ~ .

1 6, 8 (FLYWHEEL ) 1 1 1 , (4CYCLE 1 - 5 - 3 - 6 - 2 - 4 , 1, 5, 3 / 6, 2, 4 1 6

, 6 (CYLINDER) (ROCKER ARM) ) INJECTION 1 .( .) . (FUEL TIMING). , (Main plate), , . ) YANMAR 6RAL -18 ~ 20, NIIGATA 6L16XC -19 ~ 21 .

FLYWHEEL , ( PLUNGER .) . , .

Das könnte Ihnen auch gefallen

- Fuel Injection Pumps, In-Line (005-012) : General Information Preparatory Steps Remove Install Finishing Steps PrimeDokument19 SeitenFuel Injection Pumps, In-Line (005-012) : General Information Preparatory Steps Remove Install Finishing Steps PrimePanagiotis Panagos100% (2)

- Zexel Rhd6 & Rhd10 Service Manual GovernorDokument0 SeitenZexel Rhd6 & Rhd10 Service Manual GovernorAbsar Mamun83% (6)

- Bosch MW ManualDokument59 SeitenBosch MW Manualsteynhen100% (7)

- Fuel PumpsDokument8 SeitenFuel Pumpskarthick_sailor100% (5)

- Inline Fuel Injection PumpsDokument16 SeitenInline Fuel Injection Pumpsdivyanshpancholi100% (2)

- ZEXEL NozzlesDokument24 SeitenZEXEL NozzlesBogdanNoch keine Bewertungen

- Part Description DaihatsuDokument147 SeitenPart Description Daihatsuxxxvvvyyywww100% (5)

- Man B&W L60MCCDokument379 SeitenMan B&W L60MCCTHARAKA100% (3)

- Bosch Injector Part CatalogDokument36 SeitenBosch Injector Part Catalog金盧德100% (1)

- Zexel Calib PDFDokument11 SeitenZexel Calib PDFduongbk24 luu quang duong100% (1)

- Injection Pump R&RDokument17 SeitenInjection Pump R&RMahdi Besbes100% (2)

- Bosch Nozzle & Injectors Cross References PDF - ListDokument11 SeitenBosch Nozzle & Injectors Cross References PDF - Listviemey1952100% (3)

- Man B W L32 40Dokument321 SeitenMan B W L32 40Aleksanrd Mihailov100% (1)

- Fuel Injection PumpDokument8 SeitenFuel Injection PumpSai Indrakaran Reddy Cherabuddi100% (1)

- 4BD1 Workshop Manual PDFDokument174 Seiten4BD1 Workshop Manual PDFVươngNoch keine Bewertungen

- Heavy Duty FIRAD CatalogueDokument55 SeitenHeavy Duty FIRAD CatalogueRoberto ParisiNoch keine Bewertungen

- Bosch Pump Rotari PDFDokument41 SeitenBosch Pump Rotari PDFDiat BenhillNoch keine Bewertungen

- Inspection and Requalification of Flywheels Before Remounting - 09197Dokument5 SeitenInspection and Requalification of Flywheels Before Remounting - 09197Mark ChapmanNoch keine Bewertungen

- Fuel Injection Pump #73112988Dokument144 SeitenFuel Injection Pump #73112988rjcp0194% (17)

- Yanmar 6KFLDokument124 SeitenYanmar 6KFLIrwansyah Harahap100% (2)

- Jinjiang Junri Machinery Co - LTD Develop and Design Marine NozzleDokument17 SeitenJinjiang Junri Machinery Co - LTD Develop and Design Marine Nozzle1070242585100% (3)

- Operational Manual DaihatsuDokument112 SeitenOperational Manual Daihatsuseltonjapao100% (3)

- Governor Adjust Idle SpeedDokument6 SeitenGovernor Adjust Idle SpeeddarioNoch keine Bewertungen

- Gov Mec - WSM - 0001158 - 01Dokument36 SeitenGov Mec - WSM - 0001158 - 01ARY TOGINHO100% (7)

- Ue60ls IiDokument5 SeitenUe60ls IiHaziq IsmailNoch keine Bewertungen

- ТНВД 4D88E YANMMARDokument58 SeitenТНВД 4D88E YANMMARАлексей100% (2)

- lt1000d6 PDFDokument3 Seitenlt1000d6 PDFJo Ferry0% (1)

- L35MC MK6Dokument161 SeitenL35MC MK6chuan ding100% (1)

- CR Presentation PDFDokument100 SeitenCR Presentation PDFPolStone100% (1)

- 2008 Robert Bosch VE-type Injection PumpDokument15 Seiten2008 Robert Bosch VE-type Injection PumpBrian Hammer50% (4)

- Bosch Pe Injection PumpDokument59 SeitenBosch Pe Injection PumpDavies Emmanuel100% (1)

- Delphi NozzlesDokument16 SeitenDelphi Nozzlesanshel100% (1)

- Modifikacii HP 3Dokument5 SeitenModifikacii HP 3pankituna5487Noch keine Bewertungen

- Firad Nozzle Catalogue 1Dokument52 SeitenFirad Nozzle Catalogue 1davide50% (2)

- Stanadyne Nozzle and Holders Cross ReferenceDokument59 SeitenStanadyne Nozzle and Holders Cross ReferenceDavid Lincoln75% (4)

- Diesel BasicDokument44 SeitenDiesel BasicQuangvu HoangNoch keine Bewertungen

- Bosch Ve 0460424060 DespieceDokument5 SeitenBosch Ve 0460424060 DespieceMas Inyeccion ElectronicaNoch keine Bewertungen

- Denso Type CR Injector ShimsDokument11 SeitenDenso Type CR Injector ShimsCostinDodenech100% (2)

- RLD J Co RM Ee13e-11141Dokument99 SeitenRLD J Co RM Ee13e-11141Luis Enrique Ñaupari Villarruel100% (3)

- AE Yanmar Diesel Engine 3 6KDLDokument56 SeitenAE Yanmar Diesel Engine 3 6KDLmedelin spot100% (1)

- Yanmar ManualDokument56 SeitenYanmar ManualScott Erik Chisling100% (1)

- Dpa Pump Delphi PDFDokument127 SeitenDpa Pump Delphi PDFasadiqbalansari100% (8)

- Pe and Tics Type Injection Pump Connector Part Numbers For North AmericaDokument9 SeitenPe and Tics Type Injection Pump Connector Part Numbers For North AmericaSubhojit Samonta100% (1)

- 001-04 Merlin Equipment and Accessories Catalogue 0810 - On Web 0211Dokument173 Seiten001-04 Merlin Equipment and Accessories Catalogue 0810 - On Web 0211kampeeNoch keine Bewertungen

- PumpDokument24 SeitenPumpفتحى محسوبNoch keine Bewertungen

- ECOTRONS Turbo VZ21 Technical SpeclDokument16 SeitenECOTRONS Turbo VZ21 Technical SpeclMauricio López AyalaNoch keine Bewertungen

- TVS Apache RTR 180 Service ManualDokument25 SeitenTVS Apache RTR 180 Service ManualSandino JoseNoch keine Bewertungen

- Bosch Fuel - TechDokument3 SeitenBosch Fuel - TechMoaed KanbarNoch keine Bewertungen

- Performer X Turbocharging System For 1996-2000 Honda Civic D16Y8 Catalog #1500 Installation InstructionsDokument14 SeitenPerformer X Turbocharging System For 1996-2000 Honda Civic D16Y8 Catalog #1500 Installation Instructionsdiaz_almarazNoch keine Bewertungen

- Bosch Diesel Emissions InformationDokument28 SeitenBosch Diesel Emissions InformationBarcanescu ConstantinNoch keine Bewertungen

- Q: Which VRZ and COVEC-F Mechanism and Control System Are Similar? Which Are Different?Dokument37 SeitenQ: Which VRZ and COVEC-F Mechanism and Control System Are Similar? Which Are Different?Cabral RANoch keine Bewertungen

- Busch R 5 0160 0250 0400 0502 0630 B MRDokument32 SeitenBusch R 5 0160 0250 0400 0502 0630 B MRgoran100% (1)

- SKF Epb Pump en MMDokument4 SeitenSKF Epb Pump en MMEbied Yousif AlyNoch keine Bewertungen

- Pompe EssenceDokument24 SeitenPompe Essencedenys92500Noch keine Bewertungen

- Boiler Feed PumpDokument88 SeitenBoiler Feed PumpVivek Tiwari100% (8)

- 1812 e Vtbs P 01 019 en Voith Turbo Bhs Turbo Gear UnitsDokument20 Seiten1812 e Vtbs P 01 019 en Voith Turbo Bhs Turbo Gear Units0506780% (1)

- Hydraulic Proportional Servo TechnologiesDokument37 SeitenHydraulic Proportional Servo Technologiescristi_amaNoch keine Bewertungen

- EHVSDokument24 SeitenEHVSCochintu RaduNoch keine Bewertungen

- Ehvs PDFDokument24 SeitenEhvs PDFantoniomecptNoch keine Bewertungen

- Gear Pumps: Spare Parts, Rate Increase, Overhauling, RepairDokument2 SeitenGear Pumps: Spare Parts, Rate Increase, Overhauling, RepairAngel GutierrezNoch keine Bewertungen

- JsmeaDokument24 SeitenJsmea송성훈Noch keine Bewertungen

- PART 1 Classification and SurveysDokument413 SeitenPART 1 Classification and Surveys송성훈100% (1)

- Annex I Port State Inspection Check List: Section A Initial Control Ship'S DetailsDokument7 SeitenAnnex I Port State Inspection Check List: Section A Initial Control Ship'S Details송성훈Noch keine Bewertungen

- PSC Pocket ChecklistDokument16 SeitenPSC Pocket Checklistparamjyot_sabharwalNoch keine Bewertungen

- Wellhead Completion Equipments 1689794492Dokument13 SeitenWellhead Completion Equipments 1689794492Saeed AbdNoch keine Bewertungen

- Prospekt - SCROLL - ENG RENNERDokument8 SeitenProspekt - SCROLL - ENG RENNERAriantoNoch keine Bewertungen

- Viessmann Commercial Vitogas 050-RS Boiler BrochureDokument2 SeitenViessmann Commercial Vitogas 050-RS Boiler Brochuree-ComfortUSANoch keine Bewertungen

- Problem Set - Thermodynamics & ICEDokument2 SeitenProblem Set - Thermodynamics & ICEBea Therese RadubanNoch keine Bewertungen

- Chapter 3 Gas Turbine: 3.1 Brayton CycleDokument10 SeitenChapter 3 Gas Turbine: 3.1 Brayton CycleBryan AveigaNoch keine Bewertungen

- Datos Oreda Modos de Falla Parte MantenibleDokument135 SeitenDatos Oreda Modos de Falla Parte MantenibleCarlos Jose Sibaja Cardozo100% (1)

- Fundamentals of Microgrid Jang JangDokument25 SeitenFundamentals of Microgrid Jang JangClement RaphaelNoch keine Bewertungen

- SMR For Fuel Cell Grade HydrogenDokument6 SeitenSMR For Fuel Cell Grade HydrogenDan MatNoch keine Bewertungen

- 10-I C Engines PPT PDFDokument67 Seiten10-I C Engines PPT PDFS.m. ChandrashekarNoch keine Bewertungen

- 3827-E10-062 - Two Position Valve - DDokument4 Seiten3827-E10-062 - Two Position Valve - DMohamed Elsaid El ShallNoch keine Bewertungen

- Duflo PompDokument2 SeitenDuflo Pomphufuents-1Noch keine Bewertungen

- MWP3 Fire Water Network SketckDokument3 SeitenMWP3 Fire Water Network SketckYaser AhmadNoch keine Bewertungen

- Experiment No 08Dokument4 SeitenExperiment No 08Muhammad Zohaib ShahidNoch keine Bewertungen

- 18 Brayton Cycle-Jet EngineDokument14 Seiten18 Brayton Cycle-Jet Engineinam vfNoch keine Bewertungen

- Variable Geometry Turbine Technology For Marine Gas Turbines-Springer (2022)Dokument227 SeitenVariable Geometry Turbine Technology For Marine Gas Turbines-Springer (2022)miladNoch keine Bewertungen

- HIS KIT Includes THE Following Parts: Installation ManualDokument4 SeitenHIS KIT Includes THE Following Parts: Installation ManualOPER123Noch keine Bewertungen

- COPs OF R718 IN COMPARISIONDokument7 SeitenCOPs OF R718 IN COMPARISIONThanhNoch keine Bewertungen

- Operation Manual: ABB TurbochargingDokument170 SeitenOperation Manual: ABB TurbochargingDodi SuhendraNoch keine Bewertungen

- Assignment IIDokument3 SeitenAssignment IIPawan SubediNoch keine Bewertungen

- 2016-Me-58 Lab ReportDokument8 Seiten2016-Me-58 Lab Reporthassaan qayyumNoch keine Bewertungen

- Factsheet Slinky Installation V5Dokument4 SeitenFactsheet Slinky Installation V5pusicantonijeNoch keine Bewertungen

- Date: 14.10.22: Revised OnDokument1 SeiteDate: 14.10.22: Revised Onvipul gandhiNoch keine Bewertungen

- Data Sheet EjectorDokument4 SeitenData Sheet EjectorGunturMudaAliAkbarNoch keine Bewertungen

- Power Stations and SubstationsDokument12 SeitenPower Stations and SubstationsrakibNoch keine Bewertungen

- ASC Presentation PDFDokument89 SeitenASC Presentation PDFAhmadHussain09Noch keine Bewertungen

- Project Id Project Ref No Project TitleDokument1 SeiteProject Id Project Ref No Project TitleSagar JadhavNoch keine Bewertungen

- Steam Injectors ARI CONA 651Dokument2 SeitenSteam Injectors ARI CONA 651CalinNoch keine Bewertungen

- Mitsui Wall Type Series On-Off MVE - Technical SpecificationDokument1 SeiteMitsui Wall Type Series On-Off MVE - Technical SpecificationBruno Faria CotaNoch keine Bewertungen

- Windpods BrochureDokument8 SeitenWindpods BrochurelhotapNoch keine Bewertungen

- Two Lobe vs. Three Lobe-Tcm91-124599Dokument3 SeitenTwo Lobe vs. Three Lobe-Tcm91-124599gopalkrishnaNoch keine Bewertungen