Beruflich Dokumente

Kultur Dokumente

Mechatronics and Automotive Systems Design

Hochgeladen von

scientificstuffOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Mechatronics and Automotive Systems Design

Hochgeladen von

scientificstuffCopyright:

Verfügbare Formate

Mechatronics and automotive systems design

Peter James Electronics and Software, Prodrive Ltd, Kenilworth, UK E-mail: pjames@prodrive.com

Abstract As the complexity of automotive vehicles increases, so does the need for high calibre, multidisciplined engineers. This paper provides a discussion into the type of control systems found in modern automotive vehicles and the skills required by the engineers working in this mechatronic system environment. Keywords automotive systems; mechatronics

The motor-car has evolved over the years and most cars on the road today incorporate automatic computer control of the vehicle mechanics.1 This type of system is a good example of a mechatronic system2 and can be noted by the complexity of operation, consisting of a large number of sensors and actuators under computer software control. Such an arrangement has a very pronounced effect on the vehicle dynamics. The purpose of adding this complexity to the design and manufacture of the vehicle is to improve the vehicle performance, with the improvements considered by the end-user requirements. Additionally, depending on the system requirements, these may be considered to be simple, but still involve overcoming mechanical, electrical and control problems, or termed safety critical, and so are required to have redundancy and advanced failure mode analysis built-in. The move towards increased electronics within the automotive system overall is a response to legislative requirements such as emissions, and more stringent safety demands (ABS, ESP, airbags, etc.), as well as demands for new features (heated seats, climate control, etc.). This results in a need for active or intelligent control of vehicle functions. Advances in automotive control systems increase the need for highly skilled engineers capable of designing these control systems. These advances in turn led to an increase in the requirement for engineers to be able to use modern rapid prototyping tools to reduce the time taken to model and develop the control systems. With the continuous increase in the complexity of automotive vehicles, the need for high-calibre, multi-disciplined engineers needs to be met with suitable education. This paper describes the type of control systems found on modern automotive vehicles and the problems faced by engineers developing the embedded control systems. The paper then describes the development process, and discusses the skills required by the engineers and the similarity of these skills to those of the mechatronic engineer. The paper concludes with suggestions for the education that these engineers need to ensure they are best educated for automotive control system engineering.

International Journal of Electrical Engineering Education 41/4

308

P. James

Control systems in vehicle

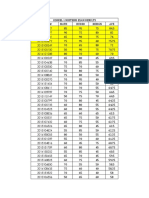

0 1980

10

15

20

1985

1990

1995 Years

2000

2005

2010

Fig. 1

Increase in embedded control systems.

Automotive electronics The use of electronics in automotive systems has changed radically over the last 25 years.3 The electronics are now required to implement a range of operations, including automatic control system functions. Figure 1 (taken from Ref. [4]) shows the dramatic increase in the number of control systems within the automotive system, with each control system required to operate to a strict specication and to operate robustly in a demanding application. The early electrical system arrangement that existed in the automobile consisted of basic wiring technologies that supplied power to various vehicle systems. The electrical system on the vehicle was only made up of switches, wires, relays and controlled motors or lamps. Modern vehicles however, incorporate a range of sensors and actuators that have a different set of requirements. Alongside the high-power electric circuits controlling for example heated windows or heated seats, there are very low level, high bandwidth signals for data communications such as data from knock sensors or CAN5 data. The modern automotive electrical/electronic engineer now has to deal with a wide variety of electronic system designs and has to develop vehicle electrical systems to strict specications. These specications are mainly concerned with the environmental properties of the electrical system. For example, they dene the operating temperature range, radiated EMI (electromagnetic interference)6 emissions, and EMI susceptibility. Legislation has dened a standard to which vehicle electronics are designed, but vehicle manufacturers also utilise their own set of specications, most of which are very much more stringent than are required by the legislation. For example, the European standard for susceptibility for vehicle-mounted electronics7 is 30 V per m, but many vehicle manufacturers dene their limits at over 100 V per m.

International Journal of Electrical Engineering Education 41/4

Mechatronics and automotive systems design

309

Cost aspects are also a key concern in the design decisions undertaken. In order to reduce the cost of these systems, many are now integrated with each other, sharing input and output signals. As an example, the Electronic Stability Program (ESP)8 system is integrated with the anti-lock braking system (ABS). This however increases the complexity of the control system design and further relies on good design practice, with designers using simulation techniques to validate ideas prior to prototyping and manufacture. The simulation models need to model all eventualities and perform extensive Failure Mode Analysis (FMA). Vehicle manufactures also have the need to increase the desirability of their vehicles and to achieve this, they have to increase the features of their vehicles whilst maintaining compliance with legislation . . . all this is required with no extra or even reducing the cost of the vehicle. The electrical system on a modern vehicle is highly integrated with the mechanical system and much of the electronics on a vehicle control mechanical parts. The simplest example of this is probably the electrically operated window. Although on the surface an electric window consists of just a switch and motor, safety and security requirements make this system much more complex. The window, for example, has to be able to stop moving if an arm or nger is trapped in the window and yet still close or open in the winter when the glass might be frozen and the motor has to provide a large power to move the window glass. It also should close if the user locks the vehicle via central locking, thus it needs to be integrated with the central locking system. Other systems are very much more complicated, e.g. an electronically controlled differential (Fig. 2) will have many sensors and actuate (either directly via an electric motor or indirectly via a hydraulic system) a clutch which controls the amount of slip across the differential. The control for this system not only has to take inputs from the driver and status of the vehicle, but also has to operate knowing the status

Propshaft Crown Wheel and Pinion Differential Active Clutch Pack

Rear Differential

Fig. 2

Electronically controlled differential.

International Journal of Electrical Engineering Education 41/4

310

P. James

of the mechanical parts of the differential. For example, is the clutch overheating? The challenge for the designer of such a system is to combine skills in the operation and limitations of mechanical systems, in electronic design, and in control theory to provide e.g. the clutch or hydraulic actuator; suitable drive and input signal conditioning electronics; and a control algorithm. These mechatronic systems are becoming increasingly important to the vehicle manufacturer and are changing the way in which vehicles are designed. Many of the compromises that purely mechanical systems have can be overcome using mechatronic design approach, and this provides the enhancements many of the vehicle manufacturers require. This in turn means that the role of the automotive electrical engineer is changing. Twenty years ago, they could have been a pure electrical engineer, 10 years ago they needed electronics capabilities, now, and increasingly so in the future, they will need to have an understanding of mechanical systems and the control of such systems. Vehicle enhancements that are currently being developed and involve huge amount of mechatronics include, electronically controlled suspension using magnetically rheological uids, stability systems using active differentials, and dual clutch transmissions. Modern engineering methods The types of systems encountered in an automotive environment are complex and require long development times. In addition to providing the control, systems that are used on vehicles have to comply with legislation and safety requirements dened by both the vehicle manufacturers and the countries in which the vehicle is sold. These requirements can be electronic, mechanical and functional. Functional requirements can take many forms and are often dened to ensure a safety standard. Active control systems must fail in a dened and safe way. In the example of an active limited slip differential, if the control system that is controlling the clutch in the differential should fail, the differential should release its clutches and the system should act like a conventional non-limited slip differential. Other functional requirements may involve other vehicle systems. For example any active control system that is controlling a limited slip differential should release the clutches in the differential if the ABS (anti-lock braking system) is activated, and for this action there are dened response times that have to be met. Many vehicle manufacturers are looking at rapid prototyping to reduce the development time and therefore cost of designing such systems. Rapid prototyping involves designing a control system using a CAD package that allows the user to simulate the various elements of the control system. The most widely used CAD package that is used is from The Mathworks9 is Simulink,10 part of the MATLAB suite of development tools. Simulink allows the user to draw the control system and simulate the control system before the hardware is created and control algorithm coded. This visual representation of the control algorithm is called the control model. Models can be created to represent the mechanical and vehicle elements of the control system and these too can be simulated. These are the plant models. When the control algorithm is thought to be correct the control model is then auto coded

International Journal of Electrical Engineering Education 41/4

Mechatronics and automotive systems design

311

in to C source code. It is then complied in the conventional way and downloaded to an electronic controller. The electronic controller is then connected to the vehicle and the control system tested and calibrated on real world hardware. If changes need to be made to the control model, these can be done using Simulink and, either the model is tested by simulation, or the control model is auto coded and downloaded once again to the ECU. Depending on the control system and the company, any number of engineers could be working on the project. It is not uncommon for one person to be responsible for delivering the entire control system, and this one person may have to dene the system specication, model and develop the control algorithm, and test the system on the vehicle. This requires a very high calibre of engineer. The role of the mechatronics engineer Automotive manufacturers have in the past employed both mechanical and electronic engineers each with their own well-dened capabilities. These engineers worked together but rarely got involved with each others activities. As described previously in this paper, modern vehicle system requirements increase the need for cross discipline engineers who have an in depth understanding of both mechanical and electronic systems. Engineers will often have to design a control system from a blank piece of paper, specifying both the mechanical and electronic components. They will then have to do the entire computer modelling of the control system and implement it on the vehicle. Pure mechanical engineers usually design the mechanical parts of the control system. But the control system engineer will need a thorough understanding of the mechanical parts so they can be modelled correctly in the control algorithm development. They will also need to be able to design advanced electronic circuits to actuate the new types of actuators currently in development, write control software to control these actuators and have a complete understanding of the mechanical system they are controlling. The automotive control system engineer role is ideally suited to an engineer with mechatronics training. Many of the control engineers working in automotive engineering have their educational background in mechanical engineering and often only specify the requirements of the ECU to be used on a control system. This means that they do not have to design the electronics used. But, when the system is being tested and commissioned the controller needs to also be tested and this is often done in isolation. This task needs an in depth knowledge of electronic principles and again this is something to which a mechatronics engineer would be very well suited. As vehicle control systems become increasingly common, the need for welltrained mechatronic engineers will also increase. Vehicle manufacturers are reducing the size of their work forces and looking at other ways in which they can reduce their costs. Reducing the size of their design teams whilst increasing or not reducing the skills is something they are very keen to do. This makes the prospect of a multi disciplined mechatronics engineer even more interesting, but this puts a lot of responsibility on the mechatronics engineers and these engineers have to have a very high level of skill.

International Journal of Electrical Engineering Education 41/4

312

P. James

Mechatronics in education The mechatronic engineer is an ideal solution to the problem faced by vehicle manufacturers but there are very few engineers of this type available. This is mainly due to a lack of courses and students are not encouraged to move in to this eld. Mechatronics courses need to be marketed in a different way, making them more attractive and, although they are seen to be a difcult course students need to be aware of the rewards and the knowledge that manufacturers have difculty in nding these types of engineers. In automotive engineering, engineers with a mechatronics capability are very highly respected and can command high salaries. For an automotive application, the ideal mechatronics course would encompass mechanical design incorporating hydraulic theory, electronics design incorporating analogue, digital, microprocessor, mixed signal and EMC theory, and a thorough understanding of control theory. Mechatronics is a highly skilled discipline and although the training should involve a high level of theory practical experience is also needed. This practical training is best given through projects where engineers can work together as a team especially with external engineers. Many manufacturers have projects that would be ideal for mechatronic students and would give the students a valuable experience of working on real life control systems. These projects can be allocated to students similarly to in industry, providing the students with the experience of working to deadlines and with project management. Conclusions This paper has described various control systems which are currently available or in development on automotive vehicles and shown these control systems to be true mechatronic systems. It has described the modern design methods that vehicle manufacturers use to develop these control systems and the ways in which the design engineers have to work to carry out this development. From this, the need for highly skilled mechatronic engineers is realised. This paper concludes by describing the training that these mechatronic engineers require from educational establishments. References

1 U. Kiencke and L. Nielsen, Automotive Control Systems: For Engine, Driveline and Vehicle (Springer, New York, 2004). 2 D. Bradley, D. Dawson, D. Seward and S. Burge, Mechatronics and the Design of Intelligent Machines and Systems (Stanley Thornes, Cheltenham, 2000). 3 AutoTechnology, December 2002. 4 AutoTechnology, December 2002. 5 CAN, Controller Area Network for vehicle data transfer, Robert Bosch GmbH and Intel Inc. USA. 6 EMI, BS EN 50082-2: 1995. 7 European standard for susceptibility for vehicle-mounted electronics, BS EN 50082-2: 1995. 8 ESP, Electronic Stability Program, Robert Bosch GmbH. 9 Matlab, Version 6, The Mathworks Inc., USA. 10 Simulink, Version 4, The Mathworks Inc., USA.

International Journal of Electrical Engineering Education 41/4

Das könnte Ihnen auch gefallen

- Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid DriveVon EverandBosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid DriveRobert Bosch GmbHNoch keine Bewertungen

- P1301 1306Dokument6 SeitenP1301 1306Surendar AWESOMENoch keine Bewertungen

- Automotive ElectronicsDokument4 SeitenAutomotive ElectronicsAnonymous E4Rbo2s100% (1)

- Electric Drives and Electromechanical Systems: Applications and ControlVon EverandElectric Drives and Electromechanical Systems: Applications and ControlNoch keine Bewertungen

- Intro to Control Systems - Components, Applications, and ExamplesDokument4 SeitenIntro to Control Systems - Components, Applications, and ExamplesShiva HarshNoch keine Bewertungen

- Introduction to Hybrid Vehicle System Modeling and ControlVon EverandIntroduction to Hybrid Vehicle System Modeling and ControlBewertung: 4 von 5 Sternen4/5 (1)

- Fault Tolerance in Automotive Systems - ReportDokument10 SeitenFault Tolerance in Automotive Systems - ReportJagat RathNoch keine Bewertungen

- Group5 - Electronics in Automobile Industry ReportDokument10 SeitenGroup5 - Electronics in Automobile Industry ReportJidnesha KharkarNoch keine Bewertungen

- Seminar Report On Embedded System in AutomobilesDokument21 SeitenSeminar Report On Embedded System in AutomobilesJobin Philip Varghese71% (7)

- Design and Development of Automatic Pneumatic Bumper SystemDokument6 SeitenDesign and Development of Automatic Pneumatic Bumper SystemSahaya robin singh MNoch keine Bewertungen

- Mechatronics 2003Dokument6 SeitenMechatronics 2003SashankSashankNoch keine Bewertungen

- HOW WILL EVs IMPACT COMMERCIAL TRUCK BRAKING SYSTEMSDokument3 SeitenHOW WILL EVs IMPACT COMMERCIAL TRUCK BRAKING SYSTEMS吳坤益Noch keine Bewertungen

- X-by-Wire: Fred SeidelDokument9 SeitenX-by-Wire: Fred SeidelHồng TháiNoch keine Bewertungen

- Controle Digital para Aviões Comparação Analógico Excelente Fala Também Sobre Monitoramento Texto TraduzidoDokument20 SeitenControle Digital para Aviões Comparação Analógico Excelente Fala Também Sobre Monitoramento Texto TraduzidoGardenia AndradeNoch keine Bewertungen

- Chapter 1Dokument18 SeitenChapter 1safal shaNoch keine Bewertungen

- Iceeit 2021Dokument11 SeitenIceeit 2021moh hadiNoch keine Bewertungen

- Embedded Control Systems Design/AutomotiveDokument7 SeitenEmbedded Control Systems Design/AutomotiveJnsk SrinuNoch keine Bewertungen

- Title:: Design and Manufacturing of Future Electrical Steering SystemDokument1 SeiteTitle:: Design and Manufacturing of Future Electrical Steering SystemSp PatelNoch keine Bewertungen

- Cruise Control: Vehicle Speed Control: Principles of Operation and ImplementationDokument22 SeitenCruise Control: Vehicle Speed Control: Principles of Operation and ImplementationJonelou CusipagNoch keine Bewertungen

- Managing Electrical Complexity With A Platform Level Approach and Systems EngineeringDokument9 SeitenManaging Electrical Complexity With A Platform Level Approach and Systems EngineeringMauroNoch keine Bewertungen

- Seminar ReptDokument14 SeitenSeminar Reptmanishdahiya94Noch keine Bewertungen

- Mechatronics Notes Unit1Dokument4 SeitenMechatronics Notes Unit1Varun BanurNoch keine Bewertungen

- Design ConsiderationDokument28 SeitenDesign ConsiderationKarthik RamNoch keine Bewertungen

- Electrical Motor Control TrainingDokument4 SeitenElectrical Motor Control TrainingdenramrNoch keine Bewertungen

- Presented by M.Shino Prathibha Iii-It V.Priyanga Iii-ItDokument17 SeitenPresented by M.Shino Prathibha Iii-It V.Priyanga Iii-ItkalanchiyaraniNoch keine Bewertungen

- Control Systems Project Report (180501008) (180501016) (180501018) (180501020)Dokument19 SeitenControl Systems Project Report (180501008) (180501016) (180501018) (180501020)Shahzaib Anwar OffNoch keine Bewertungen

- Automotive Engine ElectronicsDokument4 SeitenAutomotive Engine Electronicsmachine tunisieNoch keine Bewertungen

- AUTOMOTIVE MECHATRONICsDokument9 SeitenAUTOMOTIVE MECHATRONICsshubham goleNoch keine Bewertungen

- ELK 1109 22 Manuscript 2Dokument16 SeitenELK 1109 22 Manuscript 2Neshvar DmitriNoch keine Bewertungen

- Electronic Control UnitDokument4 SeitenElectronic Control UnitBhaswati MajumdarNoch keine Bewertungen

- Electro-Hydraulic Brake (EHB) System - Seminar Reports - PPT - PDF - DOC - Presentation - Free Download For Mechanical EngineeringDokument3 SeitenElectro-Hydraulic Brake (EHB) System - Seminar Reports - PPT - PDF - DOC - Presentation - Free Download For Mechanical EngineeringAnup PatilNoch keine Bewertungen

- Introduction To X-by-WireDokument15 SeitenIntroduction To X-by-Wiremanishdahiya94Noch keine Bewertungen

- Meeting Increased Data Security DemandsDokument8 SeitenMeeting Increased Data Security DemandsAakash HoskotiNoch keine Bewertungen

- Automation Solution Guide 2008Dokument310 SeitenAutomation Solution Guide 2008cristipocNoch keine Bewertungen

- Automation Solution Guide 2008Dokument312 SeitenAutomation Solution Guide 2008Freddy SuhartonoNoch keine Bewertungen

- AOTODokument4 SeitenAOTOahim mahalasNoch keine Bewertungen

- ASV Ieee Micro03 2Dokument12 SeitenASV Ieee Micro03 2vidya gubbalaNoch keine Bewertungen

- Automatic Toll Collection Using MicrocontrollerDokument13 SeitenAutomatic Toll Collection Using MicrocontrollerShalabh AgarwalNoch keine Bewertungen

- Case Study of Engine ControlDokument4 SeitenCase Study of Engine ControlNarean SharmaNoch keine Bewertungen

- Automotive Electronics - Top 5 Tech Trends of Tomorrow's Smart CarsDokument5 SeitenAutomotive Electronics - Top 5 Tech Trends of Tomorrow's Smart CarsKusumavathi KNoch keine Bewertungen

- ImplementationDokument19 SeitenImplementationkeerthipati vinaykumarNoch keine Bewertungen

- AutotronicsDokument100 SeitenAutotronicsWaleed B MNoch keine Bewertungen

- BL DC Motor ControlDokument11 SeitenBL DC Motor ControlDonz RahmandaniNoch keine Bewertungen

- Automation ManualDokument250 SeitenAutomation ManualDev SwainNoch keine Bewertungen

- Improving VehicleDokument25 SeitenImproving VehicleArun Kumar0% (1)

- EMC Modeling of Automotive Electrical System Reduces CostsDokument23 SeitenEMC Modeling of Automotive Electrical System Reduces CostsU Soe Min ThuNoch keine Bewertungen

- Servicing Engine Electrical System of Toyota 4KDokument52 SeitenServicing Engine Electrical System of Toyota 4KYesuf DawudNoch keine Bewertungen

- Control System Integration for Automating an Electric Golf CartDokument11 SeitenControl System Integration for Automating an Electric Golf CartHeartking BibhuNoch keine Bewertungen

- Embedded System in AutomobilesDokument42 SeitenEmbedded System in AutomobilesManpreet SinghNoch keine Bewertungen

- Intelligent Motor ManagementDokument3 SeitenIntelligent Motor ManagementjunfaNoch keine Bewertungen

- Automation FileDokument56 SeitenAutomation FileLoveable ShubhamNoch keine Bewertungen

- Automotive Microelectronics - 2001 PDFDokument93 SeitenAutomotive Microelectronics - 2001 PDFjovopavlovic100% (3)

- Embedded System Applications in Automobiles ReportDokument30 SeitenEmbedded System Applications in Automobiles Reportkurupathi100% (1)

- DRIVE-BY-WIRE SYSTEMS PRESENTATION BY KOTA ADITYA SRIKARDokument30 SeitenDRIVE-BY-WIRE SYSTEMS PRESENTATION BY KOTA ADITYA SRIKARADITYA SRIKAR KOTANoch keine Bewertungen

- Automotive MechatronicsDokument9 SeitenAutomotive MechatronicsLau YeowhongNoch keine Bewertungen

- ECU Measurement Calibration and Diagnostics BrochureDokument44 SeitenECU Measurement Calibration and Diagnostics Brochureemmaclick100% (1)

- ABSTRACT: - : MechatronicsDokument33 SeitenABSTRACT: - : MechatronicsAparajita ThadaniNoch keine Bewertungen

- Model-Based Testing of Automotive Systems: Piketec GMBH, GermanyDokument9 SeitenModel-Based Testing of Automotive Systems: Piketec GMBH, GermanyGururaj BandaNoch keine Bewertungen

- Project Report On: "Engine Control UnitDokument9 SeitenProject Report On: "Engine Control UnitL13 Krushna NemadeNoch keine Bewertungen

- Variations and Clearance Computation in Overconstrained MechanismsDokument11 SeitenVariations and Clearance Computation in Overconstrained MechanismsscientificstuffNoch keine Bewertungen

- MBSE Using SysML Part 1 PeakDokument107 SeitenMBSE Using SysML Part 1 PeakscientificstuffNoch keine Bewertungen

- ModelicaML Getting Started v02Dokument27 SeitenModelicaML Getting Started v02scientificstuffNoch keine Bewertungen

- ModelicaML Getting Started v02Dokument27 SeitenModelicaML Getting Started v02scientificstuffNoch keine Bewertungen

- 12 Animation Q1 AnswerDokument38 Seiten12 Animation Q1 AnswerBilly Joe TanNoch keine Bewertungen

- Curtis CatalogDokument9 SeitenCurtis CatalogtharngalNoch keine Bewertungen

- Notes Measures of Variation Range and Interquartile RangeDokument11 SeitenNotes Measures of Variation Range and Interquartile RangedburrisNoch keine Bewertungen

- Pneumatic Tyres: CMR Engineering CollegeDokument17 SeitenPneumatic Tyres: CMR Engineering CollegeHemanth Rama Krishna YernagulaNoch keine Bewertungen

- Midterm Exam Result Ce199-1l 2Q1920Dokument3 SeitenMidterm Exam Result Ce199-1l 2Q1920RA CarpioNoch keine Bewertungen

- Dynamic model of manipulatorsDokument20 SeitenDynamic model of manipulatorsbalkyderNoch keine Bewertungen

- Windows Mbox Viewer User Manual 1.0.3.4Dokument33 SeitenWindows Mbox Viewer User Manual 1.0.3.4Billy NoelNoch keine Bewertungen

- CBSE Class 5 Mathematics Sample Paper Set NDokument4 SeitenCBSE Class 5 Mathematics Sample Paper Set NRamanjeet KaurNoch keine Bewertungen

- Mathematics of Finance: Simple and Compound Interest FormulasDokument11 SeitenMathematics of Finance: Simple and Compound Interest FormulasAshekin MahadiNoch keine Bewertungen

- PTP - Level MethodsDokument23 SeitenPTP - Level Methodssasikiran mNoch keine Bewertungen

- VRV A 12 PDFDokument1 SeiteVRV A 12 PDFMoe Thiri ZunNoch keine Bewertungen

- Product Presentation Nova Blood Gas AnalyzerDokument38 SeitenProduct Presentation Nova Blood Gas Analyzerlaboratorium rsdmadani100% (1)

- Astm D5501Dokument3 SeitenAstm D5501mhmdgalalNoch keine Bewertungen

- Lsantos - Reflecting Writing For Optimization ProjectDokument2 SeitenLsantos - Reflecting Writing For Optimization Projectapi-341418797Noch keine Bewertungen

- Sem 2Dokument128 SeitenSem 2Agustin A.Noch keine Bewertungen

- Pragathi Full Test-6, Paper-2 (Qp+Key) - 18.07.22Dokument14 SeitenPragathi Full Test-6, Paper-2 (Qp+Key) - 18.07.22Ganesan MuthukrishnanNoch keine Bewertungen

- BetaDokument16 SeitenBetaAkshita Saxena100% (2)

- c1Dokument19 Seitenc1vgnagaNoch keine Bewertungen

- Power Theft Identification Using GSM TechnologyDokument3 SeitenPower Theft Identification Using GSM TechnologyIJORAT100% (1)

- Geophysical Report Megnatic SurveyDokument29 SeitenGeophysical Report Megnatic SurveyShahzad KhanNoch keine Bewertungen

- Tutorial CorelDRAW-X8Dokument10 SeitenTutorial CorelDRAW-X8Ajay BhargavaNoch keine Bewertungen

- Gallium Nitride Materials and Devices IV: Proceedings of SpieDokument16 SeitenGallium Nitride Materials and Devices IV: Proceedings of SpieBatiriMichaelNoch keine Bewertungen

- M6 2020 Binomial Distribution Lecture NotesDokument27 SeitenM6 2020 Binomial Distribution Lecture Notescoyite8695Noch keine Bewertungen

- NEC Article 250Dokument42 SeitenNEC Article 250unknown_3100% (1)

- Rochor Station Pile Design CalculationsDokument15 SeitenRochor Station Pile Design CalculationsDifa LiuNoch keine Bewertungen

- Practice Workbook LR Method For Addition Subtraction PDFDokument4 SeitenPractice Workbook LR Method For Addition Subtraction PDFEsa KhanNoch keine Bewertungen

- Superalloy Brochure PDFDokument16 SeitenSuperalloy Brochure PDFDaren NeradNoch keine Bewertungen

- dp0 PDFDokument4 Seitendp0 PDFSimonNoch keine Bewertungen

- 13 - Wool-And-Coir-Fiber-Reinforced-Gypsum-Ceiling-Tiles-Wit - 2021 - Journal-of-BuilDokument9 Seiten13 - Wool-And-Coir-Fiber-Reinforced-Gypsum-Ceiling-Tiles-Wit - 2021 - Journal-of-BuilJenifer TejadaNoch keine Bewertungen

- Apex Ch10c1 Chassis At2408s Ch04t1002 Om8839ps Tda4605 TV SMDokument61 SeitenApex Ch10c1 Chassis At2408s Ch04t1002 Om8839ps Tda4605 TV SMAlejo Alex CondeNoch keine Bewertungen

- The Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityVon EverandThe Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityBewertung: 4.5 von 5 Sternen4.5/5 (115)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindVon EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNoch keine Bewertungen

- PLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsVon EverandPLC Programming & Implementation: An Introduction to PLC Programming Methods and ApplicationsNoch keine Bewertungen

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationVon EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Dark Aeon: Transhumanism and the War Against HumanityVon EverandDark Aeon: Transhumanism and the War Against HumanityBewertung: 5 von 5 Sternen5/5 (1)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureVon EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureBewertung: 4.5 von 5 Sternen4.5/5 (2)

- In the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkVon EverandIn the Age of AI: How AI and Emerging Technologies Are Disrupting Industries, Lives, and the Future of WorkBewertung: 5 von 5 Sternen5/5 (1)

- Artificial You: AI and the Future of Your MindVon EverandArtificial You: AI and the Future of Your MindBewertung: 4 von 5 Sternen4/5 (3)

- Arduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Von EverandArduino: The complete guide to Arduino for beginners, including projects, tips, tricks, and programming!Bewertung: 4 von 5 Sternen4/5 (3)

- Atlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceVon EverandAtlas of AI: Power, Politics, and the Planetary Costs of Artificial IntelligenceBewertung: 5 von 5 Sternen5/5 (9)

- Artificial Intelligence: From Medieval Robots to Neural NetworksVon EverandArtificial Intelligence: From Medieval Robots to Neural NetworksBewertung: 4 von 5 Sternen4/5 (3)

- Design and Operation of Human Locomotion SystemsVon EverandDesign and Operation of Human Locomotion SystemsMarco CecarelliNoch keine Bewertungen

- Artificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Von EverandArtificial Intelligence: The Complete Beginner’s Guide to the Future of A.I.Bewertung: 4 von 5 Sternen4/5 (5)

- Modeling, Dynamics, and Control of Electrified VehiclesVon EverandModeling, Dynamics, and Control of Electrified VehiclesBewertung: 5 von 5 Sternen5/5 (1)

- Create Profitable Side Hustles with Artificial IntelligenceVon EverandCreate Profitable Side Hustles with Artificial IntelligenceNoch keine Bewertungen

- Collection of Raspberry Pi ProjectsVon EverandCollection of Raspberry Pi ProjectsBewertung: 5 von 5 Sternen5/5 (1)

- Building Server-side and Microservices with Go: Building Modern Backends and Microservices Using Go, Docker and KubernetesVon EverandBuilding Server-side and Microservices with Go: Building Modern Backends and Microservices Using Go, Docker and KubernetesNoch keine Bewertungen

- Visions Of Technology: A Century Of Vital Debate About Machines Systems AVon EverandVisions Of Technology: A Century Of Vital Debate About Machines Systems ABewertung: 4 von 5 Sternen4/5 (9)

- ChatGPT: The Future of Intelligent ConversationVon EverandChatGPT: The Future of Intelligent ConversationBewertung: 3.5 von 5 Sternen3.5/5 (8)

- Comprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessVon EverandComprehensive Guide to Robotic Process Automation (RPA): Tips, Recommendations, and Strategies for SuccessNoch keine Bewertungen

- The Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityVon EverandThe Fourth Age: Smart Robots, Conscious Computers, and the Future of HumanityBewertung: 3.5 von 5 Sternen3.5/5 (22)