Beruflich Dokumente

Kultur Dokumente

Tuga Sabtan

Hochgeladen von

Shavick CivilOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Tuga Sabtan

Hochgeladen von

Shavick CivilCopyright:

Verfügbare Formate

International Journal of Earth Sciences and Engineering 59 ISSN 0974-5904, Volume 04, No 06 SPL, October 2011, pp 59-62

Expansive Soil Stabilization Using Marble Dust

Vinay Agrawal Assistant Prof., Structural Engg. Department, MNIT, JAIPUR-302017, agrawal_vinay_2000@yahoo.com Mohit Gupta M.Tech, Structural Engg. Department, MNIT, JAIPUR-302017, mohdadeha@yahoo.co.in Email:

Email:

ABSTRACT: Expansive soil causes serious problem on civil engineering structures due to its tendency of swelling when it is in contact with water and shrinks when they dry out. Soil stabilization using chemical admixtures is the oldest and popular method of ground improvement. In this study, the potential of marble dust (by-product of marble industry) as stabilizing additive to expansive soil is evaluated. The evaluation involves the determination of the swelling potential of expansive soil in its natural state as well as when mixed with varying proportion of marble dust (from 0 to 30%). The marble dust in experimental program is obtained from cutting of Makrana marble. The environmental degradation due to marble mining is much less than the environmental degradation caused by the waste from marble processing plants. Many researchers have reported that marble has very high lime (CaO) content up to 55% by weight. Thus, stabilization characteristics of Makrana marble dust are mainly due to its high lime content. Marble dust finds bulk utilization in roads, embankment and soil treatment for foundation. Particle size distribution, consistency limits, specific gravity, swelling percentage, and rate of swell were determined for the samples. Addition of marble dust decreases liquid limit, plasticity index and shrinkage index, increase plastic limit and shrinkage limit. Also experimental results shows that the swelling percentage decreases and rate of swell increases with increasing percentage of marble dust in expansive soils. Specimens have been cured for 7 and 28 days. The rate of swelling and swelling percentage of the stabilized specimens was affected by curing in a positive direction such that effectiveness of the stabilizer increases.

INTRODUCTION One of the challenges faced by civil engineers is the design of foundation for sites having expansive Soils. Most economical and effective method for stabilizing expansive soils is using admixtures that present change in volume. Many problems arise from the industrial development. One of them is the proper and effective disposal of its waste. Generally, ndustrial waste causes many serious environment problems. So utilization of industrial waste in construction industry is the best way to dispose it. Using industrial waste in construction industry is beneficial in many ways such as disposal of waste, saving biodiversities, increasing soil properties like strength, reduce permeability, etc., preserve the natural soil and making economical structures. Expansive soils contain the clay mineral montinorillonite with claystones, shales, sedimentary and residual soils. Clay exists in the moisture deficient, unsaturated conditions. The expansive nature of the clay is less near the ground surface where the profile is subjected to seasonal and environment changes (Frilund & Rahardjo 1993). There are some visual indications by which expansive soil can identify (Waync et al 1984): (a) soil sticky and soft when contains moisture, but hard like rock when dry, (b) Deep and dry shrinkage cracks occur during dry season, and (c) It damage the surrounding structures due to its expansion/shrinkage. The Swelling potential of the clayey soil mainly depends upon the properties of soil and environmental factors. Some physical factors like initial water content, dry density, amount and type of compaction may also affects the swelling potential of soil (Nelson & Miller 1992). Marble is defined as the metamorphic rock which fully recrystallized and hardened under hydrothermal conditions (Coats 1996). In India, marble is the most preferred stone. Marbles dust produced from cutting and grinding of marble has very fine particle size, nonplastic and almost well grated. The use of traditional techniques to stabilize the soil faces problems like high cost, and/or environment issues. The improvement of soil by marble dust is the alternative solution .The soil stabilized by marble dust can be utilized in the construction of canal lining, pavement structures and foundations. This work aims to reduce the expansion of expansive soils by using marble dust and notice the change in index properties of soil samples with increasing percentage of marble dust.

EXPERIMENTAL STUDY Materials Used Materials used in this study are marble dust, Expansive clay soil and bentonite. The expansive clay soil used in this research was obtained from Bharatpur District, Rajasthan, India. The soil is classified as high plasticity clay (CH) according to Indian Standard Soil

Classification System (ISSCS). Marble dust is a byproduct of marble cutting/grinding industries. Marble dust was obtained from Kishangarh, District Ajmer, Rajasthan, India. The specific gravity of the material is 2.87. Bentonite (montmoillonite) is obtained from Jodhpur mines, Rajasthan, India in the form of the grain size. Bentonite has extremely fine sized particles so there was no need to sieve it during sample preparation.

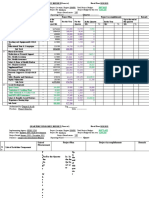

Specimen Preparation and Their Properties The soil sample were prepared by replacing the natural clay by 10% bentonite to make it more expansive, then the marble dust was added to the prepared sample from 0% to 30% at an interval of 5% (by weight). Totally seven different samples were analyzed in this study. Firstly, all the materials viz. soil, bentonite and marble dust were oven dried at 60oC for 24 hours. Before mixing all different materials all of them were sieved through 2.36mm sieve. For the preparation of each specimen, all the materials were mixed thoroughly by trowel and passing the mixture by 20mm sieve. Index properties of the samples were listed in Table 1.

Test Program Hydrometer test, Proctors Compaction test, Atterbergs limit and specific gravity tests were performed according to IS: 2720. Clay and silt percentage were found by grain size distribution from hydrometer test. Specific gravity test for each samples were determined by Pycnometer. Classification of soil has been done according to Indian Standard Soil Classification system (ISSCS) by plotting test results on plasticity chart. Swelling potential of each specimen has been calculated according to plasticity index values and clay percentage.

Activity = (P.I/Clay percentage)

Free swell ratio test and free swell test were also performed. First of all, the maximum dry density and optimum moisture content of the prepared samples was determined using proctors compaction test. Then the samples were prepared for Free swell test at their respective MDD and OMC to determine the swelling percentage of the samples.

Free Swell Ratio test To determine the swell property, Sridharan & Prakash proposed the free ratio method of characterizing the soil swelling. FSR (free swell ratio) is defined as the ratio of sediments volume of 10g oven dried soil passing through 425 micron sieve in distilled water (Vw) to that of Kerosene (Vk) (Sridharan & Prakesh 2004).

In this study, recommended procedure of Sridharan and Prakash was adopted. 10gm of prepared sample was added to 100ml of distilled water in a jar and another 10gm of same sample was added to 100ml Kerosene. After 24hrs, sediment volumes of samples were measured to determine FSR. Classification of soil based on FSR is given in Table 2.

Free Swell test using Oedometer Free swell test is done by Oedometer. Free swell method was used to determine the effectiveness of the marble dust on the swell properties of the specimens. Prepare the samples at their respective OMC and MDD (determine by Proctors test) and transfer it to the consolidation ring. Then, this compacted sample with consolidation ring is placed into the Oedometer after placing the filter paper on top and bottom of it. Porous stone plates were also placed after the filter paper. Porous stone plates should be air-dried. Then, the dial gauge measuring the vertical deflection was set to zero and token load of 5kpa is applied. Pour the samples into the water through stand pipes. Change in the height of the specimen were recorded after 0.5min, 1min, 2min, 4min, 15min, 30min, 1hr, 2hr, 4hr, 8hr, 1day, 2days, 3days, and 4days. To determine the swelling potential, establish the relationship between swelling percentage and time. After this, dismantle the Oedometer and weigh it for water content determination. The percentage of free swell can be expressed as Free swell = (H/H) 100 Where: H=Initial height of the specimen. H=change in initial height of the specimen

RESULTS AND DISCUSSIONS Effect of Stabilizer on Particle Size Distribution Addition of marble dust shifted the particle size distribution curve of sample 1 to coarser side as shown in figure 1. The shifting of curve is mainly due to the addition of coarser material to sample 1 and also due to the pozzolanic reactions causing the formation of flocculation of clay particles.

Effect of Stabilizer on Liquid Limit, Plastic Limit and Shrinkage Limit Table 1 shows the changes in LL, PL and SL with the addition of marble dust. Liquid limit of sample 1 decreases as the stabilizer percentage increases. The maximum reduction was 4.3% at 30% marble dust. Plastic limit of sample 1 increases with the increasing percentage of marble dust and the maximum increase was 12.6% at 30% marble dust. Same trend was found in the variation of shrinkage limit. Shrinkage limit also increases with the increase in marble dust and maximum increase was 9.9% at 30% marble dust.

Effect of Stabilizer on Plasticity Index and Shrinkage Index Plasticity index is the difference between liquid limit and plastic limit. Table 1 shows the variation in plasticity and shrinkage index. Since LL decreases and PL increases, plasticity index decreases with the addition in marble dust. The maximum reduction was 46.9% at 30% marble dust. Same decreasing pattern was noticed in the change of shrinkage index with the maximum reduction of 44.2% at 30% marble dust.

Effect of Stabilizer on Free Swell Ratio Test Figure 2 shows the changes in the free swell ratio with varying percentage of marble dust. Free swell ratio (FSR) of sample 1 was 2.42. According to Swell classification based on FSR (table2), sample 1 is considered as high swelling soil and dominant clay mineral type was Montmorillonite. As the percentage of marble dust increases, the FSR value decreases and decreased up to 1.22 at 30% marble dust and makes the soil low expansive.

Effect of Stabilizer on Swell Percentage of Expansive Soil Replacing the expansive soil by non-expansive material reduces the swelling percentage. Figure 3 shows the changes in swelling percentage for the samples without cure, 7 days cure and 28 days cure. Swelling percentage of samples decreased with the addition of marble dust. Maximum decrease is 18.1% at 30% marble dust, without cure sample. Swelling percentage was reduces after curing the samples.

Effect of Stabilizer on Rate of Swell of Expansive Soil Time required for the 50% swelling of the sample is denoted by t50. From figure 4, t50 decreases with the addition of stabilizer and hence the rate of swelling decreases. The maximum decrease in the rate of swelling is 43.6% at 30% marble dust. After curing, the

reduction in rate of swell was lowered. Especially, 28 days cured samples had much tendency to decrease in rate of swell. (t50) and (H/H)without cure > (t50) and (H/H)7days cure > (t50) and (H/H)28days cure

CONCLUSIONS The addition of the marble dust to the expansive clay reduces the clay content and thus increases in the percentage of coarser particles, reduces the LL, raises the SL and decrease in the plasticity index of soil and thus swelling potential. Activity of the soil reduces by the addition of marble dust. As the percentage of stabilizer increases, swelling percentage, free swell ratio and rate of swell decreases. Samples having marble dust reached the 50% of total swelling earlier. By curing the samples, the rate of swell and swelling percentage decreased. Expansive soils can be replaced by marble dust for reducing the swelling up to 25% to 30% because there is not much difference in swelling potential and rate of swell for 25% and 30% marble dust added samples.

REFRENCES [1] [2] Craig, R.F. (2004), Soil Mechanics, 7th Edition, Spon Press, London. elik, M.Y. (2001), Mermer Atklarnn (Para-Tozlarn) Deerlendirilmesi, M. S. Thesis, Afyon Kocatepe University, Natural and Applied Sciences, 119 pages, 1996. [3] oka, E.(2001), Use of Class C Fly Ashes for the Stabilization of an Expansive Soil, Journal of Geotechnical and Geoenvironmental Engineering, Vol. 127, No.7, pp. 568-573. [4] Fredlund, D.G. and Rahardjo, H. (1993), Soil Mechanics for Unsaturated Soils, John Wiley and Sons Inc., New York. [5] pek, T. (1998), Stabilization of Expansive Soils Using Lime, Cement and Fly Ash, M.S. Thesis, METU, Turkey, 119 pages. [6] [7] [8] IS: 2720 (Part 1, 2, 4, 5, 7 & 15): Methods for test of soils. Kun, N. (2000), Mermer Jeolojisi ve Teknolojisi, Tezer Matbaas, zmir. Mishra, A.K., Dhawan S., Rao, S.M. (2008), Analysis of Swelling and Shrinkage Behavior of Compacted Clays, Geotechnical and Geological Engineering, Vol. 26, No. 3, pp. 289-298. [9] Mitchell, J. K. and Soga, K. (2005), Fundamentals of Soil Behavior, 3rd Edition, John Wiley and Sons Inc., New York. [10] Nelson, J.D. and Miller, D.J. (1992), Expansive Soils, Problems and Practice in Foundation and Pavement Engineering, John Wiley and Sons Inc., New York. [11] Prakash, K. and Shidhara, A. (2004), Free Swell Ratio and Clay Mineralogy of FineGrained Soils, Geotechnical Testing Journal, Vol. 27, No.2, pp.1-6. [12] Wayne, A.C., Mohamed, A.O. and El-Fatih, M.A. (1984), Construction on Expansive Soils in Sudan, Journal of Construction Engineering and Management, Vol. 110, No. 3, pp. 359-374.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Product Sheet - Parsys Cloud - Parsys TelemedicineDokument10 SeitenProduct Sheet - Parsys Cloud - Parsys TelemedicineChristian Lezama Cuellar100% (1)

- Post Traumatic Stress DisorderDokument2 SeitenPost Traumatic Stress Disorderapi-188978784100% (1)

- LWT - Food Science and Technology: A A B ADokument6 SeitenLWT - Food Science and Technology: A A B ACarlos BispoNoch keine Bewertungen

- Site Quality ManualDokument376 SeitenSite Quality ManualsNoch keine Bewertungen

- AppendicitisDokument7 SeitenAppendicitisTim LuoNoch keine Bewertungen

- Senographe Crystal: The Choice Is Crystal ClearDokument7 SeitenSenographe Crystal: The Choice Is Crystal ClearmuhammadyassirNoch keine Bewertungen

- ScienceDokument17 SeitenScienceTambong HailyNoch keine Bewertungen

- Formulas Related Question, PebcDokument1 SeiteFormulas Related Question, PebcBhavesh NidhiNoch keine Bewertungen

- Medical Representative Healthcare Sales in Fort Myers FL Resume Greg HejlikDokument2 SeitenMedical Representative Healthcare Sales in Fort Myers FL Resume Greg HejlikGregHejlikNoch keine Bewertungen

- Quarterly Progress Report FormatDokument7 SeitenQuarterly Progress Report FormatDegnesh AssefaNoch keine Bewertungen

- Existensive Happiness by AristotleDokument2 SeitenExistensive Happiness by AristotleIan Robert Roa NovalNoch keine Bewertungen

- Phenotype and GenotypeDokument7 SeitenPhenotype and GenotypeIrish Claire Molina TragicoNoch keine Bewertungen

- Lesson 2 Basic Osah, General Provisions, Safety Rules..Dokument30 SeitenLesson 2 Basic Osah, General Provisions, Safety Rules..GM VispoNoch keine Bewertungen

- Manual Gavita Pro 600e SE EU V15-51 HRDokument8 SeitenManual Gavita Pro 600e SE EU V15-51 HRwhazzup6367Noch keine Bewertungen

- Drug Development: New Chemical Entity DevelopmentDokument6 SeitenDrug Development: New Chemical Entity DevelopmentDeenNoch keine Bewertungen

- RCM Design and ImplementationDokument34 SeitenRCM Design and ImplementationRozi YudaNoch keine Bewertungen

- RISK MANAGEMENT - Imo Multilingual Glossary On Risk Management (Secretariat)Dokument17 SeitenRISK MANAGEMENT - Imo Multilingual Glossary On Risk Management (Secretariat)Martin NiNoch keine Bewertungen

- PSB 3441 CH 1 HallucinogensDokument2 SeitenPSB 3441 CH 1 HallucinogensAnonymous lm3GIU45Noch keine Bewertungen

- Lathe Operators Manual 96-8900 Rev A English January 2014Dokument458 SeitenLathe Operators Manual 96-8900 Rev A English January 2014coyoteassasin0% (1)

- Capstone-ModDokument25 SeitenCapstone-ModMohammad Ryyan PumbagulNoch keine Bewertungen

- Sonesse 30 Databook NewestDokument32 SeitenSonesse 30 Databook Newestsunii19847908Noch keine Bewertungen

- Guidelines For Forensic Report Writing: Helping Trainees Understand Common PitfallsDokument54 SeitenGuidelines For Forensic Report Writing: Helping Trainees Understand Common PitfallsNorfolk Journal100% (1)

- RNP Rnav PDFDokument31 SeitenRNP Rnav PDFhb2enbjxNoch keine Bewertungen

- BARCODESDokument7 SeitenBARCODESChitPerRhosNoch keine Bewertungen

- Snap Bore Ring PDFDokument8 SeitenSnap Bore Ring PDFlaaliNoch keine Bewertungen

- Posi LokDokument24 SeitenPosi LokMarcel Baque100% (1)

- Pentacam Four Maps RefractiveDokument4 SeitenPentacam Four Maps RefractiveSoma AlshokriNoch keine Bewertungen

- Chan v. ChanDokument2 SeitenChan v. ChanjdpajarilloNoch keine Bewertungen

- Rediscovering Alginate Wound DressingsDokument4 SeitenRediscovering Alginate Wound DressingstanveerhusseinNoch keine Bewertungen