Beruflich Dokumente

Kultur Dokumente

Beauveria Production

Hochgeladen von

Ps KarthikeyanOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Beauveria Production

Hochgeladen von

Ps KarthikeyanCopyright:

Verfügbare Formate

. : Coffee Board of India - PRODUCTION, STORAGE, FORMULATION AND APPLICATION OF BEAUVERIA BASSIA...

Page 1 of 4

PRODUCTION, STORAGE, FORMULATION AND APPLICATION OF BEAUVERIA BASSIANA FOR THE MANAGEMENT OF COFFEE BERRY BORER

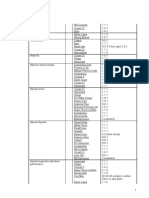

The white muscardine fungus Beauveria bassiana is a potential bio-control agent that could be used against the berry borer very effectively. This pathogen, which kills the borer can be cultured at the estate level and sprayed on the infested plants. B. bassiana, the white muscardine fungus, is a common pathogen of a range of insects belonging to different groups. This fungus often exerts a good degree of natural biological control under humid conditions. Under conditions not so favourable for natural epizootics, widespread artificial infection can be induced by application of the fungus (as spores or conidia), resulting in good pest suppression. One of the major constraints hindering the use of this fungus as a bio-pesticide is the non availability of cost effective and genuine formulations in the market. However, this fungus can be produced by farmers with some basic facilities available on the farms. REQUIREMENTS Capital 1. 2. 3. 4. 5. 6. 7. 8. Two rat proof rooms of approximately 10 x 10 ft Work table with hood UV lamp and fluorescent lamp Pressure cooker of 20 litre capacity Stove Heat sealer Veterinary syringe 20 ml capacity Burner and lighter

Recurring 1. 2. 3. 4. Par boiled rice as per requirement Poly propylene bags of size 14 x 10 Sponge pieces rolled into small plugs Disinfectant Sodium Hypochlorite solution

http://www.indiacoffee.org/indiacoffee.php?page=mang_coff_berry

12/4/2009

. : Coffee Board of India - PRODUCTION, STORAGE, FORMULATION AND APPLICATION OF BEAUVERIA BASSIA...

Page 2 of 4

5. 6. 7. 8. 9. 10.

Cellophane tape and insulated binding wire Pure liquid culture of B. bassiana Cotton/tissue paper rolls Surfactant (APSA 80 or ACTIVE 80) Antibiotic (chloramphenicol / streptomycin / tetracycline) Workers - 2

METHODOLOGY 1. 2. 3. 4. 5. If not properly sealed, re-seal the bottom of the polypropylene /polyethylene bags using the heat sealer. Soak rice in water for about half an hour, drain and fill in the bags at the rate of one kg equally distributed in five bags. Close the mouth of the bag with a sponge plug and fasten tightly with a piece of insulated binding wire. Hold the plugs of five bags together and cover with a piece of paper. Place about 15 bags in the pressure cooker containing some quantity of water. Close the lid and when the steam starts issuing continuously, put the weight. After three whistles reduce the flame and allow heating for 15 minutes. After this interval, put off the stove and allow the cooker to cool. 6. While pressure cooking is going on, clean the work table using 5% sodium hypochlorite solution and switch on the UV lamp. Avoid looking at the lit lamp and direct contact of the body with UV light. 7. 8. 9. 10. 11. 12. 13. Take out the bags and remove water adhering to the sides with blotting/tissue paper placed in a clean tray. Switch off the UV lamp, place the bags on the work table and allow further cooling. Light the spirit lamp/burner and heat sterilize the syringe and allow cooling. The syringe can also be sterilized in the cooker along with the rice bags. Holding the liquid culture bottle above the burner flame, remove the plug, add two drops of the surfactant and 10 drops of antibiotic and shake well. Draw 15 ml of the liquid culture into the syringe and inject into the bag through the sponge plug. Care should be taken to avoid puncturing the bag. Mix well, spread the rice grains loosely and place the bags on racks. Incubate for two weeks and watch for development of spores. Once profuse sporulation is seen, gently crush the lumps into individual grains, cut open the bags along the sides, spread the culture in the same bag and allow drying for four or five days. 14. Separate the spores by sieving, allow drying on the work bench for about three days.

http://www.indiacoffee.org/indiacoffee.php?page=mang_coff_berry

12/4/2009

. : Coffee Board of India - PRODUCTION, STORAGE, FORMULATION AND APPLICATION OF BEAUVERIA BASSIA...

Page 3 of 4

For faster drying, silica gel may be used. A good culture with one kg of rice yields about 40grams of dry conidia in two or three sieving at weekly intervals. Sieving may be done under the hood to avoid inhalation of spores. 15. Pack the dry spores in laminated aluminium foil and store in the freezer compartment of a refrigerator. Formulation and application To prepare one barrel (200L) of spray fluid with about 10 million conidia per ml (the optimum dose for field application), take the conidia extracted from one kilo of rice in a polypropylene bag. Add 100 ml of any surfactant like APSA80 or ACTIVE 80, and mix thoroughly to form a uniform paste (the conidia are not miscible with most of the ordinary wetting agents and hence they cannot be used). Add small quantities of water into the bag and mix thoroughly so that no lumps remain in the suspension. Make up to 200 litres. If the culture bags are used for immediate field application, the following method may be adopted. Crush the contents of five bags (prepared with one kg of rice) and empty into a container with a screw cap. Add 100 ml of APSA 80/ACTIVE 80 and about 2 litres of water. Close the container tightly and mix thoroughly by vigorous agitation (a churner may be used for better mixing). Filter the suspension into the barrel. Repeat mixing and filtration, three or four times, to extract maximum spores. Make up to 200 litres. Unlike chemical insecticides, B. bassiana has got very little persistence on the treated plant surface. Hence, for target pests like berry borer or shot hole borer, direct contact of the formulation with the insect cuticle is essential for effective control. To ensure proper coverage of berries or twigs, it is better to use a knapsack or rocker sprayer fitted with solid cone or adjustable nozzle of 350 to 450 cc output per minute. If suitable lances and nozzles are available, motorized sprayers can also be used. The effect of the fungus can be observed in the field in about 10 days with the development of white hyphal mass or spores on the dead insects, often projecting through the bore holes on the berries. Around 80% suppression can be achieved. Apart from environmental safety, the advantage of the fungus over insecticides is its ability to kill the stages inside the tunnels through cross contamination. Hence, field application can be taken up till berry ripening starts. June to September, when temperature is below 30o C and humidity above 70%, is the ideal period for best results. Mist as well as the microclimate in the tunnels also provides high

http://www.indiacoffee.org/indiacoffee.php?page=mang_coff_berry

12/4/2009

. : Coffee Board of India - PRODUCTION, STORAGE, FORMULATION AND APPLICATION OF BEAUVERIA BASSIA...

Page 4 of 4

humidity required for fungal development. The important precaution to be followed while handling the fungus is to avoid inhalation of spores; some people may be allergic. Training on production and use of B. bassiana is being imparted at the Central Coffee Research Institute at Balehonnur and the Regional Coffee Research Stations at Chettali in Kodagu, Chundale in Wayanad and Thandigudi in Tamil Nadu. Individual growers or groups interested in production of this fungus can source the pure culture from the Coffee Research Stations. Since there is a chance of contamination at several points of the production chain, utmost care needs to be taken to keep the conditions hygienic

http://www.indiacoffee.org/indiacoffee.php?page=mang_coff_berry

12/4/2009

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (120)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Basic Principles of Remote SensingDokument24 SeitenBasic Principles of Remote Sensingfelipe4alfaro4salas100% (1)

- Science 10 Quarter 2 Module 4Dokument6 SeitenScience 10 Quarter 2 Module 4Jess Anthony Efondo100% (4)

- Collage Lab PDFDokument145 SeitenCollage Lab PDFmaa siddhi92% (12)

- Organic Chemistry (Some Basic Principles and TechniquesDokument30 SeitenOrganic Chemistry (Some Basic Principles and TechniquesNaveen SharmaNoch keine Bewertungen

- Magneto-Convective Non-Newtonian Nanofluid With Momentum and Temperature Dependent Slip Flow From A Permeable Stretching Sheet With Porous Medium and Chemical ReactionDokument18 SeitenMagneto-Convective Non-Newtonian Nanofluid With Momentum and Temperature Dependent Slip Flow From A Permeable Stretching Sheet With Porous Medium and Chemical ReactionIOSRjournalNoch keine Bewertungen

- NCERT Solutions For Class 12 Maths Chapter 10 Vector AlgebraDokument51 SeitenNCERT Solutions For Class 12 Maths Chapter 10 Vector AlgebraKavin .J.S (KingK)Noch keine Bewertungen

- CADS Revit Scia Engineer Link Best PracticesDokument32 SeitenCADS Revit Scia Engineer Link Best PracticestrevorNoch keine Bewertungen

- Theology of Work and Practical ImplicationsDokument28 SeitenTheology of Work and Practical ImplicationsVinicius CardosoNoch keine Bewertungen

- Additive Manufacturing Objective QuestionsDokument7 SeitenAdditive Manufacturing Objective Questionsmohammad shaqib100% (4)

- Your Heart: Build Arms Like ThisDokument157 SeitenYour Heart: Build Arms Like ThisNightNoch keine Bewertungen

- Orifice Assembly With D-D2 Taps PDFDokument1 SeiteOrifice Assembly With D-D2 Taps PDFArup MondalNoch keine Bewertungen

- Jib Crane Assembly ManualDokument76 SeitenJib Crane Assembly ManualRobert Cumpa100% (1)

- 520L0586 MMF044Dokument48 Seiten520L0586 MMF044vendas servicosNoch keine Bewertungen

- Macleod - 1974 - Lucian's Knowledge of TheophrastusDokument2 SeitenMacleod - 1974 - Lucian's Knowledge of TheophrastusSIMONE BLAIRNoch keine Bewertungen

- HBT vs. PHEMT vs. MESFET: What's Best and Why: Dimitris PavlidisDokument4 SeitenHBT vs. PHEMT vs. MESFET: What's Best and Why: Dimitris Pavlidissagacious.ali2219Noch keine Bewertungen

- Ieee 802Dokument3 SeitenIeee 802M Zubair AslamNoch keine Bewertungen

- Mid-Year Examination, 2023 Science Year 7 1 HourDokument23 SeitenMid-Year Examination, 2023 Science Year 7 1 HourAl-Hafiz Bin SajahanNoch keine Bewertungen

- Solomon On Sex - Avoiding Marital Disaster: February 12, 2012Dokument14 SeitenSolomon On Sex - Avoiding Marital Disaster: February 12, 2012baimareanNoch keine Bewertungen

- IMS Institute BelgradeDokument10 SeitenIMS Institute BelgradeBoško JanjuševićNoch keine Bewertungen

- 2606 PDFDokument6 Seiten2606 PDFzainab jehangirNoch keine Bewertungen

- Mercedes (DTC) 976990001963 20220615144147Dokument3 SeitenMercedes (DTC) 976990001963 20220615144147YB MOTOR Nissan - Datsun SpecialistNoch keine Bewertungen

- Thesis 1-15Dokument15 SeitenThesis 1-15hewelirNoch keine Bewertungen

- Dinacharya HandbookDokument5 SeitenDinacharya Handbookvera sirakovaNoch keine Bewertungen

- Afectiuni Si SimptomeDokument22 SeitenAfectiuni Si SimptomeIOANA_ROX_DRNoch keine Bewertungen

- ScheduleDokument1 SeiteScheduleparag7676Noch keine Bewertungen

- Subject: Digital System Design Faculty: Mr. P.Jayakrishna Unit-5 Assignment 5 Set 1Dokument2 SeitenSubject: Digital System Design Faculty: Mr. P.Jayakrishna Unit-5 Assignment 5 Set 1Jayakrishna CharyNoch keine Bewertungen

- Sindarin-English Dictionary - 2nd EditionDokument192 SeitenSindarin-English Dictionary - 2nd EditionNea Tan100% (1)

- Tempera 2018 AbstractsDokument45 SeitenTempera 2018 AbstractsGerard Emmanuel KamdemNoch keine Bewertungen

- Israel StandardDokument15 SeitenIsrael StandardDũng Bùi Đức100% (1)

- COUNTERS IN PLC - Portal PDFDokument88 SeitenCOUNTERS IN PLC - Portal PDFAhwangg xGAMINGNoch keine Bewertungen