Beruflich Dokumente

Kultur Dokumente

Dome Valve

Hochgeladen von

saisssms9116Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Dome Valve

Hochgeladen von

saisssms9116Copyright:

Verfügbare Formate

DOME V ALVE II

I N F L ATA B L E S E AT VA LV E S I N F L ATA B L E S E AT VA LV E S

The Process Engineering Valve Solution

DOME VALVE II Standard Configurations

Bulkhead Actuator Operated

In-Line Actuator Operated

Bulkhead Hand Operated

In-Line Hand Operated

(Patent Applied For)

(Patent Applied For)

Standard Options

Size Options: 2, 4, 6, 8 10, 12 Design Temperature: 230F (110 C) / 400F (200 C) / 535F (280 C) Design Pressure: 100 psig (6.89 Barg.) Flanges: ANSI 150 / PN 10 Construction: Cast Iron A48 C40 / Stainless Steel 304/316 / Carbon Steel A516 70N

Non-Standard Options

Size Options: To 24 Design Temperature: To 660F (350 C) Design Pressure: To 630 psig (43 Barg.)

For details, please refer to Specification & Dimensional Data booklet 1-39

DOME VALVE II Inflatable Seat Valves

A pioneering and innovative departure from the traditional valve seat approach to achieving Relaxed Seat sealing efficiency and acceptable valve seat life.

Dome Component

Air Supply

Inflated Seat Dome Component

Particle entrapment prevents seat erosion, solving the cause of valve wear.

Principle Of Operation

The Dome component closes beneath the seat(seal) when the seal is relaxed (not inflated), allowing a controlled gap between the seat (seal) and the closing member (Dome). Material is allowed to pass through or enter the controlled gap if, due to its characteristics, it is pulled into the gap by the action of the Dome component moving to its closed position. In the closed position, high pressure air or other gas enters the space between the back of the seal face and the insert ring to cause the seal face to expand onto and around the periphery of the Dome component. Material particles are entrapped by the seal against the dome surface, irrespective of particle size or shape. Before opening the valve, the seat is relaxed, and the controlled gap is reestablished before the Dome component moves to its open position. The seal is a loose component clamped into place by a spigot piece and external fasteners holding the top plate assembly to the body. The seal is easily removed for inspection.

Inflatable Seats

Inflatable flexible seats entrap particles that are normally the cause of seat erosion. Particles are induced to move across valve seats under the influence of pressure differentials on either side of the closing member. Entrapping particles within a flexible face during the period of valve closure prevents particle movement and considerably reduces valve seat wear. Inflatable seats allow automatic wear compensation. U.S. Patent No. 4,137,935

Flexible Seats

Flexible seats that do not inflate require the force of engagement on closing to entrap particles. However the flexible valve seat has limited life bacause the worn surface of the flexible seat cannot continue to reengage the closing member and entrap particles. Inflatable seats compensate for wear to the seat and provide longer sealing life.

Hard Seats

The conventional hard material approach to valve seat life relies on crushing particles between the faces.This approach does not attempt to entrap particles, but causes the particles remaining to become very small to reduce their erosion effect on the valve seat. However small the particles are, each particle contributes to continuing erosion. Particle movement and initial erosion allows accelerated subsequent erosion since the hard seats cannot compensate for wear.

DOME VALVE II Advanced Features

Simplicity Durability Reliability Quality

17 16

High torque double acting acuator

Zero contact proximity switch for inflatable seal operation

18

One piece precision molded inflatable seat

Single gasket assembly

15 11

9 14 12 13 8 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

TOP PLATE BOLTS TOP PLATE INSERT RING INFLATABLE SEAL SPIGOT PIECE GASKET VALVE BODY DOME DUST SEAL PIVOT SHAFT ASSEMBLY DRIVE SHAFT ASSEMBLY SHAFT SEAL SHAFT SPACER BEARING ACTUATOR DRIVE ASSEMBLY ACTUATOR MOUNT ACTUATOR PROXIMITY SWITCH DOME-TO-SHAFT BOLT Other patents applied for

13

Simple fastener assembly in M & F Connection

U.S. Patent No.5642751

12 19

Lifetime lubricated bearings

14 9 10

Double shaft seals Stainless steel shafts

DOME VALVE II The Problem Solver

Special Performance Advantages

The Dome Valve is used in a wide variety of applications in almost every process. The unique closing and sealing action of the Dome Valve enables continuous reliable operation where conventional valves fail to perform. Here is why:

Abrasive Materials

Slurries, bulk powders, granules, lumps or dust-laden gases cause seat erosion and ineffective closure. The inflatable seal provides continuous wear compensation.

Pressure Differential

Pressure differential also causes accelerated seat wear in conventional seat valves. The inflatable seal provides continuous wear compensation.

High Temperature

Thermal expansion prevents consistent valve seat action. The inflatable seal provides compensation throughout the temperature range of 0 to 660F (350C). Temperatures above this range may be accepted using special valve configurations.

Close and Seal

The displacement action of the rotating dome within the valve housing allows rotation of a solid column of material so that a chokefilled Dome Valve will close and seal through packed material.

Seal Protection

Seal protection and dome scraper ring remove particles adhering to the dome surface to affect seal performance.

Drive Options

Power operated and manually operated options available.

Abrasion/Temperature/Pressure

Conventional seat valves cannot achieve operating reliability with any combinations of the severe application conditions listed, but the Dome Valve does. It has achieved successful performance in more than 100,000 installations in a diverse array of applications.

Reliability

A heavy-duty valve designed to perform where other valves cannot. Rated for 1 million cycles between inspections in approved applications.

Applications In Every Process Worldwide

More than 100,000 Dome Valves are in operation in almost every country of the world, providing long life and operating reliability where conventional valves have failed.

Mactenn Systems Ltd. One Bull Lane, Acton, Sudbury, Suffolk, CO10 OBD ENGLAND Phone: 44 (1787) 882 422 Fax: 44 (1787) 882 433 admin@mactenn.com Macawber Engineering Systems India Pvt. Ltd. 131, Hindustan Kohinoor Complex, L.B.S. Marg, Vikhroli (West) Bombay 400083 INDIA Phone: 91 (022) 5794624 Fax: 91 (022) 5772047 Macawber Japan 3-11-1, Shinmachi, Nishi-ku Osaka 550 JAPAN Phone: 81 (06) 538-9190 Fax: 81 (06) 533-2979 Macawber China 12F-C Da An Building 373 Jiang Ning Road Shanghai 200041 CHINA Phone: 86 (021) 6253-1188 Fax: 86 (021) 6253-1188 Macawber Do Brazil Av. Dr. Pedro Lessa, 1.447 Conj. 23 Santos Sao Paulo BRAZIL CEP 11025-001 Phone: (013) 271-3899 Fax: (013) 271-3899

Macawber

Engineering Inc.

INFLATABLE SEAT VALVES ADVANCED PNEUMATIC CONVEYING SYSTEMS CONTROLLED RATE INJECTION SYSTEMS

ISO 9001

Company Management Quality Certification

1829 Clydesdale Street, Maryville, Tennessee USA 37801 Telephone (865)984-5286 Fax (865)977-4131 macawber@macawber.com

1-800-433-2213

w w w.d o m e v a l v e . c o m

Your Local Distributor:

Product Quality Assurance Certification (Germany)

Product Safety requirements satisfy the Directives of the European Commission.

Pressure Vessel Quality Assurance Certification

Das könnte Ihnen auch gefallen

- NEA Standard 13.2kV Transmission LineDokument325 SeitenNEA Standard 13.2kV Transmission LineJS Engineering86% (29)

- 101 Science EXPERIMENTS WITH PAPERDokument49 Seiten101 Science EXPERIMENTS WITH PAPERsaisssms9116100% (5)

- TATA320 Crane ManualDokument45 SeitenTATA320 Crane Manualkatepol826450% (4)

- WPS For Different Materail by BhelDokument176 SeitenWPS For Different Materail by Bhelsaisssms911691% (46)

- Basic WeldingDokument40 SeitenBasic WeldingVishnu Vardhan . C100% (8)

- Plastic Molding TutorialDokument32 SeitenPlastic Molding TutorialSergio RodriguezNoch keine Bewertungen

- Science Action BOOK-4Dokument62 SeitenScience Action BOOK-4saisssms9116Noch keine Bewertungen

- Reduction in Boiler Cooling TimeDokument16 SeitenReduction in Boiler Cooling Timejp mishraNoch keine Bewertungen

- Premium Transmission Gear BoxDokument80 SeitenPremium Transmission Gear BoxShipra Shalini83% (6)

- Premium Transmission Gear BoxDokument80 SeitenPremium Transmission Gear BoxShipra Shalini83% (6)

- Steam TurbinesDokument45 SeitenSteam TurbinesHaseeb Bokhari100% (1)

- How To Repair The Leaking Condensor Tubes and How To Check Precisely Which Tube Leaking As As Hydrotest Not PossibleDokument25 SeitenHow To Repair The Leaking Condensor Tubes and How To Check Precisely Which Tube Leaking As As Hydrotest Not PossibleAbdulyunus Amir100% (1)

- Fan Inspection ReportDokument24 SeitenFan Inspection Reportsaisssms9116Noch keine Bewertungen

- Science Action-BOOK 5Dokument64 SeitenScience Action-BOOK 5saisssms9116Noch keine Bewertungen

- Simple Science ExperimentsDokument59 SeitenSimple Science ExperimentsArsalan Ahmed Usmani100% (4)

- Mill Reject SystemDokument22 SeitenMill Reject SystemgangatharanNoch keine Bewertungen

- Turbine Part 5Dokument15 SeitenTurbine Part 5Dilip YadavNoch keine Bewertungen

- 6.6 KV Switchgear Charging & IsolationDokument12 Seiten6.6 KV Switchgear Charging & IsolationSreekanthMylavarapuNoch keine Bewertungen

- Tanjung Jati B Training PA-FD-ID FansDokument53 SeitenTanjung Jati B Training PA-FD-ID FansFauzan Kurnia100% (1)

- Training Manual - S8000 Complete (Tier 3) PDFDokument26 SeitenTraining Manual - S8000 Complete (Tier 3) PDFJUNA RUSANDI S100% (1)

- Simple MachinesDokument105 SeitenSimple Machinesniel justin lakerNoch keine Bewertungen

- Part 2 Pressure Vessel DesignDokument281 SeitenPart 2 Pressure Vessel DesignSyedZainAli100% (1)

- Cold Start Up - CSTPS PDFDokument19 SeitenCold Start Up - CSTPS PDFAhemadNoch keine Bewertungen

- Boiler Protection Gyanendra Sharma NPTI DelhiDokument24 SeitenBoiler Protection Gyanendra Sharma NPTI DelhiNPTINoch keine Bewertungen

- Turbine Operation GuideDokument19 SeitenTurbine Operation GuidePrafull GuptaNoch keine Bewertungen

- U6OHREPORT2008Dokument89 SeitenU6OHREPORT2008Anonymous pKsr5vNoch keine Bewertungen

- Deh System CommissioningDokument11 SeitenDeh System Commissioningdreamboy87Noch keine Bewertungen

- Write Up On EHA & HPSU SystemDokument9 SeitenWrite Up On EHA & HPSU Systemraaj bharath100% (1)

- Main Turbine Lub. Oil System: Prepared byDokument44 SeitenMain Turbine Lub. Oil System: Prepared byNitish Kumar100% (1)

- Science Action - BOOK 3Dokument49 SeitenScience Action - BOOK 3saisssms9116Noch keine Bewertungen

- Faf OmDokument41 SeitenFaf OmKRSRAMANNoch keine Bewertungen

- Deh Governing-LancoDokument35 SeitenDeh Governing-LancoPRAMOD KUMAR NANDANoch keine Bewertungen

- Ogn Ops Chem 002 Stator Primary Water SystemDokument18 SeitenOgn Ops Chem 002 Stator Primary Water SystemraniNoch keine Bewertungen

- Especificaciones de Torque Motor Toyota 1GR-FEDokument3 SeitenEspecificaciones de Torque Motor Toyota 1GR-FEJose L Ramirez100% (1)

- F AdaptersDokument122 SeitenF Adaptersxuanphuong2710Noch keine Bewertungen

- # AhpDokument21 Seiten# AhprahulNoch keine Bewertungen

- How To Make Playground Using TyresDokument117 SeitenHow To Make Playground Using Tyressaisssms9116100% (5)

- Boiler Feed Pump (BFP) : Opgs Power Gujarat PVT LTD 2X150 MW Thermal Power PlantDokument11 SeitenBoiler Feed Pump (BFP) : Opgs Power Gujarat PVT LTD 2X150 MW Thermal Power PlantSaravanan SundararajNoch keine Bewertungen

- Steam Power Plant LecturesDokument36 SeitenSteam Power Plant LecturesKariem Zaki100% (1)

- Boiler ConstructionDokument4 SeitenBoiler ConstructionrpshvjuNoch keine Bewertungen

- Book ChassisDokument52 SeitenBook ChassisanglianwarriorNoch keine Bewertungen

- ASME Coal Sampling Test ProcedureDokument4 SeitenASME Coal Sampling Test ProcedureRoby SzNoch keine Bewertungen

- Smart Soot Blower SystemDokument8 SeitenSmart Soot Blower SystemidigitiNoch keine Bewertungen

- Dec 09Dokument35 SeitenDec 09Krishnan SanthanarajNoch keine Bewertungen

- FD FanDokument5 SeitenFD FanPrudhvi RajNoch keine Bewertungen

- Thermal Power PlantDokument13 SeitenThermal Power PlantSanat KumarNoch keine Bewertungen

- 6 Esp BlowerDokument2 Seiten6 Esp BlowerMithun Singh RajputNoch keine Bewertungen

- SESI-TSPL-OPN-SOP-BTG-012 (APH Fire)Dokument9 SeitenSESI-TSPL-OPN-SOP-BTG-012 (APH Fire)sourav mahapatraNoch keine Bewertungen

- Enmas India Private Limited: (SMC Power Generation LTD Unit 2)Dokument3 SeitenEnmas India Private Limited: (SMC Power Generation LTD Unit 2)Sachin nandgayeNoch keine Bewertungen

- Ash Handling PlantDokument24 SeitenAsh Handling Plantsekhar_ntpcNoch keine Bewertungen

- VHB Presentation (Compatibility Mode) PDFDokument21 SeitenVHB Presentation (Compatibility Mode) PDFhirenkumar patelNoch keine Bewertungen

- 3 APH PERFORMANCE in NTPC STATIONS AjaySharmaDokument15 Seiten3 APH PERFORMANCE in NTPC STATIONS AjaySharmaDSGNoch keine Bewertungen

- WHRB Interlocks: S. No Boiler Equipment Logic For InterlocksDokument2 SeitenWHRB Interlocks: S. No Boiler Equipment Logic For InterlocksAmeer MeerNoch keine Bewertungen

- Chapter I General Information of Pump UnitDokument42 SeitenChapter I General Information of Pump UnitRahmat Budi HartantoNoch keine Bewertungen

- SOP For BFPDokument2 SeitenSOP For BFPsambhuNoch keine Bewertungen

- Scanner Air FanDokument3 SeitenScanner Air FanSamNoch keine Bewertungen

- 57-62 1m809 - Eng72dpiDokument6 Seiten57-62 1m809 - Eng72dpiAbhinav TewariNoch keine Bewertungen

- APH PresentationDokument36 SeitenAPH PresentationBhargav Chaudhari100% (1)

- Chapter 1 Oil Seal IntroductionDokument6 SeitenChapter 1 Oil Seal IntroductionNCvetarskyNoch keine Bewertungen

- Protection & InterlocksDokument18 SeitenProtection & InterlocksSanjay GuptaNoch keine Bewertungen

- Combined HP Stop Control ValveDokument1 SeiteCombined HP Stop Control ValvePeter AntonyNoch keine Bewertungen

- Fans SoftDokument291 SeitenFans SoftAmitava PalNoch keine Bewertungen

- List of Part-3Dokument2.000 SeitenList of Part-3Gỗ Mộc100% (1)

- 13 MW Steam Turbine 50 HZ NewDokument6 Seiten13 MW Steam Turbine 50 HZ Newteewee_cuteNoch keine Bewertungen

- Sesi-Tspl-Opn-Sop-Btg-001 (Idf)Dokument14 SeitenSesi-Tspl-Opn-Sop-Btg-001 (Idf)shubham vermaNoch keine Bewertungen

- Performance of Governor Oil - Soumik Majumdar & Sanjay DasDokument21 SeitenPerformance of Governor Oil - Soumik Majumdar & Sanjay DasEXECUTIVE ENGINEEER BOILER MAINTENANCENoch keine Bewertungen

- Cooling and Sealing AirDokument3 SeitenCooling and Sealing AirKrishna VachaNoch keine Bewertungen

- 023 CepDokument12 Seiten023 Cepjp mishraNoch keine Bewertungen

- 500MW Boiler Fans and ProtectionsDokument5 Seiten500MW Boiler Fans and Protectionsshashank100% (1)

- 06 P F PlantDokument161 Seiten06 P F Planthirenkumar patelNoch keine Bewertungen

- Bhel Block 3 Turbine FileDokument35 SeitenBhel Block 3 Turbine Filerajdeep6panchalNoch keine Bewertungen

- Engineering Declaration Unit # 2 JindalDokument16 SeitenEngineering Declaration Unit # 2 JindalVIBHAV100% (1)

- Boiler Feed PumpDokument52 SeitenBoiler Feed PumpArun Kumar100% (1)

- تشغيل محطة بخارية مهم ورائع PDFDokument157 Seitenتشغيل محطة بخارية مهم ورائع PDFelsayed100% (1)

- BCP Installation & CommissioningDokument18 SeitenBCP Installation & CommissioningKrishnan SanthanarajNoch keine Bewertungen

- EmergencyDokument24 SeitenEmergencySanjeevImproveNoch keine Bewertungen

- HR 1 - 2008Dokument1.642 SeitenHR 1 - 2008Jay Rameshbhai ParikhNoch keine Bewertungen

- SERIES 22.2: Heavy Duty Gear ReducersDokument2 SeitenSERIES 22.2: Heavy Duty Gear ReducersAmir KhanNoch keine Bewertungen

- APHDokument3 SeitenAPHMallinatha PNNoch keine Bewertungen

- Tripping of Turbine On High Differential PressureDokument3 SeitenTripping of Turbine On High Differential Pressureatulbhogare7Noch keine Bewertungen

- Velan Y-Pattern Globe CAT BG 04 10Dokument12 SeitenVelan Y-Pattern Globe CAT BG 04 10mfcramer0% (1)

- IOM Ball Valve Top EntryDokument8 SeitenIOM Ball Valve Top Entrytoader56Noch keine Bewertungen

- Electrodes CalculationDokument6 SeitenElectrodes CalculationVijay RajNoch keine Bewertungen

- Amrita School of Engineering: Accredited by NAAC With A' GradeDokument2 SeitenAmrita School of Engineering: Accredited by NAAC With A' Gradesaisssms9116Noch keine Bewertungen

- List ASME Standards ListDokument1 SeiteList ASME Standards ListKeyur PatelNoch keine Bewertungen

- Afs OimDokument135 SeitenAfs OimRajesh TopiyaNoch keine Bewertungen

- Schieldrop Schieldrop: Wesman WesmanDokument1 SeiteSchieldrop Schieldrop: Wesman Wesmansaisssms9116Noch keine Bewertungen

- Troubleshooting Coal FeedersDokument3 SeitenTroubleshooting Coal Feederssaisssms9116Noch keine Bewertungen

- WasheryDokument4 SeitenWasherysaisssms9116Noch keine Bewertungen

- FRPDokument6 SeitenFRPsaisssms9116Noch keine Bewertungen

- Belt Conveyors: Mechanical Engineering Department Carlos III UniversityDokument19 SeitenBelt Conveyors: Mechanical Engineering Department Carlos III UniversityMohamed MaherNoch keine Bewertungen

- North East of Scotland Science Consortium: Learning and Concept MapsDokument50 SeitenNorth East of Scotland Science Consortium: Learning and Concept Mapssaisssms9116Noch keine Bewertungen

- Science Action - BOOK 2Dokument46 SeitenScience Action - BOOK 2saisssms911650% (2)

- Water Rocket Design ProjectDokument8 SeitenWater Rocket Design Projectsaisssms9116Noch keine Bewertungen

- Science Expeiments Using MirrorsDokument54 SeitenScience Expeiments Using Mirrorssaisssms9116Noch keine Bewertungen

- LOW COST EQUIPMENT For Sci Ence and Techno Logy EducatiDokument217 SeitenLOW COST EQUIPMENT For Sci Ence and Techno Logy Educatisaisssms9116Noch keine Bewertungen

- Grav Fields A2 M4Dokument55 SeitenGrav Fields A2 M4aby251188Noch keine Bewertungen

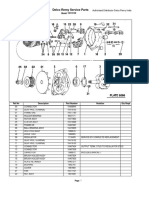

- Delco Remy Service Parts: New Indo Trading Company Authorised Distributor Delco Remy IndiaDokument2 SeitenDelco Remy Service Parts: New Indo Trading Company Authorised Distributor Delco Remy IndiaWilson AcostaNoch keine Bewertungen

- Broad X User Manual 0814 Revised PDFDokument64 SeitenBroad X User Manual 0814 Revised PDFs7ukNoch keine Bewertungen

- JC2 Physics H2 2018 RafflesDokument88 SeitenJC2 Physics H2 2018 RafflesVarshLokNoch keine Bewertungen

- 04a - Hydrapak 3 Brochure - 2015-07 - RevisedDokument2 Seiten04a - Hydrapak 3 Brochure - 2015-07 - Revisedgavsta007Noch keine Bewertungen

- Dws Info Sheet Gd31mo Alloy Slicklines For Highly Corrosive Well MediaDokument1 SeiteDws Info Sheet Gd31mo Alloy Slicklines For Highly Corrosive Well Mediaerwin atmadjaNoch keine Bewertungen

- Sunfolding Pneumatics White Paper 2020 07Dokument8 SeitenSunfolding Pneumatics White Paper 2020 07Hilmi Dhiya UlhaqNoch keine Bewertungen

- 160 Kva MangrolDokument6 Seiten160 Kva MangrolrajendranrajendranNoch keine Bewertungen

- Mark Scheme - Results Summer 2013: GCE Physics 6PH01 Paper 01R: Physics On The GoDokument18 SeitenMark Scheme - Results Summer 2013: GCE Physics 6PH01 Paper 01R: Physics On The GoAli SajjadNoch keine Bewertungen

- 1206-1906 QapDokument2 Seiten1206-1906 QapSambit NayakNoch keine Bewertungen

- Service Bulletin - Water - Pressure - Valve - AssemblyDokument3 SeitenService Bulletin - Water - Pressure - Valve - AssemblylicavitosNoch keine Bewertungen

- Rr410801 Transport PhenomenaDokument8 SeitenRr410801 Transport PhenomenaSrinivasa Rao GNoch keine Bewertungen

- Small Amplitude Soliton Propagation in A Weakly Relativistic Magnetized Space Plasma: Electron Inertia ContributionDokument10 SeitenSmall Amplitude Soliton Propagation in A Weakly Relativistic Magnetized Space Plasma: Electron Inertia ContributionSukhmander SinghNoch keine Bewertungen

- ENSC 3233 HW #1 Solution PDFDokument10 SeitenENSC 3233 HW #1 Solution PDFheem bashaNoch keine Bewertungen

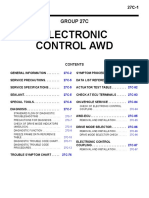

- Control Awd Gr00007300-27cDokument98 SeitenControl Awd Gr00007300-27cEdu Hdez100% (1)

- Science Unit-Wheels and LeversDokument11 SeitenScience Unit-Wheels and Leversapi-535552931Noch keine Bewertungen

- Gate&Ies - Me Postal Course Book CollectionDokument3 SeitenGate&Ies - Me Postal Course Book CollectionJaya Harshit50% (2)

- Construction and Building Materials: Ali N. AL-Gemeel, Yan ZhugeDokument9 SeitenConstruction and Building Materials: Ali N. AL-Gemeel, Yan ZhugeManisha ShewaleNoch keine Bewertungen

- Session 2Dokument74 SeitenSession 2Syed Shahzad AliNoch keine Bewertungen

- Read All Warnings: Wilwood EngineeringDokument5 SeitenRead All Warnings: Wilwood EngineeringtiagosjdrNoch keine Bewertungen

- Navier Stokes PDFDokument22 SeitenNavier Stokes PDFKhirupasagar RavibaskarNoch keine Bewertungen