Beruflich Dokumente

Kultur Dokumente

Caem Manual

Hochgeladen von

Abhijeet KatamaleOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Caem Manual

Hochgeladen von

Abhijeet KatamaleCopyright:

Verfügbare Formate

QUALITY MANAGEMENT SYSTEM

Edition No-01 Revision No-00 Dated 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

Correspondence Address: 2, SAI SAGAR OPP. TRANSMITTING STATION, HINGNA ROAD, NAGPUR, INDIA-440016

Phone-+919823274171

Standard: ISO 9001:2008QMS

This Quality Management System Manual is the sole property of M/s CAEM INDIA SHELVING PRIVATE LIMITED and should not be copied or reproduced without the prior permission of the DIRECTOR.

CAEM INDIA SHELVING PRIVATE LIMITED

QUALITY SYSTEM MANUAL

SECTION -.0.2 ISO-9001:2008 Date of Rev Rev No

QUALITY MANAGEMENT SYSTEM

EDITION HISTORY Description of changes

Doc no.: CISPL/QMS Rev. no : 00,Issue:01 Date :07/02/11 Page : 1 OF 1

APPROVED BY SINGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

QUALITY SYSTEM MANUAL

SECTION -.0.3 ISO-9001:2008 Remove Page No.: & Rev No Insert Page No. & Rev No.

QUALITY MANAGEMENT SYSTEM

REVISION HISTORY Amendment Changes made Date

Doc no. : CISPL/QMS Rev. no : 00, Issue:01 Date :07/02/11 Page : 1 OF 1 Signature of copy holder & Date

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

QUALITY SYSTEM MANUAL

SECTION -.0.4 ISO-9001:2008

QUALITY MANAGEMENT SYSTEM

SCOPE AND APPROVAL

Doc no. : CISPL/QMS Rev. no : 00,Issue:01 Date :07/02/11 Page : 1 OF 1

Quality Manual Structure

The Quality Management System is structured as per the requirements of standard ISO 90012008 through chapters 4.0 to 8.0 which are in line with the technical requirements of the products, for suitable quality achievement as envisaged by the group.

SCOPE:

The Quality Management System covers all aspects and facts of:

TRADING OF MODULAR FURNITURES. FURNITURES.

Quality Management System The Quality Management System is derived from the Quality Policy and objectives given in this manual, and is customer focused & aimed at enhancing customer satisfaction and gaining an acceptance of the product in the market. It also meets the regulatory and legal requirements of the product. It uses the process approach, systematic identification and management of activities / processes that are employed through, a sequential process of As documented in the different sections

APPROVAL

DIRECTOR approves this Quality Manual and is committed,

To meet and exceed customer requirements, & expectations, besides complying with relevant statutory and legal obligations. To practice the QMS in all sphere of working of the company and thus to serve Customers with great & prompt responsiveness To establish, implement and review the quality policy and its objectives, with a view to ensuring their continuous suitability through improvements as necessary to make available all necessary resources including providing an infrastructure of facilities For achieving this purpose.

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

QUALITY SYSTEM MANUAL

SECTION 1.0 ISO-9001:2008

QUALITY MANAGEMENT SYSTEM

TABLE OF CONTENT

Section. NO. 0.1 0.2 0.3 0.4 1.0 2.0 2.1 Cover page Edition History Revision History Scope and Approval Table of Content Introduction of Company Distribution CONTENTS

Doc no. : CISPL/QMS Rev. no: 00,Issue:01 Date :07/02/11 Page : 1 OF 1

REV. NO. 00 00 00 00 00 00 00 PAGES 01 01 01 01 02 01 02

2.2 3.0 4.0 5.0

Application Quality Policy & Quality Objectives Quality Management System-Documentation Requirement Management Responsibility Annexure-I Annexure-II Annexure-III

00 00 00 00 00 00 00 00 00 00 00 00

01 01 04 04 03 01 01 03 09 07 01 01

6.0 7.0 08 09 10

Resource Management Production Realisation Measurement Analysis & Improvement List of Record List of Work Instruction

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

QUALITY SYSTEM MANUAL

SECTION 2.0 ISO-9001: 2008

QUALITY MANAGEMENT SYSTEM

INTRODUCTION OF COMPANY

Doc no.: CISPL/QMS Rev. no: 00,Issue:01 Date :07/02/11 Page : 1 OF 1

INTRODUCTION OF COMPANY

The manufacturing facility of the company is located in the Nagpur and employee state of the art technologies and equipments, which enables it to each global scale of sales and quality. Strong raw material supply base coupled with highly competent manpower provide the plant a competitive edge in the market. CAEM INDIA SHELVING PRIVATE LIMITED is rated high on the customer satisfaction index as it gives a lot of customers focus in serving them better.

As Per CUSTOMERS REQUIREMENT.

The Company has embarked on a modernisation programme to that end it has chosen to go for Quality Management System as per ISO 9001:2008 in its organisation.

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 QUALITY SYSTEM MANUAL SECTION -.2.1 QUALITY MANAGEMENTSYSTEM DISTRIBUTION Doc no. : CISPL/QMS Rev. no : 00,Issue;01 Date :07/02/11 Page : 1 OF 2

Quality Manual is the document, which describes the Quality Management System and procedures, established and implemented by CAEM INDIA SHELVING PRIVATE LIMITED to meet the requirements of International Standard ISO 9001: 2008 and to consistently provide product that meets customer and applicable regulatory requirements. Quality Management System, which is customer focused, aims to enhance customer satisfaction through the effective application of the system and the processes for its continual improvement and the assurance of conformity to customer and applicable regulatory requirements. Manual refers supply chain of supplier - Organization - Customer. Product refers to service provides also.

DISTRIBUTION 1 The Manual, its copies or extract from it, must not be passed on to any person without the written permission of DIRECTOR of CAEM.. Unnumbered / Uncontrolled copies may be given to Customer / Outside agencies purely for information purpose. UNCONTROLLED copies are not covered under change control but are current at the time of Issue. Management Representative (MR), is responsible for establishing and maintaining the processes of the Quality Management System, for periodically reporting to the management on the performance of the system and for promoting awareness of customer requirements through out the organisation. The CONTROLLED copies are covered by change control and are stamped in red on all pages. The controlled copies are distributed to Functional Heads. It is the responsibility of CONTROLLED copyholder of this Manual to maintain and incorporate all revision on receipt and keep it up to date.

Copy No. 1- ------------- DIRECTOR. Copy No. 2 --------------Management Representative (Master Copy) Copy No. 3----------------Certification Body (KVQA) Copy No.4--------------- Quality Control

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

QUALITY SYSTEM MANUAL

ISO-9001:2008

SECTION 2.1

QUALITY MANAGEMENT SYSTEM

LIST OF ABREVATIONS SR.NO. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 ABREVATION PUR STR PRD PDEV QA MTN DEP SAL REV G.R.R. ENGG CISPL QMS M.D HOD NCP CAPA DEV COMM P.O. MR IS QMS Purchase Store Production Product Development Quality Assurance Maintenance Despatch Sales Revision Good Receipt Register Engineering

Doc no. : CISPL/QMS Rev. no. : 00,Issue:01 Date :07/02/11 Page : 2 OF 2

DESCRIPTION

CAEM INDIA SHELVING PRIVATE LIMITED Quality Management System Managing DIRECTOR Head of the department Non Conforming Products Corrective Action Preventive Action Development Commercial Purchase order Management Representative International Standard Quality Management System

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 QUALITY SYSTEM MANUAL SECTION -.2.2 QUALITY MANAGEMENT SYSTEM APPLICATION Doc no. Rev. no. Date Page : CISPL/QMS : 00,Issue:01 :07/02/11 : 1 OF 1

APPLICATION The following requirements of the ISO 9001-2008 neither affect the organizations ability nor absolve it from its responsibility, to provide product that meets customer and applicable regulatory requirements. The exclusions are limited, depending on type of product, customer requirements and applicable regulatory requirements. 1. Design and Development - As product is manufactured as per Design of Customer and from own design applicable Statutory And regulatory standard, Design activity is excluded in scope of this manual. Definitions as given in ISO 9001-2008. Following supply chain is used

Supplier

Organisation

Customer

The term organisation replaces previously used term supplier (1994 version), Sub contractor is replaced by term supplier, to match vocabulary used in general Process an activity using resources and managed to convert inputs into outputs is considered as a process. Product results of a process; is also means Service.

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 Doc no. SECTION 3.0 Rev. no QUALITY POLICY AND QUALITY OBJECTIVES Date Page QUALITY POLICY

QUALITY SYSTEM MANUAL

: CISPL/QMS : 00,Issue:01 :07/02/11 : 1 OF 1

QUALITY POLICY

WE AT CAEM INDIA SHELVING PRIVATE LIMITED ARE COMMITTED TO PROVIDE TRADING OF THE PRODUCT AS PER CUSTOMERS REQUIREMENT IN IN TIME, THROUGH

CONTINUAL

IMPROVEMENT

QUALITY

MANAGEMENT

SYSTEMS AND INVOLVEMENT OF ITS EMPLOYEES.

QUALITY OBJECTIVES

We, Employees of CAEM INDIA SHELVING PRIVATE LIMITED. Shall Achieving total Customer Satisfaction, by 100% timely delivery. Increase in sales 25% per year. Reducing rejection by, 2% every year.

Continual Improvement Quality Management System & to meet changes in technology.

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 QUALITY SYSTEM MANUAL SECTION 4.0 QUALITY MANAGEMENT SYSTEM. TITLE: Documentation Requirement Doc no. : CISPL/QMS Rev. no. : 00,Issue:01 Date :07/02/11 Page : 1 OF 4

1.0 Purpose: The purpose of this chapter is to provide an overview of the companys Quality Management System and the principles upon which it is built. (ISO 9001:2008) and. operated. 2.0 Scope: This section applies to the whole of the companys documentation establishment, Implementation, maintenance and continual improvement of the quality management System, as well as the preparation of quality plans for all products manufactured by the Company. 3.0 Responsibility: The responsibility for implementation review approval and improvement lies with the Management Representative has the overall responsibility for document control. Concern HODs. are to maintain records in their areas. 4.0 Definition : 4.1 General Requirements The company has developed and implemented a documented Quality Management System to meet the requirements of ISO 9001:2008 standards. The Quality Management System, is implemented by Processes are identified throughout the organisation including those for management activities, resources, product realisation and measurement needed for the QMS (refer Process flow Diagram annex. II) a) The sequence and interaction of these processes are determined b) The criteria and methods required to ensure the effective operation and control of these processes are suitably determined (ref.; Quality Plans) c) The availability of resources and information necessary to support the operation and monitoring of these processes is determined (through; Work Instructions) d) Measuring, monitoring and analysing these processes. e) Implementing actions necessary to achieve planned results and continual improvement of these processes. f) The company plans & manages these processes in accordance with QMS. The Quality Management system also has a provision for controlling any process/s which is / are out sourced.

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 QUALITY SYSTEM MANUAL SECTION 4.0 QUALITY MANAGEMENT SYSTEM. TITLE: Documentation Requirement Doc no. : CISPL/QMS Rev. no : 00,Issue:01 Date :07/02/11 Page : 2 OF 4

4.2 Documentation Requirements 4.2.1 General The Organisation chart and responsibility and authority of the main personnel is defined and documented. (Annexure-III and AnnexureI ) ( As per 4.2.1. of ISO 9001:2008 ) The Quality Policy & Quality Objectives provide the basis for QMS (As stated in chapter 3). The Quality Management System together with the documented procedures as required in ISO 9001-2008 are the main framework of the system. Documented operating procedures as required by the Organisation, such as Quality Plans, Work Instructions, Specifications, Drawings etc, Quality records as required by standard ISO 9001-2008 (4.2.4), for effective operation and control of activities/processes The procedures describing the logical sequence of activities with necessary control and responsibility, are established, documented, implemented and maintained. NOTE: -The Documentation including procedures is apt for the size and type of our company, complexity and inter-relation of activities and competence/skill level of personnel. It can be in any form or type of medium e.g. hard copy / Electronic media. Checklist of the key procedures as per Annexure IV. However current status of all procedures is available in Master list of procedures. 4.2.2 Quality Manual The Quality Manual, (this Manual) which is established and maintained, details the scope of the QMS, exclusions with justifications & documented procedures or reference to them. It also describes the interaction between the processes of QMS. 4.2.3 Control of Documents All Documents of the Quality Management System are controlled. A documented procedure is established in 4.2.3.1 of the section, with 4.2.3 of ISO 9001:2008 to cover the following : To approve all documents for adequacy prior to Issue. To review, update and re-approve documents. To identify the current revision status of documents. To ensure that relevant version of documents are available at the points of use. 4.2.4 Control of Quality Records A documented procedure is established in 4.2.4.1of the section, for the Identification, storage, retrieval, protection, retention-period and disposition of all Quality Records. Quality records are legible, readily identifiable and retrievable. Records required, as evidence of conformance to requirements and for effective operation of Quality Management System are controlled. APPROVED BY ISSUED BY SIGNATURE DESIGNATION DIRECTOR MR DATE 07/02/11 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 QUALITY SYSTEM MANUAL SECTION 4.0 QUALITY MANAGEMENT SYSTEM. TITLE: Documentation Requirement Doc no. : CISPL/QMS Rev. no : 00,Issue:01 Date :07/02/11 Page : 3 OF 4

Procedure :

4.2.3.1 Control Of Document, Review, Approval & Issue 1.0 Identify and document the procedures and work instructions 2.0 Discuss with DIRECTOR. 3.0 Document the procedures / work instructions on standard format 4.0 Decide and Issue Quality Policy and Objectives. 5.0 Document Quality Manual briefly covering the Quality Management System of the Company as per the clauses of the ISO 9001-2008. 6.0 Get approval of the document from authorised signatory 7.0 Sign all pages in the column marked Issued by. 8.0 Make required number of photocopies and stamp each page with Controlled Copy In red ink and distribute to the holders of controlled copies as per list. 9.0 Retain copy with mark as Master Copy on back side of each page for making Further copies. 10.0 When ever there is a change in any document and if such copies Are preserved for reference purpose retain such copies with mark Obsolete Copy In red ink. 11.0 Record the documents in Master Register. 12.0 External documents like National &International standards and statutory and legal Requirements reviewed and controlled. A list is maintained.

4.2.3.2 Document Revision & Cancellation 1.0 Discuss all changes suggested with the concerned H.O.D/DIRECTOR. 2.0 Follow procedure as listed in 5.1 ensuring that the approving and the issuing is done by the Same functional authority as was in the original approval and the next rev is marked. 3.0 Put revised documents in all controlled copies through concerned H.O.D. and complete the Revision list in the copy 4.0Remove copies of the old revision from each copy. 5.0 Retain one copy of the old revision and destroy all others copies. 6.0 Update the Master Register 7.0 Retain all documents for period of one year.

------APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 QUALITY SYSTEM MANUAL SECTION 4.0 QUALITY MANAGEMENT SYSTEM. TITLE: Documentation Requirement Doc no. : CISPL/QMS Rev. no : 00,Issue:01 Date :07/02/11 Page : 4 OF 4

4.2.4.1 Control Of Records 1.0 2.0 3.0 4.0 5.0 6.0 7.0 8.0 Maintain a list of all records Issue relevant copy to each Head Maintain the list of records to be available with each H.O.D. so that these are Easily retrievable, legible and are identifiable to each operation. Keep records in racks, other safe places to avoid damage. Maintain the records for those years as decided three years or less. Keep backup record in Computer/Electronic media for all records maintained as in Soft copy. Carry out scrutiny of obsolete records after specified retention period and dispose off Unwanted records by burning, or selling as waste.

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 QUALITY SYSTEM MANUAL SECTION 5.0 QUALITY MANAGEMENT SYSTEM. TITLE: Management Responsibility Doc no. : CISPL/QMS Rev. no : 00,Issue:01 Date :07/02/11 Page : 1 OF 4

1.0 Purpose: The purpose of this chapter is to provide an overview of the companys Management responsibility, Authority and Management commitments to enhance the customers satisfaction. 2.0 Scope: This section applies for Commitment of the top management by documenting and implementing the Quality policy and Quality objectives, Quality management system planning, Quality planning, Responsibilities and authority and maintaining effective internal communication in the organisation. 3.0 Responsibility: Managing DIRECTOR are responsible for assigning the responsibility and authority to the individual employees, deciding the Quality policy and Quality objectives and concern H.O.D. are responsible for implementing and maintaining in their respective dept. 2.0 Definition : 5.1 Management Commitment Top managements commitment to the development, implementation and improvement of the Quality Management System is evidenced by: a) Its Communication to all concerned in the organisation, the importance of meeting customer requirements of the product as well as statutory and regulatory requirement as applicable. b) Statement / establishing of the Quality Policy c) Ensuring establishment of Quality Objectives d) Conducting management review meetings. e) Ensuring the availability of necessary resources, manpower, for all activities. 5.2 Customer Focus (Refer 7.2.1 and 8.2.1)

DIRECTOR of the organisation ensure that customer requirements are determined and are fulfilled

with the aim of enhancing Customer satisfaction.

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 QUALITY SYSTEM MANUAL SECTION 5.0 QUALITY MANAGEMENT SYSTEM. TITLE: Management Responsibility Doc no. : CISPL/QMS Rev. no : 00,Issue:01 Date :07/02/11 Page : 2 OF 4

5.3 Quality Policy The Quality Policy Statement (section 3.0) defines the Organisations Quality policy. Employees are fully briefed about this policy on joining the Organisation and during planned training. All employees are responsible to implement the Quality Policy of the Organisation. The Quality Policy is displayed at prominent places within the Organisation and is controlled. Top management, while defining Quality Policy, considers the following; It is appropriate to the purpose of the Organisation. It reflects commitment to meet the requirements, and continually improve the effectiveness of Quality Management System. It has a framework for defining and reviewing of Quality Objectives. It is communicated and understood by all concerned in the Organisation. It is regularly reviewed for continuing suitability. 5.4 Planning 5.4.1 Quality Objectives (7.1a Planning of product realisation) Management ensures, establishing Quality Objectives at relevant functions and levels within the Organisation. These objectives are measurable, and consistent with the quality policy, commitment to continual improvement and also for meeting the requirements of the products. These objectives are constantly reviewed (5.6.1)

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 QUALITY SYSTEM MANUAL SECTION 5.0 QUALITY MANAGEMENT SYSTEM. TITLE: Management Responsibility Doc no. : CISPL/QMS Rev. no : 00,Issue:01 Date :07/02/11 Page : 3 OF 4

5.4.2 Quality Management System Planning The Quality Management System is Planned to meet the requirement of ISO 9001:2008 and also the Quality Objectives defined by the Organisation. The Documented Quality Management System is the result of planning and is in line with the Quality Objective that the Management set. The requirement which the system meant to meet are (4.1): a) Determination of the process needed for the system and application throughout the organisation. b) Determination of the sequence and interaction of these processes. c) Determination of the criteria and method to ensure the effectiveness of the operation and control of the processes. d) Making available the requisite resources human as well as physical to support the operation & Monitoring of the processes. e) Monitoring, Measuring and analysing the processes. f) Initiating actions to achieve planned results and also for continual improvement of the Processes. g) The Management further ensures that the integrity of the QMS is maintained wherever any Changes to the system are planned and implemented. 5.5 Responsibility, Authority & Communication 5.5.1 Responsibility and Authority Functions, responsibility and authority (Refer Annexure-I) are defined and communicated, to all concerned for effective quality managements system. 5.5.2 Management Representative Management Representative Mr. Hemant Gupta who irrespective of other responsibilities, is responsible and Authorised for following; a) To establish, implement and maintain the processes of Quality Management System. b) To report to management on the performance of the Quality Management System and also on any need for Improvement. c) To promote awareness of Customer requirements, throughout the Organisation and to liaison With external agencies on matters relating to Quality Management System, as deemed Necessary. 5.5.3 Internal Communication Appropriate communication processes regarding Quality Management System & its effectiveness, are established, within the Organisation. Management ensures such communication regarding effectiveness of Quality Management System. APPROVED BY ISSUED BY SIGNATURE DESIGNATION DIRECTOR MR DATE 07/02/11 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 QUALITY SYSTEM MANUAL SECTION 5.0 QUALITY MANAGEMENT SYSTEM. TITLE: Management Responsibility Doc no. : CISPL/QMS Rev. no : 00,Issue;01 Date :07/02/11 Page : 4 OF 4

5.6 Management Review 5.6.1 General DIRECTOR reviews the implementation of Quality Management System, at planned intervals to ensure its continuing suitability, adequacy and effectiveness. The review covers, evaluation of the need for changes, to this system, Organisations Quality Policy and Quality objectives. For this purpose a Management Committee consisting of DIRECTOR Incharge Production, In charge Quality Assurance and Incharge Marketing & a sale is appointed. Records from management review are maintained. 5.6.2 Review Inputs The Review inputs for the Management review include the current performance and opportunities for improvements on the following: Follow up Action from previous Management reviews. a) Audit reports findings. b) Customer feedback c) Process conformance and product conformity d) Status of corrective action and preventive action. e) Review of Quality Management System such as Issues related to Quality Policy and Objectives. f) Technological Up-gradation, Training needs, Resource profiles etc. g) Suitability and effectiveness of Quality Management System h) Recommendation for improvement. I) Resources required 5.6.3 Review output a) The Review outputs from the Management Reviews, include actions relating to: b) Required Improvement of the effectiveness of the Quality Management System and its Processes. 3) Required Improvement of product related to the customer requirements. 4) Resources requirements/needs. 5) The minute of the Management Review meetings are recorded and extracts circulated to Concern dept. Incharge for action by the MR.

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

QUALITY SYSTEM MANUAL

ISO-9001:2008

ANNEXURE - I

QUALITY MANAGEMENT SYSTEM

RESPONSIBILITY AND AUTHORITY 1.0 2.0

Doc no. : CISPL/QMS Rev. no : 00,Issue:01 Date :07/02/11 Page : 1 OF 3

DIRECTOR. Formulates all decisions and implements them Manages the fund flow for effective functioning of entire unit. Gives the Quality Policy and Objectives of the company. Lays down task and targets for all. Identifying training needs and preparation of training calendar. To create work environment by educating and motivating employees in organisation. To provide infrastructure for implementing quality management system. Interacts with the customer for all matters relating to product and services. Responsible for Administration, office efficiency & effectiveness Responsible for the effective operations in compliance with policies and objectives. Chairs Management review meetings. Ensure safety requirement are being followed and safety equipment are in order

Management Representative DIRECTOR have appointed as a Management Representative. Establishment, Implementation, Documentation and Maintenance of the Quality systems. Planning & Conducting Internal audits. Attend to all customer feedback Identify the training needs of all and carryout training of people . Provide service and technical support to all customers (If required) Evaluating performance of Quality systems & corrective action and preventive action Preparation of agenda for Management Review Meeting. Preparation of Management Review Meeting Schedule. Organising Management Review Meetings and corrective action Preparation of reports for consideration by the meeting. Action on the recommendations of Management Review Meetings. Co-ordination with supplier for system audits. Co-ordination with the customer for audit. Co-ordination with the certifying body.

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 QUALITY SYSTEM MANUAL ANNEXURE - I QUALITY MANAGEMENT SYSTEM RESPONSIBILITY AND AUTHORITY Doc no. Rev. no Date Page : CISPL/QMS : 00,Issue:01 :07/02/11 : 2 OF 3

3.0 4.0 5.0

Incharge Quality Control Preparation of specification for bought out and finished Components. To arrange for receiving and final inspection of raw material and finished product. To get feed back regarding product quality. To keep trend of customer complaint. Verification of records generated In process and final inspection. To monitor Calibration of all monitoring and measuring devices. Make decision regarding quality deviated products at incoming/ In process/ final stages.

Incharge Production To monitor production quantity & quality as per the targeted schedule. To get the maximum out put with available resources. To prepare and maintain production records. To finalise optimum processing condition for each process & components. To maintain plant, machinery & Equipments in order to achieve required productivity Initiation of corrective & preventive action. To maintain neat house keeping Monitoring of Preventive & break down Maintenance of tools. To monitor and maintain the proper house keeping in the shop floor

Incharge Marketing & Sales Preparation and Forwarding of Quotation for enquires received. Follow up and finalisation of orders. Co-ordination with customer and staff in the organisation Co-ordination for planning of Trial / first lot production. Follow up with customer For results of trial. Establishing new areas of business as and when the need arises. Incorporating new products in to the System and release of all relevant Information / documents to the Concerned dept. Co-ordination and follow with customer for getting the feed back on supplied product. Taking corrective and preventive action on customer complaints for entire customer satisfaction.

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

QUALITY SYSTEM MANUAL

ISO-9001:2008

ANNEXURE - I

QUALITY MANAGEMENT SYSTEM

RESPONSIBILITY AND AUTHORITY 6.0

Doc no. Rev. no Date Page

: CISPL/QMS : 00,Issue:01 :07/02/11 : 3 OF 3

Incharge Purchase Procurement of materials conforming to required specification against indent - raised. Development assessment approval of supplier Review & verification of purchase records Arrange for supplier Payment In time Take appropriate action on suppliers in case of not fulfilling the specified Requirements in the contract. Inform / Discuss Supplier quality rating to the concern and Intimate Q.A for poor quality rating of supplier.

7.0

Incharge Stores Preparation and verification of GRR. Control & monitor of handling / storage Preservation / receipt / Issue of materials. Arrange for dispatches as per customers schedule and preparation of necessary records required. Issue of materials and collection of bought out off-loaded and raw materials as per requirements. To monitor despatches for supplier for off-loaded work.

8.0

Incharge Commercial Updating the records of training of all personnel within the organisation in their respective file. Monitoring on Purchase activities. Monitoring on Sales Activities Monitoring on payment of Customer, Supplier. And Bank Transactions. Monitoring on Sales A/c s and Purchase A/cs activities. Monitoring on other commercial activities. Monitoring on Excise formalities and Excise records.

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

QUALITY SYSTEM MANUAL

ANNEXURE - II ISO-9001:2008

QUALITY MANAGEMENT SYSTEM

SEQUENCE & INTRACTION OF PROCESSES

Doc no. Rev. no Date Page

: CISPL/QMS : 00,Issue;01 :07/02/11 : 1 OF 1

S u p p l i e r s Assessment Schedule

Su p p l i e r s A u d i t

C A & PA / Im p ro v e m e n t O n n o n c o n fo r m i t i e s

In t e rn al A u d i t S c h e d u l e

Annual Plan

C h o o s e A g e n cy f o r C a l i b r a t i o n

D e p a rt m e n t P l a n ( Q u a l i t y O b j e c t i v e s ) C u s t o m e r R eq u i re m e n t C u s t o m er In t e r f ac e / E n q u i ry & O rd e r M o n t h l y S a l e s S ch e d u l e

C a l i b ra t i o n

CA & PA Is s u e t o l o ca t i o n

P ro d u ct i o n Pl an

C u s t o m e r Sp e ci fi c a t i o n CA & PA

E n q u i ry / Q u o t a t i o n s / P u r ch a s e O rd e r In t e rn al A u d i t R ec e i p t In s p e c t i o n & Is s u e

NCP

Im p ro v e m en t & C A & PA o n N o n c o n fo rm i t i e s CA & PA

P ro d u ct i o n

CA & PA

I n p ro c e s s In s p .

NCP

Analysis

P o s t O p e r at i o n

CA & PA

Fi n a l In s p e c t i o n

NCP

Customer Complaints

C u s t o m e r A c c ep t a n c e D i s p a t ch Payment

C u s t o m e r P e r ce p t i o n

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

QUALITY SYSTEM MANUAL

Annexure -III ISO-9001:2008

QUALITY MANAGEMENT SYSTEM

ORGANISATION CHART

Doc no. Rev. no Date Page

: CISPL/QMS : 00,Issue:01 :07/02/11 : 1 OF 1

Organisation Chart PROPRITOR

Production Manager

Quality Control

Marketing/ Sales

Purchase

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 QUALITY SYSTEM MANUAL SECTION 6.0 QUALITY MANAGEMENT SYSTEM TITLE: RESOURCE MANAGEMENT Doc no. : CISPL/QMS Rev. no : 00,Issue:01 Date :07/02/11 Page : 1 OF 3

1.0 Purpose: The purpose of this chapter is to provide and documented procedure for maintaining the adequate resource for smooth function of the Quality management system in the organisation. 2.0 Scope : This section applies for provision of resources, the Identification of training needs, imparting the training to employees, Maintenance of training record as well as to provide, maintain infrastructure and Manage the work environment needed for achieving conformity of product. 3.0 Responsibility: The responsibility for this lies with DIRECTOR, M.R. and concerned H.O.D. 4.0 Definition : 6.0 General : 6.1 Provision of Resources The Resources required are determined and provided in a timely manner to implement, maintain and improve the Quality Management System and continually improve its effectiveness and to enhance Customer satisfaction by meeting the customer requirements. of ISO 9001:2008. The Resources covers equipment and accessories, trained personnel, monitoring and measuring equipment. DIRECTOR ensures that personnel who are assigned responsibilities, under the Quality Management functions, are competent and are suitably qualified on the basis of education, training, skill and experience 6.2 Human Resources. 6.2.1 General The Management ensures that personnel who are assigned, responsibilities, under the Quality Management functions, are competent and are suitably qualified on the basis of education, training, skill and experience,

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 QUALITY SYSTEM MANUAL SECTION 6.0 QUALITY MANAGEMENT SYSTEM. TITLE: RESOURCE MANAGEMENT Doc no. : CISPL/QMS Rev. no : 00,Issue:01 Date :07/02/11 Page : 2 OF 3

6.2.2 Competence, Awareness and Training The organisation takes action to; Lay down competence requisites for personnel performing activities affecting Products Quality. Provide suitable training to satisfy these needs. Evaluate the effectiveness of the training provided. Ensure that its employees are aware of the relevance and importance of their activities and their contribution to achieve quality objectives. Maintain appropriate personnel records of education, skills /experience, training (4.2.4)

6.3 Infrastructure The organisation also determines, provides and maintains the requisite infrastructure of facilities for achieving conformity of product including Buildings, Workspace and associated Utilities. Process equipments, hardware and software. Supporting services such as transport or communication. 6.4 Work Environment The organisation further identifies and manages the human and physical factors of the work environment necessary to achieve conformity to product requirements.

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 QUALITY SYSTEM MANUAL SECTION 6.0 QUALITY MANAGEMENT SYSTEM. TITLE: RESOURCE MANAGEMENT Doc no. : CISPL/QMS Rev. no : 00,Issue:01 Date :07/02/11 Page : 3 OF 3

Procedure : Identify Training Needs

Preparation Of Training

Selection Of Faculty

Preparation Of Schedule

Unsatisfactory Result

Information To Employees

Conduct Training

Get Feed Back Of Training

Evaluate Effectiveness

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 QUALITY SYSTEM MANUAL SECTION 7.0 QUALITY MANAGEMENT SYSTEM. TITLE: PRODUCT REALISATION Doc no. : CISPL/QMS Rev. no : 00,Issue:01 Date :07/02/11 Page : 1 OF 10

1.0 Purpose: The purpose of this chapter is to provide procedure for total customer satisfaction by understanding and meeting their requirements in specified time. 2.0 Scope : This section applies for Planning, Purchasing, Production and Inspection of material to meet the requirement of customer Schedule with right quality of product in right time as well as it is applicable for reviewing the requirements related to products, and maintaining customers property in good condition. 3.0 Responsibility : The responsibility for this lies with DIRECTOR and concerned H.O.D. 4.0 Definition : 7.1 Planning Of Product Realisation The planning for product realisation is that sequence of processes and sub-processes required for achieving the product quality. The organisation prepares Quality Plans that describe, how the processes of quality management system are applied in planning the processes for realisation of product. The organisation determines the following, as appropriate: Quality objectives/Quality plans for the product The need to establish processes and documentation and to provide resources specific to the product Verification, validation, monitoring, inspection and test activities, specific to the product and the criteria for acceptance. The records evidencing the realisation of the processes and conformance of the resulting product, fulfils requirements. The Organisation determines product realisation processes & acceptance criteria, through Quality Plans, of QMS for specific product. 7.2 Customer related processes 7.2.1 Determination of requirement related to the product The Organisation determines the customer requirements, which includes the following; Product requirements including availability, delivery and support as specified by the customer. Product requirements necessary for intended or specified use, if not specified by the customer. Statutory requirement and regulatory requirements of product as applicable Additional requirements as decided by the Organisation related to the product.

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 QUALITY SYSTEM MANUAL SECTION 7.0 QUALITY MANAGEMENT SYSTEM. TITLE: PRODUCT REALISATION Doc no. : CISPL/QMS Rev. no : 00,Issue:01 Date : 07/02/11 Page : 2 OF 10

7.2.2Review of Requirements related to product The Organisation reviews, the identified customer requirements related to Product, together with additional requirements as determined (7.2.1 ) This review is conducted prior to the commitment to supply a product to the customer ( e.g. submission of tender, acceptance of a contract or order), to ensure following: a) Product requirements are defined. b) Where the customer does not provide any documented statement of requirements, the customer requirements are confirmed before acceptance. c) Contract or order requirements differing from that previously expressed are resolved. d) The organisation has the ability to meet the defined requirements. The results of the review and subsequent follow-up actions are recorded. (4.2.4) It is ensured that, wherever product requirements are changed, the relevant documents are amended and the concerned persons are made aware of the changed requirements. 7.2.3 Customer Communication The Organisation identifies and implements, effective arrangements for communicating with the customer relating to following; Product information; Enquires, contracts or order handling, including amendments. Customer feedback including Customer complaints.

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 QUALITY SYSTEM MANUAL SECTION 7.0 QUALITY MANAGEMENT SYSTEM. TITLEL:DESINE AND DEVELOPMENT Doc no. : CISPL/QMS Rev. no : 00,Issue:01 Date : 07/02/11 Page : 3 OF 10

7.3 Design and Development 7.3 Design and Development 7.3.1 Design and Development Planning The organization has got a separate design department functioning in the guidance of DIRECTOR named R&D. The department is responsible for the planning of design and development activities for product and installations in consultation with the DIRECTOR. Suitable processes for review, verification and validation of the design and development are also established. 7.3.2Design and Development Inputs Inputs necessary for the design ad development 1) Drawings 2) Technical requirements 3) Functional requirements are received from the customers. Drawing sketches are prepared based on these informations. the inputs are reviewed and ambiguities are resolved internally as well as with customer if necessary. 7.3.3 Design and Development Outputs Is assessed to see that output meets the input requirements All departments are involved and acceptance criteria made known to all Special safety and use conditions are made known. 7.3.4 Design and Development Review A formal review is done by DIRECTOR for the effective verification of the design and development outputs against the inputs. Representative form the various related departments like production, quality assurance, purchase, marketing and outside specialist if required take part in the review. The decisions of such reviews are recorded. Reviews enable to evaluate whether the design outputs are meeting the product requirements or not. Also the problems incurred can be resolved. 7.3.5 Design and Development verification The output results of Design ad development are verified against the planned requirements to evaluate and ascertain that they are as per the input requirements. Records of the verification and necessary actions are recorded. Verification is carried out by Head of design and approved by DIRECTOR 7.3.6Design and Development validation Design and development validation is done in accordance with the plan and it is ensured that the resulting product is capable of meeting the requirements of specified application. This is done prior to the delivery to the customer. Functional trial is also done wherever necessary. Final validation is done by Head of quality assurance and approved by DIRECTOR 7.3.7Control of Design and Development changes Drawing changes as found necessary during reviews or as suggested by the customer are recorded. New specifications are established incorporating the changes. Changes shall be reviewed before.

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 QUALITY SYSTEM MANUAL SECTION 7.0 QUALITY MANAGEMENT SYSTEM. TITLE: PURCHASING Doc no. : CISPL/QMS Rev. no : 00,Issue:01 Date : 07/02/11 Page : 4 OF 10

7.4 Purchasing 7.4.1Purchasing Process The organisation controls its purchasing processes to ensure that purchased products conform to specified purchase requirements. The type and extent of control applied to the suppliers and purchases product depends upon the effect on subsequent product realisation processes or the final product. The organisation evaluates and selects suppliers based on their ability to supply product in accordance with Organisations requirement. Criteria for selection evaluation and periodical reevaluation of suppliers are established. The results of evaluations and necessary follow up actions are recorded and maintained. (4.2.4) 7.4.2 Purchasing Information Purchasing documents contains information describing the product to be purchased including, as appropriate, the following: Requirement for approval of product, procedures, processes, and equipment. Requirement for Qualification of personnel Quality management system requirements The organisation ensures the adequacy of specified purchase requirements contained in the purchasing documents, prior to their communication to the supplier. 7.4.3 Verification of Purchased Product The organisation establishes and implements, inspection and other activities necessary for verification of the purchased product vis a vis the specified purchase requirements. Where it is proposed either by the organisation or its customer, to perform verification activities at the suppliers premises, the intended verification arrangements and method of product release, are clearly specified in the purchasing information. 7.5 Production and Service provision 7.5.1Control of production The Organisation plans and controls all production operations under controlled conditions including as applicable: a) Making available, information that describes the characteristics of the product. b) Availability of work instructions, as necessary. c) Using and maintaining suitable plant and machinery. d) *Availability and use of the monitoring and measuring devices e) Implementing of monitoring and measurement. f) The implementation of release, delivery and post-delivery activities.

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 QUALITY SYSTEM MANUAL SECTION 7.0 QUALITY MANAGEMENT SYSTEM. TITLE: PRODUCT REALISATION Doc no. : CISPL/QMS Rev. no : 00,Issue:01 Date :07/02/11 Page : 5 OF 10

7.5.2 Validation of processes for production The organisation validates any processes for production and service provisions where the resulting output cannot be verified by subsequent monitoring measurement. This includes any processes where deficiencies may become apparent only after the product is put to use. Such validation is carried out, to demonstrate the ability of the processes to achieve the planned results. The organisation defines and makes all arrangements for validation of the processes which include the following as applicable: a) Defined criteria for approval and review of processes b) Approval of equipment and qualification of personnel c) Use of defined methodology and procedures d) Requirements of records (4.2.4) e) Revalidation 7.5.3 Identification and Traceability The organisation identifies, where appropriate, the product by suitable means throughout product realisation The organisation does identify the status of the product with respect to monitoring and measurement requirements. The organisation does control and record the unique identification of the product, where Traceability is a requirement (4.2.4) 7.5.4 Customer Property The organisation does exercise care with the customer property while it is under its control or being used by it. The organisation does identify, verify, protect and safeguard customer property provided for use or incorporation into the product. Incidence of any loss, damage or unsuitability, of customer property is recorded and reported to the customer. Where applicable intellectual property are included as customer property. 7.5.5 Preservation of Product The organisation does preserve the conformity of the products, including constituent parts, with the customer requirements during internal processing and delivery to the intended destination. This covers identification, handling, packaging, storage and protection.

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 QUALITY SYSTEM MANUAL SECTION 7.0 QUALITY MANAGEMENT SYSTEM. TITLE: PRODUCT REALISATION Doc no. : CISPL/QMS Rev. no : 00,Issue:01 Date :07/02/11 Page : 6 OF 10

7.6 Control of monitoring and measuring devices The organisation determines the monitoring and measurements to be carried out and the devices required for the purpose, to assure conformity of the product to specified and determined requirements (7.2.1). The organisation puts in place appropriate processes to ensure that monitoring and measurement are carried out in a manner consistent with monitoring & measurement requirements. Where necessary, ensure valid results measuring equipments are: Verified at specified intervals and calibrated and adjusted prior to use, against traceable international or national measurement standards. Where no such standards exist, the basis used for calibration or verification is recorded. Adjusted or readjusted as necessary Identified to enable to determine the calibration status. Safe guarded from adjustments that would invalidate the calibrations/measurements results. Protected from damage and deterioration during handling, maintenance and storage. The organisation ensures that the result of calibration is recorded besides assessing and recording. The validity of previous results are assessed and recorded when the equipment is found to be out of calibration and taking corrective action on equipment and any product affected. Records of results of calibration and verifications are maintained (4.2.4). Computer Software used if any, for measuring and monitoring of specified requirement. The ability of computer software to satisfy the intended applications is confirmed prior to use and reconfirmed as necessary.

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

ADOS ELECTRONICS PVT. LTD.

ISO-9001:2008 QUALITY SYSTEM MANUAL SECTION 7.0 QUALITY MANAGEMENT SYSTEM. TITLE: PRODUCT REALISATION Doc no. : CISPL/QMS Rev. no : 00,Issue:01 Date :07/02/11 Page : 7 OF 10

Procedure Customer Related Processes : Enquiry From Customer Drawing Specification Study Of Enquiry Raise Quotation

Discussion And Negotiation

Receipt Of P.O Preparation Of Schedule

Amendment note If there is any changes

Co-Ordination For Completion Of Order Dispatch

Corrective And Preventive Action On Complaints

Follow Up For Feed Back

Analysis Customer Satisfaction / Dissatisfaction

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 QUALITY SYSTEM MANUAL SECTION 7.0 QUALITY MANAGEMENT SYSTEM. TITLE: PRODUCT REALISATION Doc no. : CISPL/QMS Rev. no : 00,Issue:01 Date :07/02/11 Page : 8 OF 10

Purchasing :

Indent from respective dept. approved by M.D.

Receipt Of Quotation Invitation of Approved

Send Enquirer Evaluation of Supplier

Placement Of Order & Approved By M.D.

Receipt Of Material

Rejected Material Send Back to Party

Verification of Purchased Product

Corrective & Preventive

Receipt of Accepted Material To Stores

Supplier Rating

Periodical Re-Evaluation

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED.

ISO-9001:2008 QUALITY SYSTEM MANUAL SECTION 7.0 QUALITY MANAGEMENT SYSTEM. TITLE: PRODUCT REALISATION

Visual

W

Doc no. : CISPL/QMS Rev. no : 00,Issue:01 Date :07/02/11 Page : 9 OF 10

Proper storage of raw

Purchasing raw material material

Incoming inspection by QA

A

. Selection of Size

H

Filling of Measurement Chart

P

Verification of filled information

X

Design generation by computer .

Cutting according to design

X

Fabrication

Checking Final inspection by Q.A.

Marking/labelling Packing

Dispatch

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 QUALITY SYSTEM MANUAL SECTION 7.0 QUALITY MANAGEMENT SYSTEM. TITLE: PRODUCT REALISATION Doc no. : CISPL/QMS Rev. no : 00,Issue:01 Date :07/02/11 Page : 10 OF 10

Control of Measuring and Monitoring Devices :

Documented & Coded List of Measuring & Testing Equipment

Recalibration

Record of Calibration

Calibration of Testing & Measuring Equipment (In house or Outside source)

Monitoring of Calibration Accuracy Out of Calibration

Schedule for Calibration Scraped/ Replacement

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 QUALITY SYSTEM MANUAL SECTION 8.0 QUALITY MANAGEMENT SYSTEM. TITLE: MEASUREMENT ANALYSIS AND IMPROVEMENT Doc no. : CISPL/QMS Rev. no : 00,Issue:01 Date :07/02/11 Page : 1 OF 7

1.0 Purpose: The purpose of this chapter is to provide procedure for Monitoring, Measurement, Analysis and Improvement of processes with help of implementation of quality management system. 2.0 Scope: This section applies for Measurement of Customers perception, Internal Audits, Monitoring and Measurement of Processes, Monitoring and Measurement of Product, Analysis of data and taking corrective and preventive action for Continual Improvement of product and system. 3.0 Responsibility: The responsibility for this lies with DIRECTOR, M.R. and concerned H.O.D. 4.0 Definition: 8.1 General The organisation does define, plan and implement the monitoring, measurement, analysis and improvement processes needed: To demonstrate conformity of the product To ensure conformity of Quality Management System To continually improve the effectiveness of quality management system. This includes the determination of the applicable methods including statistical techniques and the extent of their use. 8.2 Monitoring and Measurement 8.2.1Customer Satisfaction The organisation does monitor information relating to customer satisfaction and dissatisfaction as one of the measurements of performance of the quality management system. The organisation also monitors information relating to customer perception for fulfilment of customer requirement. The methodologies for obtaining and using this information are determined and documented in 8.2.1.1 of this section.

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 QUALITY SYSTEM MANUAL SECTION 8.0 QUALITY MANAGEMENT SYSTEM. TITLE: MEASUREMENT ANALYSIS AND IMPROVEMENT Doc no. : CISPL/QMS Rev. no : 00,Issue:01 Date :07/02/11 Page : 2 OF 7

8.2.2 Internal Audit The organisation conducts periodic planned internal audits to determine whether the quality management system Conforms to planned arrangement (7.1) of the requirements of the International Standard and to the Quality Management System established by the organisation and is effectively implemented and maintained. The organisation plans the audit program taking into consideration, the status and importance of the processes and areas to be audited, as well as the results of the previous audits. The audit criteria, scope, frequency and methods are defined. Selection of auditors and conduct the audits to bring about objectivity and impartiality of the audit process. Auditors do not audit their own work. A documented procedure is defined in 8.2.2.1 of this section specifying the responsibilities and requirements for planning and conducting audits, and for reporting results and maintaining records (4.2.4). Management takes timely corrective actions on deficiencies found and eliminate nonconformities and their causes detected, during the audit without undue delay. Follow up activities includes the verification of the implementation of corrective actions, and reporting of verification results. 8.2.3 Monitoring and Measurement of Processes The Organisation applies suitable methods for monitoring & where applicable measurement of QMS processes. These methods to demonstrate their ability to achieve planned results. When planned results are not achieved, appropriate correction & preventive action are taken to ensure conformity of the product. 8.2.4 Monitoring and Measurement of Product The Organisation monitors and measures the characteristic of the product, to verify that requirements for the product are fulfilled. This is carried out at appropriate stages of the product realisation process according to planned arrangement (7.1). Evidence of conformity with the acceptance criteria is documented. Records do indicate the person(s) authorising for release of product (4.2.4) Product release does not proceed until all the planned arrangement have been satisfactorily completed, unless otherwise approved by the relevant authority and where applicable by the customer.

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 QUALITY SYSTEM MANUAL SECTION 8.0 QUALITY MANAGEMENT SYSTEM. TITLE: MEASUREMENT ANALYSIS AND IMPROVEMENT Doc no. : CISPL/QMS Rev. no : 00,Issue01 Date :07/02/11 Page : 3 OF 7

8.3 Control of Non-Conforming product The Organisation ensures that product which does not confirm to the requirements is identified and controlled to prevent unintended use or delivery. The control and related responsibilities and authorities for dealing with non-conformance product are defined in a documented procedure as per 8.3.1 of this section. The organisation deals with nonconforming products in one or more of the following ways: By taking action, to eliminate the detected non-conformity during production and inspection. Records of nature of non-conformities and subsequent action taken, including concessions obtained, are maintained (4.2.4). Non-Conforming product is corrected; it is re-verified after correction to demonstrate conformity to the requirements. When non-conformity is detected, after delivery or use has started the Organisation takes action appropriate to the effects, or potential effects of the non-conformity. It is often required that the proposed rectification of the non-conforming product is reported for concession to the customer. 8.4 Analysis of data The Organisation collects and analyses appropriate data to determine the suitability and effectiveness of the Quality Management System and to evaluate where continual improvements of the Quality Management System can be made. This includes data generated as a result of monitoring & measurement and from other relevant sources. The Organisation collects and analyses appropriate data to determine the suitability and effectiveness of the Quality Management System and to evaluate where continual improvements of the Quality Management System can be made. This includes data generated as a result of monitoring & measurement and from other relevant sources. The Organisation analyses this data, to provide information on: a) Customer satisfaction (8.2.1) b) Conformance to product requirements (7.2.1) c) Characteristics and trends of processes and products including opportunities for Preventive action. d) Suppliers

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 QUALITY SYSTEM MANUAL SECTION 8.0 QUALITY MANAGEMENT SYSTEM. TITLE: MEASUREMENT ANALYSIS AND IMPROVEMENT Doc no. : CISPL/QMS Rev. no : 00,Issue:01 Date :07/02/11 Page : 4 OF 7

8.5 Improvement 8.5.1Continual Improvement The organisation plans and manages the processes necessary for the continual improvement of the effectiveness of Quality Management System and facilitates the continual improvement of Quality Management System through the use of Quality Policy, Quality Objectives, Audit results, Analysis of data, corrective and preventive actions and Management Review. 8.5.2 Corrective Action The organisation takes actions to eliminate the cause of non-conformity in order to prevent recurrence. Corrective actions are appropriate to the effect of non-conformities encountered. The documented procedure 8.5.2.1 of this section for corrective action defines requirements for: a) Reviewing Non-conformities (including customer complaints) b) Determining the causes of non-conformities. c) Evaluating the need for actions to ensure that non-conformities do not recur. d) Determining and implementing the action needed e) Recording results of action taken (4.2.4) and Reviewing of Corrective action taken 8.5.3 Preventive Action The organisation determines action to eliminate the causes of potential non-conformities in order to prevent their occurrence. Preventive action taken are appropriate to the effect of the potential problems. The documented procedure 8.5.3.1 of this section for preventive action defines requirements for Determining potential non-conformities and their causes Evaluating the need for action, to prevent occurrence of non-conformities Determining and implementing preventive action needed. Recording results of action taken (4.2.4) Reviewing of preventive action taken.

APPROVED BY SIGNATURE DESIGNATION DATEDIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 QUALITY SYSTEM MANUAL SECTION-08 QUALITY MANAGEMENT SYSTEM. PROCEDURES Doc no. : CISPL/QMS Rev. no : 00,Issue:01 Date :07/02/11 Page : 5 OF 7

Procedure : 8.2.1.1 Customer Satisfaction 1.0 Take customer feed back on phone, during meeting with the customer, specification sheet with customer remarks sent by customer, customer comments on receipt of goods and customer complaint. 2.0 Record the same in non conformance format. 3.0 Analyse the same and discuss in Management Review meetings . 4.0 Take necessary corrective and preventive actions for non-occurrence of the same. 5.0 Keep the other head of depts. Informed and inform customer on the outcome. 8.2.2.1 Internal Quality Audit 1.0 Prepare annual audit plan so that A) All departments are covered under the Quality Management System are audited at least once In quarter. B) Areas having large number of non-conformities are audited more frequently than stipulated. C) The audit covers all the requirements and clauses as specified in ISO 9001-2008. D) The audit covers review of customer feedback complaint. 2.0 Keep a list of all trained auditors. 3.0 Prepare and circulate audit schedules for individual audit to all concerned department having the details of departments to be covered clauses to be audited and the names of auditors. 4.0 The audit team must be independent of the function being audited. 5.0 Audit must be conducted by qualified and trained internal auditors, arrange for external auditors whenever required if necessary . 6.0 Carryout audit for compliance and effectiveness of QMS. 7.0 While conducting audit verify the non conformities found in previous audit. 8.0 Record Non conformities on nonconformity formats, observations and obtain acceptance and proposed corrective action and time required to resolve the same and report to MR. 9.0 Get Corrective actions verified. 10.0 Conduct management review meeting and discuss the non conformities recorded during the audit and prepare minutes of meeting. 11.0 Prepare audit summary report of Management Review.

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 QUALITY SYSTEM MANUAL SECTION-08 QUALITY MANAGEMENT SYSTEM. PROCEDURES Doc no. : CISPL/QMS Rev. no : 00,Issue:01 Date :07/02/11 Page : 6 OF 7

8.2.4.1 Monitoring and Measurement of Product 1.0 Carryout incoming material sampling, testing and approval as per specification for incoming materials and products specifications. 2.0 Product not under quality must be approved by the user department 3.0 As far as practicable no materials are released for further processing without approval. 4.0 Urgently required goods if released for without approval are positively identified and recalled if product produced is found non-conforming. 5.0 In process material are measured and monitored before release for next process and defective are rectified / rework as per requirements. 6.0 Records of all in process material are maintained. 7.0 Finished goods are made to pass the entire customer specified / agreed tests before being put to commercial use. Any discrepancy found at the final stage is tested as per the original plan so that it satisfies all the customer requirements. 8.3.1 Control On Non Confirming Products 1.0 The Quality Control personnel do reporting of the non-conformance when they find them either during production or at the final stage of monitoring and measurement. Such items are prevented from further processing These are usually entered in a non-conformance register. With details like type of Non- Conformance The cause of the nonconformity is recorded for root cause analysis. 2.0 Disposition of Non conforming items is done depending upon the nature of non conformance It can be Minor or Major a) Minor Nonconformity Minor non-conformance are those where minor nature. In all these cases the decision regarding rejection/rework/rectification or other use for acceptance is taken by the Head of Production Dept. with the consultation of Quality Control Dept . b) Non conformances Major These are those cases where performance is effected or can cause delay in Delivery or can result in major cost involvement due to rejection/rectification/rework In such case the decision is taken by the Head Production, QC and DIRECTOR. The disposition of non conforming product can be of the following types i) Reworked to eliminate the non conformity of product. ii) Accepted with or without repair by concession with the decision of DIRECTOR / Customer. iii) Re-graded for alternate use.

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 QUALITY SYSTEM MANUAL SECTION-08 QUALITY MANAGEMENT SYSTEM. PROCEDURES Doc no. : CISPL/QMS Rev. no : 00,Issue:01 Date :07/02/11 Page : 7 OF 7

8.5.1.1 Continual Improvement 1.0 Include results of achievements in the following areas for discussions in the Management Review Meetings. a) Results of Audits b) Customers feedback. c) Process performance and product conformity d) Status of preventive and corrective actions e) Follow-up actions from previous management reviews. f) Changes that could affect the quality management system g) Recommendations for improvement. 2.0 Discuss the same in the meeting so as to achieve continual improvements in process and products. 3.0 Record the decisions as minutes of meeting clearly defining the responsibility for implementation and the date of completion. 4.0 Implement decisions for continual improvements. 8.5.2.1 Corrective Actions 1.0 Send all customer feedback, product nonconformity and audit nonconformity to Head Production and Quality Control. 2.0 Record the same in non-conformance report. . 3.0 Analyse the causes of nonconformity. 4.0 Record the same in the non-conformance report. 5.0 Suggest suitable corrective actions. 6.0 Implement the same and monitor the results of implementation. 7.0 Non-conformity during transportation to be taken up with he transported. 8.5.3.1 Preventive Action 1.0 Identify potential nonconformity through Discussion with customer during his visit or by visiting his premises. Past experience while manufacturing similar product Problems faced during initial stage. 2.0 Get all these feedback registered in non-conformance report. 3.0 Discuss the same in Management Review Meetings to find out necessary preventive actions and record the same as minutes. 4.0 Implement decisions to avoid nonconformity.

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 QUALITY SYSTEM MANUAL Annexure -V QUALITY MANAGEMENT SYSTEM. List Of Work Instructions Doc no. : CISPL/QMS Rev. no : 00,Issue:01 Date :07/02/11 Page : 1 OF 1

List Of Work Instructions

S. No. Name of Work Instruction WI No Date /Rev No

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

CAEM INDIA SHELVING PRIVATE LIMITED

ISO-9001:2008 QUALITY SYSTEM MANUAL Annexure -IV QUALITY MANAGEMENT SYSTEM. List Of Record Doc no. : CISPL/QMS Rev. no : 00,Issue:01 Date :07/02/11 Page : 1 OF 1

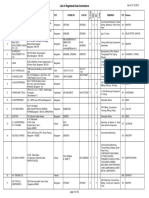

List Of Records

S. No

Records List

Responsibility

Retention Period

APPROVED BY SIGNATURE DESIGNATION DATE DIRECTOR 07/02/11

ISSUED BY MR 07/02/11

Das könnte Ihnen auch gefallen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 6 ELEMENTS OF SUPPLY CHAIN STRATEGYDokument6 Seiten6 ELEMENTS OF SUPPLY CHAIN STRATEGYPraveen ShuklaNoch keine Bewertungen

- Chapter 16 Lean Supply Chain Management XXXDokument75 SeitenChapter 16 Lean Supply Chain Management XXXNguyen Tran Thanh Thuy (K17 DN)Noch keine Bewertungen

- Six Sigma For Medical Device Design PDFDokument129 SeitenSix Sigma For Medical Device Design PDFstylish eagle100% (2)

- Lean MFG - GoldDokument4 SeitenLean MFG - Goldpragthedog100% (1)

- ASTM B165 Standard Specification of Nickel-Copper Alloy Seamless Pipe and TubeDokument2 SeitenASTM B165 Standard Specification of Nickel-Copper Alloy Seamless Pipe and TubeAmanda Ariesta ApriliaNoch keine Bewertungen

- MGMDokument5 SeitenMGMMuthukumar GovindarajuNoch keine Bewertungen

- NCC - Case StudyDokument3 SeitenNCC - Case StudyDeepika GuptaNoch keine Bewertungen

- Analyzing Inventory Management System in Textile Spinning Mill For Improving ProductivityDokument7 SeitenAnalyzing Inventory Management System in Textile Spinning Mill For Improving Productivitymahimahidev2000Noch keine Bewertungen

- Lean Software DevelopmentDokument49 SeitenLean Software Developmentabbasamir2998Noch keine Bewertungen

- Astm C1077Dokument6 SeitenAstm C1077Julio Cesar BernalNoch keine Bewertungen

- Que Es Lean Manufacturing?Dokument4 SeitenQue Es Lean Manufacturing?Jorge Andres Giron CruzNoch keine Bewertungen

- Solution Manual - RANTE COST ACCDokument127 SeitenSolution Manual - RANTE COST ACCray57% (7)

- Importance of The Kraljic Matrix As A Strategic Tool For Modern Purchasing For Modern PurchasingDokument11 SeitenImportance of The Kraljic Matrix As A Strategic Tool For Modern Purchasing For Modern Purchasingmohan raoNoch keine Bewertungen

- AccountsDokument546 SeitenAccountsRhinosmike100% (1)

- Theory of Cost & Break Even AnalysisDokument27 SeitenTheory of Cost & Break Even AnalysisSandeep Singh SikerwarNoch keine Bewertungen

- OM MCQ QuizletDokument67 SeitenOM MCQ QuizletRamya Teja VemulaNoch keine Bewertungen

- Cost 1st Summative AssessmentDokument13 SeitenCost 1st Summative AssessmentApas Pel Joshua M.Noch keine Bewertungen

- Influence of Cutting Tool Geometry On Cutting ForcesDokument5 SeitenInfluence of Cutting Tool Geometry On Cutting ForcesNicolas RiosNoch keine Bewertungen

- SCM: Managing supply chain flows boosts profitsDokument9 SeitenSCM: Managing supply chain flows boosts profitsbalajigandhirajanNoch keine Bewertungen

- Continental Tire Success Story SCLDokument2 SeitenContinental Tire Success Story SCLBhanu NimraniNoch keine Bewertungen

- Quality Management and Customer Care: Kenneth R BattyDokument44 SeitenQuality Management and Customer Care: Kenneth R BattyAshok ChawlaNoch keine Bewertungen

- Stamping Design GuidelineDokument13 SeitenStamping Design GuidelineVikram Borkhediya100% (1)

- Software Quality AssuranceDokument27 SeitenSoftware Quality AssuranceVaishnavo Devi100% (1)

- Notes Unit 3 Project ManagementDokument20 SeitenNotes Unit 3 Project ManagementAvni SharmaNoch keine Bewertungen

- Cianfrani, Charles A. - West, Jack - ISO 9001 - 2008 Explained and Expanded - Making Your Quality Management System Su PDFDokument177 SeitenCianfrani, Charles A. - West, Jack - ISO 9001 - 2008 Explained and Expanded - Making Your Quality Management System Su PDFtetay javierNoch keine Bewertungen

- Qmatic FinalDokument43 SeitenQmatic FinalnidalitNoch keine Bewertungen

- REACH Regulation Requirements for Oerlikon MetcoDokument1 SeiteREACH Regulation Requirements for Oerlikon MetcosandeepNoch keine Bewertungen

- Assignment CAED 2012Dokument3 SeitenAssignment CAED 2012Ali Nazir SaidNoch keine Bewertungen

- HAL Approved Vendors PDFDokument142 SeitenHAL Approved Vendors PDFwinmanjuNoch keine Bewertungen

- Astm A1039-A1039m-2004Dokument7 SeitenAstm A1039-A1039m-2004Jorge Toribio0% (1)