Beruflich Dokumente

Kultur Dokumente

PDF SDJ 5 Gof B0 y

Hochgeladen von

Azif SalyOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PDF SDJ 5 Gof B0 y

Hochgeladen von

Azif SalyCopyright:

Verfügbare Formate

PCB Fabrication Requirements for Multi Layer Boards Containing Blind, Buried and Micro Vias Stephen Meier

July 17th, 2006

Today PCB produces two cnc reports. The first is for un-plated for plated vias and pins. The rules for buried, blind and micro vias are:

holes the second is

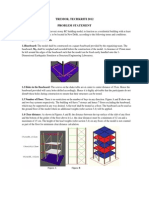

Don't mix the layers. If there is a buried via connecting layers 2, 3, and 4, there can not have a buried via connecting layers 3, 4 and 5. This is because the fab shop will build up the layers 2, 3, and 4. Drill and plate the holes for these layers. Add the other layers to make the complete board. Finally drill and plate all the normal vias. The way to present this information is with separate CNC files for each group of layers. It is also a good idea to provide the FAB shop with an fab drawing which shows the various groups of vias. Rules: 1) Any group of layers that have blind or buried layers can not be intermingled with another group of layers that have blind or buried via. There must be a separation dielectric layer between the groups Example: 8 Layer Board Group 1) Blind via connecting Layers 1, 2, 3 and 4. Buried Via connecting Layers 2, 3 and 4. This is legal. The fabrication process would be to align, press and drill Layers 2,3 and 4 then align, press and drill layer 1 with the previous set of layers. The drill bit can pass through all four layers. Adding a second Group Group 2) Buried Via connecting Layers 3, 4 and 5. Combined with the first group this is not allowed. Replacing Group 2 with Group 3 Group 3) Buried via connecting Layers 5, 6, 7 is legal since the two groups do not overlap and there is a separation layer of dielectric between them.

2) Depth Drilling from final board outer layers into inner layers is allowed to violate rule number 1 as long as the diameter of the hole is equal or greater then the required drill depth. The number of layers that Depth drilling can penetrate is a function of width to depth. Normally this limits the depths to be drilled to 1 or 2 layers. Example: 8 Layer Board Group 1) Buried Via connecting Layers 5, 6 and 7. Depth Drill from outer layer connecting layers 6, 7 and 8. Complete Example of an Eight Layer Board containing a via, blind vias, buried vias and depth drilled micro blind via.

Required Files: CNC file for layers 2 and 3 (drill_2_3.cnc) CNC file for layers 2, 3 and 4 (drill_2_4.cnc) CNC file for layers 1, 2, 3 and 4 (drill_1_4.cnc) CNC file for layers 5, 6, 7 and 8 (drill_5_8.cnc) CNC file for depth drilled from the top Layer (drill_1_2.cnc) (drill_1_3.cnc) CNC file for depth drilled from the bottom Layer CNC file for layers 1, 2, 3, 4, 5, 6, 7, 8 (drill_1_8.cnc) un-plated CNC file for layers 1, 2, 3, 4, 5, 6, 7, 8 (drill_unplated_1_8.cnc) The drawing used in the above example might be a useful tool for working the technical issues out with the fab shops. If anyone is looking for an interesting project, automatically generating such a drawing from the pcb files might be useful. History: This document is based upon conversations between the author and Pat Stroman of Hunter Technology and questions raised by D.J. Delorie.

Das könnte Ihnen auch gefallen

- Electronic Prototype Construction TechniquesDokument23 SeitenElectronic Prototype Construction TechniquesamcutechNoch keine Bewertungen

- TF4L3 We 889ar PDFDokument229 SeitenTF4L3 We 889ar PDFFelipe ChimborazoNoch keine Bewertungen

- PCB Design For Fabrication IssuesDokument45 SeitenPCB Design For Fabrication IssuesAndersonEmanuelOliveiraNoch keine Bewertungen

- Chapter - 1Dokument46 SeitenChapter - 1Vineet KumarNoch keine Bewertungen

- Brochure Cleaning Cationic Surfactant ThickenersDokument4 SeitenBrochure Cleaning Cationic Surfactant Thickenersrachmi.kartiniNoch keine Bewertungen

- Doc9 5 4 PDFDokument5 SeitenDoc9 5 4 PDFAnonymous dSFbLxc90% (1)

- Lab 4 Printed Circuit Boards (PCBS)Dokument6 SeitenLab 4 Printed Circuit Boards (PCBS)chrisdp23Noch keine Bewertungen

- Basic PCB ManufactureDokument17 SeitenBasic PCB Manufacturebobwillis1Noch keine Bewertungen

- Light Transmitting ConcreteDokument13 SeitenLight Transmitting ConcreteShivam SumanNoch keine Bewertungen

- 05 Fuel SystemDokument109 Seiten05 Fuel SystemUtomo BudidarmoNoch keine Bewertungen

- Concepts and Terminology Used in Printed Circuit Boards (PCB)Dokument9 SeitenConcepts and Terminology Used in Printed Circuit Boards (PCB)sonu24meNoch keine Bewertungen

- Solder Mask Design BasicsDokument5 SeitenSolder Mask Design BasicsbjsimardNoch keine Bewertungen

- SMT Seminar ReportDokument26 SeitenSMT Seminar ReportShruthi Uppar100% (1)

- IC Planning and Implementation (Physical Design) : FloorplanningDokument29 SeitenIC Planning and Implementation (Physical Design) : FloorplanningVakeel Mohammad AnsariNoch keine Bewertungen

- PD 1Dokument31 SeitenPD 1ajayNoch keine Bewertungen

- API 510 Mathematical CalculationsDokument26 SeitenAPI 510 Mathematical CalculationsglazetmNoch keine Bewertungen

- Questions BankDokument47 SeitenQuestions Bank1am17ec014 ashnal ahmedNoch keine Bewertungen

- Design Rules Selective SolderingDokument20 SeitenDesign Rules Selective SolderingemirNoch keine Bewertungen

- Heat of Mixing/solution PDFDokument9 SeitenHeat of Mixing/solution PDFnhalieza1067Noch keine Bewertungen

- Manual Rodillo Compactador Series Ca250 Dynapac PDFDokument70 SeitenManual Rodillo Compactador Series Ca250 Dynapac PDFMarcel Foshino Osorio Perez100% (1)

- MethodologyDokument54 SeitenMethodologyRahul ChinoyNoch keine Bewertungen

- Chemrite - 540Dokument2 SeitenChemrite - 540ghazanfarNoch keine Bewertungen

- Airtronic D2-D4 Diagnostic Repair Manual 2013Dokument33 SeitenAirtronic D2-D4 Diagnostic Repair Manual 2013sdfrNoch keine Bewertungen

- Project 1Dokument1 SeiteProject 1JakeNoch keine Bewertungen

- Otr 216 R07Dokument5 SeitenOtr 216 R07dlc352-sc1Noch keine Bewertungen

- MM 361: Advanced Manufacturing: InstructionsDokument3 SeitenMM 361: Advanced Manufacturing: InstructionsSimLo Lulumani Ko'osiko Taloanimae'aNoch keine Bewertungen

- RF Circuit Fabrication RulesDokument51 SeitenRF Circuit Fabrication Rulesazizhamdi100% (1)

- Replica Tape: A Source of New Surface Profile InformationDokument11 SeitenReplica Tape: A Source of New Surface Profile InformationMuthuKumarNoch keine Bewertungen

- CH 32Dokument5 SeitenCH 32john SmithNoch keine Bewertungen

- Printed Circuit Board Deconstruction Techniques: Joe GrandDokument11 SeitenPrinted Circuit Board Deconstruction Techniques: Joe GrandJoshua AyoolaNoch keine Bewertungen

- PCB Classification - Pattern Class and Drill ClassDokument9 SeitenPCB Classification - Pattern Class and Drill ClassjackNoch keine Bewertungen

- Cadence Virtuso Layout EditorDokument18 SeitenCadence Virtuso Layout EditorKrishna ChaitanyaNoch keine Bewertungen

- VLSI HomeworkDokument23 SeitenVLSI HomeworkTamzidul Hoque TonmoyNoch keine Bewertungen

- Project 4Dokument1 SeiteProject 4JakeNoch keine Bewertungen

- Electronic ConstructionDokument19 SeitenElectronic Constructionabbd1990Noch keine Bewertungen

- CH 34Dokument4 SeitenCH 34Eduardo Meléndez SánchezNoch keine Bewertungen

- Lab Heet 10Dokument5 SeitenLab Heet 10prashantNoch keine Bewertungen

- Open Book, Open Notes, Computers With Internet Off Time: 80 MinutesDokument15 SeitenOpen Book, Open Notes, Computers With Internet Off Time: 80 MinutesNatanaelNoch keine Bewertungen

- VCRDokument73 SeitenVCRsaikripa121Noch keine Bewertungen

- Circuit World: Emerald Article: PCB Drillability: A Material Science Approach To Resin DevelopmentDokument9 SeitenCircuit World: Emerald Article: PCB Drillability: A Material Science Approach To Resin DevelopmentAlak PatraNoch keine Bewertungen

- Sample Midterm Exam - INDU 6310 - Concordia UnicersityDokument2 SeitenSample Midterm Exam - INDU 6310 - Concordia UnicersityRapheal AdamNoch keine Bewertungen

- Lecture No-05 Course PCB Manufacturing IE-236 & Electronic Simulation and PCB Manufacturing (Repeaters Only)Dokument22 SeitenLecture No-05 Course PCB Manufacturing IE-236 & Electronic Simulation and PCB Manufacturing (Repeaters Only)Ravi Shankar 31Noch keine Bewertungen

- Laser Cut SMT StencilsDokument4 SeitenLaser Cut SMT StencilsAvadhutNoch keine Bewertungen

- Assignment For Week3Dokument3 SeitenAssignment For Week3Sujith MrinalNoch keine Bewertungen

- PCB Trace Widths Are Calculated Using Following FormulaDokument2 SeitenPCB Trace Widths Are Calculated Using Following Formulairi_scribdNoch keine Bewertungen

- One-Way Joist Part 2Dokument1 SeiteOne-Way Joist Part 2Humberto EstevezNoch keine Bewertungen

- TT 21Dokument37 SeitenTT 21Sahilpreet 5inghNoch keine Bewertungen

- Orks Block W AAC Tatement For Method S: 1-ObjectiveDokument3 SeitenOrks Block W AAC Tatement For Method S: 1-ObjectiveCatherine CatacutanNoch keine Bewertungen

- Integrated Circuits: Mohamed DessoukyDokument18 SeitenIntegrated Circuits: Mohamed DessoukyKariem AliNoch keine Bewertungen

- 2013IDEERS Undergraduate Eng V2Dokument22 Seiten2013IDEERS Undergraduate Eng V2Asyraf AbdullahNoch keine Bewertungen

- 3 DMeshingDokument19 Seiten3 DMeshingkapolaNoch keine Bewertungen

- ME409 Microendmilling Simulation Lab 1Dokument3 SeitenME409 Microendmilling Simulation Lab 1Bhuvan Gowda H NNoch keine Bewertungen

- Computer Systems Servicing NCII (G12) : (Learning Activity)Dokument10 SeitenComputer Systems Servicing NCII (G12) : (Learning Activity)Tabata Qbz TawinNoch keine Bewertungen

- Examen SPTFExtraordDokument3 SeitenExamen SPTFExtraordIRENE PASCUAL HERANZ BRONCHALONoch keine Bewertungen

- Answers of Chapter (8) : Course: Operating SystemDokument7 SeitenAnswers of Chapter (8) : Course: Operating SystemasdNoch keine Bewertungen

- Tremor Problem Statement 2012Dokument8 SeitenTremor Problem Statement 2012Ankesh MundraNoch keine Bewertungen

- Steel TestDokument4 SeitenSteel TestHarish Ashok SharmaNoch keine Bewertungen

- Dr. D.Y. Patil College of Engineering and Technology .: Shivaji University, KolhapurDokument12 SeitenDr. D.Y. Patil College of Engineering and Technology .: Shivaji University, KolhapurPooja ChavanNoch keine Bewertungen

- Assignment 3Dokument5 SeitenAssignment 3SaurabhNoch keine Bewertungen

- TKFM-Quiz 1Dokument1 SeiteTKFM-Quiz 1kathirvelus9408Noch keine Bewertungen

- 3D Placement With D2D Vertical ConnectionsDokument10 Seiten3D Placement With D2D Vertical ConnectionsAchyuthNoch keine Bewertungen

- Taming The Challenges of 20nm Custom/Analog Design: Digital DesignersDokument9 SeitenTaming The Challenges of 20nm Custom/Analog Design: Digital Designers李超Noch keine Bewertungen

- TremorProblemStatement 2Dokument7 SeitenTremorProblemStatement 2Jayanta DasNoch keine Bewertungen

- Creating Documentation For Successful PCB ManufacturingDokument38 SeitenCreating Documentation For Successful PCB Manufacturingsandee kumarNoch keine Bewertungen

- HDI Layer Stackups For Large Dense PCBDokument11 SeitenHDI Layer Stackups For Large Dense PCBSally FangNoch keine Bewertungen

- Layer Stack InformationDokument9 SeitenLayer Stack InformationMadhav DimbleNoch keine Bewertungen

- Pentadyne VSS BrochureDokument4 SeitenPentadyne VSS BrochureWalid WahyudiNoch keine Bewertungen

- HYROTEST Procedure Tank NSIDokument4 SeitenHYROTEST Procedure Tank NSIluhur prandika100% (1)

- Traymaster Boiler BookDokument7 SeitenTraymaster Boiler Bookfauzi endraNoch keine Bewertungen

- Pittcote 404 PDFDokument2 SeitenPittcote 404 PDFJuan Manuel DiazNoch keine Bewertungen

- Multiple Effect EvaporationDokument4 SeitenMultiple Effect EvaporationDianne VillanuevaNoch keine Bewertungen

- Volumetric or Cubical Expansion Coefficients of LiquidsDokument1 SeiteVolumetric or Cubical Expansion Coefficients of LiquidsImmerNoch keine Bewertungen

- Single Electron Transistor NanoDokument2 SeitenSingle Electron Transistor NanoDerry PermanaNoch keine Bewertungen

- Asm-35-2000 Aluminum Sheet Metal Work in Building ConstructionDokument31 SeitenAsm-35-2000 Aluminum Sheet Metal Work in Building ConstructionSamuel Yu LiuNoch keine Bewertungen

- Multis Ep 2 TDS v171023Dokument1 SeiteMultis Ep 2 TDS v171023Stefan UngurNoch keine Bewertungen

- Meyco Segment HR PDFDokument16 SeitenMeyco Segment HR PDFFabioSoaresNoch keine Bewertungen

- Bathtub: What Are They?Dokument5 SeitenBathtub: What Are They?John Paul DenajibaNoch keine Bewertungen

- KT62 ManualDokument30 SeitenKT62 ManualandyjwatsonNoch keine Bewertungen

- Ti 223 FenDokument12 SeitenTi 223 FenDusan OtasevicNoch keine Bewertungen

- MdriveDokument104 SeitenMdriveAlejandroSosaVieraNoch keine Bewertungen

- PM High Strength Magnetic Alloys PDFDokument13 SeitenPM High Strength Magnetic Alloys PDFSAMIT JAINNoch keine Bewertungen

- BTech Chemical RevisedDokument46 SeitenBTech Chemical RevisedRam Krishan SharmaNoch keine Bewertungen

- Armoured Unarmoured: Size (MM)Dokument3 SeitenArmoured Unarmoured: Size (MM)Bonaventure NzeyimanaNoch keine Bewertungen

- Sample Preconditioning: On-Line Liquid AnalysisDokument12 SeitenSample Preconditioning: On-Line Liquid AnalysispinitNoch keine Bewertungen

- Dryers in Word FileDokument5 SeitenDryers in Word FileHaroon RahimNoch keine Bewertungen

- Building EstimateDokument7 SeitenBuilding EstimateRamesh rammiNoch keine Bewertungen

- Competitive Industrial Performance Index 2023Dokument2 SeitenCompetitive Industrial Performance Index 2023Nigel DsilvaNoch keine Bewertungen

- Coal Conveyor GuardDokument18 SeitenCoal Conveyor GuardDSG100% (1)