Beruflich Dokumente

Kultur Dokumente

The Nuclear Track Technology: A. Waheed and M. Farmer

Hochgeladen von

nobody126Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

The Nuclear Track Technology: A. Waheed and M. Farmer

Hochgeladen von

nobody126Copyright:

Verfügbare Formate

THE NUCLEAR TRACK TECHNOLOGY

A. Waheed and M. Farmer

British Institute of Technology and E-Commerce, 258-262 Romford Road London, The

United Kingdom

Abstract: this is a review type article for our students to give them an insight about the nuclear

track technology which is applied in many fields of research. It gives the basic ideas about

nuclear track formation in solids and measurement of track parameters to extract information on

types, energy and origin of nuclear particle tracks for application in research.

1. Introduction

The discipline now called solid state Nuclear Track Detection (SSNTD) dates back to 1958 and

has its roots in the United Kingdom. Its strength stems chiefly from factors such as its simplicity,

the small size allowing them to be used in remote and difficult-to-reach locations, simple and

amenable geometry, permanent maintenance of the nuclear record, insensitivity to light, gamma

rays and x-rays, and diversified applications make it a novel technique for experimental research.

The important fields of investigation include geological studies, environmental studies for radon

and cancer risk, medical and life science studies, the study of exotic nuclear phenomena, cold fusion

& nuclear reaction studies, and oil exploration studies.

Amazing discoveries are currently being made in nanometer scale science, inspiring scientists.

Scientists are learning how to measure, manipulate and organize matter on the scale of 1 to 100

billionth of meter. The extremely important field of nanotechnology has applications in biology,

chemistry, industry, medicare & chemical technologies. Important are its applications in physics

which include electronics & microelectronics, materials design, study of the quantum effects and

fabrication of sensors to name a few. Some exciting applications were reported recently(1) of the

nuclear track technique in nanotechnology for development of nanostructure, and fabrication &

applications of nano-filters, sensors & nanowires .Efforts are underway at the British Institute of

technology and E-Commerce to introduce the discipline of nanotechnology with research applying

also the nuclear track technology. It requires that we should have an insight about this very

important experimental technique.

In this article we have attempted to provide the basics of nuclear track technique for our students

and staff in a bid to use this technique for our future research activates.

2. The Track Formation Mechanism

The passage of heavily ionizing, nuclear particles through most insulating materials create narrow

paths of intense damage on an atomic scale. In plastics like CR39 (polymer) the particle/ion

produces damage breaking the molecular bonds (a few tens of nm) along its trajectory due to the

ionization atoms resulting in the formation of the so called latent tracks. In glass and crystals the

latent tracks are formed as a result of the atomic displacements along the trajectory following the

ionization. These processes are better explained in the figures below

Fig. 1 A latent track is formed in (a) inorganic solids by the ionization and production of dense

positive ions along the ion path and (b) the breakage of polymeric chains by the passage of charged

particle.

These damage tracks may be revealed and made visible in an ordinary microscope by treatment

with a properly chosen chemical reagent that rapidly and preferentially attacks the damaged

material. It less rapidly removes the surroundings undamaged matrix in such a manner as to enlarge

the etched holes that mark and characterize the sites of the original individual, damaged region. The

most commonly applied enchant in case of plastics like CR39 are NaOH or KOH with

concentrations ranging from 1-12 N at constant temperature preferably between 40-90 C

. The

shape of an etched track in a detector depends on the charge, mass and velocity of the incident

particle/ion and also on the etching conditions applied. The sensitivity, resolution and optical

properties of CR39 are the best among the track recording detectors.

The geometrical modes developed so far have useful to extracting most of the important

information people have been looking for. The information depends on the charge, mass, velocity of

the particle/ion and the related track parameters.

3. The Geometrical model

Many track registration criteria have been proposed for the formation of an etchable latent in the

detector material, which mainly depends on the charge, mass and velocity of the incoming particle

plus the detector characteristics i.e. the density and chemical composition. Here we quote briefly on

three if them.

3.1 Total Energy Loss (dE/dx)

According to this criterion the formation of an etchabale track is possible if the total energy loss

(dE/dx)

critical >

exceeds a certain critical value which depends on the detector material. Fleischer et

al., [2], first proposed it; they used different projectiles having different Z/ values in mica and

polycarbonate detectors. The criterion explains the track formation for low energy ions but at high

a b

energy it seems to fail to reproduce some experimental data. The main shortcoming of this criterion

is that it neglects the primary ionization for the track formation.

The total energy loss is given by [2]

dx

dE

= 4rN

A

m

e

c

2

r

2

e

2

2

A

Z

2

2

1

Z

(

(

A +

|

|

.

|

\

|

L

I

c m

In

e

2

2

2

2 2 2

o

y

Where

N

A

= Avogadros number, r

e

= classical electron radius, Z

2

= Target atomic number,

A

2

= target mass number, I= mean ionization potential of the target material

Z

1

= effective charge of the incident ions; Z

1

= Z

1

( ) [ ]

3 / 2

1

/ 130 exp 1 Z

o= correction for the density effect, AL= sum of corrections needed for precision measurements

3.2 Other Possibilities

3.2.1 Primary Ionization Loss (J)

A new criterion was proposed by Fleischer et al., [3]: the o-rays are produced directly by the

incident ion and this is based on the ion explosion spike model. The material can record an etchable

track only if the linear ion density produced by the primary particle along its trajectory is greater

than a critical value for that material.

3.3 Restricted Energy Loss (REL)

Benton et al., [4] proposed in 1955 that only the o-rays emitted with an energy less than a value u

o

contribute to the track formation. An etchable track is formed only if the REL exceeds a critical

value of the detecting material.

4. Methodology of Track Detection and Visualization

4.1 Track Detection

The shape of the track formed by a charged particle is governed by the simultaneous actions of the

etchant along the latent track and on the bulk material. A schematic diagram of chemical etching of

a charged particle in a NTD is shown in Fig 2. Fresh etchants and uniform stirring should be used to

avoid deposits of etch products on the detector surface and in its build up inside the solution [8-9]

(4.2) Bulk Etch Rate (v

B

)

The v

B

is defined as the rate at which the undamaged material of the detector is etched out.

Generally, the following techniques are employed for the measurement of the bulk etch rate of the

detector:

V

B

t

V

T

t

L

e

Original Surface

Etched Surface

D

Fig.2 Sketch of a NTD track and (b) etched o particle tracks in a CR39 detector.

4.2.1 Thickness Measurement Method

For the determination of v

B

the thickness of the detector is measured in selected points. The

detector is the etched for fixed intervals of time At and the thickness is measured after each

successive etching step. The bulk etch rate is given by

v

B

=Ax/2At

Where Ax is the thickness variation after etching time At. It is assumed that the bulk etching is

the same on both sides of the detector.

4.2.2 Track Diameter Measurement Method

If v

T

/v

B

>>1 as in the case of fission fragments from a

252

CF source in CR39, the track

diameter measurement technique can be applied for the determination of v

B

as [10].

D

ff

=2h

1

1

+

p

p

were D

ff

is the diameter of fission fragments=v

T

/ v

B,

h is the thickness removed from

both sides of the detector during an etching time t.

4.2.3 Mass Change Method

The bulk etch rate may be determined from the change in the mass of the detector Am and the

density of the detector material, v

B

can be calculated as [1]

v

B

=

t A

m

o 2

A

where A is the surface area,o is the density of the detector and t is the etching time. Care must

be taken in determining Am of the same relative humidity.

4.3 Track Etch Rate (v

T

)

The track etch rate v

T

is defined as the rate at which the detector material is chemically etched

along the damage trail of the particle trajectory, i.e. the rate at which the tip of the etch cone

moves along the latent track during the etching process. The track etch rate depends on the energy

loss of the incoming particle, the temperature and concentration of the etchant.

4.4 Critical Angle of Etching (

c

) and Registration Efficiency (q)

The charged particles are incident at an angle with respect to the detector surface. For (V

T

t)

1

=

V

B

t one has the critical angle

c

measured with respect to the detector surface. Particles incident

with <

c

cannot be detected.

c

is an important parameter for NTDs, as it is connected with the

detector efficiency.

The track registration efficiency q of NTDs is defined as [1]

q=1-sin

c

4.5 Track Geomerty at Normal Incidence

Fig .3 shows the track geometry in NTDs for particles at normal incidence and constant REL: the

basic quantities are the base cone diameter, major and minor axes, the cone height of the etched

track,thebulk etch rate v

B

and the track-etch rate v

T

. The radio of the track-etch rate to bulk-

etch rate is the signal or sensitivity p of the detector material (p=v

T

/v

B

). Since it is difficult to

measure the track etch determined from the geometry of an etch-pit [11]rate during etching, its

value is

The relations between D, v

T

, v

B

and P are [12]

D=2 v

t

B

) (

) (

B T

B T

v v

v v

+

, P=

2

2

) 2 / ( 1

) 2 / ( 1

t v D

t v D

b

B

+

, P=

) ( 1

) /( 1

2 2

2 2

t v A

t v A

B

B

r

r

+

4.6 Track Geometry at Oblique Incidence

Fig.3 shows the geometry of a particle incident at an angle with respect to the detector surface and

constant REL. The following geometrical relations can be deduced from Fig.4

The following relations hold in such cases for D, d and p, [12]

D=2V

B

t

( )

) 1 sin (

1

2

+

p

p

, d=2V

B

t

1 sin

1 sin

+

p

p

, p=

( )

2

2

2

1

4

1

B

A

+

where A= (\D/2v

B

t) and =arcsin

|

|

.

|

\

|

+

-

2

2

1

1 1

B

B

p

Le=v

T

t-(v

B

t/sin )

O

r

1

r

2

o

B

R

V

B

t

Original surface

Etched surface

Fig 3 Track geometry

for a charged particle

impinging at normal

incidence in a

nuclear track detector

Fig 4 Geometry of a particle

incident at an angle with

respect to the detector

surface.

The track length, the track diameter and the track width are the important parameters for

determination of range, energy and charge of the nuclear particle tracks. The angle of inclination

and the critical angle of etching are responsible for the efficiency determination.

5. Discussion

Nanotechnology is an emerging field having a vast potential for fabrication of sensors and devices.

Materials with nanoscopic dimensions have potential technological applications in microelectronics

and micro-mechanics.

Nanophysics is the field of physics that investigates nanometer-scale samples. Today, nanophysics

overlaps with other research fields, such as nanotechnology. We use semiconductor nanowires as

building blocks for quantum devices realize semiconductor materials.

Some fascinating reports were presented(1) a couple of years ago regarding: (a) structure and

properties of micro-and nanowires formed on the base of track membranes,(b) preparation and

characterization of nanopores based on track etching technique, (c) development and

characterization of nanostructure using the heavy ions,(d) controlled etching of ion track nanopores

and its applications in membrane technology, (e) enhanced optical transmission through nanoholes

array in polycarbonate track etch membranes, and (f) preparation of single cone-like nanopores on

polymers membranes&studies on its conductivities. There are different techniques for the

development of nano-and microstructure but these reported studies sufficiently establish the fact

that template growth through etched track pores is very simple and more useful

This articles is aimed at giving the basic knowledge about this technique to our students as well as

teachers and make them prepared for research in nanotechnology.

References

1. 23

RD

International Conference on Nuclear Tracks in Solids, Beijing, China, September

11-15,2006

2. R.L. Fleischer, P.B. Price and R.M.Walker; Nuclear tracks in solids, University of

California Press, London,1975

3. R.L.Fleischer et al; phys.Rev.133 (1964) 1443

4. R.L.Fleischer et al; phys.Rev. 156(1967) 353

5. E.V.Benton and W.Henrich; Nucl.Instr.Meth.67 (1969) 343

6. S.Cecchini et al;N.Cimento 109A (1996)1119

7. S.Manzoor et al; Nucl.Instr.Meth. a453 (2000)525

8. G.Giacomelli et al; Nucl.Instr.Meth. A411(1998) 41

9. W.Enge et al; Nucl.Instr.Meth. 127(1975)125

10. H.A.Khan;Nucl.Instr.Meth.109(1973)515

11. B.Dorschel et al; Rad. Protec.Dosim.82 (1999)85

12. G.Somogyi;Proc.11

th

Intern. Conf. Solid State Nuclear Track

Detectors,Bristol,UK,1981,p.101

Das könnte Ihnen auch gefallen

- Nuclear Tracks in Solids: Principles and ApplicationsVon EverandNuclear Tracks in Solids: Principles and ApplicationsNoch keine Bewertungen

- HAL Ultrasonic TestingDokument9 SeitenHAL Ultrasonic TestingMansingh YadavNoch keine Bewertungen

- Geophysical Well Logging: Excerpted From Methods of Experimental PhysicsVon EverandGeophysical Well Logging: Excerpted From Methods of Experimental PhysicsBewertung: 5 von 5 Sternen5/5 (4)

- 2003 Particle Collection at The Plasma Edge by A Fast Reciprocating Probe at The TEXTOR TokamakDokument5 Seiten2003 Particle Collection at The Plasma Edge by A Fast Reciprocating Probe at The TEXTOR TokamakyouamareNoch keine Bewertungen

- Eddy Current PlasticsDokument11 SeitenEddy Current PlasticsmadhumitharamjiNoch keine Bewertungen

- Neutron Capture Cross Section Measurements of Paraffin WaxDokument4 SeitenNeutron Capture Cross Section Measurements of Paraffin WaxInternational Journal of Application or Innovation in Engineering & ManagementNoch keine Bewertungen

- Unit - 5 NDTDokument7 SeitenUnit - 5 NDTRAJESH. RNoch keine Bewertungen

- Nveo 8 (6) - 442Dokument20 SeitenNveo 8 (6) - 442Amar HassanNoch keine Bewertungen

- A 4.5 Μm PIN Diamond Diode for Detecting Slow NeutronsDokument5 SeitenA 4.5 Μm PIN Diamond Diode for Detecting Slow NeutronsConstance SinNoch keine Bewertungen

- Dtdfhdfevelopments and ApplicationsDokument9 SeitenDtdfhdfevelopments and ApplicationsarengifoipenNoch keine Bewertungen

- Chapter 3: Reservoir CharacterizationDokument23 SeitenChapter 3: Reservoir CharacterizationKarlina DewiNoch keine Bewertungen

- 10 PDFDokument38 Seiten10 PDFTejinder SinghNoch keine Bewertungen

- Ass2 (Q8 15)Dokument11 SeitenAss2 (Q8 15)MITHLESH KUMAR KESHARINoch keine Bewertungen

- Dhanalakshmi Srinivasan Engineering College, Perambalur Department of Mechanical Engineering Me8097 / Non-Destructive Testing and Evaluation Question Bank - 2 Marks & 16 MarksDokument11 SeitenDhanalakshmi Srinivasan Engineering College, Perambalur Department of Mechanical Engineering Me8097 / Non-Destructive Testing and Evaluation Question Bank - 2 Marks & 16 MarksRAJESH. RNoch keine Bewertungen

- Cui 2021Dokument8 SeitenCui 2021mvssrajuNoch keine Bewertungen

- Neutron RadiographyDokument97 SeitenNeutron RadiographyMeer UmerNoch keine Bewertungen

- Jirarungsatian 2010Dokument11 SeitenJirarungsatian 2010mankari.kamal.18022963Noch keine Bewertungen

- LIU 16 JMMM Effect of Interface Roughness On Superconducting TransitionDokument6 SeitenLIU 16 JMMM Effect of Interface Roughness On Superconducting TransitionElisa Baggio SaitovitchNoch keine Bewertungen

- 1 s2.0 S0168900223006344 MainDokument8 Seiten1 s2.0 S0168900223006344 MainparonimusNoch keine Bewertungen

- Well LoggingDokument9 SeitenWell Loggingviya7Noch keine Bewertungen

- EXPERIMENT 8. Monolayer Characterization: Contact Angles, Reflection Infrared Spectroscopy, and EllipsometryDokument9 SeitenEXPERIMENT 8. Monolayer Characterization: Contact Angles, Reflection Infrared Spectroscopy, and EllipsometryavniNoch keine Bewertungen

- Corrosion Detection Using Piezoelectric Wafer Active SensorsDokument5 SeitenCorrosion Detection Using Piezoelectric Wafer Active Sensorssilent spritsNoch keine Bewertungen

- Evaluation of XRD Analysis of Amorphous Alloys: Materials Science Forum November 2012Dokument6 SeitenEvaluation of XRD Analysis of Amorphous Alloys: Materials Science Forum November 2012TRA ANH KHOA NGUYENNoch keine Bewertungen

- Anghel2015 - A Plastic Scintillator-Based Muon Tomography System With AnDokument12 SeitenAnghel2015 - A Plastic Scintillator-Based Muon Tomography System With AnTanti ArdiyatiNoch keine Bewertungen

- Vaara Leinonen B 8 2012 PDFDokument46 SeitenVaara Leinonen B 8 2012 PDFFisika MedikNoch keine Bewertungen

- Al Asady2020Dokument8 SeitenAl Asady2020Shifa ChaudhariNoch keine Bewertungen

- Preprints202305 0557 v1Dokument15 SeitenPreprints202305 0557 v1Sn CalvnNoch keine Bewertungen

- Understanding Neutron Radiography Reading VIII Defence LaboratoryDokument67 SeitenUnderstanding Neutron Radiography Reading VIII Defence LaboratoryLeon Heart FCNoch keine Bewertungen

- 1957 The Spectral Emissivity and Optical Properties of TungstenDokument88 Seiten1957 The Spectral Emissivity and Optical Properties of TungstenpresledovatelNoch keine Bewertungen

- Nuclear Instruments and Methods in Physics Research B: M. Margret, M. Menaka, B. Venkatraman, S. ChandrasekaranDokument6 SeitenNuclear Instruments and Methods in Physics Research B: M. Margret, M. Menaka, B. Venkatraman, S. Chandrasekaranjuan carlosNoch keine Bewertungen

- Detection of Low-Velocity Impact Damage in Composite Plates Using Lamb WavesDokument9 SeitenDetection of Low-Velocity Impact Damage in Composite Plates Using Lamb WavesHARSHIT MAITHILNoch keine Bewertungen

- STRUCTURAL PROPERTIES OF NANOCRYSTALLINE TiN FILMDokument7 SeitenSTRUCTURAL PROPERTIES OF NANOCRYSTALLINE TiN FILMInternational Journal of Structronics & MechatronicsNoch keine Bewertungen

- 13 Nemade Biyani Feb2013Dokument2 Seiten13 Nemade Biyani Feb2013Kailash NemadeNoch keine Bewertungen

- Ai Two MarkDokument25 SeitenAi Two MarkmohanapriyaNoch keine Bewertungen

- Materials 10 01148Dokument20 SeitenMaterials 10 01148Lin TianNoch keine Bewertungen

- Eddy Current Testing: Basics: B.P.C. RaoDokument15 SeitenEddy Current Testing: Basics: B.P.C. RaoKarthikeyan GanesanNoch keine Bewertungen

- Eddy Current Testing: Basics B.P.C. RaoDokument15 SeitenEddy Current Testing: Basics B.P.C. RaoLudmila CarballalNoch keine Bewertungen

- 1Dokument5 Seiten1Jose Luis FloresNoch keine Bewertungen

- Maksymovych2011 PDFDokument12 SeitenMaksymovych2011 PDFचन्द्रभाल सिंहNoch keine Bewertungen

- Gamma LoggingDokument3 SeitenGamma Loggingalfred legacyNoch keine Bewertungen

- Assignment 5 - Investigating TechniquesDokument1 SeiteAssignment 5 - Investigating TechniquesMukesh YadavNoch keine Bewertungen

- Estimation of Radon Mass Exhalation Rate and Radium Content in Soil Samples Collected From Kolasib District of Mizoram, IndiaDokument8 SeitenEstimation of Radon Mass Exhalation Rate and Radium Content in Soil Samples Collected From Kolasib District of Mizoram, IndiaIJRASETPublicationsNoch keine Bewertungen

- Orthogonal Sensors For The Trace Detection of ExplosivesDokument4 SeitenOrthogonal Sensors For The Trace Detection of Explosivesantonio ScacchiNoch keine Bewertungen

- Dong 2021 J. Phys. Conf. Ser. 2011 012071Dokument6 SeitenDong 2021 J. Phys. Conf. Ser. 2011 0120711040437587Noch keine Bewertungen

- Determining Gas TurbineDokument11 SeitenDetermining Gas TurbineassurendranNoch keine Bewertungen

- Experimental and Numerical Analysis of A Transducer For The Generation of Guided WavesDokument9 SeitenExperimental and Numerical Analysis of A Transducer For The Generation of Guided Wavesdavood abbasiNoch keine Bewertungen

- Review of Current Neutron Detection Systems For Emergency ResponseDokument10 SeitenReview of Current Neutron Detection Systems For Emergency ResponseNelson Tovar OrjuelaNoch keine Bewertungen

- Resonant Energy Transfer Between Cdse/Zns Type I and Cdse/Znte Type Ii Quantum DotsDokument5 SeitenResonant Energy Transfer Between Cdse/Zns Type I and Cdse/Znte Type Ii Quantum DotsJugalator ZedNoch keine Bewertungen

- 1003 6068Dokument6 Seiten1003 6068Karthik RajashekarNoch keine Bewertungen

- Chemistry of Methane-Nitrogen in A Dielectric Barrier Discharge at Atmospheric PressureDokument2 SeitenChemistry of Methane-Nitrogen in A Dielectric Barrier Discharge at Atmospheric PressuremareazzurrooNoch keine Bewertungen

- Nanohole Sheet ResistanceDokument16 SeitenNanohole Sheet ResistanceVahagn MkhitaryanNoch keine Bewertungen

- Introduction To Well Logging (By: Dr/A.Mohsen)Dokument7 SeitenIntroduction To Well Logging (By: Dr/A.Mohsen)Khaled SalahNoch keine Bewertungen

- Superconductivity in Bundles of Double-Wall Carbon NanotubesDokument7 SeitenSuperconductivity in Bundles of Double-Wall Carbon NanotubesEmmanuel Isaac Rivera GutierrezNoch keine Bewertungen

- Cobalt OxideDokument5 SeitenCobalt OxideAyesha IqbalNoch keine Bewertungen

- AICTE, PCI & Affiliated To ANU: Approved by Recognized by Certified byDokument45 SeitenAICTE, PCI & Affiliated To ANU: Approved by Recognized by Certified byPenmetsa Satyanarayana Raju100% (1)

- Detection of Fine Cracks by X-Ray Technique Using Contrast Medium in ConcreteDokument16 SeitenDetection of Fine Cracks by X-Ray Technique Using Contrast Medium in ConcreteTalat Bin ZamanNoch keine Bewertungen

- NEobjective QuestionsDokument9 SeitenNEobjective QuestionskNoch keine Bewertungen

- Alpha Spectrometer ArticleDokument11 SeitenAlpha Spectrometer ArticleAndrea EspinosaNoch keine Bewertungen

- New Developments in Transmission Electron Microscopy For NanotechnologyDokument18 SeitenNew Developments in Transmission Electron Microscopy For NanotechnologyJarar HaiderNoch keine Bewertungen

- Kirchhoff's Current Law (KCL) :: Kirchhoff's First & Second Laws With Solved ExampleDokument20 SeitenKirchhoff's Current Law (KCL) :: Kirchhoff's First & Second Laws With Solved Examplenobody126Noch keine Bewertungen

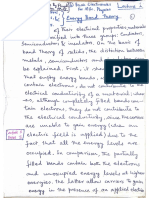

- Solid State Physics IDokument1 SeiteSolid State Physics Inobody126100% (2)

- Voltage Multiplier CircuitDokument4 SeitenVoltage Multiplier Circuitnobody126100% (1)

- Circuit and Devices by Qazi AhkamDokument90 SeitenCircuit and Devices by Qazi Ahkamnobody126Noch keine Bewertungen

- Semiconductor PhysicsDokument54 SeitenSemiconductor Physicsnobody126100% (1)

- Research ProposalDokument1 SeiteResearch Proposalnobody126Noch keine Bewertungen

- Analysis of Schottky Barrier Height in Small Contacts Using A Thermionic-Field Emission ModelDokument7 SeitenAnalysis of Schottky Barrier Height in Small Contacts Using A Thermionic-Field Emission Modelnobody126Noch keine Bewertungen

- Electronics Lab ManualDokument190 SeitenElectronics Lab Manualnobody126100% (1)

- Semiconductor Today - Transcending Frequency and Integration LimitsDokument4 SeitenSemiconductor Today - Transcending Frequency and Integration Limitsnobody126Noch keine Bewertungen

- Classification of Elements and Periodicity in PropertiesDokument3 SeitenClassification of Elements and Periodicity in PropertiesBurhanuddin SlatewalaNoch keine Bewertungen

- 1.5 Atom Structure and The Periodic TableDokument99 Seiten1.5 Atom Structure and The Periodic TableRobert ClarkNoch keine Bewertungen

- CHM1 Structure & Bonding QDokument115 SeitenCHM1 Structure & Bonding QGoutham SivagnanamNoch keine Bewertungen

- Gecaa - Theory Final Question Sheet: (Total 150 Points)Dokument11 SeitenGecaa - Theory Final Question Sheet: (Total 150 Points)Rahul M-RanjanNoch keine Bewertungen

- MCT1 Mass Spec PDFDokument29 SeitenMCT1 Mass Spec PDFMohamed DahmaneNoch keine Bewertungen

- Ironmaking and Steelmaking PDFDokument466 SeitenIronmaking and Steelmaking PDFakshukNoch keine Bewertungen

- Chem P2 Trial - 2013 - Marking SchemeDokument17 SeitenChem P2 Trial - 2013 - Marking SchemeMelody OngNoch keine Bewertungen

- Preface: (Nadeem Irshad Kayani) Programme Director Directorate of Staff Development, PunjabDokument61 SeitenPreface: (Nadeem Irshad Kayani) Programme Director Directorate of Staff Development, Punjabsalman khanNoch keine Bewertungen

- CHEM 0100 Course OutlineDokument8 SeitenCHEM 0100 Course OutlineAkisha Ali-KhanNoch keine Bewertungen

- Fizika RadiologijaDokument9 SeitenFizika RadiologijaBorislav TapavičkiNoch keine Bewertungen

- C3L6 Student Exam 2014Dokument10 SeitenC3L6 Student Exam 2014Đức ThànhNoch keine Bewertungen

- Keshe - Message in A BottleDokument21 SeitenKeshe - Message in A BottleD.Domenico100% (2)

- Xray Machine PDFDokument32 SeitenXray Machine PDFOshani pereraNoch keine Bewertungen

- Non-Thermal Plasma Technologies New Tools For Bio-Decontamination MoreauDokument8 SeitenNon-Thermal Plasma Technologies New Tools For Bio-Decontamination MoreauAnna ZimochNoch keine Bewertungen

- Mass Spectroscopy: - : Presented By:-M Asif Shaheen Lecturer KEMU LahoreDokument94 SeitenMass Spectroscopy: - : Presented By:-M Asif Shaheen Lecturer KEMU LahoreDr. Dure Najaf IqbalNoch keine Bewertungen

- Basic Principles of RadioactivityDokument143 SeitenBasic Principles of RadioactivityBulu Chandra MahantaNoch keine Bewertungen

- WorksheetDokument2 SeitenWorksheetNimisha KaushikNoch keine Bewertungen

- Chapter 13 Transition ElementsDokument5 SeitenChapter 13 Transition ElementssumathiNoch keine Bewertungen

- Toner-Print Removal From Paper by Long And...Dokument22 SeitenToner-Print Removal From Paper by Long And...Emerson EnriquizNoch keine Bewertungen

- Science 5 Sample Papers With SolutionsDokument52 SeitenScience 5 Sample Papers With SolutionsAryaman TiwariNoch keine Bewertungen

- Comprehensive Clinical Plasma MedicineDokument512 SeitenComprehensive Clinical Plasma MedicineYaudel Gomez SilvaNoch keine Bewertungen

- JEE Main 2023 Jan 31 Shift 2 Chemistry Question Paper (Memory-Based)Dokument4 SeitenJEE Main 2023 Jan 31 Shift 2 Chemistry Question Paper (Memory-Based)Nachiketha RNoch keine Bewertungen

- Section A Notes - Periodic PropertiesDokument10 SeitenSection A Notes - Periodic PropertiesBhavesh GargNoch keine Bewertungen

- Nikonov 2001Dokument9 SeitenNikonov 2001J SaranNoch keine Bewertungen

- General Chemistry I - Tutorial 4Dokument6 SeitenGeneral Chemistry I - Tutorial 4Duc Anh NguyenNoch keine Bewertungen

- Chem1 1 - Atomic StructureDokument5 SeitenChem1 1 - Atomic Structureapi-247243068Noch keine Bewertungen

- Modeling and Simulation of Single-Event Effect in CMOS CircuitDokument11 SeitenModeling and Simulation of Single-Event Effect in CMOS CircuitSaqib Ali KhanNoch keine Bewertungen

- TransducersDokument9 SeitenTransducersRo#it100% (1)

- Class: Subject: Unit No. & Name: Chapter No & Name: TopicDokument9 SeitenClass: Subject: Unit No. & Name: Chapter No & Name: TopicMayank ChoudharyNoch keine Bewertungen

- Thin Aluminum Films PDFDokument13 SeitenThin Aluminum Films PDFsmani170Noch keine Bewertungen

- A-Level Chemistry Revision: Cheeky Revision ShortcutsVon EverandA-Level Chemistry Revision: Cheeky Revision ShortcutsBewertung: 4 von 5 Sternen4/5 (5)

- A-level Biology Revision: Cheeky Revision ShortcutsVon EverandA-level Biology Revision: Cheeky Revision ShortcutsBewertung: 5 von 5 Sternen5/5 (5)

- Lower Secondary Science Workbook: Stage 8Von EverandLower Secondary Science Workbook: Stage 8Bewertung: 5 von 5 Sternen5/5 (1)

- How to Teach Nature Journaling: Curiosity, Wonder, AttentionVon EverandHow to Teach Nature Journaling: Curiosity, Wonder, AttentionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Common Core Science 4 Today, Grade 3: Daily Skill PracticeVon EverandCommon Core Science 4 Today, Grade 3: Daily Skill PracticeBewertung: 3.5 von 5 Sternen3.5/5 (2)

- AI and the Future of Education: Teaching in the Age of Artificial IntelligenceVon EverandAI and the Future of Education: Teaching in the Age of Artificial IntelligenceBewertung: 5 von 5 Sternen5/5 (1)

- Airplane Flying Handbook: FAA-H-8083-3C (2024)Von EverandAirplane Flying Handbook: FAA-H-8083-3C (2024)Bewertung: 4 von 5 Sternen4/5 (12)

- Pharmaceutical Dispensing and CompoundingVon EverandPharmaceutical Dispensing and CompoundingBewertung: 4 von 5 Sternen4/5 (2)

- The School Garden Curriculum: An Integrated K-8 Guide for Discovering Science, Ecology, and Whole-Systems ThinkingVon EverandThe School Garden Curriculum: An Integrated K-8 Guide for Discovering Science, Ecology, and Whole-Systems ThinkingNoch keine Bewertungen

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksVon EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksBewertung: 5 von 5 Sternen5/5 (1)

- Teaching STEM Outdoors: Activities for Young ChildrenVon EverandTeaching STEM Outdoors: Activities for Young ChildrenBewertung: 5 von 5 Sternen5/5 (2)

- GCSE Biology Revision: Cheeky Revision ShortcutsVon EverandGCSE Biology Revision: Cheeky Revision ShortcutsBewertung: 4.5 von 5 Sternen4.5/5 (2)

- RASPBERRY PI FOR BEGINNERS: TIPS AND TRICKS TO LEARN RASPBERRY PI PROGRAMMINGVon EverandRASPBERRY PI FOR BEGINNERS: TIPS AND TRICKS TO LEARN RASPBERRY PI PROGRAMMINGNoch keine Bewertungen