Beruflich Dokumente

Kultur Dokumente

3Ds For 3Cs Digital Design and Development For Collaborative Color Communication

Hochgeladen von

jaykg64Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

3Ds For 3Cs Digital Design and Development For Collaborative Color Communication

Hochgeladen von

jaykg64Copyright:

Verfügbare Formate

3 3

DS

FOR

By Jill M. Simmons, Lectra USA Inc., New York, N.Y.

t is becoming increasingly normal for retailers and branded apparel companies to use digital communication as a means for both the design and development process and the merchandising process. This leads to a critical need to be able to accurately define color at the beginning of the design process and then consistently and accurately communicate color throughout every stage of design, development, and merchandising, both internally and externally. As such, we must acknowledge the need to control color throughout the entire apparel process requires taking into account many factors: observers, illuminants, color standards, display devices (monitors, paper and/or fabric printers), production needs, consumer marketing (catalogs, Internet), etc.

CS

DIGITAL DESIGN & DEVELOPMENT FOR COLLABORATIVE COLOR COMMUNICATION

COLOR DEVELOPMENT

The color development process for apparel retailers and branded apparel companies will vary greatly depending on the organization and emphasis at each company. Selection of colors to be produced for a season may be a trend or a design function. Once the colors are selected, a standard for each color is produced in sufficient quantity for distribution to suppliers who must match the color to the satisfaction of the retailer/brand. This is referred to here as the color approval process, which entails at a minimum the following steps: Send standards with appropriate instructions to selected suppliers for color matching. Receive lab dip submissions from suppliers. Evaluate lab dips for color match. Approve or reject with comments to supplier.

FEBRUARY 2003

Communicate with designers when acceptability of color submissions is in question. Track progress of color approvals and administer the lab dip process.

Consistent Information Needed Once production orders are placed, the same organization may receive and approve production lot submissions. Depending on the retailer/brand organization, responsibility for the color approval process may be assigned to individuals within the design department or to individuals in other departments. These departments are given various names, including color office, product integrity, quality control, quality assurance, or color management. In some cases, the color approval process may be outsourced to testing labs. Concurrent to the color approval process, design and development must begin for the graphic design, textile design, and silhouette design. It would then seem logical that the same color standards that are initially communi-

cated externally to the suppliers for color matching should also be communicated internally for the design processes. Traditionally this has been done via small swatches that are then either entered via spectrophotometer into the design CAD systems and/or matched visually via RGB on the CAD. In every case the same process was being initiated at least two times in two different channels within the same company. With the advent and acceptance of digital color measurement devices in the first step of the process, it is now possible to communicate this initial digital color information to other steps of the process. Ideally, the color should be communicated at every step throughout the following stages of the product life cycle: Design Development (including information concerning the status of lab dip approval) Sampling Sourcing Merchandising Production E-Commerce Catalogs

WWW.AATCC.ORG

33

Retail This necessitates coherence between several different color spaces, color profiles, and output processes. Devices in RGB, devices in CMYK, devices with unique color spaces (i.e., textile dyeing), etc.it is a mind-boggling proposition. However, there are great strides being made in this direction. For the purposes of this article, I will focus the discussion on the display and manipulation of color on garments through texture mapping technology and 3D rendering. Spectral data from color standards are communicated to the design departments using the information collected from a spectrophotometer to create a palette. This spectral data is not transformed for communication, but must be converted into RGB for monitor display. Most important is that this display RGB does not affect printing or output as we will introduce monitor and printer profiles in order to calculate the overlapping color spaces between various devices. For communication to other parts of the process digitally, we will communicate in sRGB, CIE-Lab, and/or spectral data depending on the process.

Display and Communication of RGB Software packages may not communicate RGB the same way, resulting in two different values and two different displays for a single color standard. sRGB is a standard interpretation of the RGB color space and enables colors to be communicated correctly between software packages. It is a device independent color space and will not affect the display of the colors on various devices (monitors, printers) when you use monitor profiles. Display of Texture Mapped Images The appearance of color is only partially controllable by the new technologies in place. There are many more subjective items in the textile and garment design process.

For example, there is often little emphasis placed on the type of lighting used within the CAD design environment. Also, a designer will now receive the color palette from the color standards creator, but they should not be able to tweak this color. Here lies perhaps the most important issue it is not in a designers makeup NOT to change things. Ultimately the color will be applied to the texture of the fabric for visual simulation (i.e., a 3D yarn must be colored before being used in a woven fabric or a knit will be piece dyed with a color). The influence of this texture on the color can greatly change the appearance of the color in which case, the color that the designer originally asked for is not really the color that they intended. Add to this the application of the colored textile fabric to a photograph that has its own unique lighting scenario, shadows, etc. for merchandising purposes. The intent is that this merchandising photo will then be communicated either in the paper form of a catalog or electronically via the Internet. It becomes imperative that the color displayed in the photo is consistent with the product that the end consumer will finally receive so as to minimalize any returns to the re-

tailer due to color. Although there are some challenges with how the image is to be displayed in the merchandising process, it can be clearly shown that there is a value to allowing a design and merchandising team to communicate in the medium where they are most comfortable: visually. If this is done early in the process perhaps even before lab dips and/or productionmany colors may never be developed due to a lack of knowledge of how the color will look on a particular texture.

CONCLUSION

As technology progresses it will be necessary for color management systems to converge with design, development, and merchandising systems in order to properly take into account the observer, illuminant, and textures when displaying texture mapped images and 3D rendered garments. This can then be used to predict the store display.

Authors Address Jill M. Simmons, Lectra, 119 W. 40th St. Fl 3, New York, N.Y. 10018-2531; telephone 212-704-4004, ext. 261; fax 212-704-0751; e-mail j.simmons@lectra.com.

AATCC REVIEW

FEBRUARY 2003

34

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- SRA Reading Laboratory Levels Chart UpatedDokument1 SeiteSRA Reading Laboratory Levels Chart UpatedSan Htiet Oo0% (1)

- NuPolar Quality Testing and ComparisonsDokument12 SeitenNuPolar Quality Testing and Comparisonsou82muchNoch keine Bewertungen

- System Colors For Windows XP User Interface ThemesDokument30 SeitenSystem Colors For Windows XP User Interface Themesmanitou1997100% (1)

- The Fundamentals of A News PaperDokument8 SeitenThe Fundamentals of A News PaperJose AranaNoch keine Bewertungen

- The American Society For Aesthetics, Wiley The Journal of Aesthetics and Art CriticismDokument10 SeitenThe American Society For Aesthetics, Wiley The Journal of Aesthetics and Art CriticismJustine MuraoNoch keine Bewertungen

- Equivalence Table Humbrol Gunze Revell Tamiya TestorsDokument2 SeitenEquivalence Table Humbrol Gunze Revell Tamiya TestorsMarkelos ChatzitheodosiouNoch keine Bewertungen

- Master TGL 13 April 2021Dokument456 SeitenMaster TGL 13 April 2021SoniatulHarapanEmakNoch keine Bewertungen

- Shahram Hauck - Automated CTP Calibration For Offset Printing PDFDokument165 SeitenShahram Hauck - Automated CTP Calibration For Offset Printing PDFMohammad Ali ArbabNoch keine Bewertungen

- Yellow Oxide 42Dokument1 SeiteYellow Oxide 42ahboon145Noch keine Bewertungen

- Visual Information and MediaDokument2 SeitenVisual Information and Mediajosefalarka100% (2)

- The Aging ProcessDokument45 SeitenThe Aging Processsanjeev thadaniNoch keine Bewertungen

- Kalinkina JuliaDokument65 SeitenKalinkina Juliadiana.gorokhova.visualsNoch keine Bewertungen

- Laboratory Exercise in Sensory Physiology: Student Lab ManualDokument17 SeitenLaboratory Exercise in Sensory Physiology: Student Lab ManualChippy RabeNoch keine Bewertungen

- Manual - MCP 8 Control Unit - enDokument73 SeitenManual - MCP 8 Control Unit - enAdeilton santosNoch keine Bewertungen

- LIpika OffsetDokument1 SeiteLIpika OffsetThé Real BadmashNoch keine Bewertungen

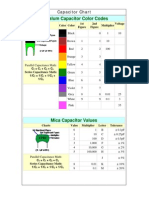

- Capacitor ChartDokument2 SeitenCapacitor ChartmuhibrazaNoch keine Bewertungen

- Cordelia SlidesCarnivalDokument28 SeitenCordelia SlidesCarnivalminjiNoch keine Bewertungen

- Aggregate Manual v075Dokument33 SeitenAggregate Manual v075Joao Arcadio SenraNoch keine Bewertungen

- Robert Bruce-Training To See AurasDokument29 SeitenRobert Bruce-Training To See AurasjohnNoch keine Bewertungen

- 3 - Book of Prime Entry - CashbookDokument37 Seiten3 - Book of Prime Entry - Cashbooknurzbiet8587Noch keine Bewertungen

- Color Layering For Colored Pencil - Susan RubinDokument2 SeitenColor Layering For Colored Pencil - Susan RubinMervi Hjelmroos-Koski0% (1)

- Khurana - Review of Ophthalmology-Jaypee Brothers Medical Publishers (2015) PDFDokument178 SeitenKhurana - Review of Ophthalmology-Jaypee Brothers Medical Publishers (2015) PDFasdfasdf100% (5)

- Aworld - Monograph Ofthe Genus Thecotheus (Ascomycetes, Pezizales)Dokument211 SeitenAworld - Monograph Ofthe Genus Thecotheus (Ascomycetes, Pezizales)Attila KoszkaNoch keine Bewertungen

- Dental Bleaching PDFDokument5 SeitenDental Bleaching PDFsantiagocastro14Noch keine Bewertungen

- Healing Language and ColoursDokument86 SeitenHealing Language and ColoursSatinder BhallaNoch keine Bewertungen

- Knight SlidesCarnivalDokument28 SeitenKnight SlidesCarnivalnurlisaNoch keine Bewertungen

- Newton's Theory of Color: Module 1 OverviewDokument5 SeitenNewton's Theory of Color: Module 1 OverviewLee Eun JiNoch keine Bewertungen

- Advanced ExteriorsDokument17 SeitenAdvanced ExteriorsAlmedinNoch keine Bewertungen

- Vocabulary Words For Art PresentationDokument3 SeitenVocabulary Words For Art PresentationBee Elorah LopezNoch keine Bewertungen