Beruflich Dokumente

Kultur Dokumente

Nadiathul Raihana BT Ismail

Hochgeladen von

Binu SbOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Nadiathul Raihana BT Ismail

Hochgeladen von

Binu SbCopyright:

Verfügbare Formate

PV MODULE MAXIMUM POWER POINT TRACKER(MPPT) USING MICROCONTROLLER

NADIATHUL RAIHANA BINTI ISMAIL

This thesis is submitted as partial fulfillment of the requirements for the award of the Bachelor of Electrical Engineering (Hons.) (Electronics)

Faculty of Electrical & Electronics Engineering Universiti Malaysia Pahang

NOVEMBER, 2008

All the trademark and copyrights use herein are property of their respective owner. References of information from other sources are quoted accordingly; otherwise the information presented in this report is solely work of the author.

Signature Author Date

: ____________________________ : NADIATHUL RAIHANA BINTI ISMAIL :

Specially dedicated with lots of loves to My beloved parent Ismail Salim & Samidah Ab Samad

ACKNOWLEDGEMENT

Thanks to God for His Almighty Kindness and Ultimate Powers for giving me the opportunity to complete my final project and writing this thesis as been required to accomplished my PSM subject.

Also a lot of thanks to the supervisor of my project Mr. Mohd. Shawal Jadin for his consistent guidances and helps along the journey to complete this projects. Not forgotten to the FKEEs staff and friends especially for them who directly and indirectly contribute in my project.

Last but not least to my beloved Moms Ibu thanks for your continuous supports and encouragement mentally and physically for me to completes this hardest task that I have gone through.

Nothing can repay all of yours help and kindness guys. Thanks very much, may ALLAH bless you.

ABSTRACT

PV Module Maximum Power Point Tracker(MPPT) , is a photovoltaic system that uses the photovoltaic array as a source of electrical power supply. Every photovoltaic (PV) array has an optimum operating point, called the maximum power point, which varies depending on cell temperature, the insolation level and array voltage. The function of MPPT is needed to operate the PV array at its maximum power point. The design of a Maximum Peak Power Tracking (MPPT) is proposed utilizing a boost-converter topology. Solar panel voltage and current are continuously monitored by a closed-loop microprocessor based control system, and the duty cycle of the boost converter continuously adjusted to extract maximum power. The design consists of a PV array, DCDC Boost converters (also known as step-up converters) and a control section that uses the PIC16F877A microcontroller. The control section obtains the information from the PV array through microcontrollers Analog to Digital Converter (ADC) ports and hence to perform )the pulse width modulation (PWM) to the converter through its Digital to Analog Converter (DAC) ports. Many such algorithms have been proposed. However, one particular algorithm, the perturb-and-observe (P&O) method, claimed by many in the literature to be inferior to others, continues to be by far the most widely used method in commercial PV MPPTs. (Keywords: Boost Converter, Pulse Width Modulation,PIC16F877A)

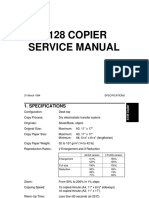

TABLE OF CONTENTS

CHAPTER

CONTENTS TITLES DECLARATION DEDICATION ACKNOWLEDGEMENT ABSTRACT TABLE OF CONTENTS LIST OF FIGURES LIST OF TABLES LIST OF ABBREVIATIONS LIST OF APPENDIXES vii i ii iii iv

PAGE

x xi xii xiii

CHAPTER 1

CONTENTS INTRODUCTION 1.1 1.2 1.3 1.4 1.5 Introduction Overview of PV Array Overview of MPPT Objective Scope of Project

PAGE

1 2 3 4 5

THEORY AND LITERATURE REVIEW

2.1 2.2 2.3 2.4 2.5 2.6

MPPT Boost Converter 2.2.1 PWM PIC16F877A MPPT Algorithm Boost Operation MOSFET Driver

6 7 8 14 14 16 16

METHODOLOGY AND DESIGN 3.1 3.2 3.3 Introduction System Design PV Array 18 19 21

CHAPTER

CONTENTS 3.4 Boost Circuit 3.4.1 3.4.2 3.5 3.6 3.7 Why Boost Boost Design

PAGE 22 23 23 26 29 29

PIC16F877A MOSFET Driver Summary

RESULT AND ANALYSIS

4.1 4.2 4.3

Introduction Analyzing using P Spice Analyzing with Real Hardware 4.3.1 4.3.2 4.3.3 MPPT Interface with Solar Panel Effect of Inductor Towards Vout Effect of D

32 32 34 36 38 40

4.4

Summary

CONCLUSION AND RECOMMENDATION 5.1 5.2 5.3 Conclusion Recommendation Costing and Commercialization 5.3.1 5.3.2 5.4 Project Costing Commercialization 42 43 43 43 45 46

References

LIST OF FIGURES

FIGURE NO.

TITLE

PAGE

3.1 4.1 4.1 4.1 4.1 4.1 4.1 4.1 3.1 3.2 3.3 3.4 3.5 3.6 3.7 3.8 3.9 3.10 3.11

MPP characteristic Boost Circuit Equivalent Circuit during t on Equivalent Circuit during t off Waveforms for the boost converter when running at CCM Waveforms for the boost converter when running at DCM PWM signals of varying duty cycles P&O Algorithm Flow Chart Block Diagram of MPPT Interface with the PV Array Sunmodule SW 80 mono/R5E Boost Circuit Simulation result using L= 36uH C=8.2uF Simulation result using L= 47uH C=680uF Final Circuit to Implement PIC16F877A Pins 5 volt DC Power Supply Clock Circuit The PWM output with D=0.4 The PWM output with D=0.5

4 8

9 9

10 13 15 17 19 21 23 25 25 26 27 27 27 28 29

FIGURE NO. 3.12 3.13 3.14 3.15 3.16 4.1 4.2 4.3 4.4 38 4.5 39

TITLE The Connection of IR2109 The Boost Circuit MOSFET Driver PIC circuit MPPT Hardware Boost circuit in Pspice Simulation Boost Simulation Result Result of MPPT circuit using Differences Power Supply Vout using difference Inductors Vout Responds Towards D value

PAGE 29 30 31 31 31 33 34 36

LIST OF TABLES

TABLE NO.

TITLE

PAGE

3.1 4.1 4.2 35 4.3 37 4.4 39

Specification of the SW 80 mono/R5E Result of varying in Vin Vout using the Difference Power Supplies Vout using difference Inductors Vout Responds towards the difference value of D

22 33

LIST OF ABBREVIATIONS

PWM MPPT PV DC D,d DCM CCM MOSFET

Pulse Width Modulation Maximum Power Point Tracker Photovoltaic Direct Current Duty Ratio Discontinuous Current Mode Continuous Current Mode Metal Oxide Silicon Field Effect Transistor

LIST OF APPENDICES

APPENDIX 1 2 3 4 5 6 7

TITLE PIC PROGRAMMING OF PWM DATASHEET OF MOSFET(IRFP150N) DATASHEET OF DIODE(D1N4148) DATASHEET OF INDUCTORS DATASHEET OF SOLAR PANEL DATASHEET OF MOSFET DRIVER(IRF2109) DATASHEET OF PIC16F877A

PAGE 47 49 52 56 59 62 66

CHAPTER 1

INTRODUCTION

1.1

Introduction

Maximum Power Point Tracker (MPPT) is an electronic system operates the Photovoltaic (PV) modules in a manner that allows the PV modules to produce all the power they are capable of. MPPT is not a mechanical tracking system that physically moves the modules to make them point more directly at the sun. MPPT is a fully electronic system that varies the electrical operating point of the modules so that the modules are able to deliver maximum available power.

The problem faced by MPPT is it not perfectly delivered the output voltage as stated, since the outputs of PV system are depends on the temperature, irradiation, and the load electrical characteristic. So, thats why MPPT is needed to be implementing in the PV system to maximize the PV array output voltage.

1.2

Overview of Photovoltaic (PV)

Photovoltaic (PV) is the field of technology and research related to the application of solar cells for energy by converting sunlight directly into electricity. Photovoltaic are generally known as a method for generating solar power by using solar cells packaged in photovoltaic modules, often electrically connected in multiples as solar photovoltaic arrays to convert energy from the sun into electricity. In the simple words the photons from sunlight knock electrons into a higher state of energy, creating electricity. The term photovoltaic denotes the unbiased operating mode of a photodiode in which current through the device is entirely due to the transduced light energy. Virtually all photovoltaic devices are some type of photodiode. Solar cells produce direct current electricity from light, which can be used to power equipment or to recharge a batterylead acid.

PV cells have a single operating point where the values of the current (I) and Voltage (V) of the cell result in a maximum power output. These values correspond to a particular resistance, which is equal to V/I as specified by Ohm's Law. A PV cell has an exponential relationship between current and voltage, and the maximum power point (MPP) occurs at the knee of the curve as shown in Figure 1.0, where the resistance is equal to the negative of the differential resistance (V/I = -dV/dI).

1.3

Overview of Maximum Power Point Tracker (MPPT)

A maximum power point tracker (MPPT) is a high efficiency DC to DC converter which functions as an optimal electrical load for a photovoltaic (PV) cell, most commonly for a solar panel or array, and converts the power to a voltage or

current level which is more suitable to whatever load the system is designed to drive. PV cells have a single operating point where the values of the current (I) and Voltage (V) of the cell result in a maximum power output. Maximum power point trackers utilize some type of control circuit or logic and algorithm to search for this point and thus to allow the converter circuit to extract the maximum power available from a cell.

In short , photovoltaic (PV) arrays are used to provide energy and MPPT are used to correct the variations in the current-voltage characteristics of the solar cells. The Figure 1.0 is an idealized curve with no deformations due to cell damage or bypass diodes kicking in. The point on the current-voltage (I-V) curve of a solar module under illumination, where the product of current and voltage is maximum (Pmax, measured in watts). The points on the I and V scales which describe this curve point are named Imp (current at maximum power) and Vmp (voltage at maximum power.).

For a typical silicon cell panel, the maximum power point (MPP) is about 17 volts for a 36-cell configuration. For the array to be able to delivered the maximum possible amount of power, either the operating voltage or current needs to be carefully controlled. This maximum power point is seldom located at the same voltage the main system is operating at, and even if the two were equal initially, the power point would quickly move as lighting conditions and temperature change (varied under the ambient condition). Hence, a device is needed that finds the maximum power point and converts that voltage to a voltage equal to the system voltage.

Figure 1.0 : MPP characteristic

1.4

Objectives

i.

Implementation of microcontroller in the MPPT system. . The used of the microcontroller to control the D (duty cycle for the boost converter) by the algorithm that has been choosen.

ii.

The operation of the PV module should be forced to operate at maximum power point under varying ambient condition.

1.5

Scopes of Project

This project relates to a method and a device for implementing the method that tracks the optimal maximum power point in a system that supplies power from a direct-current power source, such as that generated by a solar cell array (photovoltaic generator)

i.

The choosing of DC-DC converter based on the desired output voltage from the MPPT in term to ensure the PV module will operate at the maximum point. The DC-CC converter that will be used in this project is the Boost Converter. The power MOSFET in the circuit act as the switching element towards the converter due to its capability in sustaining the high level current and voltage. The PIC will act as the controller of the circuit by giving the signal to the power MOSFET for its switching mode (On and off) to produce the desired voltage.

ii.

The implementation of microcontroller (PIC16F877A) to produce

PWM.

PIC16F877A is used to generate PWM by using crystal 20MHz, the maximum PWM frequency value can be generated by PIC16F877A is 208.3 kHz. The duty cycle can be start from 0 to 0.99. [5]

CHAPTER 2

THEORY AND LITERATURE REVIEW

2.1

MPPT

MPPT is a circuit that allows extracting Maximum Power Point from PV array independently from the variation of its electrical characteristic that is function of the operative condition (temperature, illumination, and aging). The optimization of the delivered power is delivered by controlling current through the array or the voltage across it, with the best working point (MPP) of the power characteristic.[1]

Specifically the Power Point Tracker is a high frequency DC to DC converter. They take the DC input from the solar panels, change it to high frequency AC, and convert it back down to a different DC voltage and current to exactly match the panels to the loads. MPPT's operate at very high audio frequencies, usually in the 20-80 kHz range. The advantage of high frequency circuits is that they can be designed with very high efficiency transformers and small components.

2.2

Boost Converter

The need of converter in the MPPT system is to maximize the varied input of DC voltage. In term of maximized the output voltage by step up the input voltage the boost converter is ideally to be choose in the MPPT design compared to the Buck converter since the Boost converter can always track the maximum power point.[3] By referring to the input of the both topologies the Buck converter input voltage is always greater or equal to its output voltage so the output panel must exceed the battery voltage for power to flow. The maximum power point of 12V commercial PV module is above 13V for most combinations of insolation and temperature. So buck converter can operate at the MPP undermost but not at all condition. While for the Boost converter input voltage must lie between the zero and output voltage so thats why, Boost converter will always be able to operate at the panels MPP. In term of simplicity a buck converter with a MOSFET switch still requires an additional diode or MOSFETs to block the reverse current flow when the panel voltage drops below the battery voltage, as an advantages of Boost converter naturally it has this devices as part of its structure , which eliminates an additional source of voltage drop and power loss.

A boost converter has been employed in this application to regulate the power output to the load. It consists of an inductor, a logic level, Power MOSFET switch, a Schotky diode and capacitors. Figure 2.1 shows a typical connection of a boost converter. The basic Boost converter containing at least two semiconductor switches (a diode and a transistor) and one energy storage element. Filters made of capacitors (sometimes in combination with inductors) are normally added to the output of the converter to reduce output voltage ripple..

A 15 to 18volt from the solar panel will be the target operation point of the solar panel. In this case we will extract a current of 4.6 Amp from the device, which will then give us a maximum power from the PV array.

Figure 2.1 : Boost Circuit

2.2.1

Operation of Boost Converter

As known, a boost converter is capable of providing an output voltage that is greater than the input voltage. The key principle that drives the boost converter is the tendency of an inductor to resist changes in current. When being charged it acts as a load and absorbs energy like a resistor), when being discharged, it acts as an energy source (like a battery). The voltage it produces during the discharge phase is related to the rate of change of current, and not to the original charging voltage, thus allowing different input and output voltages. The basic principle of a Boost converter consists in 2 distinct states as in Figure 2.2 and 2.3.

In figure 2.2 at the On-state,, resulting in an increase in the inductor current; In Figure 2.3 at the Off-state, the Transistor (switch) is open and the only path offered to inductor current is through the flyback diode D, the capacitor C and the load R. This result in transferring the energy accumulated during the On-state into the capacitor. The input current is discontinuous, stepping between a very high inductor current and 0. The large ripple usually requires a large input bypass capacitor to reduce the source impedance.

Figure 2.2: Equivalent Circuit during t on

Figure 2.3: Equivalent Circuit during t off The operation of a boost converter can be divided into two modes the Continuous Current Mode and the Discontinuous Current Mode. Depending on the switching actions of the switching device (like MOSFET).

During the Continuous Current Mode the current through the inductor (IL) never falls to zero. Figure 2.4 shows the typical waveforms of currents and voltages in a converter operating in this mode. The output voltage can be calculated as follows, in the case of an ideal converter (i.e. using components with an ideal behavior) operating in steady conditions. During the On-state, the switch S is closed, which makes the input voltage (Vi) appear across the inductor, which causes a change in current (IL) flowing through the inductor during a time period (t) by the formula:

Figure 2.4: current and voltage in a boost converter operating in continuous mode

Waveforms of

I L / t = Vi / L

(1) At the end of the On-state, the increase of IL is given by:

I L on = (Vi .D. T) / L

(2) D is the duty cycle. It represents the fraction of the commutation period T during which the switch is On. Therefore D ranges between 0 (S is never on) and 1 (S is always on). During the Off-state, the switch S is open, so the inductor current flows

through the load. By considering there was zero voltage drops in the diode, and a capacitor large enough for its voltage to remain constant, the derivation of IL is:

Vi Vo = L dIL / dt

(3)

Therefore, the variation of IL during the Off-period is:

I L off = (Vi-Vo)(1-D) T] / L

(4) As we consider that the converter operates in steady-state conditions, the amount of energy stored in each of its components has to be the same at the beginning and at the end of a commutation cycle. In particular, the energy stored in the inductor is given by:

E = 0.5L . I L 2

(5) Therefore, the inductor current has to be the same at the beginning and the end of the commutation cycle. This can be written as

I L on + I L off = 0

Substituting I L on and I L off by their expressions yields:

(6)

I L on + I L off = [(Vi .D.T) / L] + [(Vi -Vo).(1-D)T] / L = 0

(7) This can be written as:

Vo / Vi = 1/(1-D)

(8) Which in turns reveals the duty cycle to be:

D = 1- (Vi / Vo)

(9)

From the above expression it can be seen that the output voltage is always higher than the input voltage (as the duty cycle goes from 0 to 1), and that it increases with D, theoretically to infinity as D approaches 1. This is why this converter is sometimes referred to as a step-up converter. While during the discontinuous mode occurs, the amount of energy required by the load is small enough to be transferred in a time smaller than the whole commutation period. In this case, the current through the inductor falls to zero during part of the period. The only difference in the principle described above is that the inductor is completely discharged at the end of the commutation cycle see waveforms in Figure 2.5. The difference has a strong effect on the output voltage equation. It can be calculated as follows: As the inductor current at the beginning of the cycle is zero, its maximum value IL max (at t=D.T) is

I L MAX= (Vi. D.T) / L

(10) During the off-period, IL falls to zero after .T:

I L MAX + [ (Vi Vo). .T] / L = 0

(11)

Using the two previous equations, is:

=( Vi .D) / (Vo-Vi)

(12)

The load current Io is equal to the average diode current (ID). As can be seen on figure 4, the diode current is equal to the inductor current during the off-state. Therefore the output current can be written as:

Io =ID= (IL MAX / 2) .

(13) Replacing ILmax and by their respective expressions yields:

Io= (Vi2 . D2 . T) / 2L (Vo -Vi)

(14)

Therefore, the output voltage gain can be written as :

Vo / Vi = 1 + [(Vi . D2.T) / (2L .Io)

(15) Compared to the expression of the output voltage for the continuous mode, this expression is much more complicated. Furthermore, in discontinuous operation, the output voltage gain not only depends on the duty cycle, but also on the inductor value, the input voltage, the switching frequency, and the output current.

Figure current boost in

2.5: Waveforms of and voltage in a converter operating Discontinuous mode

2.3

MOSFET Driver

A gate voltage (VG) is always needed to control the switching of the MOSFET, enabling it to behave as a switch in the boost converter. This voltage VG, directly affects the turn on and turns off time delay of the MOSFET as a switching device. As a result, a drive circuit will be needed to enhance the performance of the MOSFET, thus the overall efficiency of the MPPT circuit. The important characteristics of the MOSFET is to turn it on, the gate terminal value at least 10 volts greater than the source terminal (about 4 volts for logic level MOSFETs).[5]

The circuit driver should be able to supply a reasonable current to ensure the stray capacitance can be charged up as soon as possible. Since the large stray capacitance between the gate and the terminal is one of the important characteristic of MOSFET. Because of this characteristic the capacitance needs to be charged up before the gate voltage reaches the desired voltage.

Das könnte Ihnen auch gefallen

- Design and Implementation of Photo Voltaic System With Soft Switched Boost Converter Using Analog Fuzzy Based MPPTDokument7 SeitenDesign and Implementation of Photo Voltaic System With Soft Switched Boost Converter Using Analog Fuzzy Based MPPTskrtamilNoch keine Bewertungen

- mppt softcopyDokument42 Seitenmppt softcopysonalika.geetasureshNoch keine Bewertungen

- Implementation of Maximum Power Point Tracking (MPPT)Dokument44 SeitenImplementation of Maximum Power Point Tracking (MPPT)Emre ÖzerNoch keine Bewertungen

- Modeling and Simulation of PV Array and Its Performance Enhancement Using MPPT (P&O) TechniqueDokument8 SeitenModeling and Simulation of PV Array and Its Performance Enhancement Using MPPT (P&O) Techniqueeditor9891Noch keine Bewertungen

- A Review On Photo Voltaic MPPT Algorithms: International Journal of Electrical and Computer Engineering (IJECE)Dokument16 SeitenA Review On Photo Voltaic MPPT Algorithms: International Journal of Electrical and Computer Engineering (IJECE)saravanaselvaNoch keine Bewertungen

- Paper 04Dokument6 SeitenPaper 04Md ShafiullahNoch keine Bewertungen

- Design of Photovoltaic System Using Buck-Boost Converter Based On MPPT With PID ControllerDokument9 SeitenDesign of Photovoltaic System Using Buck-Boost Converter Based On MPPT With PID ControllerL CHNoch keine Bewertungen

- A New Controller Scheme For Photovoltaics PowerDokument10 SeitenA New Controller Scheme For Photovoltaics PowerHakan PolatkanNoch keine Bewertungen

- Performance Evaluation of Maximum Power Point Tracking Algorithm With Buck-Boost DC-DC Converter For Solar PV SystemDokument5 SeitenPerformance Evaluation of Maximum Power Point Tracking Algorithm With Buck-Boost DC-DC Converter For Solar PV SystemIJSTENoch keine Bewertungen

- 36 - A New Microcontroller-Based MPPT Algorithm For Photovoltaic AplicationDokument102 Seiten36 - A New Microcontroller-Based MPPT Algorithm For Photovoltaic AplicationMartin TrujilloNoch keine Bewertungen

- Fuzzy Logic Based MPPT Controller For A PV SystemDokument6 SeitenFuzzy Logic Based MPPT Controller For A PV SystemIJRASETPublicationsNoch keine Bewertungen

- Point Method The Photovoltaic System: Novel Maximum Power Tracking ForDokument5 SeitenPoint Method The Photovoltaic System: Novel Maximum Power Tracking Forramalakshmi_apsNoch keine Bewertungen

- Single Sensor Based Photovoltaic Maximum Power Point Tracking Technique For Solar Water Pumping SystemDokument5 SeitenSingle Sensor Based Photovoltaic Maximum Power Point Tracking Technique For Solar Water Pumping SystemPogisho LekgethoNoch keine Bewertungen

- Design and Implementation of Photo Voltaic System: Arduino ApproachDokument6 SeitenDesign and Implementation of Photo Voltaic System: Arduino ApproachjurdeNoch keine Bewertungen

- Analysis of Unified Output MPPT Control in Subpanel PV Converter System PDFDokument10 SeitenAnalysis of Unified Output MPPT Control in Subpanel PV Converter System PDFHendrayana HendraNoch keine Bewertungen

- Perturb and Observe Method MATLAB Simulink and Design of PV System Using Buck Boost ConverterDokument5 SeitenPerturb and Observe Method MATLAB Simulink and Design of PV System Using Buck Boost ConverterGss ChaitanyaNoch keine Bewertungen

- V/F Speed Control of SVPWM Based Solar Fed Induction MotorDokument7 SeitenV/F Speed Control of SVPWM Based Solar Fed Induction MotorInternational Journal of Application or Innovation in Engineering & ManagementNoch keine Bewertungen

- Design OF BUCK BOOST CONVERTERDokument11 SeitenDesign OF BUCK BOOST CONVERTERmithunprayagNoch keine Bewertungen

- A Seven Level Inverter Using A Solar Power Generation SystemDokument7 SeitenA Seven Level Inverter Using A Solar Power Generation Systemsasitharan33Noch keine Bewertungen

- Comparative Study of P&O and Inc MPPT AlgorithmsDokument7 SeitenComparative Study of P&O and Inc MPPT AlgorithmsAJER JOURNALNoch keine Bewertungen

- Investigation of Three-Phase Grid-Connected Inverter For Photovoltaic ApplicationDokument6 SeitenInvestigation of Three-Phase Grid-Connected Inverter For Photovoltaic ApplicationAmran MaulanaNoch keine Bewertungen

- MPPT New EditDokument27 SeitenMPPT New EditFarhan AkramNoch keine Bewertungen

- Application of PI and MPPT Controller to DC-DC ConverterDokument9 SeitenApplication of PI and MPPT Controller to DC-DC ConverterwafaNoch keine Bewertungen

- Pscad PV THDDokument6 SeitenPscad PV THDRavishankar KankaleNoch keine Bewertungen

- Publisher in ResearchDokument8 SeitenPublisher in Researchrikaseo rikaNoch keine Bewertungen

- 6 - Design of Solar Charge ControllerDokument6 Seiten6 - Design of Solar Charge ControllerNyanphyo AungNoch keine Bewertungen

- Fuz MPPT PumpDokument10 SeitenFuz MPPT Pumpvintin4uNoch keine Bewertungen

- MPPT AlgorithmDokument7 SeitenMPPT AlgorithmVishnu Kumar NadarNoch keine Bewertungen

- Mrs. Kapil Parikh Mahavir Singh: Supervisor Submitted byDokument27 SeitenMrs. Kapil Parikh Mahavir Singh: Supervisor Submitted byMahavir SinghNoch keine Bewertungen

- Modeling and Control of DC-DC Boost Converter Using K-Factor Control For MPPT of Solar PV SystemDokument6 SeitenModeling and Control of DC-DC Boost Converter Using K-Factor Control For MPPT of Solar PV SystemHoang ManhNoch keine Bewertungen

- Group 9 (PSE) Simulation - Assignment On ECE509Dokument9 SeitenGroup 9 (PSE) Simulation - Assignment On ECE509GodwinNoch keine Bewertungen

- Enhanced Solar PV MPPT System For 12V Battery ChargerDokument8 SeitenEnhanced Solar PV MPPT System For 12V Battery ChargerAliXmetecNoch keine Bewertungen

- Project Number: P12407: Photovoltaic Energy Harvesting SystemDokument7 SeitenProject Number: P12407: Photovoltaic Energy Harvesting Systemnehaadhikari87Noch keine Bewertungen

- Khan 2010Dokument4 SeitenKhan 2010Huy LêNoch keine Bewertungen

- Isscc 2012 / Session 5 / Audio and Power Converters / 5.6Dokument3 SeitenIsscc 2012 / Session 5 / Audio and Power Converters / 5.6Soha SherifNoch keine Bewertungen

- Incremental Conductance MPPT Method For PV Systems-LibreDokument3 SeitenIncremental Conductance MPPT Method For PV Systems-LibreRushikeshKatkarNoch keine Bewertungen

- Solar MPPTDokument16 SeitenSolar MPPTKiran ZoroNoch keine Bewertungen

- A Novel Approach On MPPT Algorithm For Solar Panel Using Buck Boost ConverterDokument5 SeitenA Novel Approach On MPPT Algorithm For Solar Panel Using Buck Boost Converterayoub reseauNoch keine Bewertungen

- Ijdacr: Simulation and Digital Implementation of Fuzzy Logic Controller For Solar Maximum Power Tracker ApplicationDokument7 SeitenIjdacr: Simulation and Digital Implementation of Fuzzy Logic Controller For Solar Maximum Power Tracker ApplicationDodik YuniarNoch keine Bewertungen

- Lab 07 UpdatedDokument13 SeitenLab 07 Updatedasifa rafiqNoch keine Bewertungen

- M.tech ThesisDokument59 SeitenM.tech ThesisRama Krishna100% (1)

- Designing of Solar PV Systems and Demonstration of Maximum Power Point Tracking (MPPT) Using MatlabDokument17 SeitenDesigning of Solar PV Systems and Demonstration of Maximum Power Point Tracking (MPPT) Using MatlabRasapalli DivyaNoch keine Bewertungen

- Design and Implementation of A Low Cost MPPT Controller For Solar PV SystemDokument6 SeitenDesign and Implementation of A Low Cost MPPT Controller For Solar PV SystemAhmed ShoeebNoch keine Bewertungen

- 02 Nvee10089Dokument8 Seiten02 Nvee10089Edu Daryl MacerenNoch keine Bewertungen

- ESPE03Dokument9 SeitenESPE03Karthi KeyanNoch keine Bewertungen

- Effect of Partial Shading in Grid Connected Solar PV System With FL ControllerDokument10 SeitenEffect of Partial Shading in Grid Connected Solar PV System With FL ControllerPtuan ThanhNoch keine Bewertungen

- Snosb84c MPPT ControlerDokument18 SeitenSnosb84c MPPT Controleraxal77Noch keine Bewertungen

- Design of A Digital Controlled Solar Water PumpDokument5 SeitenDesign of A Digital Controlled Solar Water Pumpsandeepbabu28Noch keine Bewertungen

- MPPT For Standalone PV Systems With The Help of SEPIC ConverterDokument9 SeitenMPPT For Standalone PV Systems With The Help of SEPIC ConverterIJRASETPublicationsNoch keine Bewertungen

- Photovoltaic Power Control Using MPPT and Boost ConverterDokument45 SeitenPhotovoltaic Power Control Using MPPT and Boost ConverterPedro Antonio Liberona SantibañezNoch keine Bewertungen

- 2208EE006.ourside - GridsystemDokument6 Seiten2208EE006.ourside - GridsystemssNoch keine Bewertungen

- A Single-Stage Three-Phase Grid-Connected Photovoltaic System With Modified MPPT Method and Reactive Power CompensationDokument6 SeitenA Single-Stage Three-Phase Grid-Connected Photovoltaic System With Modified MPPT Method and Reactive Power Compensationsandeepbabu28Noch keine Bewertungen

- Boost Control: MPPT Continued: - A Simple Method: Perturb and Observe (P&O)Dokument7 SeitenBoost Control: MPPT Continued: - A Simple Method: Perturb and Observe (P&O)Usman FarooqNoch keine Bewertungen

- ProjectDokument30 SeitenProjectmitesh goyal100% (1)

- Versatile P-Sim Model For PV ArrayDokument4 SeitenVersatile P-Sim Model For PV ArrayShubhashish BhaktaNoch keine Bewertungen

- VSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsVon EverandVSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsNoch keine Bewertungen

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlVon EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlBewertung: 5 von 5 Sternen5/5 (1)

- Simulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorVon EverandSimulation of Some Power System, Control System and Power Electronics Case Studies Using Matlab and PowerWorld SimulatorNoch keine Bewertungen

- Photovoltaic Power System: Modeling, Design, and ControlVon EverandPhotovoltaic Power System: Modeling, Design, and ControlNoch keine Bewertungen

- 6 3PDokument1 Seite6 3PBinu SbNoch keine Bewertungen

- Laplace Domain Circuit AnalysisDokument1 SeiteLaplace Domain Circuit AnalysisBinu SbNoch keine Bewertungen

- F C F Is The Frequency in Hertz (HZ) or Cycles Per Second: 3 10 M/s 3 10 M 10 HZDokument1 SeiteF C F Is The Frequency in Hertz (HZ) or Cycles Per Second: 3 10 M/s 3 10 M 10 HZBinu SbNoch keine Bewertungen

- 14 31PDokument1 Seite14 31PBinu SbNoch keine Bewertungen

- 6 3PDokument1 Seite6 3PBinu SbNoch keine Bewertungen

- EM Radiation Speed CalculationDokument1 SeiteEM Radiation Speed CalculationBinu SbNoch keine Bewertungen

- EM Radiation Speed CalculationDokument1 SeiteEM Radiation Speed CalculationBinu SbNoch keine Bewertungen

- 6 3PDokument1 Seite6 3PBinu SbNoch keine Bewertungen

- 10 4eDokument1 Seite10 4eBinu SbNoch keine Bewertungen

- Laplace Domain Circuit AnalysisDokument1 SeiteLaplace Domain Circuit AnalysisBinu SbNoch keine Bewertungen

- EM Radiation Speed CalculationDokument1 SeiteEM Radiation Speed CalculationBinu SbNoch keine Bewertungen

- 7205 2 1eDokument3 Seiten7205 2 1eBinu SbNoch keine Bewertungen

- 6 1PDokument1 Seite6 1PBinu Sb0% (1)

- F C F Is The Frequency in Hertz (HZ) or Cycles Per Second: 3 10 M/s 3 10 M 10 HZDokument1 SeiteF C F Is The Frequency in Hertz (HZ) or Cycles Per Second: 3 10 M/s 3 10 M 10 HZBinu SbNoch keine Bewertungen

- Commented (AA1) : Direct Answers Given Without Any DetailedDokument1 SeiteCommented (AA1) : Direct Answers Given Without Any DetailedBinu SbNoch keine Bewertungen

- P T Be The Rectangular Pulse of Width T: T PT T T T T T P CDokument2 SeitenP T Be The Rectangular Pulse of Width T: T PT T T T T T P CBinu SbNoch keine Bewertungen

- A 62.8319 B 6.3662 Ans 20 Ans 20Dokument1 SeiteA 62.8319 B 6.3662 Ans 20 Ans 20Binu SbNoch keine Bewertungen

- 7 8eDokument2 Seiten7 8eBinu SbNoch keine Bewertungen

- 6626 1 12eDokument1 Seite6626 1 12eBinu SbNoch keine Bewertungen

- V Is The Volume of The Water in The Tank, R Is The Radius in The Tank, A Is The Tank Cross Sectional Area, H Is The Tank HeightDokument2 SeitenV Is The Volume of The Water in The Tank, R Is The Radius in The Tank, A Is The Tank Cross Sectional Area, H Is The Tank HeightBinu SbNoch keine Bewertungen

- MATLAB Modeling of Chemical Reaction KineticsDokument2 SeitenMATLAB Modeling of Chemical Reaction KineticsBinu SbNoch keine Bewertungen

- F L F L: Valve GainDokument2 SeitenF L F L: Valve GainBinu SbNoch keine Bewertungen

- W Ig F G W W Di I Di G I G F I G G I G I: (A) Consider The Formula To Determine Force.Dokument3 SeitenW Ig F G W W Di I Di G I G F I G G I G I: (A) Consider The Formula To Determine Force.Binu SbNoch keine Bewertungen

- F L F L: Valve GainDokument2 SeitenF L F L: Valve GainBinu SbNoch keine Bewertungen

- 8Dokument2 Seiten8Binu SbNoch keine Bewertungen

- 21 12eDokument1 Seite21 12eBinu SbNoch keine Bewertungen

- 7 8eDokument2 Seiten7 8eBinu SbNoch keine Bewertungen

- Ps K S Y S S S: KM A B C Ps S S SDokument1 SeitePs K S Y S S S: KM A B C Ps S S SBinu SbNoch keine Bewertungen

- 8 7eDokument1 Seite8 7eBinu SbNoch keine Bewertungen

- Dwbi Org Etl Informatica 131 Important Practical Interview QDokument57 SeitenDwbi Org Etl Informatica 131 Important Practical Interview QBinu Sb67% (3)

- 1955 Chevy 235 (123 HP)Dokument5 Seiten1955 Chevy 235 (123 HP)Mikey3airNoch keine Bewertungen

- Universal Oil Burners by Kroll - . .: TUV-approvedDokument4 SeitenUniversal Oil Burners by Kroll - . .: TUV-approvedBentea MarcelNoch keine Bewertungen

- TS 41-24 - Final ECG Draft 10 October 2017 2Dokument110 SeitenTS 41-24 - Final ECG Draft 10 October 2017 2Emir KamberovicNoch keine Bewertungen

- Mobile Power: Battery Technology and Future ApplicationsDokument31 SeitenMobile Power: Battery Technology and Future ApplicationsBalaji KannanNoch keine Bewertungen

- Gunung Megang - Final PDDDokument56 SeitenGunung Megang - Final PDDbapaobaoNoch keine Bewertungen

- Synthesis Paper On Nuclear PPDokument3 SeitenSynthesis Paper On Nuclear PPchristinekehyengNoch keine Bewertungen

- Green ArchitectureDokument272 SeitenGreen ArchitectureIuliu Nicolae Borsa96% (24)

- Class4 Q A PDFDokument1.679 SeitenClass4 Q A PDFVinaik Krishnamurthy100% (3)

- Small-Scale Production of Portland Cement (HABITAT, 1993, 92 P.) V. Raw-Mix Design and Quality Control in VSK Cement Plants 5.1 Raw-Mix DesignDokument3 SeitenSmall-Scale Production of Portland Cement (HABITAT, 1993, 92 P.) V. Raw-Mix Design and Quality Control in VSK Cement Plants 5.1 Raw-Mix DesignshastrysnNoch keine Bewertungen

- Clinton Field Service Clinic ManualDokument138 SeitenClinton Field Service Clinic Manualcopyhere100% (1)

- Press Release Solar PanamaDokument2 SeitenPress Release Solar PanamaScott A. MullerNoch keine Bewertungen

- Non-Impact Wire Cutter Timer Controlled Fishing ToolDokument2 SeitenNon-Impact Wire Cutter Timer Controlled Fishing Toolehab2003yeNoch keine Bewertungen

- Office of the Chief Engineer solar net metering guidelinesDokument15 SeitenOffice of the Chief Engineer solar net metering guidelinesRitesh DhawaleNoch keine Bewertungen

- Chapter 5 - Steam Turbines and CondensersDokument21 SeitenChapter 5 - Steam Turbines and Condensersvivekfegade81100% (1)

- Batería Aokly 12V 100ahDokument2 SeitenBatería Aokly 12V 100ahAli PaulNoch keine Bewertungen

- USAID - Briquetting Feasibility Study SudanDokument95 SeitenUSAID - Briquetting Feasibility Study Sudansrachoprdoch100% (3)

- Energy and Water ResourcesDokument4 SeitenEnergy and Water ResourcesAl Jean DelgadoNoch keine Bewertungen

- Ricoh FT 4215 A128 Service ManualDokument45 SeitenRicoh FT 4215 A128 Service ManualJaime Rios100% (1)

- GGASS Investor Presentation 3-09Dokument14 SeitenGGASS Investor Presentation 3-09api-1158549167% (3)

- Power Network Analysis Using ERACSDokument41 SeitenPower Network Analysis Using ERACSAli Kaiser100% (1)

- Inductance in AC Circuits ExplainedDokument24 SeitenInductance in AC Circuits ExplainedAbdur RahmanNoch keine Bewertungen

- SCOR Week 7 Cohesion-1Dokument5 SeitenSCOR Week 7 Cohesion-1Bokamoso MabotheNoch keine Bewertungen

- Gain Green Electricity from GrainsDokument7 SeitenGain Green Electricity from GrainsJALANDONI, CRIS DWIGHT, O.Noch keine Bewertungen

- MEM 341 - Chapter 13 Pneumati CircuitDokument14 SeitenMEM 341 - Chapter 13 Pneumati CircuitMuhammad AbdullahNoch keine Bewertungen

- SHR22500 Liquid Ring Pump Datasheet - SHR22500895Dokument2 SeitenSHR22500 Liquid Ring Pump Datasheet - SHR22500895Ranjit RjtNoch keine Bewertungen

- What Is Biogas?Dokument5 SeitenWhat Is Biogas?Vitthal Pradip JoshiNoch keine Bewertungen

- Tutorial on Power Distribution CircuitsDokument13 SeitenTutorial on Power Distribution CircuitsAnupam NalgundwarNoch keine Bewertungen

- SS350 Series Air StartersDokument8 SeitenSS350 Series Air StartersRICARDO MAMANI GARCIANoch keine Bewertungen

- 09-Basic 3 Workbook Unit 9Dokument6 Seiten09-Basic 3 Workbook Unit 9Jenny Flores100% (2)