Beruflich Dokumente

Kultur Dokumente

D4236 1-12 TMiter 470 Kit

Hochgeladen von

dgomez686Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

D4236 1-12 TMiter 470 Kit

Hochgeladen von

dgomez686Copyright:

Verfügbare Formate

Bulletin No.

D4236 August 15, 2004

SMITH FIBERCAST 1-12 T-Miters with 470 Resin

INTRODUCTION It is important that you read these instructions completely and follow all of the procedures very carefully. Please contact your local Smith Fibercast authorized distributor if you have questions, or need clarification regarding these instructions. SAFETY PRECAUTIONS The resin, adhesive and catalyst are HIGHLY FLAMMABLE! It is critical to personal safety that the work area be isolated from any source of open flames. Remember that the fumes from these materials are also FLAMMABLE and can travel or build up in poorly ventilated areas. WARNING: The catalyst contains METHYL ETHYL KETONE PEROXIDE (MEKP). MEKP is a strong oxidizing agent, and it is critical that you observe proper safety measures when using products containing MEKP. Always wear chemical splash goggles for eye protection when using the resin, adhesive or catalyst. If eye contact should occur, flush immediately with water and call your physician. Always wear impermeable gloves to avoid direct skin contact with the resin, adhesive and catalyst. If direct contact should occur, wash immediately with soap and water. Never cover a container of mixed resin, catalyst or adhesive. Material Safety Data Sheets (MSDS) are available on request or at www.smithfibercast.com. CONTENTS OF T-MITER KIT: The contents of your TMiter Kit will vary according to the diameter and pressure ratings of the pipe. Please see the "Kit Contents" for a detailed listing. STORAGE OF T-MITER KITS Do not store T-Miter kit resin above 90F. The shelf life of the kit resin is dependent on storage temperature; see TMiter Kit Shelf Life and Cure Time Chart on Page 4 for specific recommendations. Storing resin at temperatures below 40F is recommended. If refrigerated, the resin should be allowed to warm slowly to room temperature for several hours prior to usage. DO NOT REFRIGERATE THE FIBERGLASS, as condensate may wet the glass and inhibit the bond of the resin. The fiberglass must be stored in a clean dry place.

FIELD WELD ENVIRONMENT Surfaces to be field welded must be thoroughly sanded, clean, dry, oil-free, and in the correct temperature range to ensure a proper bond. Field weld procedures are based on temperature ranges of 60F to 90F. For field welds where conditions exceed these ranges, follow the Cold Weather or Hot Weather Installation Instructions. The recommended temperature limits of the resin, adhesive, and surfaces to be bonded must be maintained in order to assure proper cure of the joints. All bonding surfaces and materials must remain completely dry and at temperatures above 60F. NOTE: Air temperature is not the only factor affecting cure times. EXAMPLE: When the air temperature is 60F and a pipe is exposed to direct sunlight, surface temperatures of the pipe may approach 100F or higher. Conversely, at 60F, a pipe exposed to a cold wind and no sunlight will affect adhesives as if conditions were colder. COLD WEATHER INSTALLATION INSTRUCTIONS (Below 60F) The curing time for field welds is directly related to the temperature. Colder temperatures can result in uncured weld joints. The following steps are recommended when fabricating in cold weather: 1. Field Weld Kits should be placed in a warm room for 6 to 12 hours before application so they reach temperatures of 70F to 80F. THE COMPONENTS SHOULD NOT BE APPLIED AT TEMPERATURES IN EXCESS OF 100F. 2. Fabricate piping sub-assemblies in an inside area when possible. A small portable heated shelter can also be used. 3. Warm the pipe ends and fittings before joint assembly. 4. Use a heat gun or space heater to start joint cure. Hold the nozzle of the gun 8" to 12" away from the joint and slowly rotate the heat over the joint until a tack-free surface is obtained. 5. Use Smith Fibercast heat blankets or a space heater to cure the joint according to the Cure Times Chart on Page 4. 6. To accelerate cure times in cold weather use up to 19 ml of catalyst per quart of Resin. HOT WEATHER INSTALLATION INSTRUCTIONS (Above 90F) Hot weather conditions will reduce the working time and viscosity of the mixed adhesive and resin. The following steps are recommended when fabricating in hot weather: 1. To increase pot life in hot weather, reduce catalyst to no less than 10 ml per quart of resin.

Registered trademark of Varco I/P, Inc.

SMITH FIBERCAST A VARCO COMPANY 2700 W. 65TH ST., LITTLE ROCK, AR 72209-8592 501-568-4010 FAX 501-568-4465 25 S. MAIN ST., SAND SPRINGS, OK 74063 918-245-6651 FAX 918-245-7566

1-12 T-Miters with 470 Resin

2. Avoid direct sunlight on the joining surfaces, resin, adhesive, catalyst and fiberglass. 3. Cool containers of resin, adhesive and catalyst in an ice chest with ice. 4. Plan and organize the job to reduce working time. SITE EQUIPMENT Each Field Weld kit contains the correct amount of materials for the size of joint specified in the kit. In addition to the material supplied in each kit, the following items should be on hand: 1. Clean, dry rags or paper towels. 2. Impermeable gloves. 3. Chemical splash goggles. 4. Drum, or disc sander, with 36 to 60 grit abrasive. 36 to 60 grit emery cloth may also be used for hand sanding. Do not use flapper wheels or belt sanders. 5. Lay-out table for fiberglass. 6. Extra cardboard, heavy paper, or aluminum foil, to use as a cover for the lay-out table. 7. A space heater, Smith Fibercast heat gun, or heat blanket may be required. TOOLS FOR CUTTING SMITH FIBERCAST PIPE Smith Fibercast pipe should be at least 55F before cutting and may be cut with several acceptable tools, including: 1. Circular power saw with an aluminum oxide abrasive blade, a grit edged carbide blade, or a diamond blade. Do not use toothed blades as they may damage the pipe corrosion barrier. 2. Band saw with 16-22 teeth / inch at speeds of 200' - 600' per minute. 3. Saber saw with carbide grit edged blade. 4. Chop saw with aluminum oxide blade. 5. Hack saw with 22-28 teeth per inch. STEPS FOR CUTTING SMITH FIBERCAST PIPE 1. Measure the pipe, remembering to allow for fitting dimensions. 2. Scribe a cutting guide around the pipe to ensure a perpendicular cut for proper fit. 3. Hold the pipe firmly. If chain vises or other mechanical holding devices are used, care should be taken to prevent crushing or point loading the pipe. 4. Saw the pipe as smoothly as possible. Coarse sawing with the wrong tool can result in damage to the chemically resistant inner surface of the pipe. SURFACE/END PREPARATION Note: It is essential for good fabrication that pipe and fitting surfaces be sanded, clean, dry, and free of oil, grease, and solvent contamination. 1. Prepare both ends of the pipe, or pipe and fitting to be joined together, by sanding the bonding surfaces with 36 to 60 grit abrasive (see Site Equipment, Item 2). The sanded area should be completely roughened, gloss free and extend " beyond the widest layer of fiberglass to be applied.

EXAMPLE: Dry fit the branch to the main pipe. Lay the large fiberglass branch and main pipe mats around the joint and mark 1/2" outside edges of mats for areas to be sanded. 2. Never sand more than two (2) hours before making the joint. 3. Wipe the sanded area with a clean, dry, lint-free cloth, and avoid touching the surfaces with bare hands or dirty gloves. Do not use solvents. SEALING AND SECURING THE PIPE ENDS CAUTION: Follow Safety Precautions on Page 1. The Weldfast CL-200 Adhesive included in this Kit is provided to coat the sawed ends of the branch pipe, the hole in the main pipe, and to stabilize the joint to prevent movement before applying the layers of fiberglass reinforcement. Mix according to the instructions in the Weldfast Kit. Apply a thin layer of mixed Weldfast to the outside of the cut opening edge of the main pipe for the branch pipe to sit on, the hole in the main pipe, and to cut the edge of the branch pipe. Place the adhesive end of the branch pipe onto the open cut edge of the main pipe. Use the wooden stirring stick to smooth the adhesive and make a small 45 bevel/fillet all along the edge of the joint. Make both the inside and the outside as smooth as possible to reduce sanding. Cure the Weldfast Adhesive according to the Weldfast instructions. Heat may be applied to accelerate cure times. Sand and smooth the hardened fillet and joint interior with 36 to 60 girt abrasive. MIXING THE STANDARD LAY-UP RESIN CAUTION: Follow Safety Precautions on Page 1. 1. Measure the recommended amount of catalyst, using the graduated measuring beaker. See the Cure Times Chart on Page 4. 2. Pour the measured catalyst into 1 quart of resin and stir until completely blended. When the resin is properly blended, the color will be a consistent shade of green and will start to foam. The standard resin mixture is 17 ml of catalyst for each quart of resin. After the first quart of resin is mixed and a layer of fiberglass has been applied, it may be evident that the ratio of catalyst should be changed to allow more or less working time. If more working time is required, use as little as 10 ml of catalyst to each quart of resin. This will normally double the pot life and the curing time.

1-12 T-Miters with 470 Resin

If a quicker cure time is required, use up to 19 ml of catalyst for each quart of resin. This will shorten the pot life and cure time. IMPORTANT NOTE: Never use less than 10 ml or more than 19 ml of catalyst for each quart of resin. "Smoking" or "crazing" of a joint indicates an over-catalyzed resin. Joints made with over-catalyzed resin will be structurally weak, provide poor chemical resistance, and should not be used. APPLYING FIBERGLASS TO OUTSIDE JOINT WELD The sanded pipe and fitting joint surface must be pre-wet with catalyzed Resin prior to starting the lay-up. Apply Liner to the joint first. Start with the double mat square glass (10" square) for the run of the pipe. The run is to be wetted first, then wet the branch. Pre-wet, on a table or flat surface, the double mat with catalyzed Resin first on one side. Flip it over and add more Resin. Apply sparingly to prevent the mat from coming apart. Lay the veil on top of the wet mat and pre-wet the veil, starting in the center along the star-cut. Pick up the mat and lay it (with the veil side down) squarely around the joint, making sure the diamonds of the star-cut run up the branch. Note: The veil should extend approximately 1/2" beyond the mat on all sides. Pat the mat down, and then remove the wrinkles and trapped air (indicated by "white" spots) with the 3" Paint Roller. Repeat the pre-wetting procedure with the glass mat and its veil for the branch. Pick up the mat and wrap it (veil side down) around the branch, making sure the cut sections face down on the run pipe. Use the Paint Roller to remove wrinkles and trapped air.

Make sure, when you apply each layer of the Reinforcement Fab-Mat to the joint, that you rotate the split in the Fab-Mat 90 from the previous placement, thereby staggering the location of the splits. Apply only four (4) layers at a time. After application of four layers, let the material gel and cool off. Sand the surface of the T-miter lightly and apply the next four layers, repeating this process until all layers have been installed. The final Reinforcement cover mat should cover all the Fab-Mat layers, overlapping them by approximately 1/2". Pat into place, and roll down to finish. With the roller, smooth off any runs of Resin to reduce the grinding time later. Before the Resin gels, it will run out of the uppermost areas, leaving them lighter in color. Use the roller to roll the Resin back up into these areas. If possible, you can rotate large pipe so that the branch is now pointing down, allowing the Resin to run back onto the branch. MIXING AND APPLYING THE FINISH COAT After all the layers of fiberglass have been applied to the joint, and the joint has gelled or semi-hardened, apply a final coat of catalyzed resin using the 3" paint roller or a brush. The finish coating is in a separate container marked "Finish Coat Resin". This resin should be catalyzed using the same procedure as for the standard lay-up resin. If less than one quart of finish coat resin is required, reduce the recommended amounts of catalyst proportionately. Application of the Finish Coat Resin is critical to developing a chemical resistant piping surface and joint. JOINT CURE The minimum required cure time is 36 hours at 60F. Inadequate joint strength will result if the catalyzed resin is cured at temperatures less than 60F. Cure temperatures up to 200F will accelerate cure time to two hours and increase joint strength. Heat cure is highly recommended for piping systems carrying fluids at temperatures above 120F. Before pressurizing the piping system, or moving the piping, cure the joint per the Cure Times Chart.

APPLYING THE REINFORCEMENT The Reinforcement is pre-wet and applied the same way as the Liner, except you will be using the Fab-Mat which does not have a veil. Always start with the run Fab-Mat and follow with the branch mat (on 1 -3" sizes), or T-Miter Kit Shelf Life and Cure Time Chart Fabmat (4" and larger sizes) for each of the three layers of reinforcement. Apply the Part A Part B Part B mat side toward the pipe.

Temperature Shelf Life (F) (months) 40 - 49 50 - 59 60 - 69 70 - 79 80 - 89 90 - 100 6 5 3-4 3-4 2-3 1-2

T-Miter Shelf Life Catalyst per Pot Life Gel Time Joint Cure (months) Quart Resin (minutes) (minutes) Time (hours) 12 12 12 12 9 4 NR NR 19 ml 17 ml 15 ml 10 ml NR NR 20 - 40 20 - 40 15 - 35 8 - 15 NR NR 25 - 45 25 - 45 18 - 38 10 - 18 NR NR 36 24 24 24 2

Heat Assisted Cure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1"-12"

NR= Not recommended.

1-12 T-Miters with 470 Resin

HYDROSTATIC TESTING Smith Fibercast piping systems should be hydrostatically tested prior to being put into service. Avoid water hammer during testing to prevent serious damage to the piping system. All anchors, guides, and supports must be in place prior to testing the line. Hydrostatically test the line as follows: 1. Water should be introduced at the lowest point in the test section and the air bled off through partially open valves or loose flanges at all the highest points. Slowly introduce water into the system to prevent water hammer. Slowly close the bleed points when all the air has been forced from the system. 2. Bring the system gradually up to the test pressure. Test pressure should not be more than 1 times the working pressure of the piping system, and must never exceed 1 times the rated operating pressure of the lowest rated component in the system. 3. When testing is completed, open all of the high point air bleeds before draining the piping through the fill lines. This will prevent vacuum collapse of the pipe. COMPRESSED AIR / GAS TESTING Compressed air or gas testing of Smith Fibercast piping systems is not recommended. When air or compressed gas is used for testing, tremendous amounts of energy can be stored in the system. If a failure occurs, the energy may be released catastrophically, which may result in property damage and personal injury. When system contamination or fluid weight prevents the use of hydrostatic testing, use compressed air or gas testing with extreme caution. To reduce the risk of air testing, pressurize the system to no more than 15 psig. When pressurizing the system with compressed air or gas, the area surrounding the piping must be cleared of personnel to prevent possible injury. Hold the pressure for one hour; then reduce the pressure to one half the original pressure. Personnel may then enter the area to perform "soap testing" of all the joints. If compressed air or gas testing is used, Smith Fibercast will not be responsible for any resulting injury to personnel or damage to property, including the piping system. Compressed air or gas testing is done entirely at the discretion and complete risk of the customer, contractor and user.

ADHESIVE DISPOSAL: Once the adhesive and hardener have been mixed and reacted, nothing can be extracted, and it is classified as nonhazardous material. Dispose of in a normal manner as other solid waste. Excess adhesive and hardener can be mixed, allowed to react, and disposed of as above. If extra jars of adhesive or hardener have accumulated without the other component to mix and react, contact your Smith Fibercast regional manager. Hardener jars, when empty are not subject to EPA regulation and can be disposed of in a normal manner. These guidelines are based on federal regulations. State and local regulations and ordinances should be reviewed.

SOLVENT DISPOSAL: Solvent is classified as a hazardous waste and cannot be dumped. It can be used as a solvent and allowed to evaporate during use. Empty solvent cans meet EPA regulations for disposal and can be disposed of in a normal manner. These guidelines are based on federal regulations. State and local regulations and ordinances should be reviewed.

It is the policy of Smith Fibercast to improve its products continually. In accordance with that policy, the right is reserved to make changes in specifications, descriptions, and illustrative material contained in this bulletin as conditions warrant. The information contained herein is general in nature and is not intended to express any warranty of any type whatsoever, nor shall any be implied. PRINTED IN U.S.A.204 Copyright 1993 -2004 Varco L.P.

http://www.smithfibercast.com

SMITH FIBERCAST A VARCO COMPANY 2700 W. 65TH ST., LITTLE ROCK, AR 72209-8592 501-568-4010 FAX 501-568-4465 25 S. MAIN ST., SAND SPRINGS, OK 74063 918-245-6651 FAX 918-245-7566

Das könnte Ihnen auch gefallen

- S 40Dokument9 SeitenS 40dgomez686Noch keine Bewertungen

- Level Gages PenberthyDokument34 SeitenLevel Gages PenberthySrta IncognitaNoch keine Bewertungen

- Cable FestoonDokument64 SeitenCable Festoondgomez686Noch keine Bewertungen

- Carpenter & Patterson Pipe HangersDokument164 SeitenCarpenter & Patterson Pipe HangersRobert JaszekNoch keine Bewertungen

- PSGCatalogue2010+ (High Resolution)Dokument292 SeitenPSGCatalogue2010+ (High Resolution)dgomez686Noch keine Bewertungen

- Cabletorq Thickeners/Clarifiers: Gl&V/Dorr-Oliver100Ft - Dia.Type"S"CabletorqthickenerDokument4 SeitenCabletorq Thickeners/Clarifiers: Gl&V/Dorr-Oliver100Ft - Dia.Type"S"Cabletorqthickenerdgomez686Noch keine Bewertungen

- AI RoutedSys 2008 GetStartDokument412 SeitenAI RoutedSys 2008 GetStartwee-man-eng100% (3)

- D4236 1-12 TMiter 470 KitDokument4 SeitenD4236 1-12 TMiter 470 Kitdgomez686Noch keine Bewertungen

- Tank PPM Us 0098a Eng ScreenDokument2 SeitenTank PPM Us 0098a Eng Screendgomez686Noch keine Bewertungen

- Ja 231Dokument5 SeitenJa 231dgomez686Noch keine Bewertungen

- HeatersDokument684 SeitenHeatersdgomez686100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Case Study - Montana Mountain BikingDokument6 SeitenCase Study - Montana Mountain Bikingbonny MishNoch keine Bewertungen

- 32 Hyderabad HITEC City BisleriDokument23 Seiten32 Hyderabad HITEC City BisleriSridhar ViswanathanNoch keine Bewertungen

- 1500 Series: Pull Force Range: 10-12 Lbs (44-53 N) Hold Force Range: 19-28 Lbs (85-125 N)Dokument2 Seiten1500 Series: Pull Force Range: 10-12 Lbs (44-53 N) Hold Force Range: 19-28 Lbs (85-125 N)Mario FloresNoch keine Bewertungen

- Hannah Mancoll - Research Paper Template - 3071692Dokument14 SeitenHannah Mancoll - Research Paper Template - 3071692api-538205445Noch keine Bewertungen

- What You Need To Know About Your Drive TestDokument12 SeitenWhat You Need To Know About Your Drive TestMorley MuseNoch keine Bewertungen

- Exponential Smoothing - The State of The ArtDokument28 SeitenExponential Smoothing - The State of The ArtproluvieslacusNoch keine Bewertungen

- 300u Specs Diodo 300 Amps. 25 Dolares RadiosurtidoraDokument6 Seiten300u Specs Diodo 300 Amps. 25 Dolares RadiosurtidorarepelindNoch keine Bewertungen

- Sermon Manuscript Galatians 5:16-26Dokument9 SeitenSermon Manuscript Galatians 5:16-26Nathaniel ParkerNoch keine Bewertungen

- Chapter 2.3.3 History of Visual Arts Modernism Post ModernismDokument17 SeitenChapter 2.3.3 History of Visual Arts Modernism Post ModernismKim Ashley SarmientoNoch keine Bewertungen

- RSC Article Template-Mss - DaltonDokument15 SeitenRSC Article Template-Mss - DaltonIon BadeaNoch keine Bewertungen

- Gujarat Urja Vikas Nigam LTD., Vadodara: Request For ProposalDokument18 SeitenGujarat Urja Vikas Nigam LTD., Vadodara: Request For ProposalABCDNoch keine Bewertungen

- STS Module 11Dokument64 SeitenSTS Module 11Desiree GalletoNoch keine Bewertungen

- PGCRSM-01-BLOCK-03 Research Design ExperimentalDokument29 SeitenPGCRSM-01-BLOCK-03 Research Design ExperimentalVijilan Parayil VijayanNoch keine Bewertungen

- Notice: Premerger Notification Waiting Periods Early TerminationsDokument5 SeitenNotice: Premerger Notification Waiting Periods Early TerminationsJustia.comNoch keine Bewertungen

- Measurement and Scaling Techniques1Dokument42 SeitenMeasurement and Scaling Techniques1Ankush ChaudharyNoch keine Bewertungen

- Vocabulary FceDokument17 SeitenVocabulary Fceivaan94Noch keine Bewertungen

- Play ClawDokument2 SeitenPlay ClawFrenda SeivelunNoch keine Bewertungen

- Concrete Specification (BS8500)Dokument3 SeitenConcrete Specification (BS8500)teh100% (1)

- Brahms Symphony No 4Dokument2 SeitenBrahms Symphony No 4KlausNoch keine Bewertungen

- BÀI TẬP LESSON 7. CÂU BỊ ĐỘNG 1Dokument4 SeitenBÀI TẬP LESSON 7. CÂU BỊ ĐỘNG 1Yến Vy TrầnNoch keine Bewertungen

- Angel C. Delos Santos: Personal DataDokument8 SeitenAngel C. Delos Santos: Personal DataAngel Cascayan Delos SantosNoch keine Bewertungen

- Rotating Equipment & ServiceDokument12 SeitenRotating Equipment & Servicenurkasih119Noch keine Bewertungen

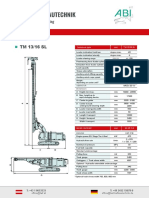

- ABI TM 13 16 SL - EngDokument1 SeiteABI TM 13 16 SL - EngJuan Carlos Benitez MartinezNoch keine Bewertungen

- IMDSI22Dokument82 SeitenIMDSI22Dang JinlongNoch keine Bewertungen

- Procter and Gamble - MarketingDokument10 SeitenProcter and Gamble - MarketingIvana Panovska100% (5)

- All India Civil Services Coaching Centre, Chennai - 28Dokument4 SeitenAll India Civil Services Coaching Centre, Chennai - 28prakashNoch keine Bewertungen

- Animal Health ChecklistDokument4 SeitenAnimal Health ChecklistcapsfastNoch keine Bewertungen

- Action ResearchDokument2 SeitenAction ResearchGeli BaringNoch keine Bewertungen

- Operating Instructions: HTL-PHP Air Torque PumpDokument38 SeitenOperating Instructions: HTL-PHP Air Torque PumpvankarpNoch keine Bewertungen

- Openvpn ReadmeDokument7 SeitenOpenvpn Readmefzfzfz2014Noch keine Bewertungen