Beruflich Dokumente

Kultur Dokumente

OCIMF Compliant Offshore Loading Hose Range

Hochgeladen von

ศุภกฤต รักในหลวงOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

OCIMF Compliant Offshore Loading Hose Range

Hochgeladen von

ศุภกฤต รักในหลวงCopyright:

Verfügbare Formate

Hose range in accordance with OCIMF Guide to Purchasing, Manufacturing and Testing of Loading and Discharge Hoses for

Offshore Moorings, Fourth Edition 1991

...your innovation provider of high integrity equipment

OVERVIEW

LOADING & DISCHARGE HOSES FOR OFFSHORE MOORINGS

EMSTEC provide a range of high quality, high performance, oil suction and discharge hoses, extensively used at offshore moorings throughout the world, which fully comply with the requirements of the OCIMF Guide to Purchasing, Manufacturing and Testing of Loading and Discharge Hoses for Offshore Moorings, Fourth Edition 1991. The EMSTEC Loading & Discharge hoses are available with rated working pressures of 15 BAR, 19 BAR and 21 BAR or higher for special applications or specific client requirements. Two distinctive designs within the EMSTEC hose range are available: EMSTEC Single Carcass Hoses (21 Series) Floating, Submarine & Catenary Hoses EMSTEC Double Carcass Hoses (22 Series) Floating, Submarine & Canenary Hoses

The EMSTEC Single Carcass hose construction consists of three main elements; i) smooth bore elastomeric lining resistant to a variety of hydrocarbons, ii) a standard elastomer reinforced carcass with multi-layers of high tensile textile cords and embedded steel wire helix. iii) a fibre reinforced smooth elastomer cover, resistant to ageing, abrasion, weathering, sunlight, tearing oil and seawater penetration. In addition to the standard hose carcass (commonly termed primary carcass), EMSTEC Double Carcass hose incorporate an additional second carcass designed to contain any product escaping from the standard carcass as a result of a slow leak or sudden failure. An effective, robust and reliable, integrated leak detection and indication system is provided. The EMSTEC Single Carcass and Double Carcass hose range includes hose construction for Floating, Submarine and Catenary applications, utilized in offloading installations worldwide EPS, MBM, SBM, CALM, SALM and Tandem Offloading. EMSTEC Single Carcass / Double Carcass Floating Hoses (utilized in high integrity surface installations such as EPS, SBM, CALM, SALM offloading in addition to FPSO, FSO Tandem offloading configurations). EMSTEC Single Carcass / Double Carcass Submarine Hoses (utilized in high integrity sub-sea installations such as MBM, SBM, CALM, SALM configurations (i.e. Steep S, Lazy S, Chinese Lantern). EMSTEC Single Carcass / Double Carcass Catenary Hoses (utilized in high integrity offloading installations subject to high tensile loads such as FPSO, FSO tandem offloading to DP Shuttle Tankers (i.e. BLS, Reel, Chute, Cantilever hang-off arrangements). The EMSTEC Single Carcass and Double Carcass hose range is complemented by a comprehensive range of Ancillary Equipment, recommended within OCIMF SPM Hose Ancillary Equipment Guide publication. For additional information on specific hose types and applications, please refer to EMSTEC hose data sheets.

EMSTEC hoses fully comply with the requirements of the OCIMF Guide to Purchasing, Manufacturing and Testing of Loading and Discharge Hoses for Offshore Moorings, Fourth Edition 1991. EMSTEC hoses are designed and manufactured under a quality system in accordance with ISO 9001, and in compliance with Pressure Equipment Directive (PED) 97/23/EC module H (hoses carry CE marking as required). Prototype Hose manufacture and testing witnessed and verified by Bureau Veritas (Certifying Authority) and GDC International (Industry Consultants).

Sniers Achterhoff 11 21224 Rosengarten Tel: +49 (0) 40 79 68 63 45 Fax: +44 (0) 40 79 68 67 02 email: info@emstec.net web: www.emstec.net

OV 1.0

...your innovation provider of high integrity equipment

PRODUCT RANGE

LOADING & DISCHARGE HOSES FOR OFFSHORE MOORINGS

EMSTEC provide a range of high quality, high performance elastomer reinforced, smooth bore, oil suction and discharge hoses, extensively used at offshore moorings throughout the world. The EMSTEC hoses fully comply with the requirements of the OCIMF Guide to Purchasing, Manufacturing and Testing of Loading and Discharge Hoses for Offshore Moorings, Fourth Edition 1991. EMSTEC hose range includes Single Carcass and Double Carcass hoses construction for Submarine, Catenary and Floating applications, utilized in high integrity offloading installations worldwide. All EMSTEC hoses are designed and manufactured under a quality system in accordance with ISO 9001, and compliance with Pressure Equipment Directive (PED) 97/23/EC module H (hoses carry CE marking as required).

Control Buoyancy - SC

21100 - Single Carcass Floating Hose

Mainline Floating - SC

21200/21300 - Single Carcass Submarine Hose

End Reinforced Floating - SC Main Line - SC

End Reinforced - SC

21400 - Single Carcass Catenary Hose

Main Line with Main Line - SC Collars - SC

Tanker Rail Floating Reinforced CATENARY - DC - SC

Control Buoyancy - DC

22100 - Double Carcass Floating Hose

Main Line Controlled / Neutral Buoyancy - SC End Reinforced - SC

Mainline Floating - DC

Tail Floating - SC

22200/22300 - Double Carcass Submarine Hose

End Reinforced - SC

End Reinforced - SC

Main Line - Reinforced Floating - DC DC End

Tapered Floating - SC DC End Reinforced -

22400 - Double Carcass Catenary Hose

End Reinforced with Collars - SC Main Line with Main Line - DC Collars - DC

End Reinforced CATENARY - DC Tanker Rail Floating - DC Reinforced Half Floating - SC

28500 - Ancillary Equipment

End Reinforced with Collars - SC

MainReinforced - DC / Neutral Buoyancy - DC End Line Controlled

Mainline Half Floating - SC Tail Floating - DC

28600/28700 - Tranport, Handling and Test Equipment

End Reinforced - DC End Reinforced - DC

Tapered Floating - DC

End Reinforced with Collars - DC

Sniers Achterhoff 11 21224 Rosengarten Tel: +49 (0) 40 79 68 63 45 Fax: +44 (0) 40 79 68 67 02 email: info@emstec.net web: www.emstec.net

For additional information on specific hose types and applications, please refer to EMSTEC hose data sheets.

End Reinforced with Collars - DC

End Reinforced Half Floating - SC

PR 1.0

Mainline Half Floating - SC

...your innovation provider of high integrity equipment

End Reinforced Floating - SC

Control Buoyancy - SC

SINGLE CARCASS FLOATING HOSE

Tanker Rail Floating Reinforced CATENARY - DC - SC Mainline Floating - SC

21 SERIES

EMSTEC provide a range of high quality, high performance, oil suction and discharge hoses, extensively used at offshore moorings throughout the world. The EMSTEC Single Carcass Floating hoses are utilized in high integrity surface installations such as EPS, SBM, CALM, SALM offloading in addition to FPSO, FSO Tandem offloading configurations. The EMSTEC hose fully complies with the requirements of the OCIMF Guide to Purchasing, Manufacturing and Testing of Loading and Discharge Hoses for Offshore Moorings, Fourth Edition 1991. All hoses are designed and manufactured under a quality system in accordance with ISO 9001, and compliance with Pressure Equipment Directive (PED) 97/23/EC module H (hoses carry CE marking as required).

For performance characteristics and specification, please refer to EMSTEC data sheet Single Carcass Hose Specification.

Tapered Floating - SC Tanker Rail Floating Reinforced CATENARY - DC - SC Control Buoyancy - SC End Reinforced Tail Floating - SCFloating - SC

21110 FSC - End Reinforced Half Floating (ie. First off Buoy)

End Reinforced Half Floating - SC Mainline Floating - SC Tail Floating - SC

21120 FSC - Controlled Buoyancy

Mainline Half Floating - SC Control Buoyancy - SC End Reinforced Floating - SC Tapered Floating - SC Control Buoyancy - SC

21130 FSC - Main Line Floating

Mainline Floating - SC Mainline ReinforcedSC Floating - SC End Floating - Half Tanker Rail Floating Reinforced CATENARY - DC - SC

21140 FSC - Main Line Half Floating

End Reinforced Floating - SC End Reinforced Floating - SC Mainline Half Floating - SC Tail Floating - SC

21150 FSC - Tapered Floating

Tanker Rail Floating Reinforced CATENARY - DC - SC Tanker Rail Floating Reinforced CATENARY - DC - SC Tapered Floating - SC

21160 FSC - Tail Floating

Tail Floating - SC End Reinforced Half Floating - SC Tail Floating - SC

Tapered Floating - SC

Sniers Achterhoff 11 21224 Rosengarten Tel: +49 (0) 40 79 68 63 45 Fax: +44 (0) 40 79 68 67 02 email: info@emstec.net web: www.emstec.net

Mainline Half Floating - SC Tapered Floating - SC

SCF-21-1-1.0

...your innovation provider of high integrity equipment

Mainline Floating - SC

Control Buoyancy - SC

SINGLE CARCASS FLOATING HOSE (continuation)

21170 FSC - Tanker Rail Floating

21 SERIES

End Reinforced Floating - SC

Tanker Rail Floating Reinforced CATENARY - DC - SC

21180 FSC - FPSO - End Reinforced High Buoyancy Floating (ie. First off FPSO to support ERC) *

Tail Floating - SC

FPSO End Reinforced Floating - SC

21190 FSC ST End Reinforced High Buoyancy Floating (ie. Shuttle Tanker connection to support HEV) *

Tapered Floating - SC

Reinforced CATENARY ST End Reinforced Floating - SC - DC

End Reinforced Half Floating - SC

* NOTE The EMSTEC Single Carcass Floating hoses designed for special end connection applications are utilized in high integrity surface installations such as FPSO, FSO Tandem offloading configurations offshore Brazil. Mainline Half Floating - SC The special hoses are installed at the ends of the floating hose string, connected to the FPSO/FSO hang-off Emergency Release Coupling (ERC) and the Shuttle Tanker bow loading system Hose End Valve (HEV). The additional buoyancy within the special FPSO end hose will support the ERC on the surface of the sea, if released in an emergency. The Shuttle Tanker end hose will support the HEV on the surface of the sea, during hose transfer and / or emergency release.

For performance characteristics and specification, please refer to EMSTEC data sheet Single Carcass Hose Specification.

Sniers Achterhoff 11 21224 Rosengarten Tel: +49 (0) 40 79 68 63 45 Fax: +44 (0) 40 79 68 67 02 email: info@emstec.net web: www.emstec.net

SCF-21-2-1.0

...your innovation provider of high integrity equipment

SINGLE CARCASS SUBMARINE HOSE

Main Line - SC

21 SERIES

Main Line - SC Main Line with Collars - SC

EMSTEC provide a range of high quality, high performance, oil suction and discharge hoses, extensively used at offshore moorings throughout the world. The EMSTEC Single Carcass Submarine hoses are utilized in high integrity sub-sea installations such as MBM, CALM, SALM configurations (i.e. Steep S, Lazy S, Chinese Lantern).

Main Line with Collars - SC End Reinforced - SC The EMSTEC hose fully complies with the requirements of the OCIMF Guide to Purchasing, Manufacturing and Testing of Loading and Discharge Hoses for Offshore Moorings, Fourth Edition 1991.

All hoses are designed and manufactured under a quality system in accordance with ISO 9001, and compliance with Pressure Equipment Directive (PED) 97/23/EC module H (hoses carry CE marking as required).

End Reinforced - SC For performance characteristics and specification, please refer to EMSTEC data sheet Single Carcass Hose Specification. End Reinforced - SC

21210 SSC - End Reinforced without float collars (i.e. under Buoy)

End Reinforced - SC End Reinforced with Collars - SC

21310 SSCF End reinforced with float collars (i.e. under Buoy) *

End Reinforced with Collars - SC End Reinforced with Collars - SC

21220 SSC - Main Line without float collars

End Reinforced with Collars - SC

Main Line - SC

Main Line - SC Main Line - SC Main Line - SC Main Line with Collars - SC

21320 SSCF - Main Line with float collars

Main Line with Collars - SC Main Line with Collars - SC Main Line with Collars - SC End Reinforced - SC

21230 SSC - End Reinforced without float collars (i.e. off PLEM)

End Reinforced - SC End Reinforced - SC End Reinforced - SC End Reinforced - SC

21330 SSCF End reinforced with float collars (i.e. off PLEM) *

End Reinforced - SC End Reinforced - SC End Reinforced - SC End Reinforced with Collars - SC

*Note: Number and distribution of float collars can be adjusted to suit client specific requirements.

End Reinforced with Collars - SC

End Reinforced with Collars - SC End Reinforced with Collars - SC

Sniers Achterhoff 11 21224 Rosengarten Tel: +49 (0) 40 79 68 63 45 Fax: +44 (0) 40 79 68 67 02 email: info@emstec.net web: www.emstec.net

End Reinforced with Collars - SC

SCS-21-1-1.0

End Reinforced with Collars - SC

...your innovation provider of high integrity equipment

SINGLE CARCASS CATENARY HOSE

21 SERIES

EMSTEC provide a range of high quality, high performance, oil suction and discharge hoses, extensively used at offshore moorings throughout the world. The EMSTEC Single Carcass Catenary hoses are utilized in high integrity floating offloading installations such as FPSO, FSO tandem offloading to DP Shuttle Tankers (i.e. Reel, Chute, Cantilever hang-off arrangements). The EMSTEC hose fully complies with the requirements of the OCIMF Guide to Purchasing, Manufacturing and Testing of Loading and Discharge Hoses for Offshore Moorings, Fourth Edition 1991. All hoses are designed and manufactured under a quality system in accordance with ISO 9001, and compliance with Pressure Equipment Directive (PED) 97/23/EC module H (hoses carry CE marking as required).

For performance characteristics and specification, please refer to EMSTEC data sheet Single Carcass Hose Specification.

21410 SCSC - End Reinforced (i.e. FPSO)

End Reinforced - SC

End Reinforced - SC

21420 SCSC - Main Line

Main Line - SC End Reinforced - SC

Main Line - SC End Reinforced - SC

Main Line Controlled / Neutral Buoyancy - SC Main Line - SC

21430 SCSC - Main Line Controlled / Neutral Buoyancy (for special applications)

Main Line - SC Main Line Controlled / Neutral Buoyancy - SC

Main Line Controlled / Neutral Buoyancy - SC End Reinforced - SC

Main Line Controlled / Neutral Buoyancy - SC End Reinforced - SC

21440 SCSC - End Reinforced (i.e. Shuttle Tanker)

End Reinforced - SC

End Reinforced - SC

Sniers Achterhoff 11 21224 Rosengarten Tel: +49 (0) 40 79 68 63 45 Fax: +44 (0) 40 79 68 67 02 email: info@emstec.net web: www.emstec.net

SCC-21-1-1.0

...your innovation provider of high integrity equipment

SINGLE CARCASS HOSE SPECIFICATION

PERFORMANCE CHARACTERISTICS & CONSTRUCTION Nominal Bore (mm): Standard Length: Hose Construction:

21 SERIES

EMSTEC Single Carcass Submarine, Floating & Catenary hoses fully comply with the requirements of the OCIMF Guide to Purchasing, Manufacturing and Testing of Loading and Discharge Hoses for Offshore Moorings, Fourth Edition 1991.

150 (6), 200 (8), 250 (10), 300 (12), 400 (16), 500 (20), 600 (24) 9.1M (30), 10.7M (35) & 12.2M (40) (non-standard less than 12.2M also available) Liner Tube NBR based Rubber, resistant to hydrocarbons with aromatic content up to 60%. Main Carcass Elastomer reinforced with multi-layers of high tensile textile cords and embedded steel wire helix. Floatation Material (Floating Hoses only) Closed Cell Foam Outer Cover Fibre reinforced smooth elastomer cover, resistant to ageing, abrasion, weathering, sunlight, tearing and oil and seawater penetration.

(Polyurethane coating available on request).

Flanges: Pressure Rating: Minimum Burst Pressure: Flow Velocity: Fluid Product: Temperature Range: Minimum Bend Radius: Electrical Continuity:

ANSI B16.5 Class 150 or 300 Flat Face (FF), Hot Dip Galvanised in accordance with BS729 Part 1. (Raised Face (RF) flange face available on request). 15 BAR, 19 BAR, 21 BAR (higher pressure ratings on request) 75 BAR, 95 BAR, 105 BAR Maximum of 21m/s Crude Oil and Liquid Petroleum Products (other than liquefied petroleum gases and liquefied natural gases). Fluid Temperature from -20oC to 82oC. Ambient Temperature from -29oC to 52oC. Submarine Hose - 4 x hose Nominal Bore Diameter. Floating Hose 6 x hose Nominal Bore Diameter Electrically Continuous or Discontinuous as required.

For information regarding hose types and applications, please refer to relevant EMSTEC hose data sheets.

DESIGN APPROVAL & QUALITY ASSURANCE All of the hoses are designed and manufactured under a quality system in accordance with ISO 9001, and is in compliance with Pressure Equipment Directive (PED) 97/23/EC module H (hoses carry CE marking as required). Prototype Hose manufacture and testing witnessed and verified by Bureau Veritas (Certifying Authority) and GDC International (Industry Consultant).

ISO 9001 Design

ISO 9001 Manufacture

Prototype Approval (BV)

Prototype Approval (GDC)

Sniers Achterhoff 11 21224 Rosengarten Tel: +49 (0) 40 79 68 63 45 Fax: +44 (0) 40 79 68 67 02 email: info@emstec.net web: www.emstec.net

SCHS-21-1-1.0

...your innovation provider of high integrity equipment

Mainline Floating - DC

DOUBLE CARCASS FLOATING HOSE

Control Buoyancy - DC End Reinforced Floating - DC

22 SERIES

Mainline Floating - DC

Reinforced Tanker Rail Floating used at DC EMSTEC provide a range of high quality, high performance, oil suction and discharge hoses, extensively- DC CATENARY -offshore moorings throughout the world. The EMSTEC Double Carcass Floating hoses are utilized in high integrity surface installations such as EPS, SBM, CALM, SALM offloading in addition to FPSO, FSO Tandem offloading configurations.

In addition to the standard hose carcass (commonly termed primary carcass), EMSTEC Double Carcass Floating hoses End Reinforced Floating - DC incorporate an additional second carcass designed to contain any product escaping from the standard carcass as a result of a slow leak or sudden failure. An effective, robust and reliable leak detection and indication system is provided. EMSTEC Double Carcass Submarine hoses fully comply with the requirements of the OCIMF Guide to Purchasing, Manufacturing and Testing of Loading and Discharge Hoses for Offshore Moorings, Fourth Edition 1991. All hoses are designed and manufactured under a quality system in accordance with ISO 9001, and is in compliance with Control Buoyancy - DC Pressure Equipment Directive (PED) 97/23/EC module H (hoses carry CE marking as required). Tanker Rail Floating - DC CATENARY - DC Reinforced

Tapered Floating For performance characteristics and specification, please refer to EMSTEC data sheet Double Carcass Hose Specification. - DC Tail Floating - DC

22110 FDC - End Reinforced Half Floating (ie. First off Buoy)

Mainline Floating - DC

End Reinforced Tail Floating - DC Half Floating - SC

22120 FDC - Controlled Buoyancy

End Reinforced Floating - DC Control Buoyancy - DC

Control Buoyancy- -DC Tapered Floating DC Mainline Half Floating - SC Control Buoyancy - DC

22130 FDC - Main Line Floating

Mainline Floating - DC Reinforced Tanker Rail Floating - DC CATENARY - DC End Reinforced Half Mainline Floating - DC Floating - SC Mainline Floating - DC

22140 FDC - Main Line Half Floating

End Reinforced Floating - DC

End Reinforced Floating - DC Mainline Tail Floating - DC Half Floating - SC End Reinforced Floating - DC

22150 FDC - Tapered Floating

Reinforced Tanker Rail Floating - DC CATENARY - DC Tapered Floating - DC Reinforced Tanker Rail Floating - DC CATENARY - DC Reinforced Tanker Rail Floating - DC CATENARY - DC

22160 FDC - Tail Floating

End Reinforced Half Floating - SC Tail Floating - DC

Tail Floating - DC Tail Floating - DC

Sniers Achterhoff 11 21224 Rosengarten Tel: +49 (0) 40 79 68 63 45 Fax: +44 (0) 40 79 68 67 02 email: info@emstec.net web: www.emstec.net

TaperedMainline Half Floating - SC Floating - DC

Tapered Floating - DC Tapered Floating - DC

DCF-22-1-1.0

Control Buoyancy - DC

...your innovation provider of high integrity equipment

Mainline Floating - DC

DOUBLE CARCASS FLOATING HOSE (continuation)

22160 FDC - Tanker Rail Floating

22 SERIES

End Reinforced Floating - DC

Reinforced Tanker Rail Floating - DC CATENARY - DC

22180 FDC - FPSO - End Reinforced High Buoyancy Floating (ie. First off FPSO to support ERC) *

Tail Floating - DC

FPSO End Reinforced Floating - DC

Tapered Floating - DC

22190 FDC ST End Reinforced High Buoyancy Floating (ie. Shuttle Tanker connection to support HEV) *

Reinforced Reinforced Half ST End Reinforced Floating - DC - DC Floating - SC End CATENARY

* NOTE: The EMSTEC Doublee Carcass Floating hoses designed for special end connection applications are utilized in high integrity Mainline Half Floating - SC surface installations such as FPSO, FSO Tandem offloading configurations offshore Brazil. The special hoses are installed at the ends of the floating hose string, connected to the FPSO/FSO hang-off Emergency Release Coupling (ERC) and the Shuttle Tanker bow loading system Hose End Valve (HEV). The additional buoyancy within the special FPSO end hose will support the ERC on the surface of the sea, if released in an emergency. The Shuttle Tanker end hose will support the HEV on the surface of the sea, during hose transfer and / or emergency release

For performance characteristics and specification, please refer to EMSTEC data sheet Double Carcass Hose Specification.

Sniers Achterhoff 11 21224 Rosengarten Tel: +49 (0) 40 79 68 63 45 Fax: +44 (0) 40 79 68 67 02 email: info@emstec.net web: www.emstec.net

DCF-22-2-1.0

...your innovation provider of high integrity equipment

DOUBLE CARCASS SUBMARINE HOSE

Main Line - DC

22 SERIES

Main Line - DC Main Line with Collars - DC

EMSTEC provide a range of high quality, high performance, oil suction and discharge hoses, extensively used at offshore moorings throughout the world. The EMSTEC Double Carcass Submarine hoses are utilized in high integrity sub-sea installations such as MBM, CALM, SALM configurations (i.e. Steep S, Lazy S, Chinese Lantern). In addition to standard hose carcass (commonly termed primary carcass), EMSTEC Double Carcass Submarine hoses incorporate an additional second carcass designed to contain any product escape from the standard carcass as a result of a slow Main Line with Collars - DC End leak or sudden failure. Effective, robust and reliable leak detection and indication system is provided.Reinforced - DC The EMSTEC Double Carcass Submarine hoses fully comply with the requirements of the OCIMF Guide to Purchasing, Manufacturing and Testing of Loading and Discharge Hoses for Offshore Moorings, Fourth Edition 1991. All hoses are designed and manufactured under a quality system in accordance with ISO 9001, and is in compliance with Pressure Equipment Directive (PED) 97/23/EC module H (hoses carry CE marking as required).

End Reinforced - DC End Reinforced - DC

For performance characteristics and specification, please refer to EMSTEC data sheet Double Carcass Hose Specification.

22210 SDC - End Reinforced without float collars (i.e. under Buoy)

End Reinforced - DC

End Reinforced with Collars - DC

22310 SDCF - End reinforced with float collars (i.e. under Buoy) *

End Reinforced with Collars - DC End Reinforced with Collars - DC Main Line - DC

22220 SDC - Main Line without float collars

End Reinforced with Collars - DC Main Line - DC Main Line - DC Collars - DC Main Line with Main Line - DC

22320 SDCF - Main Line with float collars

Main Line with Collars -- DC End Reinforced - DC Main Line with Collars DC Main Line with Collars - DC

22230 SDC - End Reinforced without float collars (i.e. off PLEM)

End Reinforced - DC

End Reinforced -- DC End Reinforced DC End Reinforced - DC

22330 SDCF - End reinforced with float collars (i.e. off PLEM) *

End Reinforced -- DC End Reinforced DC End Reinforced - DC

End Reinforced with Collars - DC

*Note: Number and distribution of float collars can be adjusted to suit client specific requirements.

Sniers Achterhoff 11 21224 Rosengarten Tel: +49 (0) 40 79 68 63 45 Fax: +44 (0) 40 79 68 67 02 email: info@emstec.net web: www.emstec.net

End Reinforced with Collars -- DC End Reinforced with Collars DC End Reinforced with Collars - DC End Reinforced with Collars - DC

DCS-22-1-1.0

...your innovation provider of high integrity equipment

DOUBLE CARCASS CATENARY HOSE

22 SERIES

EMSTEC provide a range of high quality, high performance, oil suction and discharge hoses, extensively used at offshore moorings throughout the world. The EMSTEC Double Carcass Catenary hoses are utilized in high integrity floating offloading installations such as FPSO, FSO tandem offloading to DP Shuttle Tankers (i.e. Reel, Chute, Cantilever hang-off arrangements). In addition to the standard hose carcass (commonly termed primary carcass), EMSTEC Double Carcass Catenary hoses incorporate an additional second carcass designed to contain any product escaping from the standard carcass as a result of a slow leak or sudden failure. Effective, robust and reliable leak detection and indication system is provided. The EMSTEC Double Carcass Catenary hoses fully comply with the requirements of the OCIMF Guide to Purchasing, Manufacturing and Testing of Loading and Discharge Hoses for Offshore Moorings, Fourth Edition 1991. All hoses are designed and manufactured under a quality system in accordance with ISO 9001, and is in compliance with Pressure Equipment Directive (PED) 97/23/EC module H (hoses carry CE marking as required).

For performance characteristics and specification, please refer to EMSTEC data sheet Double Carcass Hose Specification.

22410 SCDC - End Reinforced (i.e. FPSO)

End Reinforced - DC

End Reinforced - DC

22420 SCDC - Main Line

End Reinforced - DC Main Line - DC End Reinforced - DC Main Line - DC

Main Line - DC Main Line Controlled / Neutral Buoyancy - DC Main Line - DC

22430 SCDC - Main Line Controlled / Neutral Buoyancy (for special applications)

Main Line Controlled / Neutral Buoyancy - DC

Main Line Controlled / Neutral Buoyancy - DC

End Reinforced - DC

Main Line Controlled / Neutral Buoyancy - DC

22440 SCDC - End Reinforced (i.e. Shuttle Tanker)

End Reinforced - DC

End Reinforced - DC

End Reinforced - DC

Sniers Achterhoff 11 21224 Rosengarten Tel: +49 (0) 40 79 68 63 45 Fax: +44 (0) 40 79 68 67 02 email: info@emstec.net web: www.emstec.net

DCC-22-1-1.0

...your innovation provider of high integrity equipment

DOUBLE CARCASS HOSE SPECIFICATION

PERFORMANCE CHARACTERISTICS & CONSTRUCTION Nominal Bore (mm): Standard Length: Hose Construction:

22 SERIES

EMSTEC Double Carcass Submarine, Floating & Catenary hoses fully comply with the requirements of the OCIMF Guide to Purchasing, Manufacturing and Testing of Loading and Discharge Hoses for Offshore Moorings, Fourth Edition 1991.

150 (6), 200 (8), 250 (10), 300 (12), 400 (16), 500 (20), 600 (24) 9.1M (30), 10.7M (35) & 12.2M (40) (non-standard less than 12.2M also available) Liner Tube NBR based Rubber, resistant to hydrocarbons with aromatic content up to 60% Primary Carcass Elastomer reinforced with multi-layers of high tensile textile cords and embedded steel wire helix. Secondary Carcass Elastomer reinforced with multi-layers of high tensile textile cords Floatation Material (Floating Hoses only) Closed cell foam Outer Cover Fibre reinforced smooth elastomer cover, resistant to ageing, abrasion, weathering, sunlight, tearing and oil and seawater penetration.

(Polyurethane coating available on request).

Flanges: Pressure Rating: Minimum Burst Pressure: Flow Velocity: Fluid Product: Temperature Range: Minimum Bend Radius: Electrical Continuity: Leak Detection:

ANSI B16.5 Class 150 or 300 Flat Face (FF), Hot Dip Galvanised in accordance with BS729 Part 1. (Raised Face (RF) flange face available on request). Primary Carcass Primary Carcass Maximum of 21m/s Crude Oil and Liquid Petroleum Products (other than liquefied petroleum gases and liquefied natural gases). Fluid Temperature from -20oC to 82oC. Ambient Temperature from -29oC to 52oC. Submarine Hoses - 4 x hose Nominal Bore Diameter. Floating Hose 6 x hose Nominal Bore Diameter. Electrically Continuous or Discontinuous as required. Pressure compensated leak detection system for Floating, Submarine & Catenary applications. 15 BAR, 19 BAR, 21 BAR (higher pressure ratings on request) 75 BAR, 95 BAR, 105 BAR Secondary Carcass - 15 BAR, 19 BAR, 21 BAR. Secondary Carcass - 30 BAR, 38 BAR, 42 BAR

For information regarding hose types and applications, please refer to relevant EMSTEC hose data sheets.

DESIGN APPROVAL & QUALITY ASSURANCE All of the hoses are designed and manufactured under a quality system in accordance with ISO 9001, and is in compliance with Pressure Equipment Directive (PED) 97/23/EC module H (hoses carry CE marking as required). Prototype Hose manufacture and testing witnessed and verified by Bureau Veritas (Certifying Authority) and GDC International (Industry Consultant).

ISO 9001 Design

ISO 9001 Manufacture

Prototype Approval (BV)

Prototype Approval (GDC)

Sniers Achterhoff 11 21224 Rosengarten Tel: +49 (0) 40 79 68 63 45 Fax: +44 (0) 40 79 68 67 02 email: info@emstec.net web: www.emstec.net

DCHS-22-1-1.0

...your innovation provider of high integrity equipment

ANCILLARY EQUIPMENT

For performance characteristics and specification, please refer to EMSTEC equipment data sheets.

ANCILLARIES

EMSTEC provide a range of high quality, high performance, oil suction and discharge hoses, extensively used at offshore moorings throughout the world. The EMSTEC Single Carcass and Double Carcass hose range is complemented by a range of Ancillary Equipment in addition to equipment to aid Transportation, Handling and Testing.

28510 - Flange Jointing 28511 - Studs and Nuts 28512 - Gaskets 28513 - Anodes 28514 -Flange Insulation Kits

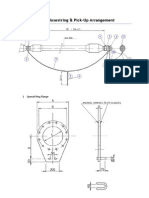

28520 - Chain assemblies 28521 - Pick-up Chain 28522 - Snubbing Chain

28530 - Hose End Fittings 28531 - Butterfly Valve 28532 - Lifting Spool Piece 28533 - Camlock Coupling 28534 - Lightweight Blind Flange

28540 - Buoyancy Equipment 28541 - Pick-up Buoy 28542 - Floating Concentric Reducer 28543 - Floating Y Piece 28544 - Hose Floats

28550 - Hose Marker Lights 28551 - Winker Light

Sniers Achterhoff 11 21224 Rosengarten Tel: +49 (0) 40 79 68 63 45 Fax: +44 (0) 40 79 68 67 02 email: info@emstec.net web: www.emstec.net

AC-A-1-1.0

...your innovation provider of high integrity equipment

ANCILLARY EQUIPMENT (continuation)

28560 - Continuous Leak Detection System 28561 - Single Line Leak Detection 28562 - Closed Circuit Leak Detection 28563 - Visual Indicator

LDS-27562

Leak Detection System

ANCILLARIES

28570 - Special Hose Connector / Couplings 28571 - Hose End Valve (i.e. Hose connection to BLS) 28572 - Emergency Release Coupling (ERC) 28573 - Marine Breakaway Coupling (MBC)

Sniers Achterhoff 11 21224 Rosengarten Tel: +49 (0) 40 79 68 63 45 Fax: +44 (0) 40 79 68 67 02 email: info@emstec.net web: www.emstec.net

AC-A-2-1.0

...your innovation provider of high integrity equipment

TRANSPORT, HANDLING AND TEST EQUIPMENT

For performance characteristics and specification, please refer to EMSTEC equipment data sheets.

ANCILLARIES

EMSTEC provide a range of high quality, high performance, oil suction and discharge hoses, extensively used at offshore moorings throughout the world. The EMSTEC Single Carcass and Double Carcass hose range is complemented by a range of Ancillary Equipment in addition to equipment to aid Transportation, Handling and Testing.

28600 - Hose Transport and Handling Equipment 28610 Lifting Beam 28620 Hose Transport / Storage Pallet

28700 - Hose Test Equipment 28710 Test Unit Pressure Pump 28720 Test Unit Vacuum Pump 28730 Test Unit Pressure & Vacuum Pump 28740 Test Unit Filling, Pressure and Vacuum Pumps

Sniers Achterhoff 11 21224 Rosengarten Tel: +49 (0) 40 79 68 63 45 Fax: +44 (0) 40 79 68 67 02 email: info@emstec.net web: www.emstec.net

THTE-A-1-1.0

EMSTEC Loading & Discharge hoses fully comply with the requirements of the OCIMF Guide to Purchasing, Manufacturing and Testing of Loading and Discharge Hoses for Offshore Moorings, Fourth Edition 1991. Designed and manufactured under quality system in accordance with ISO 9001, and in compliance with Pressure Equipment Directive (PED) 97/23/EC module H (hoses carry CE marking as required). Prototype Hose manufacture and testing witnessed and verified by Bureau Veritas (Certifying Authority) and GDC International Ltd. (Industry Consultant).

Tel. +49 (0)40 79 68 63 45 Fax +49 (0)40 79 68 67 02 e-mail: info@emstec.net web: www.emstec.net

Das könnte Ihnen auch gefallen

- Buoyed Up: Proven in The Past, Prepared For The FutureDokument10 SeitenBuoyed Up: Proven in The Past, Prepared For The FutureantidemosNoch keine Bewertungen

- Single Point Mooring System Construction, Design, Commissioning, Operation and MaintenanceDokument24 SeitenSingle Point Mooring System Construction, Design, Commissioning, Operation and MaintenanceRajNoch keine Bewertungen

- Hoses BassiDokument60 SeitenHoses Bassirobisiz7299100% (2)

- Our Activities: Technology Creating ValueDokument12 SeitenOur Activities: Technology Creating Valuenazwan14Noch keine Bewertungen

- 23792turret Buoy BookDokument32 Seiten23792turret Buoy BookTeck Tiong Huan100% (1)

- Single Buoy Mooring ProcedureDokument3 SeitenSingle Buoy Mooring ProcedureKannan100% (1)

- OCIMF Floating HosestringDokument5 SeitenOCIMF Floating HosestringEd Othman100% (2)

- SPM-34 Hose Failure Investigation Report2Dokument25 SeitenSPM-34 Hose Failure Investigation Report2Abdullah Al-Zahrani100% (2)

- Comparison OCIMF 2009 and OCIMF 1991Dokument14 SeitenComparison OCIMF 2009 and OCIMF 1991Rashidi Yaakob100% (1)

- B23-14 - TERMPOL Surveys and Studies - Section 3.14 - Single Point Mooring Provisions and Procedures A1Z6J8Dokument17 SeitenB23-14 - TERMPOL Surveys and Studies - Section 3.14 - Single Point Mooring Provisions and Procedures A1Z6J8HASHMI MAHMOODNoch keine Bewertungen

- SPM Operational LimitationsDokument5 SeitenSPM Operational LimitationshabibmusthafaNoch keine Bewertungen

- Offshor Mooring SystemDokument6 SeitenOffshor Mooring SystemcudalbgeoNoch keine Bewertungen

- SBM PDFDokument22 SeitenSBM PDFFabricio Correa100% (1)

- Guide to Single Point Mooring Systems (SPMsDokument14 SeitenGuide to Single Point Mooring Systems (SPMsBanjoNoch keine Bewertungen

- SPM (Single Point Mooring) or SBM OperationsDokument9 SeitenSPM (Single Point Mooring) or SBM OperationsGiorgi Kandelaki100% (2)

- Mooring Rules Operations SPM BerthsDokument10 SeitenMooring Rules Operations SPM BerthsHRC100% (1)

- 1.single Point MooringsDokument2 Seiten1.single Point MooringsAman SinghalNoch keine Bewertungen

- Mooring Buoy Maintenance Within Komodo National Park: 2009 ReportDokument20 SeitenMooring Buoy Maintenance Within Komodo National Park: 2009 ReportAndrew HarveyNoch keine Bewertungen

- OIL Hoses Brochure 1 PageDokument24 SeitenOIL Hoses Brochure 1 Pagefle92Noch keine Bewertungen

- 14 - NRG - Pipe Installation - Davit LiftDokument16 Seiten14 - NRG - Pipe Installation - Davit LiftBalanNoch keine Bewertungen

- Turret Bouy Tech DescriptionDokument36 SeitenTurret Bouy Tech Descriptiondbekos100% (1)

- 1 Inspection Intl of Damaged Marine Floating Hose Tail PDFDokument3 Seiten1 Inspection Intl of Damaged Marine Floating Hose Tail PDFDavid_SaryNoch keine Bewertungen

- Application of Submarine and Floating Hoses in Offshore SPMDokument60 SeitenApplication of Submarine and Floating Hoses in Offshore SPMSabila Shani TalsaNoch keine Bewertungen

- Buoy Installation ProcedureDokument26 SeitenBuoy Installation ProcedureFadliAnanda100% (1)

- CB Mooring SystemsDokument5 SeitenCB Mooring SystemsCojocaru LaviniaNoch keine Bewertungen

- SOFEC CALM BUOY FINAL 3page RedDokument3 SeitenSOFEC CALM BUOY FINAL 3page RedJ. Jorge TorresNoch keine Bewertungen

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityVon EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityNoch keine Bewertungen

- Mono BuoyDokument40 SeitenMono BuoyCaptIsqan100% (4)

- Mooring Equipment GuidelinesDokument3 SeitenMooring Equipment GuidelinesJason Roberts100% (1)

- TowingSailaway Transportation and Installation PlanDokument27 SeitenTowingSailaway Transportation and Installation PlaneNoch keine Bewertungen

- Guidances For Single Point MooringDokument53 SeitenGuidances For Single Point Mooringgenesis L. OrtizNoch keine Bewertungen

- Structural Integrity Assessment of Offshore Conversions - ISE and TSADokument21 SeitenStructural Integrity Assessment of Offshore Conversions - ISE and TSAAnonymous100% (2)

- FLEXIBLE FLOWLINE RELOCATION & TIE-IN PROCEDURE Rev A - 12022-AMC-TIN-PRO-0016 - IssuedDokument94 SeitenFLEXIBLE FLOWLINE RELOCATION & TIE-IN PROCEDURE Rev A - 12022-AMC-TIN-PRO-0016 - IssuedWilliam O Okolotu100% (1)

- Appendix II - Marine Specification (Installation)Dokument184 SeitenAppendix II - Marine Specification (Installation)haydarburedahNoch keine Bewertungen

- Pigging Head and Spool InstallationDokument38 SeitenPigging Head and Spool InstallationWilliam O OkolotuNoch keine Bewertungen

- Offshore Pipelines: Design, Installation, and MaintenanceVon EverandOffshore Pipelines: Design, Installation, and MaintenanceBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Subsea Riser Pipeline Visual Inspection ProcedureDokument13 SeitenSubsea Riser Pipeline Visual Inspection ProcedureMy Osoef100% (1)

- Olokola Gas Supply Project Pipeline Feed: Constructability StudyDokument22 SeitenOlokola Gas Supply Project Pipeline Feed: Constructability StudyAdvisNoch keine Bewertungen

- Mooring Hawser Conoco PhiliphinDokument15 SeitenMooring Hawser Conoco PhiliphinhaitacvietnamNoch keine Bewertungen

- Fire Wires or Emergency Towing-Off Pennants (ETOP's), MEG 4, ISGOTT Edn 6th RecommendationsDokument6 SeitenFire Wires or Emergency Towing-Off Pennants (ETOP's), MEG 4, ISGOTT Edn 6th RecommendationsGiorgi KandelakiNoch keine Bewertungen

- Dynamic positioning The Ultimate Step-By-Step GuideVon EverandDynamic positioning The Ultimate Step-By-Step GuideNoch keine Bewertungen

- Byco SPM InformationDokument83 SeitenByco SPM InformationMohamed HuseinNoch keine Bewertungen

- Subsea Rigid Pipelines – Methods of InstallationVon EverandSubsea Rigid Pipelines – Methods of InstallationBewertung: 5 von 5 Sternen5/5 (1)

- Cathodic Protection Design Report for Fateh and South West Fateh FieldsDokument27 SeitenCathodic Protection Design Report for Fateh and South West Fateh FieldsAnonymous rPV6LRE1Noch keine Bewertungen

- The Mooring of Oil Carriers at Single Point Moorings: Guide ForDokument9 SeitenThe Mooring of Oil Carriers at Single Point Moorings: Guide ForydmisraNoch keine Bewertungen

- MOSES Advanced TrainingDokument4 SeitenMOSES Advanced TrainingYudha MeremNoch keine Bewertungen

- Treleborg MS-OIM Offshore BrochureDokument8 SeitenTreleborg MS-OIM Offshore BrochureAdrianBuzamatNoch keine Bewertungen

- Underwater Hull Cleaning and Diving Survey in Vietnam AsiaDokument54 SeitenUnderwater Hull Cleaning and Diving Survey in Vietnam AsiaInspectionNoch keine Bewertungen

- 23 Mooring Analysis During ShorepullDokument53 Seiten23 Mooring Analysis During ShorepullNoverdo Saputra100% (1)

- Spool and Riser Flooding & HydrotestDokument30 SeitenSpool and Riser Flooding & HydrotestPhani Kumar G SNoch keine Bewertungen

- Hawser Operating ManualDokument14 SeitenHawser Operating ManualFaisal AwanNoch keine Bewertungen

- Offshore Mooring StandardsDokument8 SeitenOffshore Mooring StandardsradrottenNoch keine Bewertungen

- Mooring System Engineering for Offshore StructuresVon EverandMooring System Engineering for Offshore StructuresBewertung: 5 von 5 Sternen5/5 (1)

- OCIMF PublicationsDokument8 SeitenOCIMF PublicationsSahil BiswasNoch keine Bewertungen

- ABS GUIDE FOR-Position-Mooring-Systems-2018 - 05 PDFDokument92 SeitenABS GUIDE FOR-Position-Mooring-Systems-2018 - 05 PDFjeedan100% (1)

- Oil & Gas UK 2008 Mooring Integrity GuidanceDokument177 SeitenOil & Gas UK 2008 Mooring Integrity GuidanceSRAR100% (1)

- Strength in Depth: Single Point MooringDokument20 SeitenStrength in Depth: Single Point MooringVincinius Axel100% (1)

- 1 - Side by Side Mooring AnalysisDokument11 Seiten1 - Side by Side Mooring AnalysisYong KimNoch keine Bewertungen

- API 650 Load CombinationsDokument10 SeitenAPI 650 Load Combinationsศุภกฤต รักในหลวงNoch keine Bewertungen

- DNV OcimfDokument8 SeitenDNV OcimfHungulit HaNoch keine Bewertungen

- Fabricators' and Erectors' Guide To Welded Steel Construction - 1999 (Structural Welding)Dokument58 SeitenFabricators' and Erectors' Guide To Welded Steel Construction - 1999 (Structural Welding)johnknight000Noch keine Bewertungen

- Aws - Symbols For Welding, Brazing and End PDFDokument27 SeitenAws - Symbols For Welding, Brazing and End PDFiradankeNoch keine Bewertungen

- Hose Test Unit SpecsDokument4 SeitenHose Test Unit Specsศุภกฤต รักในหลวงNoch keine Bewertungen

- Foundations For CompressorsDokument1 SeiteFoundations For Compressorsศุภกฤต รักในหลวงNoch keine Bewertungen

- Fabrication of Carbon Membranes For Gas SeparationDokument19 SeitenFabrication of Carbon Membranes For Gas Separationศุภกฤต รักในหลวงNoch keine Bewertungen

- Eia Tia 222 FDokument122 SeitenEia Tia 222 Fsvrao4uNoch keine Bewertungen

- DNV OcimfDokument8 SeitenDNV OcimfHungulit HaNoch keine Bewertungen

- VIV Analysis of PipelineDokument5 SeitenVIV Analysis of Pipelineศุภกฤต รักในหลวงNoch keine Bewertungen

- OCIMF Anuual Report (2008)Dokument36 SeitenOCIMF Anuual Report (2008)ศุภกฤต รักในหลวงNoch keine Bewertungen

- Us 3572041Dokument16 SeitenUs 3572041ศุภกฤต รักในหลวงNoch keine Bewertungen

- 3412C 725 kVA Prime LowBsfc EU 50Hz1 PDFDokument6 Seiten3412C 725 kVA Prime LowBsfc EU 50Hz1 PDFKhaleel KhanNoch keine Bewertungen

- Leighton Engineering ProfileDokument4 SeitenLeighton Engineering ProfileYuyus UskaraNoch keine Bewertungen

- Sen06284-06 HM400-3 5000Dokument1.986 SeitenSen06284-06 HM400-3 5000Papulo82% (11)

- Magnesium and Aluminum Alloys in Automotive Industry PDFDokument11 SeitenMagnesium and Aluminum Alloys in Automotive Industry PDFΝΙΚΟΛΑΟΣ ΚΑΡΑΓΚΙΑΟΥΡΗΣNoch keine Bewertungen

- Nissan Zd30ddti Engine Workshop ManualDokument2 SeitenNissan Zd30ddti Engine Workshop ManualCollin Tjizu20% (15)

- Alternador Con ReguladorDokument26 SeitenAlternador Con ReguladorIlarion Ciobanu100% (1)

- Abstract BookDokument173 SeitenAbstract BookChau MaiNoch keine Bewertungen

- Hybrid Cars - PowerPointDokument47 SeitenHybrid Cars - PowerPointFranklin RegeNoch keine Bewertungen

- Alpha Call-Ups A330Dokument18 SeitenAlpha Call-Ups A330János Rédei100% (4)

- COREX MIDREX An Ideal Concept For Economic and Environmental Steel Production BoehmDokument15 SeitenCOREX MIDREX An Ideal Concept For Economic and Environmental Steel Production BoehmFernanda Brito100% (3)

- Cola VolvoDokument102 SeitenCola Volvovicente100% (1)

- Think Fuels, Think AftonDokument8 SeitenThink Fuels, Think AftonSerge1976Noch keine Bewertungen

- NP300Dokument8 SeitenNP300sfsman1100% (1)

- Libro de Mano de Recarga de Combustible AviacionDokument113 SeitenLibro de Mano de Recarga de Combustible AviacionOzkhar AFNoch keine Bewertungen

- Ajax Integral Engine-Compressor DPC-2804: 800-845 BHP 440 RPMDokument2 SeitenAjax Integral Engine-Compressor DPC-2804: 800-845 BHP 440 RPMRafael ZuritaNoch keine Bewertungen

- LNGC Al Ghashamiya - Imo 9397286 - Machinery Operating ManualDokument537 SeitenLNGC Al Ghashamiya - Imo 9397286 - Machinery Operating Manualseawolf50Noch keine Bewertungen

- KP D30SDokument5 SeitenKP D30SDerek ChenNoch keine Bewertungen

- Auxiliary Engine SafetyDokument4 SeitenAuxiliary Engine Safetyasep achmad mNoch keine Bewertungen

- Merits Demerits of Fluid Power SytemDokument2 SeitenMerits Demerits of Fluid Power SytemSriram Nanjangud SubramanyaNoch keine Bewertungen

- Piawaian PKK Yang Tidak Perlu Pengeluaran Sijil Perakuan BahanDokument5 SeitenPiawaian PKK Yang Tidak Perlu Pengeluaran Sijil Perakuan BahanAshiteru BestNoch keine Bewertungen

- Quasi TurbineDokument30 SeitenQuasi TurbineStark288100% (2)

- CH414 Petroleum Refinery EngineeringDokument14 SeitenCH414 Petroleum Refinery EngineeringHaider AliNoch keine Bewertungen

- ONWJ BlockDokument4 SeitenONWJ BlockwidiNoch keine Bewertungen

- BJB BKC Bru Bls Bxe BXF BXJ Engine EngDokument207 SeitenBJB BKC Bru Bls Bxe BXF BXJ Engine EngMihai Lungu50% (2)

- V2403-M-E3B engine specsDokument2 SeitenV2403-M-E3B engine specsWai Min100% (1)

- Soot Blowers Keep The Heat Transfer Surfaces in A Boiler CleanDokument50 SeitenSoot Blowers Keep The Heat Transfer Surfaces in A Boiler Cleanajanthalakshmi100% (1)

- New Holland b110 b115 en Service Manual 12n17446Dokument20 SeitenNew Holland b110 b115 en Service Manual 12n17446james100% (51)

- Parallel Operation of Three-Phase AlternatorsDokument12 SeitenParallel Operation of Three-Phase AlternatorsNayan Manna100% (2)

- D4B8076AC8A-Servicing - 4-Cylinder 1 8L 2 0L 4V TFSI Engine (EA 888 Generation II) PDFDokument268 SeitenD4B8076AC8A-Servicing - 4-Cylinder 1 8L 2 0L 4V TFSI Engine (EA 888 Generation II) PDFWiller Corporan Ruiz100% (7)

- Diesel Locomotive RosterDokument11 SeitenDiesel Locomotive RosterAgnivesh SharmaNoch keine Bewertungen