Beruflich Dokumente

Kultur Dokumente

PCB Design Guidelines

Hochgeladen von

Edwin Kwame SaforiOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PCB Design Guidelines

Hochgeladen von

Edwin Kwame SaforiCopyright:

Verfügbare Formate

PCB Design Guidelines

Below are a number of Guideline Rules to follow and keep in mind when designing PCBs. These are general rules that apply for the most PCB fabricators, but it is advisable to check with your fabricator.

Board Size

PCB manufacturers have a maximum size board they can handle. Typically this is also their panel size. The PCB fabrication house's panel size is also important when mass producing boards. In this situation one would want to fit as many boards as possible on a panel with as little wasted board space as possible (in order to reduce costs). Normal board spacing for routing (how boards are separated on a panel) is 0.3", plus there is typically a 1.0" to 2.0" border on the board for handling it during processing. Board thickness may also be specified. A standard thickness and type of board is .062" FR4. Other typical board thickness are .010", .020", .031", and .092".

Trace Width and Spacing

The chemical and photographic processes used to produce a PCB put requirements on the minimum width of trace and the minimum spacing between traces. If a trace is made smaller than this minimum width there is some chance it will open (no connection) when manufactured. If two traces are closer together than the minimum spacing there is some chance they will short when manufactured. These parameters are usually specified as "x/y rules", where x is the minimum trace width and y is the minimum trace spacing. For example, "8/10 rules" would indicate 8 mil minimum trace width and 10 mil minimum trace spacing. These rules (especially spacing) apply to any metal on the PCB, including pad to track spacing and line widths for strings on the PCB. Typical modern process rules are 8/8 rules with values as small as 2/2 rules being available. For Press-nPeel people have had success using 12/12 rules, but values a little larger are easier to make work consistently. However, keep in mind that the board must be soldered and a trace within 8 mils (8/8 rules) of a pad is easier to short than one with greater spacing when hand soldered. For hand soldering 10/10 rules are much easier to solder (if the design density can allow spacing this large).

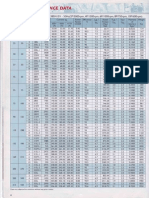

Pad Sizes

The biggest issues with pad size are solder ability and manufacturability. Solder ability is really just a matter of skill and will not be discussed here. Manufacturability is concerned with whether or not the pad will be broken when the hold is drilled in it. This is mainly a function of the accuracy of the PCB manufacturer's drilling. If a drill hole is slightly off center the pad may be broken at one edge possibly leading to an open in the circuit. A standard requirement for pad sizes is a 5 mil annulus. This means there must be .005" all around the hole (i.e. a 28 mil hole would require a 38 mil pad). Something a little larger than this (maybe 10 T mils) is recommended for solder ability. AP Circuits states they have had relatively consistent success with a h 2 E 2.5 mil annulus (i.e. a 20 mil hole with only a 25 mil pad), but they don't recommend it. N i 1 o c 1 G F Hole Sizes m k 6 7 1 l i i n /a 6 n Most PCB manufacturers have a wide selection of drill (hole) sizes 0 available. Some charge per drill size n (s 2 8 i used, others offer a standard set of e sizes for no charge and then charge for any non-standard drill sizes. drill s 3 2 8 0 s s AP Circuits uses the a latter approach. When choosing a hole size remember that the plate-through will cause s )varies h the hole to effectivelyl be more narrow. The plate-through thickness/c from .001" to .003". AP Circuits' 0 t D t 7 2 o e plate-through thickness is approximately .015" (meaning the "finished hole" diameter is 3 mils smaller). 1 3 10 h 3D . ri o D 6 3 2D n d D 80 M V 62/2 i 0 2- i i ll 0 Standard H l i M Drill Sizes G 2 (s 1 3 H D i or D 2 3 1 B bi 31 0 NI e . 0E . aM o I 6 4 8 2 3 10 Do I tr I k Ca 0 C c Dbi a e 7 5 1 . 6 2 0 0 it tDL 3/ a (3) 1 th k ri t m o 0 1 8 I/ C L . . un0 00 . rI 0. mg 0 .ri2 l . n 0. . ) /u. 3m ri l N . I/ n @Bm . C0. . 21 C 6- ru "( llM 4 . th n a 0 r 3 -2 1 2 3 4 5 6 I 80 O ar 2 e R r C 0 0 P Ill 0 - P S I A S T L C C D 5 4 R3 1 m a 02 1c0 0 1 1 1 5 - c 1. M 160 lle ST 1 1 0 0. R 1 7 /c 2 1R 0O 2 R0 1 C0. c 1 ar0 BVP V ru n 1C 0. V . E 0 e 5. 6. 6. R . 2. C /V 1. IS 0. 5. 3 8 6 5 4 0 1 + 2V V V G 0.V R C V S V E A B d I 5. 0. 3. W V 0. 1. R 2. CV 1 3 4 5 e 6 B 8 E 0 S 2 V 5. W 0. V O R C P A E V + V O0. U R C05. B E V A S T d CL 0. 0. S E F0. 1 9 1.84 2 4 2.95 32 3 3.p 8 b43 / p (I 5 0 8 6A 4 m /2 2 3 4 5 6 7 8 9 0 1 N h 1 R1 4 3 2 1 0 9 8 7 60. 8E 6 9 C 5C 7 8 R 4 R 8 7 D0. 3 D 0. 0. 6 ST1Re Re K Re 6 Re G Rep C R S V itA A NW-(I 0. dSe e 7.Re6 0 +41 2 6.Re 3.5 1 4.02 2.3 0 5.10 S 0. 46 1 30 2 32 3 34 4 36 5 40 6V 7A 0E m O G 1.32 1 6 3.21 0 7 6.10 0. 8- - B a 6. 2 2.hn A Re d G/ 00S 0.S Re50 5 AI 31(I0 NS- W 00A 3.h MG0Re 1 A 2 E 3 O 4 G 5 M 6 W 8 55 0S 4 3. V S 1 C 2 19 N 1 25 R 0 34 D 0 43 V P E S A 3. p 48. 0 DS30 59.00 2 G 01 V A ti S S E 6 p3. d48.AI 0 2. S 4 3 O(I2-2 M 1. S5 4 B01 2 A 37.S K V 1 2 3 2 4 1 5 0 E S V 6. A 7. p00 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 14 15 11 12 13 t. t. R t.W 3/ t.t. H C t. A S t. 01 1 6.c.1 2 2.p.68 0 8.1.02 00 mec W Lo B N M 5.iz PiLot.01 m G2Wn0 oLo G 01W We HEL0Lo " 1.0 22 A 81 E 0 Lo 40 D 5 t..8 58 N 2 9 66 Q A 1 3 A5W 0. 6 6 9901 740 00 3 2 n d 2. 2 5 1960 e37 21/ 5t. 1 R 012. 8. 5 4 3102/ 5 2 0 7 1 8 20 2 05 4 16 5 4 2W3. 5 4 2 1 8 6 0 7 3 9 e Pi1.a lt. oWn 01 B95 s 8 N 0 A 300 5 5 A 7 1 2W 4 6 E 4 4 1W 7 7 D 9 0 + /7 6 0.Lo1 4 5 W 8 4.Lo 9.8 71 93 65 27 59 02 84 46 1o P1. 5 1 7 + D A1. 1. 8 3 5.9A P N3881 2iz N A 3 4 4 . Q2/ 6 8 6 c 5 6 27 p 49 1 05 e W 1 0 W V 0 4. Y 2/ 7. T u 2 L2 7 p8 9 13 1 04 6 co 8.3 0.4 2.5 4.6 6.7 7.83 D 153 15 D 2/ 4 5 7 E 20 V 02 T 2. 4 o 107 p 2 1 o1 c W A 02 R 0 3. W B LoE 1 2. 2.9 81 2 73 1 65 e 53 G 6 8 6 46 T 3 u 1 39 K 2 1. 2 9 4 6 8 c 0 p 3 6 5 7 4 9 8 0 5 1 0 2 3 Rn1 D3 3 N1 4 Y4Lo P52 K65 S78 VA 0 T2 07 u3 10 2 95 3 98 p n 01 1 u 04 c 89 I 86 .5 .8 .9 .3 .4 .7 .2 .1 .6 .9 .0 .2 .3 .4 .5 .7 65 70 75 80 89 94 99 05 10 15 20 26 31 37 42 48 54 60 66 72 78 84 .0 .1 .2 16 19 23 26 32 36 39 42 46 49 52 59 63 67 70 74 78 81 85 89 93 97 01 05 09 13 17 21 25 29 34 38 43 47 51 56 61 15 17 20 22 24 27 29 31 34 36 39 41 44 46 49 51 54 56 59 62 64 67 70 72 75 78 81 83 U Lo MP 13 H 92 8 7 6 5 4 3 2 1 0 1117 2014 3#56 4751 5608 6586 7464 8 Ws"c G 2ss m K" 379V " n 4ssV W ry 18.) .mssm 6 G 057 z.E#.)55 rR5 m 0 342 -2 s. 0815 6 781 "52 3 1 408 -3 03D 2 7 804 4 # 6 01 -8 #8 985 3 7 5 24 -7 79 8849 1 637 8 6 4 49 -6 50e838 0 209 52 5 3 77 -5 31V824 9 154 00 4 2 ss -4 12C 1 8 929 3 00 1 99 0 98 8 97 7 96 9 95 4 94 G 0 5 9 8 7 6 4 3 2 1 8 6 3 0 n 8e3 9 2 R 0 6Wss 9" 7 8 1 964 0ss 7 0 863 112 5 9 762 286 4 8 661 330 3 7 560 404 2 6 459 1 4V 06 579 1 V 5 358 2 20 64 5 8 o47 n6k " .V3ss /V 0G 95 84 73 62 51 40 39 1 8P 6 0 28 s 9Y 0 4 170 ) 0ry.) 1 m R R 899 4D 8 1c58 2244 5818 0999 3 5 7 1 25 44 63 o51 e 9 1 -1 N# 5800 e 5 560 o T9195 6 2 0 18 4 6 490 2 8 5 26 5 84 389 1 9 2 36 6 45 288 9 1 8 64 7 26 187 7 0 7 81 -9 97 086 R R 4 98 3 sss 2 067 0RR 9828 8727 0 655 # 0 4 2 s 9 #5 2 7626 5 721 T 5 3 1R 8 s7 8 55250 44242 33239 22221 11216 #0203 c 29 D 30 6 5 4 3 2 1 0 # 9 D V 65 8 c 7 80 9 73 1 72 4 71 6 70 8 69 0 68 5 67 2 66 983 751 509 3 6ss 1 31 0 17 O 0 c28 D 39 38 37 36 35 34 33 32 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 ss 47 36 31 40 55 77 45 92 49 16 93 83 85 01 32 79 28 34 20 07 27 89 43 50 49 48 47 46 45 44 43 42 41 40 78 77 76 75 74 73 72 71 70 69 68 67 66 65 64 63 62 61 60 59 58 57 56 55 54 53 D V 19 79 43 11 63 39 20 02 85 70 57 45 34 9 25 8 13 0 .) R 09 1 R 793 07 2 D 692 12 3 c 591 17 16 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 32 97 63 30 9 3 7 5 1 0 20 45 84 56 55 54 53 52 51 50 49 48 47 46 45 44 43 42 41 40 39 38 37 36 35 34 33 32 31 80 95 94 93 92 91 90 89 88 87 86 85 84 83 82 81 80 79 78 77 76 75 74 G #

Das könnte Ihnen auch gefallen

- Windsor Saber S28 PartsDokument32 SeitenWindsor Saber S28 PartsNestor Marquez-DiazNoch keine Bewertungen

- API Pipe DimensionDokument9 SeitenAPI Pipe DimensionKoko MykNoch keine Bewertungen

- ALL Purspose Excel SheetDokument329 SeitenALL Purspose Excel SheetRajput PratiksinghNoch keine Bewertungen

- Mechanical seal detailsDokument2 SeitenMechanical seal detailsSalsa AmorirNoch keine Bewertungen

- 37° Flared Tube Fitting GuideDokument13 Seiten37° Flared Tube Fitting GuidehernychtNoch keine Bewertungen

- L I G H TDokument4 SeitenL I G H TPrem SharmaNoch keine Bewertungen

- Manual Rotex CouplingDokument21 SeitenManual Rotex CouplingAndrei MorariuNoch keine Bewertungen

- Final Layuot For 8 KNM GBDokument40 SeitenFinal Layuot For 8 KNM GBashishkhaterNoch keine Bewertungen

- Assembly Part ListDokument15 SeitenAssembly Part ListAnonymous nQ9RqmNoch keine Bewertungen

- Ow-En AirpelDokument4 SeitenOw-En AirpelmuppetscrapNoch keine Bewertungen

- Bavaria Reverse RdsDokument15 SeitenBavaria Reverse RdsDušan JovanovićNoch keine Bewertungen

- Output StaadproDokument16 SeitenOutput StaadproImam KhafidhNoch keine Bewertungen

- Sony Vaio Mbx-126 - Quanta Je5.1Dokument36 SeitenSony Vaio Mbx-126 - Quanta Je5.1nunoq171Noch keine Bewertungen

- L I G H TDokument4 SeitenL I G H TPrem SharmaNoch keine Bewertungen

- Design AidsDokument28 SeitenDesign Aidsresurrection786Noch keine Bewertungen

- Daewoo DVG 6000DDokument12 SeitenDaewoo DVG 6000DOssian Valera PinedaNoch keine Bewertungen

- IS 1239 steel pipe sizesDokument4 SeitenIS 1239 steel pipe sizesPrem SharmaNoch keine Bewertungen

- bl01 Aa0104 4Dokument6 Seitenbl01 Aa0104 4chris110Noch keine Bewertungen

- 78981330457854Dokument35 Seiten78981330457854César FernándezNoch keine Bewertungen

- Brother m4318 PartsDokument69 SeitenBrother m4318 PartsPlinio Ricardo PiconiNoch keine Bewertungen

- PMO - Planning & Control Formats: Doc. No. - PMO - Planning Guide Rev. 1 DT 30 Jan. 2012Dokument33 SeitenPMO - Planning & Control Formats: Doc. No. - PMO - Planning Guide Rev. 1 DT 30 Jan. 2012Abdelrhman ElmohrNoch keine Bewertungen

- Motor Types WL Class F Insulation, 380i4 - 5V - 50Hz (2Pl3000rpm, 4Pl - 500rpm, 6pi I000rpm, 8P/750rpm, - 0P/600rpm) TRTDokument2 SeitenMotor Types WL Class F Insulation, 380i4 - 5V - 50Hz (2Pl3000rpm, 4Pl - 500rpm, 6pi I000rpm, 8P/750rpm, - 0P/600rpm) TRTDamar SasongkoNoch keine Bewertungen

- Design flow and dimensions of bar screen and fine screenDokument73 SeitenDesign flow and dimensions of bar screen and fine screenDavid LambertNoch keine Bewertungen

- GOST 7798 Dimension PropertiesDokument4 SeitenGOST 7798 Dimension Propertiesbhavin26570Noch keine Bewertungen

- L I G H TDokument4 SeitenL I G H TPrem SharmaNoch keine Bewertungen

- Multi-Function Air Conditioner GuideDokument21 SeitenMulti-Function Air Conditioner GuideLaura VillarroelNoch keine Bewertungen

- L I G H TDokument4 SeitenL I G H TPrem SharmaNoch keine Bewertungen

- GgooDokument4 SeitenGgooPrem SharmaNoch keine Bewertungen

- ANSI PipeDokument10 SeitenANSI PipeEkki Petrus BubunNoch keine Bewertungen

- 4 Urbanismo 2014 Default 000Dokument1 Seite4 Urbanismo 2014 Default 000jsmoralesantamariaNoch keine Bewertungen

- IS 1239 steel pipe sizesDokument4 SeitenIS 1239 steel pipe sizesPrem SharmaNoch keine Bewertungen

- Enginnering DemandsDokument23 SeitenEnginnering Demandswaqas_asad3081Noch keine Bewertungen

- L I G H TDokument4 SeitenL I G H TPrem SharmaNoch keine Bewertungen

- Description Matl. OD ID Leng. Width Area Thk. Qty. WT-Remarks Price Total Pric No. MM MM MM MM m2 MM Nos KgsDokument8 SeitenDescription Matl. OD ID Leng. Width Area Thk. Qty. WT-Remarks Price Total Pric No. MM MM MM MM m2 MM Nos KgsManikandanNoch keine Bewertungen

- CoturiDokument1 SeiteCoturitomescu_sorinNoch keine Bewertungen

- Steel Pipes - Pipe Schedule ChartDokument1 SeiteSteel Pipes - Pipe Schedule ChartShatish KumarNoch keine Bewertungen

- Placute Filetare Taegu TecDokument16 SeitenPlacute Filetare Taegu TecVladislav VatamaniucNoch keine Bewertungen

- L I G H TDokument4 SeitenL I G H TPrem SharmaNoch keine Bewertungen

- Hydraulic Cylinders CHDokument8 SeitenHydraulic Cylinders CHStoianovici CristianNoch keine Bewertungen

- IS 1239 and IS 3589 pipe sizesDokument4 SeitenIS 1239 and IS 3589 pipe sizesPrem SharmaNoch keine Bewertungen

- Machinery Canada - DC Swiss Taps Rigid Tapping SynchroDokument5 SeitenMachinery Canada - DC Swiss Taps Rigid Tapping SynchromachineCanNoch keine Bewertungen

- 13 - Copes-Vulcan ValvesDokument7 Seiten13 - Copes-Vulcan ValvesshalegpNoch keine Bewertungen

- L I G H TDokument4 SeitenL I G H TPrem SharmaNoch keine Bewertungen

- Otterspool Way Service Road: Watford Audi - Garage PorcelanosaDokument1 SeiteOtterspool Way Service Road: Watford Audi - Garage PorcelanosaAnonymous qEPNPwANoch keine Bewertungen

- Tube & Pipe Marketing Guide for Medium-Weight Screwable Steel TubesDokument0 SeitenTube & Pipe Marketing Guide for Medium-Weight Screwable Steel TubesAdrian MarinNoch keine Bewertungen

- Assessment and Control of Hard Waste in Spinning Mill'Dokument44 SeitenAssessment and Control of Hard Waste in Spinning Mill'chavanhrishi1488% (8)

- Tah Hsin Industrial Corp.: Packing ListDokument5 SeitenTah Hsin Industrial Corp.: Packing ListThien ThaiNoch keine Bewertungen

- Design Calculation Roof ShadeDokument26 SeitenDesign Calculation Roof ShadeAbuAhmedQuazi100% (1)

- Bom - Sentsor Core Esp32-MicroDokument1 SeiteBom - Sentsor Core Esp32-MicroAlexander Figueroa100% (1)

- EN6114Dokument14 SeitenEN6114akayirNoch keine Bewertungen

- Maintaining rolling gearDokument15 SeitenMaintaining rolling gearSATISHNoch keine Bewertungen

- 70-130 Autocreaser Pro 50 Parts Manual REV.7Dokument29 Seiten70-130 Autocreaser Pro 50 Parts Manual REV.7Peter GaluszkaNoch keine Bewertungen

- Rexnord Elastomer CouplingDokument20 SeitenRexnord Elastomer Couplingidontlikeebooks100% (1)

- TDS No - FPVS-2K03: Oa A Aa ADokument4 SeitenTDS No - FPVS-2K03: Oa A Aa AMehdi Hajd KacemNoch keine Bewertungen

- Measurements, Sizes, Shafts, KeywaysDokument91 SeitenMeasurements, Sizes, Shafts, KeywaysVenkat DoraNoch keine Bewertungen

- Pipe Reinforcing at SupportDokument12 SeitenPipe Reinforcing at SupportSeungmin Paek100% (3)

- Marine & Subsea Cylinder SpecificationsDokument22 SeitenMarine & Subsea Cylinder SpecificationsIan_SmythNoch keine Bewertungen

- Electronic Circuit Design Ideas: Edn Series for Design EngineersVon EverandElectronic Circuit Design Ideas: Edn Series for Design EngineersBewertung: 5 von 5 Sternen5/5 (2)

- British Commercial Computer Digest: Pergamon Computer Data SeriesVon EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNoch keine Bewertungen

- Toyota - Quantum - Workshop Manual - 2004 - 2004Dokument10 SeitenToyota - Quantum - Workshop Manual - 2004 - 2004Abri van NiekerkNoch keine Bewertungen

- Service Manual: Published in May 2017 843R8111 3R8SM061 Rev.1Dokument151 SeitenService Manual: Published in May 2017 843R8111 3R8SM061 Rev.1juanNoch keine Bewertungen

- Rc2004a Biw EsxDokument27 SeitenRc2004a Biw EsxUjio37Noch keine Bewertungen

- Installation and Operation Manual: SPM-A SynchronizerDokument32 SeitenInstallation and Operation Manual: SPM-A Synchronizerpolish22Noch keine Bewertungen

- ACL-5100 - Operation ManualDokument16 SeitenACL-5100 - Operation ManualGianniNoch keine Bewertungen

- DIY ArduinoDokument47 SeitenDIY Arduinogudi_manoj100% (1)

- Cisco PGDokument158 SeitenCisco PGthanh cong TruongNoch keine Bewertungen

- Laminator Mod - PCB Toner Transfer From ParchmentDokument7 SeitenLaminator Mod - PCB Toner Transfer From Parchmentvali29Noch keine Bewertungen

- 47LE5300Dokument43 Seiten47LE5300garcia5Noch keine Bewertungen

- High Quality 8 Layer PCB ManufacturingDokument13 SeitenHigh Quality 8 Layer PCB ManufacturingjackNoch keine Bewertungen

- Technical Information For The Release of The DR-G11301100Dokument33 SeitenTechnical Information For The Release of The DR-G11301100ReneeNoch keine Bewertungen

- Hcdslk1i DVD Receiver PDFDokument88 SeitenHcdslk1i DVD Receiver PDFfrgonzalezcNoch keine Bewertungen

- TECO FM50 Manual PDFDokument68 SeitenTECO FM50 Manual PDFMuhamad Irfan100% (1)

- Woodward 2301D ManualDokument104 SeitenWoodward 2301D ManualAbdul Samad MahmoodNoch keine Bewertungen

- Manual Servico TV LCD LG 32lg4000 32lg4000 Za Chassis Ld86aDokument28 SeitenManual Servico TV LCD LG 32lg4000 32lg4000 Za Chassis Ld86aJose SantanaNoch keine Bewertungen

- APCT Holdings Acquires Cartel Electronics & Affiliate CirtechDokument2 SeitenAPCT Holdings Acquires Cartel Electronics & Affiliate CirtechPR.comNoch keine Bewertungen

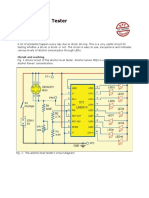

- Alcohol Level TesterDokument3 SeitenAlcohol Level TesterAsad WaseemNoch keine Bewertungen

- IPC Training and Reference Guide - DRM-18HDokument19 SeitenIPC Training and Reference Guide - DRM-18HLane MedaNoch keine Bewertungen

- Smart Fabrics 8953 YHnhPqyDokument31 SeitenSmart Fabrics 8953 YHnhPqyanushadv 9899Noch keine Bewertungen

- Using 3070 For Insystem ProgrammingDokument12 SeitenUsing 3070 For Insystem ProgrammingFer TorresNoch keine Bewertungen

- 4x20 LCDDokument17 Seiten4x20 LCDFuture TechnovationNoch keine Bewertungen

- 555 Full PWM CircuitDokument2 Seiten555 Full PWM CircuitNash_HoleNoch keine Bewertungen

- Manual de Servicio Ichem Velocity Rev DDokument271 SeitenManual de Servicio Ichem Velocity Rev DJohny Ronald Gutierrez DelgadoNoch keine Bewertungen

- Serial Number Range: From SN 3084-101 To 3090-2213Dokument118 SeitenSerial Number Range: From SN 3084-101 To 3090-2213Святослав ВороновNoch keine Bewertungen

- AIR Intelligence - Manual - 33 308100 001 - ASD 160H PDFDokument56 SeitenAIR Intelligence - Manual - 33 308100 001 - ASD 160H PDFKm IshraNoch keine Bewertungen

- Addressable Loop Modules: Introduction FC410MIMDokument8 SeitenAddressable Loop Modules: Introduction FC410MIMLORIUNEANoch keine Bewertungen

- New Test Strategy for Complex PCB AssembliesDokument13 SeitenNew Test Strategy for Complex PCB AssembliesrahulNoch keine Bewertungen

- Computerized Lensmeter Repair ManualDokument52 SeitenComputerized Lensmeter Repair ManualMohamed Abdulaal100% (1)

- 50UX58BDokument88 Seiten50UX58Bnip27Noch keine Bewertungen

- EGCP-2 Application ManualDokument188 SeitenEGCP-2 Application Manualharis khanNoch keine Bewertungen