Beruflich Dokumente

Kultur Dokumente

Kavitha Project

Hochgeladen von

gowthamikcOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Kavitha Project

Hochgeladen von

gowthamikcCopyright:

Verfügbare Formate

JKTYRE &INDUSTRIES Ltd

EXECUTIVE SUMMARY

Vikrant Tyre Ltd was a Public Ltd Co with available areas of 53 acres in Karnataka. The company has good infrastructure facilities, abundant labour & man power, good housetrain facilities, (encouraged with the retirement plans to) selected Mysore as their ideal factory location. J.K. Industries, Vikrant Tyres unit has a devoted work force of around 2.200 employees. The company has come into existence as a prestigious Organization which is connected to the manufacturing of quality tyres in the future electronic city of Mysore. In May 1997, HJ I was inducted as a strategic alliance plans (SAP) with a view to give a turn around to the co as a profit making unit. A memorandum of understanding was signed between ISSIDC and JK tyres by which ISSIDC has invested majority of shares with JK Tyres Ltd. Thus JKL has acquired more than 51% of enhanced issued and paid-up Capital of Vikarath Tyres Ltd (VTL). The board of Vikranth Tyres Ltd VTL was reconstituted with nominated Shri Arun Kumar- Bajaria to be the president and managing director and to be the Executive Director of VTL. As a result the VTL is now under the control of J.K. Industries Ltd.Exports now a burgeoning fields after the liberalization, due to the dynamic nature of the foreign markets. India has now realized that exports is the gateway to sell its products abroad and has come a long way from selling its surplus to the present day status of ( exclusive /manufacturers) export market potential .

Department of Management Rajeev Institute of Technology, Hassan 1

JKTYRE &INDUSTRIES Ltd

CHAPTER 1 INDUSTRY PROFILE

History In the year 1887 the word rubber industry came in existence, with the process of tube vulcanization by Charles Good Year. However, towards the end of the century the industrial growth received a big boost. Bond Dunlop succeeded in making the vulcanization rubber into inflatable preamatic tyres. Since then the tyre industry has constituted a major segment of the rubber industry all over the world. Even in India, automotive tyres and tubes account for a major part of the Indian rubber product industry. Tyre Industry in India History of the Indian tyre industry could be classified into 4 periods 1920 to 1935 {multinational trading in tyre} 1935 to 1960 {multinationals manufacturing era} 1961 to 1974 {broadening of production base}

Trading tyres in India was first started in 1920 by Firestone, followed by Good Year in 1922 and later by Dunlop in 1926. Dunlop set up the first tyre at saharganj, West Bengal, in the year 1936. Firestone set up a factory at Mumbai. At present there are 20 licensed companies and 24 factories with 11 large companies manufacturing the full range of tyres and tubes. The Indian tyre companies are having collaboration

Department of Management Rajeev Institute of Technology, Hassan 2

JKTYRE &INDUSTRIES Ltd

with tyre companies of U.S.A, U.K, West Germany and Japan. Significant changes occurred in the tyre manufacturing process, change over from rayon to nylon and introduction of radial tyres of both steel belt and fiber glass are most important. The hot cure conventional rethreading process is replaced with cold cure rethreading process. The truck and bus tyre mileage and load carriage capacity has gone up by 25%. The tyre industry is Rs.3500 Crore plus which manufacture tyres for truck and buses, light trucks, jeeps, cars, tractors trailer, power tillers, scooter, motor cycle, moped, cycle, earth moving equipments and dumpers, aircraft and special defense vehicles. The tubes are manufactured from natural rubber as well as imported butyl rubber. Tyre inner tubes are covered under packaged commodities Act. The Government for the tyre industry set up various committees. Way back in 1955, the tariff commission was set up. The major trust of the commission report was the decentralization of the tyre industry. Between 1974 and 1985 the government referred to Bureau of industry cost and price {BICP} five timers for cost and price study of tyre industry. But, the studies of the BICP were not made public. In May 1974 the government set up a committee on tyre industry with Mr. M. Satyapal as chairman. This committee submitted its report to the government in 1985. Report has not been published. Dunlop, MRF, Ceat, Apollo and Modi rubber dominates the industry together accounting for much as 60% of the total output. Among individual companies, MRF is moving into aircraft tyre manufacturing in collaboration with Uni, Royal Goodrich.

Department of Management Rajeev Institute of Technology, Hassan 3

JKTYRE &INDUSTRIES Ltd

The total capacity of ceat has gone up to 45 lacks tyres with the commence of walaj plant and has plans to manufacture nylon cord tyres. Modi rubber industry has the modipuram plant and modinagar plant is under implementation. Vikrant tyres with a new all steel radial tyre plant for trucks and buses is the only company modernizing the existing plant and manufacturing new technological tyres of international standards and acceptability, Indian tyre industry is all set to capture a major share in export market and increases its share of export to various countries. The tyre industry is a raw material intensive industry. Raw materials account for about 55% of the total production cost. Two of the four major raw materials used in the tyre making i.e. Nylon tyre cord and synthetic rubber to natural petroleum based derivatives.

Department of Management Rajeev Institute of Technology, Hassan 4

JKTYRE &INDUSTRIES Ltd

CHAPTER 2 COMPANY PROFILE

Jk Industries JK Organization owes its name to Late Lala Juggilal Singhania, a dynamic personality with a broad vision, Inspired by the Swadeshi movement of Mahatma Gandhi, and driven by the zeal to set up an Indian enterprise, Lala Kamlapat Singhania founded JK organization in the 19th century in India. The process of industrialization and diversification was worthily and successfully carried on by Lala Kamlapats three illustrious sons Sir Padampat, Lala Kailashpat and Lala Laksmipat, aided in no small measure by the late Gopal Krishna son of sir Padampat. JK Organization has been a forerunner in the economic and social advancement of India. It always aimed at creating job opportunities for a multitude of country men and provides high quality of products. It has driven to make India self reliant by pioneering the production of number of industrial and consumer products, by adopting latest as well as developing its own know-how. It has also under taken industrial ventures in several other countries. JK Organization is an association of industrial and commercial companies and charitable trust. Its member companies, employing nearly 50000 persons are engaged in the manufacture of variety of products and in diverse fields of commerce.

Department of Management Rajeev Institute of Technology, Hassan 5

JKTYRE &INDUSTRIES Ltd

Trust are devoted to promoting industrial, technical and medical researchers, education, religious values and providing better living and recreational facility. With the spirit of social consciousness uppermost in mind, JK organization is committed to cause the human advancement.

2.1 BACKGROUND OF THE COMPANY

Sri Anjaneya Agro-Tech Pvt. Ltd. Davangere Company at a glance Serial No. 1 2 Company at a Glance Name of the Industrial Concern : Address : a) Registered office : Athani Complex R.M.C Link Road, Bamboo Bazaar, Davangere -577001. b) Factory : Sy No. 80/81, Hanagawadi , Harihar APMC Link Road, Harihar Taluk, Davangere Dist. Karnataka. Name of the industrial concern M/S Sri Anjaneya Agro-Tech PVT. Ltd.

Department of Management Rajeev Institute of Technology, Hassan 6

JKTYRE &INDUSTRIES Ltd

3. Directors : Sri B.K. Rajashekarappa Sri. A.K. Prashanth Sri. Savan.Y.Amberker Sri. A.S. Veeranna Sri R. Manjunath Sri. A.S. Kotrappa Sri. K.K. Mahesh Sri. A. Channappa Sri A.C. Chek 4 5 6 Line of activity Size of the industry Capacity a) Installed-existing capacity b) Maximum Operating Capacity SEPI Rice bran/cake 150/200MTS/day SEPII Soya bean, rice bran/oil lake 150/200 TS/day Edible oil refinery TS MTS per day capacity 90% c) Main raw materials 7 8 9 End use of finished products Turnover in 2008 Year Power requirement Rice bran, oil cakes and Soya bean seeds Refined edible oils, wholesale and retail Consumers Rs. 16,973.59Lakhs 500 Kva Chairman Managing Director Executive Director Director Director Director Director Director Director Edible oil extraction Medium Scale Industry

2.2

NATURE OF THE BUSINESS CARRIED

Department of Management Rajeev Institute of Technology, Hassan 7

JKTYRE &INDUSTRIES Ltd

JK Tyres Limited is engaged in design, development, manufacturing and marketing automotive pneumatic tyres, tubes. The product range includes the following. Cross Ply and Radial Tyres for Trucks and Buses. Cross Ply and Radial Tyres for light Commercial vehicles. Cross Ply Tyres for Passenger Cars. Cross ply Tyres for Agricultural Vehicles. Cross Ply Tyres for Off-The-Road Vehicles. Automotive inner Tubes for Trucks, Buses, Light Commercial vehicles, passenger Cars and Agricultural Vehicles. Flaps for Trucks, Buses and Light Commercial Vehicles.

2.3

VISION:

VISION, MISSION & QUALITY POLICY:

To be amongst the most admired companies in India committed to excellence

MISSION:

To be the largest most profitable Tyre company in India. To retain # 1 Position in Truck and Bus segment and to be amongst Top 2 in all 4wheelers Tyre segment

To make Truck/Bus Radial operations Profitable and Retain Leadership in the

passenger Radial Market.

To be the largest Indian Tyre exporter continues to be a significant player in

the world in the truck Bias segment.

To be a customer obsessed company. To develop a highly motivated team with a sense of Amanda. To excel as a value driven organization. To be the most preferred Tyre Brand in India. Department of Management Rajeev Institute of Technology, Hassan 8

JKTYRE &INDUSTRIES Ltd

2.4

AREA OF OPERATION

The head office at Mysore is connected with various Regional Offices, District Offices, Branch Offices and Carrying and Forwarding Agents throughout the country. The common Marketing Organization (CMO) manages the marketing of Nylon BiasTyres of both VTL and JK. The head of the CMO is at New Delhi. The Truck Radial Group (TRG) manages the marketing of All Steel Truck Radial Tyres. The Head office of TRG is situated at Bangalore.

2.5

PRODUCTS / SERVICE PROFILE

Quality Policy: The employees of Vikrant Tyres Limited assure the quality of products by ensuring strict compliance with the approved quality standards and documented materials and components as also proper upkeep of our machinery. The principal goal for every Vikrant Employee will be customer satisfaction. They shall reach this goal by proper training of personnel at all levels, continuous technology up gradation and minimization of waste. They continuously anticipate and understand customer requirement, convert these into performance standards for their product and service and meet the standards every time. Product Profile: In Todays Health Conscious lifestyle, moderate use of right type and quality of cooking oil is very important to maintain sound physical and mental health. Keeping in view the innovative trends in health and nutrition the company has

Department of Management Rajeev Institute of Technology, Hassan 9

JKTYRE &INDUSTRIES Ltd

launched a unique oil-Akshath, Refined Rice Bran oil (RBO). It is termed as Olive oil of India, called as Heart Oil in Japan and as Health oil in USA. Akshath RBO is rich in color. Dark color is due to presence of more micro nutrients, which is beneficial for good health. Akshath RBO is a unique cooking oil which besides having a balanced fatty acid composition and an ideal Omega6/Omega3 ratio, also contains three categories of natural anti-oxidants i.e., Tocopherols, Tocotrienols and Oryzanols.

2.6

OWNERSHIP PATTERN Rs. In laks

Authorized Equity shares( 14% Redeemable preference shares (

cumulative

2.7

COMPETITOR INFORMATION

National Market: MRF, Good year, Falcon, CEAT, Apollo, etc International Market: Bridgestone, Michelin, Pirelli, Cooper, Sumitomo, etc

2.8

INFRASTRUCTURAL FACILITIES

Department of Management Rajeev Institute of Technology, Hassan 10

JKTYRE &INDUSTRIES Ltd

Infrastructural facilities mean the basic requirements that the company should look after in order ensure free flow of activities. The company is providing following infrastructural facilities in order to satisfy its workers, distributors and customers. The company provides all facilities stated by Factories Act of 1948.

Canteen Facilities

The canteen is well maintained and well kept with hygieneand clean drinking water facility .The food items are nutritious and are provided to the employees in concession price.

Latrines and Urinals

These are well maintained built in a manner as to it is very well ventilated .The cleanness is maintained by using anti-bacterial solution.

Safety

Safety of the employees are taken care and it is ensured that the machineries which is used in the factory are subjected to regular maintenance so that the M/c are in good condition technically which ensures safety to the employees while working with machineries.

Health Care Centre

Department of Management Rajeev Institute of Technology, Hassan 11

JKTYRE &INDUSTRIES Ltd

The management takes care of the health of the employees by providing them with clean drinking water hygienic food apart from this it has provided its employees with health care facility in its premises.

Security Parking Facilities Lighting and Ventilation

2.9

ACHIEVEMENTS AND AWARDS

J.K. Tyres ranked 16th largest tyre company in the world. ISO 14001 accreditation for environment and safety. Indias first T rated tyre launched. Mercedes Benz launched on JK STEEL RADIALS first tyre

manufactures in the world to get ISO 9001. Only tyre manufacturer to get E marks certifications. First tyre manufacturer in the world to get QS 9000. Awarded CAPEXILS highest export award for 1997-98. J.K. introduced national Go- carting championships. J . K . industries received FOCUS LAC EXPORT award for the year 19992000. Certified to ISO 9001:1994 quality managements systems. First Indian Tyre Company to adopt process based management

through business process re-engineering (BPR).

Department of Management Rajeev Institute of Technology, Hassan 12

JKTYRE &INDUSTRIES Ltd

It has ranked number one in customer satisfaction by the JD power Asia pacific study. ISI for Cross Ply Nylon Truck and Non Truck Tyres IN METRO for Cross Ply Nylon Tyres and All Steel Truck Tyres. STATE AWARD XFOR EXPORT EXCELLENCE from VTTC.

2.10

MODEL

PRODUCTION PROCEDURE / WORK FLOW

Manufacturing process with material balance for edible refined oil

Raw material processing

Bleaching

De-waxing

Deodorizing

Refined oil

Refining of rice bran oil is the process of converting of crude rice bran oil into Akshath rice bran oil. The crude oil contains various impurities such as free fatty acid, slime and aluminous substances, volatile odoriferous matters and coloring matters. Refining plant consists of various equipments and facilities to remove these impurities to produce quality edible rice bran oil at low cost.

Department of Management Rajeev Institute of Technology, Hassan 13

JKTYRE &INDUSTRIES Ltd

Raw Material Processing: After the procurement of the raw material bran which is required for manufacturing of finished product is divided into 3 types based on the colour, thickness, smoothness and then the divided raw material is sent to the next process. Bleaching: The coloring matter present in the oil is removed by treatment with bleaching earth. Neutral oil and bleaching earth are heated and agitated thoroughly in a pressure vessel. The coloring substance and other impurities are removed by adsorption with the bleaching earth. The oil mixture is then filtered to remove spent earth as filter cake. Most of the oil present in filter cake is recovered by application of high pressure stream or compressed air. The bulk oil is agitated in a vessel under temperature and vacuum to free it from moisture and gases.

De-Waxing: Rice bran oils from some of the sources contain waxes which are not removed in conventional de-gumming or bleaching units. In such cases, the bleached oil is chilled by application of refrigeration system to precipitate the wax present in it. The de-waxed oil is sent for de-adoring unit. The wax is separated from the oil by filtration. The wax is collected in the drums and disposed as solid waste.

Deodorising: The neutral bleaching clear oil still contains other odoriferous and taste producing impurities. These being volatile gases are removed by heating the oil to very high temperature under high vacuums the equipment consists of barometric

Department of Management Rajeev Institute of Technology, Hassan 14

JKTYRE &INDUSTRIES Ltd

condenser and steam ejector with citric acid as a preservative to improve its keeping quality. The refined oil obtained after complete treatment and purification is collected in the bulk refined oil storage tank. The oil is disposed to market through lorry tankers.

Enzymatic De-Gumming: Water de-gumming oil is heated and treated with citric acid. Acidified oil is cooled and neutralized with caustic. The enzyme is them mixed with the oil. The gum present in oil is reacted and stabilized.

Acid Oil Processing: The soap stock separated from neutralizer is a viscous emulsified mass containing soap oil and other impurities. It is collected in an acid proof tank and treated with sulphuric acid solution. The acidified soap stock is then boiled with live steam. The soap is decomposed in to acid oil and floats on the surface. The acid oil is collected in drums and sold to soap manufactures or as a boi-fuel for use in furnaces.

2.11

FUTURE GROWTH AND PROSPECTUS

The growth of Akshath is mainly attributed to the sustained high quality of the oil being supplied to its customers. Akshath RBO with its unique properties not just looks after the health but also reduces calories intake. In the near future, we see that Rice Bran Oil will be a preferred choice for most households. He further added, Akshath now is available in most parts of Karnataka and keeping in mind the growth strategy of the company we will soon be able to penetrate into other states also.

Department of Management Rajeev Institute of Technology, Hassan 15

JKTYRE &INDUSTRIES Ltd

Akshath RBO contains Oryzanol, an antioxidant which is proven by research to reduce bad cholesterol. It minimises heart ailments and cancer possibilities. Oryzanol helps to reduce bad cholesterol (LDL-C), improves good cholesterol (HDLC) and prevents cardiovascular ailments. Unlike the conventional method of chemical refining wherein chemicals like Phosphoric acid and Caustic acid are used for refining, Sri Anjaneya Agrotech is one of the few companies in India that use a physical refining process to manufacture oil (using enzymes instead of chemicals), hence making Akshath far superior and a more heart friendly oil in its category.

Department of Management Rajeev Institute of Technology, Hassan 16

JKTYRE &INDUSTRIES Ltd

CHAPTER 3 MCKINSEYS 7S FRAME WORK

Introduction: The 7-s model is better known as McKenzie 7s. This was developed by Tom Peters and Robert Waterman who had been consultants at the firm McKenzie. They published their 7-S model in their article Structure is not Organization (1980) and in their books The Art of Japanese Management(1981) and In Search of Excellence (1982). Just as the 7wonders of the world serve as the mirror to worlds beauty, so does these 7elements constitute the entire company as a whole. The mode consists of 7 elements. Those 7 elements are distinguished in so called hard Ss and soft Ss . The hard elements are feasible and easy to identify. They are strategy, structure and system of the organization. The four soft Ss are hardly feasible. They are highly determined by the people at work in the organization i.e., style , staff , skills and shared values.

Department of Management Rajeev Institute of Technology, Hassan 17

JKTYRE &INDUSTRIES Ltd

Structure Includes the policies and the procedure that given the way in which the organization acts within itself and within the environment.

ORGANIZATION STRUCTURE

Managing Director Executive Director

Production Dept. Production Manager Shift Incharge

HR Dept. HR Manager

Financial Dept. Financial Manager Asst. Managers

Accounts Dept.

Accounting Manager Sales Account Asst Transportation Account

Marketing Dept. Marketing Manager Sales Officers

Workers

Department of Management Rajeev Institute of Technology, Hassan 18

JKTYRE &INDUSTRIES Ltd

Skill: It is the character that is should posses to perform a given job. It includes those characteristics the company expects its members to have to perform the assigned job efficiency. Skill refers to the organization must posses competences to achieve the companys objectives. Skills can be acquired through proper training. Skills are those capabilities that are possessed by the whole as opposed to the people in it.

Man Power: Administration 1) General Manager 2) Chief Accounts 3) Clerk 4) Typists 5) Sales-Clerks 6) Store- Keepers 7) Supervisors 08) Attender 9) Security Technical 1) Engineer 2) Plant Operators 3) Preparatory Operators 4) Boiler attainders 5) Electronics 6) Others 7) Unskilled labors

The Man Power required is two categories Skilled and Unskilled. The Skilled workers like boiler operators, plant operator, electricians etc., and the company has already having the skilled workers who are working in the existing solvent extraction unit. The additional Manpower required will be recruited & Trained in the existing plant.

Department of Management Rajeev Institute of Technology, Hassan 19

JKTYRE &INDUSTRIES Ltd

Some of the above manpower which are already available in the existing setup, and additional people wherever necessary will be recruited & trained in the existing plant.

Style: Style of an organization is evident through the patterns of actions taken by members of the top-level management team over a period of time. Style is one of the 7 levels, which top managers can use to bring about organizational change. Organizations differ from each others in their styles of working. Reporting relationships will convey the style of the organization. In organization, the quality control function is embedded in the manufacturing function but in others it may be separate function directly under Managing Directors.

Beurocratic Style: Sri Anjaneya Agro-Tech Private Limited follows the top down leadership style. Which does not allow the subordinates to involve in decision making and decisions are taken by the departmental head. Departmental head delegate enough authority to carry on the tasks and subordinates can discuss the job activities with the immediate superiors and feasible suggestions are welcomed from the employees.

Strategy: Product strategy: The company producing only a single type of edible oil that is rice Bran Oil. It is different from other regular edible oil. This oil has been called heart oil in Japan as

Department of Management Rajeev Institute of Technology, Hassan 20

JKTYRE &INDUSTRIES Ltd

it contains original which increases HOL (good) cholesterol and lowers LDL (bad) cholesterol and triglycerides over oil contains sequence. Which improves skin tone, and delay wrinkles formation over oil contain vitamin e, which helps in maintaining balance of nervous system. Over oil observes 15% less oil which can be lower in caloric intake.

System: System on 7s frameworks refers to the rules, regulations and procedures; both formal and informal rules complement the organization structure. It includes production planning and control system, capital budgeting system. In this company they have separate department for planning and controlling the production activities. Every year the company publishes its annual performances report of the company. Capital budgeting and FIFO Method will be done at the accounts department in the unit itself. Funds will be allocated from the unit itself.

Staff: Staff of the company has hired able people, trained them well and assigned them to the right jobs. Employees are the functional unit of the organization. Their selection, training, placement and induction everything is important for the organizations. The company deals with the process by which employees are recruited, deployed and develop their current position, future up-gradation are doing., Selection, training, rewards, recognition, retention, motivation and assignment to appropriate work are considering.

Department of Management Rajeev Institute of Technology, Hassan 21

JKTYRE &INDUSTRIES Ltd

The company is making selection of employees according to that particular culture and the fact that whether the employees have blended into and accepted the culture or not. In most there were 550 members working in the company. They work together in order to achieve the objectives of the firm. Likewise responsibilities are also started to all the employees of the organization based on many aspects that are taken into the consideration. Each employee is expected to discharge his shares of responsibility with utmost observance.

Shared Values: It refers to the core of fundamental values that are widely shared in the organization and serve as guiding principles that are important. The Values and believes of the Company ultimately guide employees towards valued behavior. The Values might well include simple goal statements in determining corporate destiny. To fit the concept, most people in the organization must share the values. Anjaneya Agro Tech Pvt. Ltd is a customer- oriented organization. The company is maintaining good quality of production system. The product which is given by the Sri Anjaneya Agro-tech Pvt. Ltd has good quality products and the price of the products is also reasonable.

Department of Management Rajeev Institute of Technology, Hassan 22

JKTYRE &INDUSTRIES Ltd

CHAPTER 4 SWOT ANALYSIS

SWOT analysis is a conceptual frame work for the systematic analysis that facilitates external threats and opportunities with the internal weakness and strength of the organization. The organization study was a great learning experience and certainly enabled me for systematic evaluation of the strength, SWOT analysis was due in the course of internship training in the company for simplified purpose and easy reference on overall SWOT analysis of the company as follows: STRENGTH

Over six decades of experience in tyre manufacturing. Self sufficient in tyre production Successful & fast absorption of international technology to suit Indian condition & needs. Well knit distribution network. Tyre is easily available & serviced even in remotest parts of the country.

WEAKNESS In comparison with the global standards, smaller size of plant & hence less economic units. Lower productivity of labour in comparison to world standards.

Out dated labour laws. Proliferation of units. High cost of raw materials.

OPPORTUNITIES Robust economic growth, particularly vehicle production growth resulting in health demand growth for tyre in the feature. Export culture inculcated enabling

THREATS Faster pace of opening up of the economy will increase import of tyre. Reduction in important duties will lead to high volume of type

Department of Management Rajeev Institute of Technology, Hassan 23

JKTYRE &INDUSTRIES Ltd

participation in world tyre market. Excellent brand equity of Indian cross ply/bias truck Tyres in the world market can open market opportunities for radial tyre. Emergence of Indian as a hub for production of small car is expected to give a thrust to auto component & tyre segment.

Improved road infrastructure

imports. Multinationals with financial muscle setting do manufacturing facilities in the country. Concessional import tariffs for countries like china & South Korea under regional trade agreements will lead to additional imports

especially on the golden quadrilateral &north-south, east-west national highway project will result in significant increase in movement of goods & passenger traffic through roads with resultant growth in demand for tyres

Department of Management Rajeev Institute of Technology, Hassan 24

JKTYRE &INDUSTRIES Ltd

CHAPTER 5 ANALYSIS OF FINANCE STATEMENT

In the share holders fund the share capital remains constant in the year 2009 and 2010. The reserves and surplus in year 2009 was 42985368 then it has been increased to 64855499 in the year 2010. Loan funds the year 2009 it was Rs.35,25,10,032 and it has decreased to Rs 33,58,80,171. Deferred tax liability in the year 2009 was Rs.2,51,64,208 and in 2010 it has decreased to Rs. 36,67,656 In the year 2009 the inventories were Rs.23,11,30,388 and it has decreased to Rs.22,88,26,722 in year 2010. In the year 2009 the current assets were Rs.8,41,69,185 ad it has decreased to Rs.6,67,00,508 in the year 2010. Sales of refined oils, solvent extracted oils in the year 2009 was Rs.1,41,37,82,031 and it has decreased in the year 2010 to Rs.94,12,93,385 The profit of the company in the year 2009 was 26902271 and it has been increased to 31915368.

Department of Management Rajeev Institute of Technology, Hassan 25

JKTYRE &INDUSTRIES Ltd

CHAPTER 6 LEARNING EXPERIENCE

Doing internship at Anjenaya Agro-tech Pvt Ltd was a rewarding experience. Inpant training period undergone was for the period of four weeks, where I have learnt so many things about the organization. I reported to Anjenaya Agro-tech Private Ltd which gave instructions on how to behave in the factory premises and instructed me to follow the rules and regulations of the organization. The most significant lessons, which I have learnt from the organization, is that employees are the most valuable assets of the organization and it is very important to keep them satisfied. Being in the organization for four weeks, I have learnt the following disciplines:

Managerial knowledge such as planning, organizing, directing, controlling and

decision making. Production process of the manufacturing of the Rice Bran Oil. Knowledge of rules, regulations, polices, procedures, etc of the company,

which will guide in the work flow.

By this organization I came to know how to motive, counsel and lead the

subordinates. Human resources skills, which indicate ability to deal with subordinates in a

human approach to their problem, develop personal support and team spirit.

Department of Management Rajeev Institute of Technology, Hassan 26

JKTYRE &INDUSTRIES Ltd

I also came to know about the importance of all the departments and its

functions.

PART-B

STATEMENT OF THE PROBLEM

1) GENERAL INTRODUCTION

Successful business relies on many factors, one of which is a reliable inventory management system. Inventory management consists of everything from accurate record keeping to shipping and receiving of products. Inventory management that is properly maintained can keep a companys supply chain running smoothly and efficiently. However, there are many common inventory management problems that can occur. Inventory management problem can interfere with a companys profit and customer service. They can cost a business more money and can lead to an excess of inventory overstock that is difficult to move. Most of these problems are usually due to poor inventory processes and out-of date systems.

2) OBJECTIVES OF THE STUDY:

To assess the efficiency of inventory management in Sri Anjaneya Agro Tech Pvt ltd. To analyze the purchases and stores procedures followed by the company.

Department of Management Rajeev Institute of Technology, Hassan 27

JKTYRE &INDUSTRIES Ltd

3) SCOPE OF THE STUDY:

The purposes of inventory management is to keep the stocks in such a way that neither there is over stocking nor under stocking. This study covers the area of inventory needs and inventory requirement for the organization and it reveals the importance of inventory. And the study focuses on planning of purchasing, handling, storing and accounting inventory. The companys purchase procedure for stores will influence more on the level of inventory of the company. So the study of purchase has vital role to understand the efficient system of the company.

4) METHODOLOGY:

Secondary data have been collected and used to bring out this project report. Secondary data have been collected through annual report and literature.

5) LIMITATIONS OF THE STUDY:

The limitations of the study are as follows: 1. This project has completed with annual reports; it just constitutes one part of data collection i.e. secondary. 2. Lack of data. 3. Inventory data is not proper.

Department of Management Rajeev Institute of Technology, Hassan 28

JKTYRE &INDUSTRIES Ltd

INTRODUCTION OF INVENTORY MANAGEMENT

Inventories constitute the major element in the working capital of many business enterprises. For instance, inventories on an average constitute 60 percent of current assets in public limited companies in INDIA. It is, therefore, necessary to manage inventories efficiently and effectively to avoid unnecessary investments in them .Inventories have a direct Impact on the profits of the firm. Profit is affected by inventories in several ways. Firstly, too much, or too little inventory affects the firms rate of return on investment. Secondly, the rate at which the inventories move through the production on distribution process also affects the cost of doing business. It is therefore, necessary to formulate and initiate inventory policies which will serve as guides in determining the correct level of inventory to maintain and the correct amount of working capital to invest in inventory. To develop adequate inventory plan, it is necessary to have thorough knowledge of the objectives of inventory management and inventory management techniques

DEFINITION OF INVENTORIES

The American institute of Accountants has set forth a definition of inventories which has been accepted both by accountants and finance executives. The definition is as follows: The term inventory designate the aggregate of those items of tangible personal property which (1) are held for sale in the course of business,(2) are in the process of

Department of Management Rajeev Institute of Technology, Hassan 29

JKTYRE &INDUSTRIES Ltd

production for sale, or (3) are to be currently consumed in the production of goods or services to be available for sale. The definition implies that there are four types of inventories; finished goods, work in progress, raw material, and supplies which are consumed in the creation and distribution goods and services.

Raw materials Raw materials are those basic inputs that are converted into finished product through the manufacturing process. Raw materials inventories are those units which have been purchased and stored for future productions.

Work-in-progress Are semi-manufactured products. They represent products that need more work before they become finished products for sale.

Finished goods Inventories are those completely manufactured products which are ready for sale. Stocks of raw materials and work-in-progress facilitate production while stock of finished goods is required for smooth marketing operations .Thus; inventories serve as a link between the production and consumption of goods.

Stores and Supplies: These represent that part of the inventory, which does not become a part of final product but are required for production process. They may be in the form of

Department of Management Rajeev Institute of Technology, Hassan 30

JKTYRE &INDUSTRIES Ltd

cotton waste, oil and lubricants, soaps, brooms, light bulbs etc. Normally, they form a very minor part of total inventory and do not involve significant investment.

The final category includes materials and supplies other than raw materials which are necessary to the normal operation. Let us have a look on Different Inventory Management Views. emphasis role of Inventory Management in different Sectors. Means

OBJECTIVES OF INVENTORY MANAGEMENT

The twin objectives of inventory management are operational and financial. The operational objective means that the materials and spares would be available in sufficient quantity on time so that work is not disrupted for want of inventory. The financial objective means that investment in inventories should not remain idle and minimum amount of capital should be locked in inventories. The objectives of inventory management are summarized as follows:

Operating Objectives 1. 2. To ensure continuous supply of materials To ensure uninterrupted production

4. To minimize risks and losses 5. To ensure better customer service 6. To avoiding stock out danger.

Financial objectives

Department of Management Rajeev Institute of Technology, Hassan 31

JKTYRE &INDUSTRIES Ltd

1. To minimize investment 2. To minimize inventory related cost 3. To ensure economy in purchasing

Physical Inventory Management Meaning: Keeping of goods is also a type of management. Whenever requirements comes from the production department, providing of those required materials in a proper manner & providing those at the specified period, is the main motto of Physical Inventory Management.

Benefits for Holding Inventory: Benefits in Purchasing Benefits in Production Benefits in Work-in-Process Benefits in Sales

Working Capital: The Company is having a working capital facility from the below banks for the add requirement, they are making application for the sanction of the same and hopeful of getting it. 1. 2. Canara Bank, Mandipet branch, Davangere. State Bank of Mysore, Mandipet branch, Davangere.

Department of Management Rajeev Institute of Technology, Hassan 32

JKTYRE &INDUSTRIES Ltd

Financial Inventory Management Meaning: Recording, maintaining and evaluating of stocks in a value terms is known as Financial Inventory Management. In other words valuation of stocks, and

controlling of ordering and holding costs and also maintaining of sufficient valued stocks in Inventory is known as Financial Inventory Management. Financial Inventory Management is again divided into three different categories. 1) Based on Valuation 2) Based on Cost Analysis 3) Based on Financial Statement

1) Based on Valuation

There are number of generally accepted methods of determining the cost of inventories at the close of the accounting period. The selection of a suitable method assumes significance in view of the fact that it has a direct bearing on the cost of goods sold and consequently on profit. Therefore, the method should be selected in the light of probable effects on profits over a period of years. Note: It may not be out of place to mention that once a method is selected, it must be used consistently and cannot be changed from year to year. The discussion here of the methods to value inventory should, therefore be viewed in this perspective.

Department of Management Rajeev Institute of Technology, Hassan 33

JKTYRE &INDUSTRIES Ltd

First in First Out (FIFO) Method: The FIFO method of valuation of inventory is based on the assumption that the inventory is consumed in chronological order, that is, those received first are issued/consumed first and value fixed accordingly. The merit of FIFO method is that the physical flow of materials matches the flow of cost.

Last in First Out (LIFO) Method: Under the LIFO method, the cost of goods sold and the value of closing inventory can be determined only after the final lot of the year has been received. This is because of the assumption underlying the valuation of inventory, according to this method. As the name LIFO suggests, the use of inventory is valued on the basis of the inverse sequence of receipts. Since the LIFO method assumes that the latest item in is the first item out, the current cost of materials are matched with the current selling price/current revenues. This matching of current costs with current revenues is the essence of the argument for the LIFO method.

Average Cost Method: According to average cost method, each purchase is added to inventory and an average cost determined. Materials are charged into cost of sales at this average until another lot is received, when a new average unit inventory cost is calculated. Note: There are so many other than these above methods but most wide usefully methods are these three so here we discussed those three methods only.

Department of Management Rajeev Institute of Technology, Hassan 34

JKTYRE &INDUSTRIES Ltd

2) Based on Cost Analysis

Cost of Holding Inventory: One operating objective of inventory management is to minimize cost. Excluding the cost of merchandise, the costs associated with inventory fall into two basic categories:

1)

Ordering or Acquisition or Set-up Costs, and

2) Carrying Costs. These costs are an important element of the optimum level of inventory decisions.

1) Ordering Cost:

It is the fixed cost of placing & receiving an inventory order. Like

a) Preparing a purchase order or requisition form. b) Receiving,

inspecting & reordering goods received to ensure both

quantity and quality. It is also called as setup cost.

2) Carrying Cost:

The second broad category of costs associated with inventory is the carrying costs. They are involved in maintaining or carrying inventory. The cost of olding inventory may be divided into two categories.

Department of Management Rajeev Institute of Technology, Hassan 35

JKTYRE &INDUSTRIES Ltd

Those that Arise Due to the Storing of Inventory: The main components of this category of carrying costs are (i) storage cost, that is, depreciation, insurance, maintenance of the building and utilities; (ii) insurance of inventory against fire and theft; (iii) deterioration in inventory because of pilferage, fire, technical obsolescence, style obsolescence and price decline; (iv) serving costs, such as labor for handling inventory, clerical and accounting costs.

The Opportunity Cost of Funds: This consists of expenses in raising funds (interest on capital) to finance the acquisition of inventory. If funds were not locked up in inventory, they would have earned a return. This is the opportunity cost of funds or the financial cost component of the cost.

Linking of Costs based and Physical Based Inventory Management: The carrying costs and the inventory size are positively related and move in the same direction. If the level of inventory increases, the carrying costs also increase and vice-versa.

Total Cost: The sum of inventory increases, the carrying costs represent the total cost of inventory. This is compared with the benefits arising out of inventory to determine the optimum level of inventory.

Department of Management Rajeev Institute of Technology, Hassan 36

JKTYRE &INDUSTRIES Ltd

Inventory turnover ratio: The inventory turnover is a measure of the number of times inventory is sold or used in a time period such as a year. The equation for inventory turnover equals the cost of goods sold divided by the average inventory. Inventory turnover is also known as inventory turns, stock turns, turns and stock turnover. And also this establishes the relationship between the cost of goods sold during the year and average inventory held during the year.

Raw materials turnover ratio: Inventory of raw material the inventory turnover ratio is calculated using the following formula

ABC Analysis: ABC analysis [Always Better Control] is an application of the principle of Management by Exception to the field of inventory control. If we look at the inventory mix of a firm, it would constitute of hundreds of items. Most of these items would be inexpensive and the frequency of their use would be less. The remaining

Department of Management Rajeev Institute of Technology, Hassan 37

JKTYRE &INDUSTRIES Ltd

items would be expensive, more frequently used and account for large proportion of firms investment in inventories. It would be an expensive and cumbersome act to adopt a common policy and determination of economic order quantity and reorder point for management of all these items of inventory. In this technique all the items of inventory are classified in three categories viz., A, B and C based on the usage rate, rupee value and criticality of the item. A category items are those inventory items which have maximum usage rate and constitute 70% to 80% of inventory value, but only 5% to 10% of the inventory volume. These type of inventories requires frequent monitoring and strict control. B category items are those inventory items which have moderate value and usage rate and constitute 20% to 25% of inventory value, but only 20% to 30% of the inventory volume. These types of inventories require less monitoring and control. C category items are of low or negligible value and usage rate. The remaining items of inventory representing 5% to 10% of inventory value, but 60% to 70% of the total quantity of inventory fall in this category and require general control.

Process of ABC Analysis Classification: On the basis of expected use, the items of inventory are classified according to their categories and per unit Price of each item is determined.

Department of Management Rajeev Institute of Technology, Hassan 38

JKTYRE &INDUSTRIES Ltd

Ascertainment of Total Cost: The total cost is calculated by multiplying the expected units to be used by the per unit cost.

Rank Determination: Cost-wise rank is determine for each item of inventory. First rank is assigned to the item with the highest total cost.

Computation of Ratio or Percentage: Two ratios/percentages are calculated (i) Percentage of number of units of each item to total units of all items. (ii) Total cost of each item to the total cost of all items.

Determination of ABC Category: ABC categories are formed by combining the items on the basis of their relative values.

Department of Management Rajeev Institute of Technology, Hassan 39

JKTYRE &INDUSTRIES Ltd

ANALYSIS & INTERPRETATION OF DATA

Inventory turnover ratio Table No. 1: Inventory Turnover Ratio Particulars Cost of goods sold Average inventory RATIO 31.03.2008 1611266859 157192350 10.25 31.03.09 1302148855 215571796 6.04 31.03.10 842716738 229978555 3.664

Inventory Turnover Ratio

12 10 8 6 4 2 0 31.03.2008 31.03.09 31.03.10 6.04 3.664 10.25

Table No. 1 deals with the inventory turnover ratio of 3 preceding years from 2008- 10. The ratios are 10.25, 6.04, 3.004 respectively. Which is arrived from cost of goods sold divided from average inventory. The ratio has come down over the years because of a drop in sales.

Department of Management Rajeev Institute of Technology, Hassan 40

JKTYRE &INDUSTRIES Ltd Raw materials turnover ratio

Table No. 2: Raw material turnover ratio Particulars Sales Raw Materials RATIO 31.03.2008 1697358734 13192000 128.66 31.03.09 1413782031 37436018 37.76 31.03.10 941293385 31784289 29.61

Raw material turnover ratio

140 120 100 80 60 40 20 0 31.03.2008 31.03.09 31.03.10 37.76 29.61 128.66

The above table no. 2 & graph we can estimate the raw Material Turnover ratio of three years from 2008-10. We can see that the ratios are coming down as the sales are coming down. This ratio indicates that how fast inventory is used or sold. A high ratio is good from the view point of liquidity and vice versa. A low ratio would indicate that inventory is not used or sold or lost and stays in a store or in the warehouse for a long time.

Table No 3. Consumption price Data of 14 Items of Sri Anjaneya Agro-tech Private limited in the year 2008

Department of Management Rajeev Institute of Technology, Hassan 41

JKTYRE &INDUSTRIES Ltd

Particulars Activated fuller earth Alum N/Flumps Amol decollate Bleaching earth Carbon powder Caustic soda lye Citiric acid Enzymer lecitase nova Hydrated lime Hydrochloric acid Korvi activated earth Phosphoric acid Supharic acid TBHQ food grade chemical Annual usage 120150 1375 9160 135091 8500 71723 9175 920 36145 3480 91350 27245 283860 150 Price 9.86 10.36 30.00 4.79 5.60 23.40 61.47 2109.36 5.39 9.59 14.03 36.54 1.45 471.09 Annual consumption 11,84,679.00 14,245.00 2,74,800.00 6,47,085.89 47,600.00 16,78,318.20 5,63,987.25 19,40,611.20 1,94,821.55 33,373.20 12,81,640.50 9,95,532.30 4,11,597.00 70,663.50 Rank 4 14 9 6 12 2 7 1 10 13 3 5 8 11

Table No. 4 Revised table with items arranged according to their respective ranks Annual consumption 1940611.50 Reordered rank 1 CF 1940611.50 Percentages 20.78 Rank category A

Particulars Enzymes

Department of Management Rajeev Institute of Technology, Hassan 42

JKTYRE &INDUSTRIES Ltd

Caustic soda lye Korvi activated earth Activated fuller earth Phosphoric acid Bleaching earth Citric acid Sulphuric acid Amol decolate Hydrated lime TBHQ food grade chemical Carbon powder Hydrochloric acid Alum N/F lumps 1678318.20 1281640.50 1184679.00 995532.30 647085.89 563987.25 411597.00 274800.00 194821.55 70663.50 47600.00 33373.20 14245.00 2 3 4 5 6 7 8 9 10 11 12 13 14 3618929.40 4900569.90 6085248.90 7080781.20 7727867.09 8291854.34 8703457.34 8978251.34 9173072.89 9243736.39 9291336.39 9324709.59 9338954.59 17.97 13.72 12.68 10.66 6.90 6.04 4.40 2.94 2.08 0.75 0.50 0.35 0.15 A A A B B B C C C C C C C

ABC Analysis 25 20.78 20 15 10 5 0 Caustic soda lye Enzymes Phosphoric acid Activated fuller earth Korvi activated earth Bleaching earth Citric acid 17.97 13.72 12.68 10.66 6.9 6.04

4.4

2.94

2.08

0.75 TBHQ food grade chemical

0.5 Carbon powder

0.35 Hydrochloric acid

0.15 Alum N/F lumps

Sulphuric acid

Department of Management Rajeev Institute of Technology, Hassan 43

Amol decolate

Hydrated lime

JKTYRE &INDUSTRIES Ltd

From the ABC analysis Sri Anjaneya Agro-tech Private limited (here took major group of raw materials for the analysis) it is clear that A class items that is high value item, constitute for 65.15% of annual inventory consumption and B class items constitute 23.66% of total annual value and 23.08% of total item this class is called as middle classed value item. When compared to A class this inventory required less control and C class item constitute 11.17% of total annual value , this is called low value terms. So the control on this inventory does not require when compare to the A and B class items.

Department of Management Rajeev Institute of Technology, Hassan 44

JKTYRE &INDUSTRIES Ltd

Table No 5. Consumption price Data of 13 Items of Sri Anjaneya Agro-tech Private limited in the year 2009

Particulars Activated fuller earth Amol decollate Bleaching earth Carbon powder Caustic soda lye Citiric acid Enzymer lecitase nova Hydrated lime Hydrochloric acid Korvi activated earth Phosphoric acid Supharic acid TBHQ food grade chemical

Annual usage 3290500 19000 172955 31625 59432 25100 4614 473200 13260 232000 21000 225785 330

Price 10.68 30.00 4.01 4.94 25.87 71.13 1147.52 2.83 6.29 17.87 64.52 9.70 495.45

Annual consumption 3514257.00 570000.00 693549.55 156227.50 1537505.84 1785363.00 5294657.28 1339156.28 83405.40 4145840.00 1354920.00 2190114.50 163498.50

Rank 3 10 9 12 6 5 1 8 13 2 7 4 11

Table No. 6: Revised table with items arranged according to their respective ranks

Department of Management Rajeev Institute of Technology, Hassan 45

JKTYRE &INDUSTRIES Ltd

Particulars Enzymes Korvi activated earth Activated fuller

Annual consumption 5294657.28 4145840.00 3514254.00 2190114.50 1785363.00 1537505.84 1354920.00 1339156.00 693549.55 57000.00 163498.50 156227.50 83405.40

Reordered rank 1 2 3 4 5 6 7 8 9 10 11 12 13 CF 5294657.28 9440497.28 12954751.28 15144865.78 16930228.78 18467734.62 19822654.62 21161810.62 21855360.17 22425360.17 22588858.17 22745085.67 22828491.07 Percentages 23.19 18.16 15.39 9.59 7.82 6.73 5.93 5.87 3.04 2.50 0.72 0.68 0.36

Rank category A A A A B B B C C C C C C

earth Sulphuric acid Citric acid Caustic soda lye Phosphuric acid Hydrated lime Bleaching earth Amol decolate TBHQ food grade chemical Carbon powder Hydrochloric acid

Department of Management Rajeev Institute of Technology, Hassan 46

JKTYRE &INDUSTRIES Ltd

ABC Analysis

25 23.19

20

18.16 15.39

15

10

9.59 7.82 6.73

5.93

5.87 3.04 2.5 0.72 0.68 Carbon powder 0.36 Hydrochloric acid

Sulphuric acid

0 Enzymes Activated fuller earth Korvi activated earth

From the ABC analysis Sri Anjaneya Agro-tech Private limited (here took major group of raw materials for the analysis) it is clear that A class items that is high value item, constitute for 66.33% of annual inventory consumption and B class items constitute 20.48% of total annual value and 20.48% of total item this class is called as middle classed value item. When compared to A class this inventory required less control and C class item constitute 13.17% of total annual value , this is called low value terms. So the control on this inventory does not require when compare to the A and B class items.

Department of Management Rajeev Institute of Technology, Hassan 47

TBHQ food grade chemical

Caustic soda lye

Phosphuric acid

Hydrated lime

Bleaching earth

Amol decolate

Citric acid

JKTYRE &INDUSTRIES Ltd

Table No 7. Consumption price Data of 13 Items of Sri Anjaneya Agro-tech Private limited in the year 2010

Particulars Activated fuller earth Amol decollate Bleaching earth Carbon powder Caustic soda lye Citiric acid Enzymer lecitase nova Hydrated lime Hydrochloric acid Korvi activated earth Phosphoric acid Supharic acid TBHQ food grade chemical

Annual usage 219575 7140 88025 10875 60513 10125 1380 482805 13985 166000 16500 184610 170

Price 11.42 30.00 4.06 5.35 23.42 54.63 2822.68 2.90 3.32 18.40 56.12 3.30 4809.90

Annual consumption 2507546.50 214200.00 357381.50 58181.25 1417214.46 553128.75 3895298.40 1400134.50 46430.20 3054400.00 925980.00 609213.00 83283.00

Rank 3 10 9 12 4 8 1 5 13 2 6 7 11

Table No. 8: Revised table with items arranged according to their respective ranks Particulars Annual consumption Reordered CF Percentages Rank category

Department of Management Rajeev Institute of Technology, Hassan 48

JKTYRE &INDUSTRIES Ltd

Enzymes Korvi activated earth Activated fuller 3895298.40 3054400 2507546.50 1417214.46 1400134.50 925980.00 609213.00 553128.75 357381.50 214200.00 83283.00 58181.25 46430.20 rank 1 2 3 4 5 6 7 8 9 10 11 12 13 3895298.40 6949698.40 9457244.90 10874459.36 12274593.86 13200573.86 13809786.86 14362915.61 14720297.11 14934497.11 15017780.11 15075961.36 15122391.56 25.75 20.19 16.58 9.37 9.25 6.12 4.03 3.65 2.36 1.41 0.55 0.38 0.31 A A A A B B B C C C C C C

earth Caustic soda lye Hydrated lime Phosphoric acid Sulphuric acid Citric acid Bleaching earth Amol decollate TBHQ food grade chemical Carbon powder Hydrochloric acid

ABC Analysis

30 25.75 25 20.19 20 16.58 15 9.37 9.25 6.12 5 4.03 3.65 2.36

10

1.41

0.55 TBHQ food grade chemical

0.38 Carbon powder

0.31 Hydrochloric acid

Caustic soda lye

Hydrated lime

Sulphuric acid

0 Enzymes Activated fuller earth Phosphoric acid Korvi activated earth

Department of Management Rajeev Institute of Technology, Hassan 49

Bleaching earth

Amol decollate

Citric acid

JKTYRE &INDUSTRIES Ltd

From the ABC analysis Sri Anjaneya Agro-tech Private limited (here took major group of raw materials for the analysis) it is clear that A class items that is high value item, constitute for 66.33% of annual inventory consumption and B class items constitute 20.48% of total annual value and 20.48% of total item this class is called as middle classed value item. When compared to A class this inventory required less control and C class item constitute 13.17% of total annual value , this is called low value terms. So the control on this inventory does not require when compare to the A and B class items.

Table No 9: Consumption price Data of 13 Items of Sri Anjaneya Agro-tech Private limited in the year 2010 Particulars Activated fuller earth Amol decollate Bleaching earth Carbon powder Caustic soda lye Citiric acid Enzymer lecitase nova Hydrated lime Annual usage 219575 7140 88025 10875 60513 10125 1380 482805 Price 11.42 30.00 4.06 5.35 23.42 54.63 2822.68 2.90 Annual consumption 2507546.50 214200.00 357381.50 58181.25 1417214.46 553128.75 3895298.40 1400134.50 Rank 3 10 9 12 4 8 1 5

Department of Management Rajeev Institute of Technology, Hassan 50

JKTYRE &INDUSTRIES Ltd

Hydrochloric acid Korvi activated earth Phosphoric acid Supharic acid TBHQ food grade chemical 13985 166000 16500 184610 170 3.32 18.40 56.12 3.30 4809.90 46430.20 3054400.00 925980.00 609213.00 83283.00 3 2 6 7 11

Table No. 10: Revised table with items arranged according to their respective ranks Annual consumption 3895298.40 3054400 2507546.50 1417214.46 1400134.50 925980.00 609213.00 553128.75 357381.50 214200.00 Reordered rank 1 2 3 4 5 6 7 8 9 10 CF 3895298.40 6949698.40 9457244.90 10874459.36 12274593.86 13200573.86 13809786.86 14362915.61 14720297.11 14934497.11 Percentages 25.75 20.19 16.58 9.37 9.25 6.12 4.03 3.65 2.36 1.41 Rank category H H H M M M M M M M

Particulars Enzymes Korvi activated earth Activated fuller

earth Caustic soda lye Hydrated lime Phosphoric acid Sulphuric acid Citric acid Bleaching earth Amol decollate

Department of Management Rajeev Institute of Technology, Hassan 51

JKTYRE &INDUSTRIES Ltd

TBHQ food grade chemical Carbon powder Hydrochloric acid 83283.00 58181.25 46430.20 11 12 13 15017780.11 15075961.36 15122391.56 0.55 0.38 0.31 L L L

Table No. 11 Summary of HML analysis for ten items No. of items 3 7 3 % of items 23 54 23 Total annual % of Category H M L

price annual price 9457244.44 62.52 142952541.96 34.78 187894.45 1.24

It is clear that H class items that is high value price items, constitute for 62.52% of annual inventory consumption price, and M class item that is medium level value price that constitute 34.78% of total annual price and L class items that is low price items constitute 1.24%. This shows in Table 10 &Table 11 respectively.

Department of Management Rajeev Institute of Technology, Hassan 52

JKTYRE &INDUSTRIES Ltd

FINDINGS

From the Physical Observation of Inventory Management it was found that the company is having only those materials for which they are having orders in hand. The question of issuing materials LIFO method does not arise. In this industry as supply of rice bran oil are against the customers requirement. Due to increased volume of stock the store manager required to look into storage management so that orderly storage of stocks at Godown can be done. Company has not bifurcated materials like VED or any other method. Holding Cost or Ordering Cost is not applicable in this type of Company by virtue of its business activities. And therefore here there is no question of EOQ, Re-order Level, Lead-time, Safety Stock etc., and it is good for company.

Department of Management Rajeev Institute of Technology, Hassan 53

JKTYRE &INDUSTRIES Ltd

SUGGESTIONS

After the analysis, suggestion could be as follows.

Inventory turnover ratio of Sri Anjaneya Agro Tech Pvt Ltd., in the year

2009-2010 is satisfied but company should try Minimize inventory and Keep the level of inventory according to market demand.

The company should follow the E.O.Q. Model. Since there is a lack of clarity and transparency in the communication so, management should appoint a localite and know the problems of employees and fullfil their needs which further helps the company to maintain a cordial relationship between the union and management As the inventory ratio is having a decreasing tendency, the company is not able to move the stocks efficiently. The company should concentrate on inventory management system and utilize the inventory efficiently

Department of Management Rajeev Institute of Technology, Hassan 54

JKTYRE &INDUSTRIES Ltd

The advancement in technology is improving day by day. The company has to train its existing employees with the advancement technologies so that they are well equipped with the improved version of technologies. This will help the organization to increase its production. The industry is still running with the old machineries which take a long time while processing the raw materials. There have been the invention of many advanced version of machineries and certain machineries come with computer aided programmes. The company can build a strategy in purchasing these types of advanced machineries so that it makes the work easier providing a major increase in the production. This will also help the company in increasing its profit share in the market and can also give a stiff competition for its competitors. Let me conclude by saying that great businesses are never built on the quick sands of opportunism. I reiterate that, if living by our values means, perhaps growing at a pace slower than we would otherwise have liked, so be it. For us, leadership lies at the heart of knowing what we stand for.

Department of Management Rajeev Institute of Technology, Hassan 55

JKTYRE &INDUSTRIES Ltd

CONCLUSIONS

We have discussed inventory management of Akshath Refined Rice Bran Oil with special reference to Sri. Anjaneya Agro Tech (P) Ltd., throughout the course, my main concern was to analyses the inventory stores and give suggestion to the firm for inventory control system.

Department of Management Rajeev Institute of Technology, Hassan 56

JKTYRE &INDUSTRIES Ltd

RECOMMENDATIONS

An Analysis of Inventory control system, procedure and vendor rating analysis of Sri Anjaneya Agro Tech Private limited. Has drawn the following facts

Inventory control system: A Sri Anjaneya Agro Tech Private limited is second largest rice bran oil producing industry in India. As per the study, the raw materials will increase the efficiency of the inventory performance and drastically reduce the transportation cost. 1) The reduction of inventory holding levels will considerably reduce the overall inventory requirements of the company. 2) The company should follow the E.O.Q method in maintenance the stock level 3) Implementation of better and new information system entrepreneur resource planning software packages as discussed will cater to the additional information requirements of the company which in turn will improve the efficiency of management of inventory control system. 4) For making ABC analysis usually companies consider value and consumption. In Sri Anjaneya Agro Tech Private limited also they are consider the value and consumption of the raw materials. This is one of the best evaluation of ABC analysis in which the company has developed 5) The company is making open order for the whole year to the supplier and the inventories are produced by the rice bran according to weekly schedule.

Department of Management Rajeev Institute of Technology, Hassan 57

JKTYRE &INDUSTRIES Ltd

BIBLIOGRAPHY

Financial management (Prasanna Chandra) Cost accounting and financial management(ICAI MATERIAL) Company Broachers. Company Reports.

Website: www.akshathoil.com www.google.com

Department of Management Rajeev Institute of Technology, Hassan 58

JKTYRE &INDUSTRIES Ltd

ANNEXURE

SRI ANJANEYA AGRO-TECH PRIVATE LIMITED

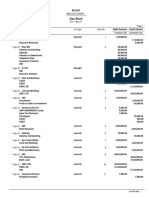

RMC Link Road, Bamboo Bazar, Davangere. PROFIT AND LOSS ACCOUNT FOR THE YEAR ENDING MARCH 31, 2008 Particulars INCOMES Sale of Refined Oils, Solvent Extracted oils, oil cakes, Rice Bran and De-Oiled Cakes/Rice Bran, Broken Rice, By products of Refinery Other Incomes Increase (Decrease) in Inventories TOTAL EXPENDITURE Cost of Raw Materials Consumption Purchases Employees Remuneration and Benefits Other Manufacturing Expenses Administrative, Selling and Other Expenses Finance Costs Depreciation TOTAL Profit (Loss) Before Income Tax Less: Provision for Taxation i. Current Tax ii. Fringe Benefit Tax iii. Deferred Tax M N 8,42,781 49,12,245 94,70,48,411 76,56,57,341 2,11,64,873 74,48,275 5,16,29,633 6,57,30,990 2,55,98,335 93,77,118 94,66,06,565 4,41,845 68,266 (2,14,96,552) (2,14,28,286) 6,26,671 22,62,347 1,41,66,71,049 1,16,20,33,954 2,10,10,545 7,615,283 6,43,44,647 11,21,50,104 3,02,25,830 95,89,711 1,40,69,07,074 97,00,975 9,93,658 53,802 35,70,801 46,18,261 SCH L Year ended 31.03.2010 94,12,93,385 Year ended 31.03.2009 1,41,37,82,031

O O P Q Q Q E

Department of Management Rajeev Institute of Technology, Hassan 59

JKTYRE &INDUSTRIES Ltd

Profit (Loss) After Income Tax Add/Less: Prior Period and Extra Ordinary Items Add: Profit (Loss) Brought Forward

2,18,70,131 2,18,70,131 3,19,15,368 5,37,85,499 5,37,85,499 R

5,082,714 (69,617) 50,13,097 2,69,02,271 3,19,15,368 3,19,15,368

Balance Carried to Balance Sheet Notes on Accounts

Schedules L to Q and E and R form an integral part of the Profit and Loss Account

For and on behalf of the Board

A.S. Veeranna Chairman

A.K. Prashant Managing Director

A.C. Chetak Director

S. S. Hurkadli Partner

As per our report of even date For Santhappa & Co., Chartered Accountants M. No. 032400

Date: 02.06.2010

SRI ANJANEYA AGRO-TECH PRIVATE LIMITED

Department of Management Rajeev Institute of Technology, Hassan 60

JKTYRE &INDUSTRIES Ltd

RMC Link Road, Bamboo Bazar, Davangere.

BALANCE SHEET AS AT MARCH 31, 2008 Particulars SOURCES OF FUNDS: 1. Share Holders Funds: a) Share Capital b) Reserves & Surplus 2. Load Funds a) Secured Loans b) Unsecured Loans 3. Deferred TAs Liability TOTAL APPLICATION OF FUNDS 1. Fixed Assets: a) Gross Block b) Less: Depreciation Net Block: 2. Capital work in progess 3. Investments : a) National Savings Certificates 4. Current Assets, Loans and Advances: A) Current Assets: i) Inventories ii) Sundry Debtors iii) Cash in Hand iv) Cash at Bank B) Loans and Advances (a+b) Less: C) Current Liabilities and Provisins: i) Current Liabilities ii) Provisions J K 6,58,33,048 51,51,454 F G I I H 23,11,30,388 7,87,46,492 1,91,969 52,30,724 5,203,724 83,06,680 SCH As at 31.03.2009 19,230,000 As at 31.03.2008

A B C D

19,230,000 42,985,368 62,215,368 24,06,81,271 11,18,28,761 35,25,10,032 2,51,64,208 43,9889,608

22,24,69,835 3,66,96,256 18,57,73,579 14,84,278 10,000

Department of Management Rajeev Institute of Technology, Hassan 61

JKTYRE &INDUSTRIES Ltd

(c) Net Current Assets [(a+b)-c] 5. Miscellaneous Expenditure : (to the extent not written off a) Preliminary Expenses Total R Notes on Accounts: Schedules A to K and R form an intergral part of the Balance Sheet For and on behalf of the Board 43,98,89,608 7,09,84,502 25,26,21,751

Department of Management Rajeev Institute of Technology, Hassan 62

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Rural TourismDokument30 SeitenRural TourismWaleed Abdalla El SayedNoch keine Bewertungen

- Pakistan Exams BC Bank AccountsDokument4 SeitenPakistan Exams BC Bank AccountsGH473Noch keine Bewertungen

- About ATA CarnetDokument4 SeitenAbout ATA CarnetRohan NakasheNoch keine Bewertungen

- Strategic ManagementDokument22 SeitenStrategic ManagementAhmad Azhar Aman ShahNoch keine Bewertungen

- Deed of Undertaking - AbelidasDokument2 SeitenDeed of Undertaking - AbelidasatazanjearickNoch keine Bewertungen

- G.O. 361-I&prDokument3 SeitenG.O. 361-I&prBalu Mahendra SusarlaNoch keine Bewertungen

- Assignment of Career PlanningDokument10 SeitenAssignment of Career PlanningShaon Salehin100% (1)

- Capital Alert 6/13/2008Dokument1 SeiteCapital Alert 6/13/2008Russell KlusasNoch keine Bewertungen

- MemosDokument42 SeitenMemosRhod Bernaldez EstaNoch keine Bewertungen

- Group Directory: Commercial BankingDokument2 SeitenGroup Directory: Commercial BankingMou WanNoch keine Bewertungen

- The Effect of Management TrainingDokument30 SeitenThe Effect of Management TrainingPulak09100% (1)

- Bharti Realty Report - FinalDokument89 SeitenBharti Realty Report - FinalArnob G MazumdarNoch keine Bewertungen

- International Journal of Euro-Mediterranean Studies, Volume 3, 2010, Number 1Dokument164 SeitenInternational Journal of Euro-Mediterranean Studies, Volume 3, 2010, Number 1goblin1313Noch keine Bewertungen

- Uab AugimitaDokument1 SeiteUab Augimitaozel tekstilNoch keine Bewertungen

- Ahrend Sen 2012Dokument12 SeitenAhrend Sen 2012sajid bhattiNoch keine Bewertungen

- Quizzes Property Combined Questions and AnswersDokument10 SeitenQuizzes Property Combined Questions and AnswersCars CarandangNoch keine Bewertungen

- Banks Guarantee Rules Under UNCITRALDokument6 SeitenBanks Guarantee Rules Under UNCITRALjewonNoch keine Bewertungen

- Isa 315 (Revised), Identifying and Assessing The Risks of Material Misstatement Through Understanding The Entity and Its EnvironmentDokument5 SeitenIsa 315 (Revised), Identifying and Assessing The Risks of Material Misstatement Through Understanding The Entity and Its EnvironmentDlamini SiceloNoch keine Bewertungen

- Pepsi Cola Brand ArchitectureDokument13 SeitenPepsi Cola Brand ArchitectureAyrushNoch keine Bewertungen

- C Hanaimp142Dokument2 SeitenC Hanaimp142karamananNoch keine Bewertungen

- Oral Communication - Noise Barriers To CommunicationDokument24 SeitenOral Communication - Noise Barriers To Communicationvarshneyankit1Noch keine Bewertungen

- CreditMangerEurope Number 4 - 2013Dokument40 SeitenCreditMangerEurope Number 4 - 2013Anonymous bDCiOqNoch keine Bewertungen

- T3.Hull Chapter 10Dokument11 SeitenT3.Hull Chapter 10Abhishek Gupta100% (1)

- United States Court of Appeals Second Circuit.: Nos. 256-258. Docket 27146-27148Dokument16 SeitenUnited States Court of Appeals Second Circuit.: Nos. 256-258. Docket 27146-27148Scribd Government DocsNoch keine Bewertungen

- Lecture 2 OrganizationalcommunicationDokument12 SeitenLecture 2 OrganizationalcommunicationAdilaAnbreenNoch keine Bewertungen

- E-Way Bill: Government of IndiaDokument1 SeiteE-Way Bill: Government of IndiaAtendra SinghNoch keine Bewertungen

- Day Book 2Dokument2 SeitenDay Book 2The ShiningNoch keine Bewertungen

- Brics EconomyDokument36 SeitenBrics EconomyTushar PatilNoch keine Bewertungen

- Beauty salon business transactionsDokument13 SeitenBeauty salon business transactionsMariam AyyadNoch keine Bewertungen

- Kaizen Management for Continuous ImprovementDokument39 SeitenKaizen Management for Continuous ImprovementSakshi Khurana100% (4)