Beruflich Dokumente

Kultur Dokumente

Hunt&Angulo 1999 Base Lining Boulders

Hochgeladen von

swhuntOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Hunt&Angulo 1999 Base Lining Boulders

Hochgeladen von

swhuntCopyright:

Verfügbare Formate

From: Hunt, S.W. and Angulo, M., 1999.

Identifying and Baselining Boulders for Underground Construction, Geo-Engineering for Underground Facilities, Proceedings of Third National Geo-Institute Conference, University of Illinois at Urbana-Champaign, ASCE Geotechnical Special Publication No. 90, pp 255-270.

Identifying and Baselining Boulders for Underground Construction Steven W. Hunt1 and Mauricio Angulo2 Abstract This paper focuses on identification of boulders during subsurface exploration and on baselining of boulder quantities for construction of underground facilities. Comments are provided on the sensitivity and reliability of conventional and other subsurface exploration methods in identifying boulders based on a literature study and survey sent to exploration drillers. Geologic assessment and documentation of drilling observations are two keys to boulder identification. Boulder quantities may be baselined by utilizing statistical relationships between boulder indications in boreholes and quantities encountered in excavations, experience databases, and probabilistic methods of data evaluation. Introduction Boulders are often a cause of significant excavation difficulty for many shafts and soft-ground tunnels. They are a major concern when micro-tunneling. They can result in delays, lost ground problems, face instability and tunnel alignment difficulty (Cording et al., 1989; Tarkoy, 1994). A 1984 study of many tunnels found that boulders and other obstructions accounted for approximately 12 percent of tunneling problems and are a common cause of differing site condition claims (US National Committee on Tunneling Technology, 1984). Schmidt (1974) listed obstructions (including boulders) as one of five high priority parameters to be assessed in a subsurface investigation for a tunnel project. To appropriately allocate risks and minimize unnecessary claims for extra work, various tunneling committees and support organizations have concluded that pertinent subsurface parameters such as boulder quantities should be thoroughly investigated during design and baseline quantities included in contract documents for use by bidders. The culmination of this effort is an American Society of Civil Engineers guideline document entitled Geotechnical Baseline Reports for Underground Construction

1 2

P.E., M. ASCE, Senior Geotechnical Engineer, Harza Engineering Company, Milwaukee, WI 53202 Ph.D., M. ASCE, Geotechnical Engineer, Harza Engineering Company, Chicago IL, 60606-6392 255

256

GEO-ENGINEERING FOR UNDERGROUND FACILITIES

(Technical Committee on Geotechnical Reports of the Underground Technology Research Center, 1997). The guideline explains how baselining may be performed. The focus of this paper is on baselining boulder quantities. components to boulder baselining are presented: Three primary

1. Researching available geologic and excavation case history information. 2. Properly monitoring and documenting boulder signs during subsurface exploration. 3. Estimating boulder quantities based on empirical correlations with boring data, statistical databases, and probabilistic methods. A boulder is defined as a stone or rock fragment that has a diameter or width of at least 300 mm (12 inches). Boulder properties of most interest to underground professionals are considered to be: Frequency volumetric density, occurrence per foot of tunnel (probably the most important property to baselined since it directly affects excavation effort and cost). Distribution random (scattered) or geologically concentrated (lags or nests). Size approximate diameter or width, length and depth (many tunnel boring machines [TBMs] can not process boulders that are larger than approximately 20 to 30 percent of the excavated diameter). Shape spherical, cubic, slaby, irregular, and angularity or roundness of corners (affects breaking by TBM cutters and disks and passage through mucking system). Composition rock mineralogy, compressive strength, lithology, degree of weathering (affects ease of breaking by TBM cutters and the rate of cutter wear or the effort needed for manual drilling and splitting). Matrix soil composition density, strength, grain-size distribution, permeability (affects ability to push partially contacted boulders aside, to hold them rigid for fracturing by disc cutters, to dig around them with excavating tools or to control soil and groundwater inflows at the heading when exposing them for drilling and splitting). Geologic Setting The distribution and properties of boulders within a soil unit should be assessed in conjunction with the geology of the formations involved. Baselining of boulders based on soil type, e.g. silty clay or gravelly sand, may not result in reasonable correlations. Instead, boulder occurrence should be assessed for individual geologic soil units with consideration of common geologic characteristics and anomalies. The importance of using a geologic framework when assessing boulder occurrence (and other parameters that affect tunneling) has been explained by Essex (1993), Gould (1995), Heuer (1978), Legget (1979), Terzaghi et al. (1996) and others.

257

GEO-ENGINEERING FOR UNDERGROUND FACILITIES

Typical characteristics of boulders and likelihood of occurrence within various glacial units and morphological features are discussed by Flint (1971). If available, local geologic papers should be studied to better understand the regional structure of geologic features and typical characteristics of the units and formations that are likely to be encountered. The previously listed boulder properties can be better understood and explained in reports, and baselined if subsurface exploration data is evaluated in a geologic context. Subsurface Exploration for Identifying Boulders Subsurface exploration is the most important component of baselining boulders for a specific project location or alignment. It is the source of site-specific data on geologic conditions and of indications that boulders are present. Despite its importance, cobble and boulder presence may not be addressed and quantities may often be underestimated within many geotechnical reports (Gould, 1995 and Cording et al., 1989). Poor exploration practices often fail to identify boulders where they are abundant. Tarkoy (1992) cites poor subsurface exploration and reporting practices as a primary cause of unanticipated boulder conditions and related tunneling problems and claims. Hunt and Fradkin (1991) describe a Milwaukee project where drilling was not monitored in the field by an engineer or geologist. As a result, the logs of 16 borings that were drilled into bedrock through moderately bouldery till failed to report any boulders. In addition to missing scattered boulders in an upper till, an underlying bouldery lodgment till was misinterpreted as weathered bedrock. Excavation and ground support problems at two shafts resulted in differing site condition claims and extra costs over $500,000. Tarkoy (1994) cites three case histories where borings did not properly identify boulders, bedrock or both. Wallis (1993) describes a Seattle microtunneling project where boulders were not anticipated by the geotechnical report, but where frequent cobbles and small boulders were encountered. Abbott (1995) describes another Seattle project where no boulders were reported on boring logs, but where frequent boulders up to 0.6 m in size stopped and severely damaged a 1.17 m Isecki Unclemole. Stoll (1976) describes a Michigan project where 17 borings failed to indicate any boulders but where numerous boulders were encountered during tunneling. Many more examples can be cited. A study of these projects and other references (Gould, 1995; Osterberg, 1978) suggests the following reasons why many subsurface investigations and geotechnical reports fail to adequately predict boulder occurrence: 1. Lack of geologic assessment in planning, evaluating and reporting of subsurface exploration data resulting in a poor understanding of the geologic setting, character and uncertainties.

258

GEO-ENGINEERING FOR UNDERGROUND FACILITIES

2. Lack of a phased exploration program that progressively reduces key uncertainties that remain from the previous phase. 3. Lack of focused drilling instructions and monitoring of drilling by a geotechnical engineer or geologist (or one with proper training and experience). 4. Inadequate documentation and reporting of drilling observations and historical information. 5. Over reliance on drilling refusal or extremely high Standard Penetration blow counts as the primary indicators of cobbles and boulders. 6. Insufficient exploration budget (including boring spacing) and lack of redundancy in exploration methods causing over-reliance on only conventional drilling methods that are often chosen for speed and cost of drilling rather than sensitivity to cobbles and boulders. Conventional Drilling and Sampling Methods Drilling and sampling methods that are selected affect the relative volume of ground sampled, the sensitivity of drilling tools to boulder presence and the ability to recover boulder samples. Very little guidance was found in the literature on selecting drilling and sampling methods that help improve cobble and boulder identification. To supplement this deficiency, a survey on boulder drilling and identification was sent to 15 subsurface exploration drillers and drilling managers in Wisconsin, Michigan and Illinois. Five responses were received. The results are summarized below: 4 of 5 said that a 205 mm (8-inch) hollow-stem auger is usually more sensitive to cobble and boulder presence than 75-100 mm (3-4 inch) rotary wash drilling. 4 of 5 said that smaller, lower torque drill rigs are generally more sensitive to cobbles and boulders than bigger, higher torque drill rigs. 4 of 5 said that larger 150-200 mm (6-8 inch) wash rotary drilling would be more suitable for identifying cobbles and boulders than similar size auger drilling. 5 of 5 said that larger diameter and stiffer rotary wash drill rods help increase sensitivity to cobbles and boulders by minimizing deflections and bending. 5 of 5 said that cobbles and boulders could still be detected (despite less sensitivity) when using a high torque rig with augers equipped with tungsten carbide fingers. 3 of 5 said that augers often wrap around some cobbles and boulders thereby decreasing sensitivity. 5 of 5 said that they could distinguish between gravel and cobbles based on the nature of chatter and degree of rig jumping. 4 of 5 said that they could distinguish between cobbles and boulders based on the nature of chatter and degree of rig jumping. 3 of 5 said that very high (refusal or near refusal) Standard Penetration Test blow counts are not a reliable indicator of cobbles and boulders unless drill rig chatter also suggests the presence of rocks larger than gravel.

259

GEO-ENGINEERING FOR UNDERGROUND FACILITIES

4 of 5 said that drilling with a rock-coring barrel is not a better method than auger or rotary wash drilling for identifying cobbles and boulders. 3 of 5 said that boulder samples could be obtained by use of rock coring, but warned that if the cobble or boulder moves the bit may be destroyed or the core barrel may become stuck. 4 of 5 said that boulder thickness could be better determined by auger or rotary wash drilling than by rock coring. 3 of 5 said that documenting drilling rates (e.g. mm/min) was not practical and not a good indicator of relative drilling resistance.

Boring Spacing An appropriate spacing between borings for boulder identification is dependent on many factors including nature and complexity of the site geology, availability of previous borings and subsurface experience, the borehole diameter, use of supplementary exploration methods (such as probe holes or seismic reflection/refraction), tunnel depth, anticipated tunneling methods and subsurface exploration budget. A National Research Council subcommittee on geotechnical site investigations found that an average boring spacing of approximately 80 m (260 feet) was completed for 84 non-mountainous tunnel projects studied (US National Committee on Tunneling Technology, 1984). To further reduce tunneling risks and provide better overall exploration results they recommended an average of 1.5 linear feet of borehole per route foot of tunnel alignment. This converts to a much closer average spacing of 20 m (66 feet) assuming average borehole depths of 30 m (100 feet) are appropriate. Terzaghi et al. (1996) recommend a minimum spacing of 30 to 60 m for subway [tunnel] projects. Essex (1993) recommends a minimum of one borehole per shaft and a maximum spacing from 46 m to 61 m (150 to 200 feet) for micro-tunnel and pipe jacking projects. Klein (1996) made essentially the same recommendation, but with the maximum spacing at 91 m (300 feet). Horn and Ciancia (1989) provide a detailed evaluation of the effect of boring spacing variations from 3 m to 30 m (10 to 100 feet) on the number of boulders encountered within a well documented, 91 m (300 foot) long bouldery stretch of the Red Hook Intercepting Sewer in New York. Although they found that more borings hit boulders as the spacing decreased, the percentage of borings hitting boulders did not increase appreciably. An average spacing of 30.5 m (100 feet) was determined to be reasonable for that project. They also concluded that borings should be spaced closer in the vicinity of geologic features that may contain boulder concentrations. Stoll (1976) found from a study of randomly distributed 305 mm (1 foot) diameter boulders projected onto a plane, that about five times as many 102 mm (4-inch) diameter holes as 914 mm (3-foot) diameter holes are required to achieve the same degree of certainty on boulder concentrations. This study demonstrates that borehole diameter should also be considered when determining the spacing of borings and probes.

260

GEO-ENGINEERING FOR UNDERGROUND FACILITIES

Large Diameter Auger Drilled Shafts Large diameter, 760 mm to 1.22 m (2.5 to 4 feet), auger drilled shafts appear to be a very effective method of boulder exploration. The unit volume explored for a 914 mm (3 feet) diameter drilled shaft is over 80 times greater than for a 102 mm (4 inch) diameter borehole. Cobbles and boulders up to approximately 305 mm (1 foot) can be removed and examined using a 914 mm (3 feet) diameter single helix or bucket auger such as commonly used for drilled shaft construction (Stoll, 1976). In addition, temporary casings can be set to allow ground conditions to be examined and sampled at the shaft base or within windows cut within the casing (Brierley et al., 1991; Smirnoff and Lundin 1985). Selected large diameter holes could be left accessible through a bidding period to allow contractors and their geotechnical advisors to directly examine ground conditions. Alternatively, the holes can be converted to wells and utilized for full scale pump tests. Multiple uses should help improve cost-effectiveness of large diameter drilled shafts in an exploration program. Stoll (1976) demonstrated the value of large diameter holes. On one southeastern Michigan project, 17 convention boreholes failed to identify one boulder. However, fifty percent of the drilling logs from 150 dewatering wells having a 914 mm (3 foot) diameter indicated boulder presence. Stoll found from a study of randomly distributed 315 mm (1 foot) diameter boulders projected onto a planar surface, that when a boulder concentration ranges from 1 to 16 percent, 914 mm (3 foot) diameter holes encounter boulders from three to five times more often than do 102 mm (4-inch) diameter holes. Hammer and Rotosonic (Percussive) Drilling References indicate that percussive hammer and rotosonic drilling methods are effective at penetrating through bouldery soil at faster and more economical rates than by conventional drilling methods. Brierley et al. (1991) describe exploration in bouldery ground on a Tempe, Arizona project using a hammer drill. The method involved driving of a double-walled casing with a diesel pile hammer that cuts and fractures the soil encountered. The material encountered was removed by air forced down the casing annulus and up the inner casing. The resulting disturbed sample material and measured penetration rates were analyzed by a geologist to estimate the nature of cobbles, boulders and matrix soil encountered. Hammer drilling allows boulder presence and composition to be determined, but may not provide adequately reliable information on boulder size and frequency. Rotosonic drilling involves advancement of a casing with a drill head having tungsten carbide embeds. The drill head is vibrated at a high frequency and progressively rotated downward. As the casing cuts through the ground, an inner core barrel advances around the cut material to obtain continuous core samples from 75 to 228 mm (3 to 9inches) in diameter and 0.3 to 6.1 m (1 to 20 feet) in length (Davis and Oothoudt, 1997). Case histories show that rotosonic drilling can obtain core samples of cobbles and boulders at relatively high production rates. Boulder composition and size (chord length

261

GEO-ENGINEERING FOR UNDERGROUND FACILITIES

cored) can be determined. In addition to its ability to core boulders, rotosonic drilling is well suited for piezometer installation and environmental sampling. Exposed Cuts, Test Pits, Shafts and Pilot Tunnels Available boulder information from large excavations in the vicinity of a site should be gathered and reviewed to help plan future subsurface explorations and to provide data for boulder baselining. Relatively large excavations (e.g. shafts, test pits, cofferdams, pilot tunnels and roadway cuts) or eroded bluffs that expose geologic units of interest provide a good opportunity to determine cobble and boulder characteristics within relatively large volumes of soil. If available, case histories of previous cofferdam, shaft and tunnel excavations that documented cobble and boulder occurrence within the same or a similar geologic units are also a valuable source of information. Geophysical Methods Geophysical methods may in some cases successfully complement conventional drilling and sampling, but are generally ineffective for identifying and quantifying boulders. Geophysical methods including active seismics (surface and borehole crosshole reflection/refraction), ground penetrating radar, magnetometer surveys, resistivity and others have been performed along tunnel alignments with limited success. Past discussions on use of geophysical methods in tunneling are presented in Alsup (1974) and Schmidt (1974). De Pasquale and Pinelli (1998), Hindle (1995), and Miller (1996) present more recent discussions of geophysical use on tunnel and directional drilling projects. In general, geophysical methods have the highest resolution at shallow depths (less than 3 to 10 m) and where significant contrast in properties exists between boulders and the soil matrix. In addition, signal penetration is limited to shallow depths for some methods. For example, ground penetrating radar penetration is generally limited to 2 to 3 m depths in clay and saturated granular strata. Most tunnels are deeper than 3 m and are overlain by some clay or saturated strata. Furthermore, boulders at the tunnel zone may be embedded in dense soils that provide poor contrast in reflective properties. Surface application of seismic reflection/refraction is perhaps the most useful of the geophysical methods, particularly when the tunnel zone is within 10 m of bedrock. Although boulders are unlikely to be identified, this method can be effective at identifying variations between boreholes in the level of bedrock and possibly of a dense bouldery till surface. Knowing the proximity of the tunnel zone to bedrock is an important factor in baselining boulders because bouldery ground is often more likely within approximately 3 m of bedrock. Monitoring, Documenting and Reporting of Drilling Observations and Data Monitoring, documenting and reporting of drilling observations and data are critically important aspects of identifying cobble and boulder presence, (Brierley, 1996;

262

GEO-ENGINEERING FOR UNDERGROUND FACILITIES

Gould, 1995; Legget, 1979; Neyer, 1985; Osterberg, 1989). Despite its importance, many subsurface exploration programs for tunneling projects are performed without field monitoring by an experienced geologist or geotechnical engineer. Drillers should not be relied upon to document their observations of cobble and boulder presence. They are busy operating the equipment and trying to be profitably efficient at advancing the borehole. They are generally reluctant to spend extra time carefully describing depths and indications of cobbles and boulders. However, most drillers are willing to orally report their cobble and boulder observations and assessments of relative drilling resistance. With good cooperation between the driller and a monitoring professional, more accurate and thorough information can be recorded. In addition, a monitoring professional should be able to make timely decisions on drilling program changes such as sample type and interval in response to the conditions encountered. Boring Logs Final boring logs included in geotechnical reports often fail to adequately report information on drilling methods and observations such as chatter, bouncing, relative drilling resistance and estimated boulder and boulder zone thickness (Gould, 1995). Even if drilling information and observations are fully documented on field logs, its value is diminished unless it is transferred to the final logs. Field logs are seldom conveniently available to bidders and their consultants. Therefore, the final boring logs should contain detailed information on drilling behavior and boulder observations (Neyer, 1985). Limited Milwaukee-Chicago Area Boulder Experience in Tunnels Records from five tunneling projects in the Milwaukee and Chicago metropolitan areas were examined to assess boulder quantities encountered and boulder indications on boring logs. Pertinent data from these projects is summarized in Table 1. These tunnels were mostly mined within Wisconsinan age Oak Creek/Wadsworth till and associated outwash and ice-margin soils that are more than 3 m (10 feet) above bedrock. Without other guidance, the boring log boulder data for these projects seems to suggest that only a small number of boulders might be expected during tunneling. The percentage of borings hitting boulders ranged from 0 to 35 percent. The percentage of total length of boulders drilled as compared to lengths bored within potentially bouldery till, outwash or ice-margin soils varied from 0 to 3.5 percent. The reported number of boulders encountered during tunneling on the project segments studied varied from as few as 5 to as many as 282. Boulder sizes generally ranged from 0.3 to 1.5 m (1 to 5 feet) diameter. Shapes mostly ranged from spherical to rounded corner cubes. Boulder compositions were not well documented, but are estimated to have been approximately two-thirds erratics (non-native igneous boulders) and one-third native dolomite boulders. The average number of boulders ranged from 0.2 to 3.4 and averaged 1.9 per 30 m (100 feet) of tunnel. The percentage of estimated boulder volume relative to total excavated volume ranged from 0.01 percent to 0.72 percent (boulder volume was estimated as 0.7 D3 which is approximately the average

263

GEO-ENGINEERING FOR UNDERGROUND FACILITIES

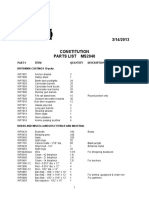

Table 1 Limited Milwaukee and Chicago Area Boulder Experience

Case No. Case Name 1 Milwaukee, Interplant Solids Pipeline 2295 (7529) 2.29 (7.5) 16 143.3 (470) 2.9% 7 25% 232 3.1 7.1 49.0 44.3 (58.0) 0.47% 1.08% 2 Milwaukee, South Pennsylvania Ave. MIS 2498 (8195) 1.40 (4.6) 44 131.4 (431) 3.5% 25 25% 282 3.4 9.0 27.1 27.4 (35.9) 0.72% 1.82% 3 Milwaukee, Ramsey Avenue Relief Sewer 941 (3088) 1.00 (3.3) 8 125.9 (413) 0.4% 1 12.5% 7 0.3 0.3 7.0 0.6 (0.8) 0.08% 0.08% 4 Milwaukee, CT-7 Collector, Bruce St. 656 (2151) 3.54 (11.6) 8 82.0 (269) 0.0% 0 0% 5 0.2 0.2 1.0 0.6 (0.8) 0.01% 0.01% 5 Elgin IL, Northeast Interceptor 1313 (4308) 1.98 (6.5) 17 77.1 (253) 2.4% 8 35% 112 2.6 2.6 32.3 19.3 (25.2) 0.35% 0.35%

Tunnel Length, m (ft) Excavated Diameter, m (ft) No. of Borings Avg. Boring Spacing, m (ft) % Boulder Length Drilled in Borings No. of Boulders Hit By Borings % Borings Hitting Boulders No. of Boulders In Tunnel Avg. Boulders per 30m (100 ft) Avg. Till Boulders per 30m (100 ft) Max. Boulders per 30m (100 ft) Estimated Boulder Volume, m3 (yd3) Avg. % Boulders By Volume Avg. % Boulders By Volume Mined in Till/Outwash/ Ice-Margin Max % Boulders By Volume, 60m (200) Segment +/-

10.52%

5.11%

1.21%

0.03%

1.12%

264

GEO-ENGINEERING FOR UNDERGROUND FACILITIES

volume of a sphere with diameter D and a cube with width D). At four of the projects (Cases 1, 2, 3 and 5) 10 to 60 m (30 to 200 foot) long tunnel segments encountered boulder concentrations (nests and lag zones) that accounted for much of the total boulder quantities. Maximum boulder volume concentrations by volume within 60 m (200 foot) long segments ranged from 0.03 to 10.52 percent. The limited number of Milwaukee-Chicago area tunneling projects evaluated provide some useful information for baselining boulders, particularly in the study area. A comparison of boulder volume mined to boulder length drilled in borings is shown in Figure 1. The normalized percent boulder length drilled in borings (x-axis) was computed as the percent boulder length drilled in borings times the average boring spacing in feet divided by 30.5 m (100 feet). The percentages of both the boulder length drilled in borings and volumes of boulders to volumes of tunnel excavated are limited to the potentially bouldery soils encountered, i.e. till, outwash and ice-margin units. Although based on only five cases, Figure 1 shows that the data points fall reasonably close to a linear trend line. This relationship could be used as a guideline for estimating the boulder volume likely to be encountered when tunneling through potentially bouldery glacial soil.

2.0%

Average Percent Boulders By Volume Mined in Till/Outwash/Ice-Margin Units

1.8% 1.6% 1.4% 1.2% 1.0% 0.8% 0.6% 0.4% 0.2% 0.0% 0.0% 2.0% 4.0% 6.0% 8.0% 10.0% 12.0% 14.0% 16.0%

Normalized Percent Boulder Length Drilled in Borings

Figure 1. Boulder Volume from Normalized Length Drilled in Borings

265

GEO-ENGINEERING FOR UNDERGROUND FACILITIES

Establishing A Boulder Baseline Guidelines for baselining quantities to be presented in a geotechnical baseline report and contract documents are thoroughly discussed in an ASCE publication entitled Geotechnical Reports for Underground Construction, (Technical Committee on Geotechnical Reports of the Underground Technology Research Center, 1997). Much thought should be given on what boulder sizes are important, how quantities will be measured, how payments will be made and upon the conservatism used for the quantities listed. For example, on micro-tunnel and small tunnel projects all boulder sizes are likely to be important. On larger tunnels and those with more face access, only large boulders may need to be baselined. Use of Conventional Borings and Empirical Relationships Percent boulder volume and a boulder quantity may be estimated using boulder fraction data interpreted from conventional soil borings and probes. Boulder fraction data (boulder length divided by length drilled in a unit) from borings should be geologically evaluated to assess boulder distribution for specific units. For example, one data set may be for a unit with randomly distributed boulders and another data set for concentrated boulders within a lag zone unit. Distinctions might also be made for different segments of alignment, particularly if most of the borings that encountered boulders are located in a segment. After estimating average boulder fractions for the units and segments selected, percent boulder volume may be estimated using a relationship such as that shown in Figure 1. Boulder volumes may be estimated for estimated soil volumes to be excavated/mined within each of the soil types and segments involved. Even if a relationship between boulder fraction in borings to percent boulder volume is not locally available, boulder data from excavation projects within local geologically similar soil units may be used as limits for baselining boulders. Table 1 shows that the minimum average boulder volume within the till evaluated could be assumed as approximately 0.05 percent. The maximum boulder volume averaged over a 60-m (200-foot) segment within this unit could be assumed as approximately 11 percent. Additional data for common soil units or concentration zones could be collected from adequately documented excavations in a region. For example, observations made from a 12.2 m (40 foot) square shaft that was excavated into rock in southern Milwaukee (Hunt and Fradkin, 1991) indicate that bouldery till within approximately 2 m of bedrock had an average cobble and boulder concentration of approximately 70 percent by volume at that site. Probabilistic Methods for Analysis of Boring Data Probabilistic approaches may also be used for baselining boulder quantities where sufficient high quality data exists. Given that conventional borings at a typical spacing

266

GEO-ENGINEERING FOR UNDERGROUND FACILITIES

actually sample only a very small portion of the soil volume to be excavated and due to inherent geologic variability, data uncertainties will exist for the frequency, distribution, size, shape, composition and other characteristics of boulders in a soil stratum. Probability tools may be useful in analyzing uncertainties in a systematic manner to complement more traditional geotechnical evaluation methods rather than to replace them. Stoll (1976) evaluated the sensitivity of conventional and larger diameter boreholes in indicating boulder presence. Stoll assumed a random concentration of 315 mm (1 foot) diameter boulders projected onto a plane. The diameter of the boring and the concentration of boulders are the only variables that controlled the likelihood of detecting boulders. A chart was presented to determine the number of borings required for a 95% certainty of encountering at least one boulder for different boulder concentrations. The chart is of limited practical use since it is related to the nonencounter of only one boulder size. Although the paper presents a valid approach for statistical analyses, it appears to be somewhat limited for practical application. An improvement over this method would be to incorporate a variable boulder concentration (dependent on the site geology) and to incorporate boulder size variability. Tang and Quek (1986) developed statistical models of boulder size and boulder fraction. The first model uses intercepted boulder chord length data to estimate the distribution of boulder diameters for the entire boulder population. Bayesian analysis is used to update the mean boulder size. This method is very thorough from a mathematical perspective but may not be practical due to the difficulty in measuring chord lengths during drilling and where sufficient data is lacking. In addition, the method assumes that all the boulders are spheres. The second probabilistic model presented by Tang and Quek (1986) relates the fraction of boulder volume encountered at boring locations within a bouldery stratum to boulder volume within the stratum. This parameter may be easier to use in practice since the required data may be directly obtained from boring logs. A key assumption with the method is that the boulders are randomly distributed. Based on two Singapore sites studied, Tang and Quek found that a lognormal cumulative distribution function correlated well with the data. They hypothesized that Bayesian updating methods as described in Ang and Tang, 1975 could be used to incorporate data from additional sites. If the parameters of the distribution function can be updated or verified for a site, then boulder fraction data may be used to estimate boulder volume within a selected volume of the same soil mass. An effort was made to evaluate the data from the five Milwaukee/Chicago area cases that were previously discussed. A simple method based on the percentage of borings that encountered boulders proved to be ineffective. The data in Table 1 shows that the percentage of borings encountering boulders is not directly related to either the

267

GEO-ENGINEERING FOR UNDERGROUND FACILITIES

number of boulders or the boulder volume encountered. Such a simple method fails to account for borehole diameter, boring spacing, boring depth, occurrence within specific geologic units and the excavated tunnel volume. Attempts were also made to develop cumulative distribution functions for correlating boulder fraction encountered in borings to boulder volumes encountered during tunneling at the five Milwaukee/Chicago area sites. Insufficient data was available to establish useable relationships. Our results suggest that this probabilistic approach may not be applicable for typical tunnel projects unless a database correlation between boulder fraction in borings and percentage boulder volume within the soil mass can be developed for soil units within a region. Even if an applicable cumulative distribution function can be established for a soil unit, this method would only help provide baseline estimates for the more randomly distributed boulders. Boulder estimates for concentrations and anomalies would have to be independently assessed. Conclusions The primary conclusions of this paper are as follows: 1. Boulder quantities may be baselined by combining local geologic knowledge and boulder experience with the results of a phased subsurface investigation program. 2. Boulder baselining should start with a desk study of available information on the geologic setting of the site and of local boulder experience within similar geologic units. This information should be utilized to plan an initial subsurface exploration program. Subsequent exploration phases should reduce geologic uncertainties by more intensively exploring the ground, reducing data gaps and providing redundancy. 3. Conventional subsurface exploration should provide useful boulder data if drillers are instructed to carefully report indications of boulders and if a properly qualified geotechnical professional is assigned to monitor drilling in the field and to document all pertinent observations. Final boring logs should include field observations. 4. Redundant or supplementary exploration methods should be considered for one or more phases of exploration. These methods might include use of auger borings where rotary wash borings were previously used. Larger diameter borings, more sensitive (less powerful) drill rigs, percussive methods such as rotosonic drilling, test pits, 0.9 to 1.2 m diameter auger drilled shafts and geophysical methods such as seismic refraction/reflection may also provide useful supplementary or redundant information. 5. The normal criteria recommended in the literature for determination of boring spacing on tunnel projects should be suitable for boulder detection. An average borehole spacing ranging from 30 to 90 m (100 to 300 feet) is typical for soft-ground tunnel projects. For randomly distributed boulders, the average percentage of borings hitting boulders is generally not sensitive to borehole spacing within this range. Closer borehole spacing (e.g. 30 m or less) guided by geologic interpretation may be

268

GEO-ENGINEERING FOR UNDERGROUND FACILITIES

selectively utilized within specific areas to help minimize the risk of missing large boulder nests or lag deposits. 6. Normalized percent length of boulders intercepted in borings within potential bouldery soil appears to have a linear relationship to boulder volume as a percentage of excavated volume. Where local experience is lacking, the relationship shown in Figure 1 could be utilized to estimate an order of magnitude for boulder volume. Local experience should be accumulated to verify or modify this relationship. 7. A local experience database should be developed to document ranges in boulder quantities, sizes, and composition for common local soil units and for geologic features such as nests within filled gullies or ice-margin deposits, lag zones between geologic units of different age, and soil-rock interface zones. This database could be used as a guide when evaluating subsurface exploration results. Local boulder experience on projects should be published to help a local database to grow. 8. Probabilistic methods may be useful where there is sufficient understanding of the site geology and where a large enough population of high quality data exists to perform a Bayesian analysis and to establish a probability density function. Where sufficient quantity and quality of data is not available, probabilistic methods are not likely to be useful. References Abbott, D.G. (1995). Another Perspective on Teamwork .. Trenchless Technology. July 1995, 6-7. Ang, A. H.-S., and Tang, W. H. (1975). Probability Concepts in Engineering Planning and Design, Vol. 1 - Basic Principles, John Wiley & Sons, New York, NY. Alsup S. (1974). Recommended Borehole Investigation for Soft Ground Subsurface Exploration for Underground Excavation and Heavy Construction. American Society of Civil Engineers, New York, 117-127. Brierley, G.S. (1996). Microtunneling! Schmicrotunneling! Trenchless Technology. September 1996, 8. Brierley G.S., Howard, A.L. and Romley R.E. (1991). "Subsurface Exploration Utilizing Large Diameter Borings for the Price Road Drain Tunnel." Proceedings, 1991 Rapid Excavation and Tunneling Conference. Society for Mining Metallurgy and Exploration. Littleton CO. Chapter 1, 3-15. Cording, E.J., Brierley, G.S., Mahar J.W., and Boscardin M.D. (1989). Controlling Ground Movements During Tunneling. The Art and Science of Geotechnical Engineering. Editors: Cording, E.J., Hall W.J., Haltiwanger J.D., Hendron, A.J. Jr., and Mesri G. Prentice Hall. New Jersey, 478-482. Davis R. and Oothoudt T. (1997). The Use of Rotosonic Drilling in Environmental Investigations, Soil and Groundwater Cleanup, May 1997, 34-36.

269

GEO-ENGINEERING FOR UNDERGROUND FACILITIES

De Pasquale, G. and Pinelli G. (1998). No-Dig Application Planning Using Dedicated Radar Techniques. No-Dig International, Mining Journal LTD, London, February 1998, I-12 I-14. Essex, R.J. (1993). Subsurface Exploration Considerations for Microtunneling/Pipe Jacking Projects. Proceedings of Trenchless Technology: An Advanced Technical Seminar. Trenchless Technology Center, Louisiana Tech University, Ruston, LA. 276-287. Flint, R.F. (1971). Glacial and Quaternary Geology. Wiley. New York. 147-197. Gould, J.P. (1995). Geotechnology in Dispute Resolution. Journal of Geotechnical Engineering. ASCE. New York. Vol. 121, No. 7. July 1995, 523-534. Heuer. R.E. (1978). Site Characterization for Underground Design and Construction. Site Characterization & Exploration. ASCE. New York, 39-55. Hindle D.J. (1995). Geotechnical Appraisal. World Tunneling. London. Nov. 1995, 371-373. Horn H. M. and Ciancia A.J. (1989). Geotechnical Problems Posed by the Red Hook Tunnel. The Art and Science of Geotechnical Engineering. Editors: Cording, E.J., Hall W.J., Haltiwanger J.D., Hendron, A.J. Jr., and Mesri G. Prentice Hall. New Jersey, 367-385. Hunt, S.W. and Fradkin, S.B. (1991). "Costly Environmental and Geotechnical DSC Claims Resulting from Exploration Program and Reporting Inadequacies." Proceedings, 34th Annual Meeting of Association of Engineering Geologists. Association of Engineering Geologists, Greensburg, PA, 127-136. Klein S.J., Nagle G.S., Raines, G,L. (1996). Important Geotechnical Considerations in Microtunneling. No-Dig Engineering. Vol. 3. No. 4. July/August (1996), 9-12. Legget R.F. (1979). Geology and Geotechnical Engineering. Journal of the Geotechnical Engineering Division. ASCE. New York. Vol. 105, No. GT3. March 1979, 342-391. Miller R.J. (1996). Hazard Recognition in Trenchless Technology. No-Dig Engineering. Vol.3. No. 6. November/December 1996, 13-15. Neyer, J.C. (1985). Geotechnical Investigation For Tunnels in Glacial Soils. Proceedings, 1985 Rapid Excavation and Tunneling Conference. . Society for Mining Metallurgy and Exploration. Littleton CO. Chapter 1, 3-15. Osterberg, J.O. (1978). Failures in Exploration Programs. Site Characterization & Exploration. ASCE. New York, 3-9. Osterberg, J.O. (1989). Necessary Redundancy in Geotechnical Engineering. Journal of Geotechnical Engineering. ASCE. New York. Vol. 115, No. 11. November 1989, 1513-1531. Schmidt, B. (1974). Exploration for Soft Ground Tunnels - A New Approach. Subsurface Exploration for Underground Excavation and Heavy Construction. American Society of Civil Engineers, New York, 84-96.

270

GEO-ENGINEERING FOR UNDERGROUND FACILITIES

Smirnoff T.P. and Lundin T.K. (1985). " Design of Initial and Final Support of Pressure Tunnels in the Phoenix "SGC". Proceedings, 1985 Rapid Excavation and Tunneling Conference. . Society for Mining Metallurgy and Exploration. Littleton CO. Chapter 26, 428-438. Stoll, U.W. (1976). Probability That A Soil Boring Will Encounter Boulders. Conference on Better Contracting for Underground Construction. Michigan Section of American Society of Civil Engineers. Detroit. 34-48. Tang, W. and Quek S.T., (1986). Statistical Model of Boulder Size and Fraction. Journal of Geotechnical Engineering. ASCE. New York. Vol. 112, No. 1. January 1986, 79-90. Tarkoy, P.J., (1992). The Achilles Heel of Trenchless Technology: An Editorial Comment. Trenchless Technology. September/October 1992, 25, 41. Tarkoy P.J., (1994) Case Histories in Trenchless Excavation. No-Dig Engineering. Vol. 1. No. 1, 17-21. Technical Committee on Geotechnical Reports of the Underground Technology Research Center. (1997). Geotechnical Baseline Reports for Underground Construction. Randall J. Essex, Editor. ASCE. New York. Terzaghi, K., Peck, R.B. and Mesri, G., (1996). Article 12 - Program for Subsurface Exploration, Soil Mechanics in Engineering Practice, Wiley, New York, 3rd Ed., 55-58. U.S. National Committee on Tunneling Technology, (1984). Geotechnical Site Investigations for Underground Projects. National Academy Press. Washington D.C. Vol. 1 Wallis, S. (1996). Shepard Subway. North American Tunneling (World Tunneling). London. Vol. 9. No. 7, N17-N23.

Das könnte Ihnen auch gefallen

- Hunt UC 2017 Microtunneling in Mixed Ground Slides-FDokument21 SeitenHunt UC 2017 Microtunneling in Mixed Ground Slides-FswhuntNoch keine Bewertungen

- Hunt Del Nero 2012 - Microunneling in Cobbles and Boulders PaperDokument36 SeitenHunt Del Nero 2012 - Microunneling in Cobbles and Boulders PaperswhuntNoch keine Bewertungen

- Hunt 2015 Tunneling in Cobbles and Boulders, FinalDokument39 SeitenHunt 2015 Tunneling in Cobbles and Boulders, FinalswhuntNoch keine Bewertungen

- Notes On Singapore Geology PPT PresentationDokument44 SeitenNotes On Singapore Geology PPT Presentationadf500Noch keine Bewertungen

- Hunt Frank RETC 2021 Abrasivity and Cutter Life Assessment For TBM Tunneling in Cobbles and Boulders, RFDokument15 SeitenHunt Frank RETC 2021 Abrasivity and Cutter Life Assessment For TBM Tunneling in Cobbles and Boulders, RFswhuntNoch keine Bewertungen

- R2013-18, Hunt Et Al, Microtunneling in Gravel, Cobbles and Boulders, FDokument11 SeitenR2013-18, Hunt Et Al, Microtunneling in Gravel, Cobbles and Boulders, FswhuntNoch keine Bewertungen

- Pinhole Erosion Test For Identification of Dispersive ClaysDokument28 SeitenPinhole Erosion Test For Identification of Dispersive ClaysAndyra Jaiz Baddu100% (1)

- Desing Methods With Yielding SupportDokument13 SeitenDesing Methods With Yielding SupportSriram NambiNoch keine Bewertungen

- Fulltext StampedDokument13 SeitenFulltext StampedAl Gamal Riau KelanaNoch keine Bewertungen

- Time Dependent Deformations of Shafts and Tunnels in The Greater Toronto AreaDokument13 SeitenTime Dependent Deformations of Shafts and Tunnels in The Greater Toronto AreaAndrew CushingNoch keine Bewertungen

- Geology of Labuan - 1852Dokument13 SeitenGeology of Labuan - 1852Martin LavertyNoch keine Bewertungen

- Mechanical ExcavationDokument17 SeitenMechanical Excavationmohan_manoj43Noch keine Bewertungen

- Hoek - Characterisation Andengineering Properties of Tectonically Undisturbed But Lithologically Varied Sedimentary Rock MassesDokument9 SeitenHoek - Characterisation Andengineering Properties of Tectonically Undisturbed But Lithologically Varied Sedimentary Rock Massesecossich123100% (1)

- L4-Stereonets (SupplementaryMaterial)Dokument9 SeitenL4-Stereonets (SupplementaryMaterial)Afrizal SyahbanaNoch keine Bewertungen

- Friction Capacity of SoilDokument8 SeitenFriction Capacity of SoilkushaljpNoch keine Bewertungen

- Design and Construction of The Billy Bishop City Airport Pedestrian Tunnel, Toronto, CanadaDokument8 SeitenDesign and Construction of The Billy Bishop City Airport Pedestrian Tunnel, Toronto, CanadaAndrew Cushing100% (1)

- Forensic - Intro PDFDokument16 SeitenForensic - Intro PDFPrakashNoch keine Bewertungen

- AMWLecture 2011-BD2Dokument32 SeitenAMWLecture 2011-BD2ovion_itaNoch keine Bewertungen

- Analytical Tools For Managing Rock Fall Hazards in Australian Coal Mine RoadwaysDokument150 SeitenAnalytical Tools For Managing Rock Fall Hazards in Australian Coal Mine RoadwaysScott DownsNoch keine Bewertungen

- Engineering Geology For Infrastructure Planning in EuropeDokument10 SeitenEngineering Geology For Infrastructure Planning in EuropeAdeshola FunmilayoNoch keine Bewertungen

- 81 PalmstromStille On Ground Behaviour and Tools PDFDokument19 Seiten81 PalmstromStille On Ground Behaviour and Tools PDFJacky LeongNoch keine Bewertungen

- Temporary Excavation Support System For A New Railway Bridge and Highway Underpass in Pittsburgh, Pennsylvania by Andrew G. Cushing and Christopher J. LewisDokument8 SeitenTemporary Excavation Support System For A New Railway Bridge and Highway Underpass in Pittsburgh, Pennsylvania by Andrew G. Cushing and Christopher J. LewisAndrew CushingNoch keine Bewertungen

- Time Dependent Movements On The Billy Bishop Toronto City Airport Pedestrian Tunnel, Ontario, CanadaDokument15 SeitenTime Dependent Movements On The Billy Bishop Toronto City Airport Pedestrian Tunnel, Ontario, CanadaAndrew CushingNoch keine Bewertungen

- NGI - Publ - Ralph - B - Peck Engineer Educator A Man of Judgement PDFDokument76 SeitenNGI - Publ - Ralph - B - Peck Engineer Educator A Man of Judgement PDFRicomartiniNoch keine Bewertungen

- Asadzadeh - Direct Shear Testing On A Rockfill MaterialDokument18 SeitenAsadzadeh - Direct Shear Testing On A Rockfill MaterialDavid CastañoNoch keine Bewertungen

- Ground Settlement Considerations For The Design of Long Culverts Beneath High Embankments On ClayDokument12 SeitenGround Settlement Considerations For The Design of Long Culverts Beneath High Embankments On ClayLuca BrandiNoch keine Bewertungen

- Putting Geological Focus Back Into Rock Engineering DesignDokument22 SeitenPutting Geological Focus Back Into Rock Engineering DesignAna RobadorNoch keine Bewertungen

- Influence of Geological Conditions On Design and Construction of Tunnels2-LibreDokument29 SeitenInfluence of Geological Conditions On Design and Construction of Tunnels2-LibreGEOMAHESHNoch keine Bewertungen

- BasRock Trajec3D ManualDokument21 SeitenBasRock Trajec3D Manualcajimenezb8872Noch keine Bewertungen

- Barton-High Pressure Pre-Grouting. TTI Sept 2004 p28-30 PART IDokument3 SeitenBarton-High Pressure Pre-Grouting. TTI Sept 2004 p28-30 PART Icastille1956Noch keine Bewertungen

- Ground Freezing 1980: Selected Papers from the Second International Symposium on Ground Freezing, Trondheim, Norway, 24-26 June 1980Von EverandGround Freezing 1980: Selected Papers from the Second International Symposium on Ground Freezing, Trondheim, Norway, 24-26 June 1980Noch keine Bewertungen

- 61-65E - Compensation Grouting For Limiting Settlements of Two Railway Bridges Induced by A Twin-Tunnel ExcavationDokument13 Seiten61-65E - Compensation Grouting For Limiting Settlements of Two Railway Bridges Induced by A Twin-Tunnel Excavationno indicadoNoch keine Bewertungen

- Geo Technical Investigation Volume 1Dokument23 SeitenGeo Technical Investigation Volume 1Cele Adu-wusuNoch keine Bewertungen

- 0085 BartonDokument8 Seiten0085 BartonR. Venugopala RaoNoch keine Bewertungen

- Slope Stability Guidelines For Devt ApplicationsDokument24 SeitenSlope Stability Guidelines For Devt ApplicationsJose Leo MissionNoch keine Bewertungen

- Inclinometer AccuracyDokument3 SeitenInclinometer AccuracyBobby SetiawanNoch keine Bewertungen

- 4-th ICEGE Workshops - Tessaloniki, Greece PDFDokument559 Seiten4-th ICEGE Workshops - Tessaloniki, Greece PDFioan_nebunuNoch keine Bewertungen

- Discussion Muir Wood Circular Tunnel in Elastic GroundDokument7 SeitenDiscussion Muir Wood Circular Tunnel in Elastic GroundAmmar SohailNoch keine Bewertungen

- ASTM D 653 03 Standard Terminology Relating To Soil Rock and Contained FluidsDokument35 SeitenASTM D 653 03 Standard Terminology Relating To Soil Rock and Contained FluidsRockLab EnsayosNoch keine Bewertungen

- The Stability Assessment of Arch Dams and Corresponding Reinforcement TechnologyDokument11 SeitenThe Stability Assessment of Arch Dams and Corresponding Reinforcement TechnologyQingcheng YuNoch keine Bewertungen

- Seepage and Slope Stability Modelling of Rainfall Induced Slope Failures in Topographic HollowsDokument27 SeitenSeepage and Slope Stability Modelling of Rainfall Induced Slope Failures in Topographic HollowsAgditya PriksawanNoch keine Bewertungen

- Rules of Thumb Geotech MonitoringDokument1 SeiteRules of Thumb Geotech MonitoringMadan Kumar AnnamNoch keine Bewertungen

- Advances in Rockfill StructuresDokument27 SeitenAdvances in Rockfill StructuresHesbon MoriasiNoch keine Bewertungen

- Design of Large Span Tunnels and Caverns: Back To BasicsDokument10 SeitenDesign of Large Span Tunnels and Caverns: Back To Basicsdafo407Noch keine Bewertungen

- RCK - Effect of Weathering On The Strength and Modulus of Basalt and Siltstone (Gu Et Al, 2008)Dokument8 SeitenRCK - Effect of Weathering On The Strength and Modulus of Basalt and Siltstone (Gu Et Al, 2008)sandycastleNoch keine Bewertungen

- Weak Rocks Classifications IAEG PDFDokument9 SeitenWeak Rocks Classifications IAEG PDFthadikkaranNoch keine Bewertungen

- SEM Mined Tunnel PDFDokument3 SeitenSEM Mined Tunnel PDFqaisarmehboob82Noch keine Bewertungen

- Lesson Learn From Instrumentation Tunnel ProjectDokument16 SeitenLesson Learn From Instrumentation Tunnel ProjectNguyen Quoc KhanhNoch keine Bewertungen

- ShallowTunnels PDFDokument12 SeitenShallowTunnels PDFManuel Jose Parot GreveNoch keine Bewertungen

- Dynamics of Plate Tectonics and Mantle ConvectionVon EverandDynamics of Plate Tectonics and Mantle ConvectionJoao C. DuarteNoch keine Bewertungen

- The Direct Shear Strength and Dilatancyof Sand-Gravel MixturesDokument27 SeitenThe Direct Shear Strength and Dilatancyof Sand-Gravel MixturesPipatpong NookhaoNoch keine Bewertungen

- Aftes Repair TunelDokument26 SeitenAftes Repair Tunelbabersultan52Noch keine Bewertungen

- Ground Control For A Deep Basement Excavation in Sydney's Gpo Fault ZoneDokument14 SeitenGround Control For A Deep Basement Excavation in Sydney's Gpo Fault Zonedafo407Noch keine Bewertungen

- Geotechnical Risk in Rock Mass Characterisation - A ConceptDokument11 SeitenGeotechnical Risk in Rock Mass Characterisation - A ConceptAzeNoch keine Bewertungen

- Shotcrete and Sprayed Concrete References, 2017-02-01Dokument18 SeitenShotcrete and Sprayed Concrete References, 2017-02-01swhuntNoch keine Bewertungen

- 2016, Earle, Engineers Beware, California Courts Have Held Engineers Owe A Duty of Care and Are Liable .... 2pDokument2 Seiten2016, Earle, Engineers Beware, California Courts Have Held Engineers Owe A Duty of Care and Are Liable .... 2pswhuntNoch keine Bewertungen

- 2019, Dornfest Et - Al, What's The Deal With GBRS, 7pDokument7 Seiten2019, Dornfest Et - Al, What's The Deal With GBRS, 7pswhuntNoch keine Bewertungen

- 2022, Hunt, GBRs - Baselining Precise Values vs. Ranges Vs Histograms, 5pDokument5 Seiten2022, Hunt, GBRs - Baselining Precise Values vs. Ranges Vs Histograms, 5pswhuntNoch keine Bewertungen

- Value Engineering References, 2020-11-06Dokument2 SeitenValue Engineering References, 2020-11-06swhuntNoch keine Bewertungen

- Liner Plate References, 2020-09-18Dokument7 SeitenLiner Plate References, 2020-09-18swhuntNoch keine Bewertungen

- Shotcrete and Sprayed Concrete References, 2017-02-01Dokument18 SeitenShotcrete and Sprayed Concrete References, 2017-02-01swhuntNoch keine Bewertungen

- 2000, Agc, Glossary of Trenchless Terminology, 9pDokument9 Seiten2000, Agc, Glossary of Trenchless Terminology, 9pswhuntNoch keine Bewertungen

- About Tunneling, Main Glossary of Terms: "A" Line "B" Line Abrasiveness AcceleratorDokument50 SeitenAbout Tunneling, Main Glossary of Terms: "A" Line "B" Line Abrasiveness AcceleratorswhuntNoch keine Bewertungen

- R2013-18, Hunt Et Al, Microtunneling in Gravel, Cobbles and Boulders, FDokument11 SeitenR2013-18, Hunt Et Al, Microtunneling in Gravel, Cobbles and Boulders, FswhuntNoch keine Bewertungen

- Hunt Frank RETC 2021 Abrasivity and Cutter Life Assessment For TBM Tunneling in Cobbles and Boulders, RFDokument15 SeitenHunt Frank RETC 2021 Abrasivity and Cutter Life Assessment For TBM Tunneling in Cobbles and Boulders, RFswhuntNoch keine Bewertungen

- Hunt&Angulo 1999 Base Lining BouldersDokument16 SeitenHunt&Angulo 1999 Base Lining BouldersswhuntNoch keine Bewertungen

- Jet Grouting References, 2020-03-22Dokument7 SeitenJet Grouting References, 2020-03-22swhunt100% (1)

- Frequently Used Tunneling Terms PDFDokument6 SeitenFrequently Used Tunneling Terms PDFOrebic ViganjNoch keine Bewertungen

- No-Dig 2009 Paper B-2-01 Hunt-Del Nero - r5 - FinalDokument11 SeitenNo-Dig 2009 Paper B-2-01 Hunt-Del Nero - r5 - FinalswhuntNoch keine Bewertungen

- 2000, Agc, Glossary of Trenchless Terminology, 9pDokument9 Seiten2000, Agc, Glossary of Trenchless Terminology, 9pswhuntNoch keine Bewertungen

- 2006, DEFINITIONS AND TERMS FROM MISC TUNNEL SPECS, 5pDokument5 Seiten2006, DEFINITIONS AND TERMS FROM MISC TUNNEL SPECS, 5pswhuntNoch keine Bewertungen

- 2006, Boyce, What Is Trenchless Technology Anyway, 2pDokument2 Seiten2006, Boyce, What Is Trenchless Technology Anyway, 2pswhuntNoch keine Bewertungen

- 2007, Herrenknecht, Tunneling Glossary, 7pDokument7 Seiten2007, Herrenknecht, Tunneling Glossary, 7pswhunt100% (1)

- Microtunneling and Tunneling in Cobbles and Boulders References, 2019-08-11Dokument35 SeitenMicrotunneling and Tunneling in Cobbles and Boulders References, 2019-08-11swhuntNoch keine Bewertungen

- The International Society For Trenchless Technology: GlossaryDokument15 SeitenThe International Society For Trenchless Technology: GlossaryswhuntNoch keine Bewertungen

- 2009, Del Nero, Auger Boring Nomenclature, 1pDokument1 Seite2009, Del Nero, Auger Boring Nomenclature, 1pswhuntNoch keine Bewertungen

- Hunt and Fradkin 1991 AEG, Costly DSC Claims From Sub Invest Inadequacies - SIDokument9 SeitenHunt and Fradkin 1991 AEG, Costly DSC Claims From Sub Invest Inadequacies - SIswhuntNoch keine Bewertungen

- Hunt&Angulo 1999 Base Lining BouldersDokument16 SeitenHunt&Angulo 1999 Base Lining BouldersswhuntNoch keine Bewertungen

- Water Control: ChairmanDokument23 SeitenWater Control: ChairmanswhuntNoch keine Bewertungen

- 2016, Hunt, Conquering Cobbly, Bouldery Ground, Tunnels & Tunnelling North America, 8p PDFDokument7 Seiten2016, Hunt, Conquering Cobbly, Bouldery Ground, Tunnels & Tunnelling North America, 8p PDFswhuntNoch keine Bewertungen

- 2016, Hunt, Conquering Cobbly, Bouldery Ground, Tunnels & Tunnelling North America, 8p PDFDokument7 Seiten2016, Hunt, Conquering Cobbly, Bouldery Ground, Tunnels & Tunnelling North America, 8p PDFswhuntNoch keine Bewertungen

- 2016, Hunt, Conquering Cobbly, Bouldery Ground, Tunnels & Tunnelling North America, 8pDokument7 Seiten2016, Hunt, Conquering Cobbly, Bouldery Ground, Tunnels & Tunnelling North America, 8pswhuntNoch keine Bewertungen

- Costly Environmental and Geotechnical DSC Claims Resulting From Exploration Program and Reporting InadequaciesDokument11 SeitenCostly Environmental and Geotechnical DSC Claims Resulting From Exploration Program and Reporting InadequaciesswhuntNoch keine Bewertungen

- Hunt, S.W., 2017, Breakthroughs in Tunneling, Paper, Tunneling in Cobbles and BouldersDokument16 SeitenHunt, S.W., 2017, Breakthroughs in Tunneling, Paper, Tunneling in Cobbles and BouldersswhuntNoch keine Bewertungen

- Flood RateDokument367 SeitenFlood RatetpktpkNoch keine Bewertungen

- Wire Rope Forensics Letter PDFDokument50 SeitenWire Rope Forensics Letter PDFAshley DeanNoch keine Bewertungen

- Chapter 01 Vacuum Chambers Special Components PDFDokument14 SeitenChapter 01 Vacuum Chambers Special Components PDFmindrumihaiNoch keine Bewertungen

- 96-09302-00-01 Reva Technical Manual Inogen One G5Dokument18 Seiten96-09302-00-01 Reva Technical Manual Inogen One G5Paula Andrea MarulandaNoch keine Bewertungen

- Odd Semester Time Table Aug - Dec22 Wef 22.08.2022.NEWDokument4 SeitenOdd Semester Time Table Aug - Dec22 Wef 22.08.2022.NEWKiran KumarNoch keine Bewertungen

- Government Schemes: Ministry of Agriculture and Farmers' WelfareDokument29 SeitenGovernment Schemes: Ministry of Agriculture and Farmers' WelfareDushyant MudgalNoch keine Bewertungen

- Parasites in Reptile PDFDokument21 SeitenParasites in Reptile PDFRamadhani SyafitriNoch keine Bewertungen

- RB in Poultry Feed - 3Dokument17 SeitenRB in Poultry Feed - 3Vishwanath HebbiNoch keine Bewertungen

- MS2040 Constitution Parts ListDokument6 SeitenMS2040 Constitution Parts ListTemptationNoch keine Bewertungen

- Worksheet 3 (Partial Pressures)Dokument2 SeitenWorksheet 3 (Partial Pressures)Jose Ruben SortoNoch keine Bewertungen

- SUNANDA Hack Aid Plast SPL PDFDokument2 SeitenSUNANDA Hack Aid Plast SPL PDFSheezan KhanNoch keine Bewertungen

- Introduction To ProbabilityDokument50 SeitenIntroduction To ProbabilityJohn StephensNoch keine Bewertungen

- Renal New Growth - NCM 103 - or CaseDokument19 SeitenRenal New Growth - NCM 103 - or CasePat EnriquezNoch keine Bewertungen

- J. Agric. Food Chem. 2005, 53, 9010-9016Dokument8 SeitenJ. Agric. Food Chem. 2005, 53, 9010-9016Jatyr OliveiraNoch keine Bewertungen

- Abnormal Uterine Bleeding - Surgical ManagementDokument14 SeitenAbnormal Uterine Bleeding - Surgical ManagementNikhil DevNoch keine Bewertungen

- Infant of A Diabetic MotherDokument17 SeitenInfant of A Diabetic MotherLovina Falendini AndriNoch keine Bewertungen

- PX 150 UsaDokument138 SeitenPX 150 UsaramiroNoch keine Bewertungen

- DinmjgDokument10 SeitenDinmjghaker linkisNoch keine Bewertungen

- Bearing Solutions and Service For Wind TurbinesDokument16 SeitenBearing Solutions and Service For Wind TurbinesDrZEIDINoch keine Bewertungen

- Middle East ManufacturerDokument6 SeitenMiddle East Manufacturerhsco rdNoch keine Bewertungen

- CEBUANO ERNESTO CODINA (Astonaut Hardware Designer)Dokument1 SeiteCEBUANO ERNESTO CODINA (Astonaut Hardware Designer)Dessirea FurigayNoch keine Bewertungen

- SCSM 2022 Runners Information GuideDokument36 SeitenSCSM 2022 Runners Information GuideDollar SurvivorNoch keine Bewertungen

- STAN Statistika 12 PDFDokument25 SeitenSTAN Statistika 12 PDFPembelajaran Jarak JauhNoch keine Bewertungen

- kAmAxI Muka Panchashati EngDokument25 SeitenkAmAxI Muka Panchashati EngSrinathvr100% (1)

- Final Cor 011 Reviewer PDFDokument104 SeitenFinal Cor 011 Reviewer PDFMary JuneNoch keine Bewertungen

- CPHL 214 Assignment 6Dokument2 SeitenCPHL 214 Assignment 6NazNoch keine Bewertungen

- Fact Sheeton Canola OilDokument15 SeitenFact Sheeton Canola OilMonika ThadeaNoch keine Bewertungen

- 9500 MPR Wireless TransmissionDokument46 Seiten9500 MPR Wireless TransmissionMahdi AhmadiNoch keine Bewertungen

- Pirastro Extract From Catalogue 2022-05-22Dokument72 SeitenPirastro Extract From Catalogue 2022-05-22arno8817Noch keine Bewertungen

- MOE XT2-XT4 110... 125V Ac/dcDokument3 SeitenMOE XT2-XT4 110... 125V Ac/dcLê Xuân ĐịnhNoch keine Bewertungen