Beruflich Dokumente

Kultur Dokumente

229 16 18 Techn Informationen

Hochgeladen von

Carina GhitaOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

229 16 18 Techn Informationen

Hochgeladen von

Carina GhitaCopyright:

Verfügbare Formate

Technical Information

7.01

Technical Information

7.02

Technical Information

European Quality Standards

Extruded Ceramic Tiles Product Standards

(simplified and based on 10 x 10 cm (BIII), or 30 x 30 cm (BI))

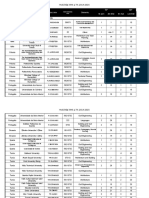

Dry-pressed Ceramic Tiles DIN EN 14411 group BIa + BIb group B III Test Standards

DIN EN 14411 group AIa + AIb Nature Precision 2% 10 % | 1.0 % | 10 % group AIIa - part 1 Nature Precision 2% 10 % | 1.25 % | 10 %

A)

1. 2. 3. 4. 5.

Dimensions + Surfaces Length and Width Thickness Straightness of Edges Rectangularity Surface Flatness

5.1 5.2 5.3

0.75 % 5% 0.5 % 0.6 % 0.5 % 0.5 % 0.5 % at least 95 %

0.75 % 10 % 0.3 % 0.5 % + 0,5 /-0,3% + 0,5 /-0,3% 0.5 % at least 95 % glazed

DIN EN ISO 10545-2 DIN EN ISO 10545-2 DIN EN ISO 10545-2 DIN EN ISO 10545-2 DIN EN ISO 10545-2 DIN EN ISO 10545-2 DIN EN ISO 10545-2 DIN EN ISO 10545-2 DIN EN ISO 10545-2 DIN EN ISO 10545-16 Deutsche Steinzeug Deutsche Steinzeug

0.6 % | 0.5 % 1.0 % | 1.0 % 1.5 % | 0.5 % 1.5 % | 0.5 % 1.5 % | 0.8 % at least 95 %

0.6 % | 0.5 % 1.0 % | 1.0 % 1.5 % | 0.5 % 1.5 % | 0.5 % 1.5 % | 0.8 % at least 95 %

Curvature at Centre Curvature at the Edges Skewness

6. 7.

Surface Quality Colour Deviations

7.1

Colour Shade Grading

8.

Size Grading1) Physical Properties Water Absorption on average / Modulus of Rupture

2.1.Breaking

B)

1.

max. individual value

AIa E 0.5%/0.6% AIb 0.5% < E 3%/3.3% AIa min. 28 (21) N / mm2 AIb min. 23 (18) N / mm AIa min. 1300 N AIb min. 1100 N at least 600 N

2

6/6.5 %

BIa 0.5% BIb 3%

> 10 %

DIN EN ISO 10545-3

2.

Value in brackets = min. individual value

min. 20 (18) N / mm2

BIa min. 32 N/mm2 BIb min. 27 N/mm

2

Thick. < 7.5 mm : 15 N/mm2 DIN EN ISO 10545-4 Thick. > 7.5 mm : 12 N/mm2

at least 600 N

Strength 7.5 mm

at least 950 N

BIa min. 1300 N BIb min. 1100 N

DIN EN ISO 10545-4 DIN EN ISO 10545-4 DIN EN ISO 10545-5 DIN EN ISO 10545-6 DIN EN ISO 10545-7 DIN EN ISO 10545-8 DIN EN ISO 10545-9 DIN EN ISO 10545-10 DIN EN ISO 10545-11 Deutsche Steinzeug DIN EN 1081 DIN EN ISO 12572 DIN EN ISO 10545-12 DIN 51094

3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16.

thickness 2.2.Breaking Str. < 7.5 mm thickn. Resistance to Shock Resistance to Deep Abrasion Resistance to Glaze Abrasion Max. Coefficient of Expansion Thermal Shock Resistance Moisture Expansion Resistance to Glaze Cracking2) Thermal Conductivity Electrical Leakage Resistance Steam Diffusion Resistance Resistance to Frost Light and Colour Fastness Luminance Behaviour in Fire Chemical Properties3) Resistance to Chemicals Resistance to Household Chemicals and Bath Water Additives Stain Resistance (glazed) Lead and Cadmium Delivery Hydrotect Slip resistance Coefficient of Friction

1.1 Industrial

at least 600 N

at least 700 N

at least 200 N

275 mm3 0-5 < 0.001mm/m required appr. 1 W/mK > 1010 Ohm4) appr. 120.000 required acc. to specifications A1 non-combustible

393 mm3 0-5 < 0.001mm/m required appr. 1 W/mK > 1010 Ohm4) appr. 120.000

not required, but met by AGROB BUCHTAL

175 mm3 0-5 appr. 0.001mm/m required appr. 1 W/mK 1010 Ohm appr. 120.000 required acc. to specifications A1 non-combustible

0- 5 appr. 0.01mm/m required appr. 0.8 W/mK 1010 Ohm appr. 100.000

acc. to specifications A1 non-combustible

acc. to specifications Deutsche Steinzeug A1 non-combustible DIN 4102

C)

1. 2.

see test certificate min. GB or UB min. Cl. 3 see test certificate

see test certificate min. GB or UB min. Cl. 3 see test certificate

see test certificate min. GB or UB min. Cl. 3 see test certificate

see test certificate min. Cl. 3 see test certificate

DIN EN ISO 10545-13

3.

DIN EN ISO 10545-14 DIN EN ISO 10545-15 Deutsche Steinzeug

Technical Information

4. 5.

D)

1.

Groups R9-13/V4-10 Groups A/B/C

Groups R9-13/V4-10 Groups A/B/C

Groups R9-13/V4-10 Groups A/B/C

DIN EN ISO 10545-17 DIN 51130 BGR 181 DIN 51097 GUV-I 8527

Areas (BG) Trade Associations Areas (BUK) German National Association of Accident Insurance Companies

1.2 Barefoot

1) 2) 3) 4)

Boxes marked according to size and colour shade. Exceptions are marked. Hydrofluoric acid and its compounds excluded. Exceptions: Eladuct/KerAion: ELA 10.6: 106 Ohm; colours 958, 070S: 10 8 Ohm.

Deutsche Steinzeug tiles present better values than required by the standards. In addition, they are construction biologically, ecologically, hygienically and bacteriologically safe; this is guaranteed through the choice of raw materials, method of processing and firing technique.

Price list 2010, status December 2009

Technical Information

7.03

Terms and Classification according to DIN EN 14411

All our tiles are processed, refined and fired building materials of natural mineral origins such as clay, quartz sand and flux. Depending on the application they are manufactured with a glazed (GL) or unglazed (UGL) surface. They can be classified in accordance with DIN EN 14411 as follows: Classification of the ceramic tiles according to their groups of water absorption (E) and their shaping

Shaping group I E 3% group AIa A extruded tiles E 0.5% (Annex M) group AIb 0.5 % < E 3 % (Annex A) group BIa B dry-pressed tiles E 0.5 % (Annex G) group BIb 0.5 % < E 3 % (Annex H) a) The groups AIIa and AIIb are subdivided into two parts (parts 1 and 2) with different product requirements. b) Group BIII exclusively applies to glazed tiles. There is a small number of dry-pressed unglazed tiles manufactured with a water absorption of more than 10 % to which this product group does not apply. group BIIa (Annex J) group BIIb (Annex K) group BIIIb) (Annex L) group AII a-2a) (Annex C) group AII b-2a) (Annex E) group IIa 3% < E 6% group AII a-1a) (Annex B) group IIb 6 % < E 10 % group AII b-1a) (Annex D) group AIII (Annex F) group III E > 10 %

dry-pressed tiles (marked with B) Tiles that are formed from a finely ground mass by pressing under high pressure. Split tiles are frost-resistant, extruded double-tiles which are fired at a temperature of up to max. 1280 C in upright position. Stoneware tiles are frost-resistant, single extruded vitrified tiles with a firing temperature of appr. 1260 C. KerAion is the unique extruded ceramic large-size panel from AGROB BUCHTAL. Vitrified dry-pressed tiles are frost-resistant, single dry-pressed tiles with a firing temperature of up to 1200 C. Porcelain stoneware stands for especially densely pressed and sintered tiles with a water absorption of < 0.5 %. Mosaics are small vitrified tiles stuck onto sheets. Earthenware tiles are non-frost-resistant, single dry-pressed tiles with a firing temperature of up to appr. 1100 C. The water absorption E in weight-% is determined in accordance with DIN EN ISO 10545-3.

Description of dimensions Traditionally the following terms are used: extruded tiles (marked with A) Tiles that are cut off with a certain length from a bar formed from the plastic mass by means of an extruder.

C W

J d

Coordinating dimension (C) in cm = Work size (W) + Joint (J) Work size (W) in mm = Dimensions of the visible surfaces and thickness (d)

Dimensions and Surfaces

1 - 5. Dimensions, DIN EN ISO 10545-2 Length, width, thickness, straightness of sides, rectangularity and surface flatness are measured as the deviation from the work size resp. as the deviation from the average side length (10 samples). The work sizes of our special pieces are given according to visual sides. 6. Surface Quality, DIN EN ISO 10545-2 The surfaces of 1 m2 or 30 pieces are tested at 300 lux for visible defects at a distance of 1 m.

Permissible length and width tolerances corresponding to the product standards

DIN EN 14411

group AIa / AIb (25 x 12.5 cm)

Nature Precision

group AIIa (25 x 12.5 cm)

Nature Precision 2% 1.25 %

group group BIII BIa / BIb (10 x 10 cm) (30 x 30 cm)

Deviation from the work size Deviation from the average side length

2%

1.0 %

0.75 %

0.75 %

7.1. Colour Shade Grading The colour shade code is stamped on the box. Only identical colour shades will result in a uniform surface look. In the case of rustic split tiles greater colour deviations are normal. During laying, tiles from different boxes should be mixed. 8. Size Grading The production sizes vary for technical reasons. The production size is coded and stamped on the box. Only boxes with the same coding should be laid together. According to VOB, the differences are evened out in the joints.

1.5 %

1.0 %

1.5 %

1.0 %

0.5 %

0.5 %

Price list 2010, status December 2009

Technical Information

7. Colour Deviations, DIN EN ISO 10545-16 Mono-coloured products with values of E cmc < 0.75 are considered as identical in colour.

7.04

Technical Information

Physical Properties

1. Water Absorption, DIN EN ISO 10545-3 The water absorption (E) gives the weight increase in % as compared to the dry weight of boiled samples saturated with water. 1.1 Apparent Density, DIN EN ISO 10545-3 It gives the ratio between mass and external volume. 2. Modulus of Rupture, DIN EN ISO 10545-4 The breaking strength F is determined on samples by means of the three-point load in N. From this, the modulus of rupture is calculated according to the following formula. Modulus of Rupture R = 3 F L2 2bh Breaking Load S= FL b

Table Breaking Strength Ceramic Tiles DIN EN 14411 group A Ia group A Ib group A IIa group B Ia group B Ib group B III F breaking Strength

F = breaking strength in N L = bearing span in mm b = width in mm h = thickness in mm R = modulus of rupture

h thickness

L bearing span

thickn. Requirements Dt. Steinzeug Requirements Dt. Steinzeug Requirements Dt. Steinzeug Requirements Dt. Steinzeug Requirements Dt. Steinzeug Requirements Dt. Steinzeug

acc. to standard approx. values acc. to standard approx. values acc. to standard approx. values acc. to standard approx. values acc. to standard approx. values acc. to standard approx. values (R=28N/mm2) (R=42N/mm2) (R=23N/mm2) (R=42N/mm2) (R=20N/mm2) (R=30N/mm2) (R=32N/mm2) (R=55N/mm2) (R=27N/mm2) (R=40N/mm2) (R=15N/mm2) (R=18N/mm2)

5 mm 6 mm 7 mm 8 mm 9 mm 10 mm 11 mm 12 mm 13 mm 14 mm 15 mm 16 mm 18 mm 20 mm

1200 N 1500 N 1850 N 2200 N 2650 N -

1000 N 1400 N 1800 N 2300 N 2800 N 3400 N 4000 N 4700 N 5500 N 6300 N 7200 N 9100 N 11200 N

550 N 750 N 980 N 1250 N 1500 N 1850 N 2200 N 2600 N 3000 N 3500 N 4000 N 5000 N 6100 N

1000 N 1400 N 1800 N 2300 N 2800 N 3400 N 4000 N 4700 N 5500 N 6300 N 7200 N 9100 N 11200 N

850 N 1100 N 1300 N 1600 N 1900 N 2300 N 2600 N 3000 N -

1280 N 1620 N 2000 N 2420 N 2880 N 3380 N 3920 N 4500 N -

550 N 750 N 1050 N 1350 N 1700 N 2100 N 2600 N 3100 N 3600 N 4200 N 4800 N -

900 N 1350 N 1800 N 2350 N 3000 N 3700 N 4400 N 5300 N 6200 N 7200 N 8300 N -

450 N 650 N 880 N 1150 N 1450 N 1800 N 2200 N 2600 N 3000 N 3500 N 4000 N 4600 N 5800 N 7200 N

670 N 960 N 1300 N 1700 N 2200 N 2700 N 3200 N 3800 N 4500 N 5200 N 6000 N 6800 N 8600 N 10700 N

250 N 360 N 490 N -

300 N 430 N 600 N -

Possible Applications

Stress Group

Breaking load under 1,500 N, normal duty, e.g. housing construction, swimming pools Breaking load 1,500 3,000 N, practicable with pneumatic tyres, e.g. trade and administration, exhibitions and sales areas Breaking load 3,000 5,000 N, practicable with elastic and solid rubber tyres, e.g. trade and industry Floor pressure up to 6 N/mm2 Breaking load 5,000 8,000 N, practicable with vulkollan tyres, e.g. industry and hypermarkets Floor pressure 6-20 N/mm2 Breaking load above 8,000 N, practicable with polyamide tyres, e.g. heavy-duty areas Floor pressure above 20 N/mm2

100 80 40

fork lift truck (manual and electric drive)

steel wheels

2

20 10 8 6 4 Medium floor pressure in N/mm 2 2 1 0,8 0,6 0,4 0,2 0,1 1000 2000 3000

Technical Information

front stacker (battery electrical drive) pneumatic tyres front stacker (combustion engine drive)

Important note: The application possibilities are of course only recommendations, as the method and quality of laying are decisive factors. Our recommendations are based on conventional, professional laying. With increasing mechanical load as well as harder tyres a thicker tile is required.

Load bearing capacity in kg

4000

5000

Price list 2010, status December 2009

Valuation:

unproblematic

polyamide C-push frame stacker fork lift truck polyurethane (manual and electric drive) hand pallet truck solid rubber fork lift truck tyres (electric drive) C-push frame stacker superelastic tyres trailer

critical

fork lift truck (manual and electric drive)

to be rejected

200

Technical Information

7.05

Mechanical Strength Deutsche Steinzeug offers tiles in thicknesses from 6 up to 20 mm for extreme loads in industrial and commercial areas. The breaking resistance values in Newton for our products are by far better than the required standard values (see table on page 7.04). The calculated breaking resistance indicates the suitability for floors subject to mechanical loads. The stress itself is caused by bending rather than by pressure. The extra strong tiles from our programme with their high pressure, breaking and bending strength values are the ideal covering for floors subject to heavy loads. They withstand the wheels of industrial trucks, fork lift trucks and platform lift-trucks with their high floor pressure. They are especially suitable as floor coverings for industrial logistics, hyper- and supermarkets. Floor pressure in N/mm2 of industrial truck wheels according to a FMPA test in Stuttgart The table illustrates the floor loads and indicates the effect of the different wheel types: steel wheels should be rejected and polyamide (Nylon and Perlon) is not advisable. Softer tyres ( 75 Shore-A-Hardness) as well as larger wheel diameters and wider supporting surfaces are especially advantageous. 3. Compressive Strength The compressive strength of tiles is not standardized. In the case of vitrified dry-pressed tiles it reaches values of up to 300 N/mm2. The following conversion table shows the importance of a perfect and professional embedding of the tiles on site. The relatively low values for cement and thin-bed mortar can only be compensated by special and professional laying (mortar composition, water/cement value and manual or mechanical compression). 4. Resistance to Shock, DIN EN ISO 10545-5 Rebound measurement with 5 samples.

5. Resistance to Deep Abrasion, DIN EN ISO 10545-6 With regard to the deep abrasion on unglazed tiles, the abrasion is determined by means of fusion corundum and a rubbing plate. The lower the value, the higher the wear resistance of the material. 6. Glaze Abrasion, DIN EN ISO 10545-7 The stress group of glazed tiles is established in the wet test. Artificial abrasion is produced with the help of aluminium oxide grains, steel balls and the addition of water in an eccentrically revolving system. The number of revolutions at which a visible change of the test surface occurs results in the following classification:

Resistance to Surface Abrasion Class 0 1 2 3 4 5

Revolutions 100 150 600 750 /1500 2100/6000/12000 >12000*

* Must pass the stain test according to DIN EN ISO 10545-14.

Vitrified material has a compressive strength approx. 10 20 times higher than cement mortar, cast plaster floors and reinforced concrete.

Conversion table for different materials

Types of material N/mm2 N/cm2 KN/cm2

Vitrified dry-pressed tiles Extruded split tiles Cement mortar Gr. III High-grade cement mortar Thin-bed mortar Epoxy resins Cement screed CT, C12 (ZE 12) CT, C20 (ZE 20) CT, C30 (ZE 30) Mechanically resistant floor 65 Reinforced concrete C 20/25 (B 25) C 30/37 (B 35)

250 300 180 250 10 20 15 30 60 75 12 20 30 65 25 35

25,000 30,000 18,000 25,000 1,000 2,000 1,500 3,000 6,000 7,500 1,200 2,000 3,000 6,500 2,500 3,500

25 30 18 25 1 2 1.5 3 6 7.5 1.2 2 3 6.5 2.5 3.5

Price list 2010, status December 2009

Technical Information

7.06

Technical Information

Class 0 The use of glazed tiles of this class for floor coverings is not recommended. Class 1 Floor coverings in areas mainly walked on in soft footwear or barefoot and not exposed to abrasive dirt (e.g. bathrooms and bedrooms without direct access from outside). Class 2 Floor coverings in areas occasionally walked on with soft or normal footwear and exposed to only little abrasive dirt (e.g. rooms in living areas of houses, except kitchens, entrances and similar heavily frequented rooms). This does not apply to special footwear such as e.g. hobnailed boots. Class 3 Floor coverings in areas frequently walked on with normal shoes and exposed to little abrasive dirt (e.g. kitchen-cum-living-rooms, halls, corridors, balconies, loggias and terraces). This does not apply to special footwear such as e.g. hobnailed boots. Class 4 Floor coverings walked on regularly and exposed to little abrasive dirt, so that they are subject to greater stress as in the case of class 3 (e.g. commercial kitchens, hotels, exhibition and sales rooms). Class 5 Floor coverings subject to heavy pedestrian traffic over long periods of time and exposed to little abrasive dirt, so that they are subject to the most extreme stress under which glazed tiles can be applicable (e.g. public areas such as shopping centres, entrance halls of airports, hotel foyers, public footpaths and industrial applications). Every floor covering is subject to wear. This depends on the area of application and the frequency of use, the kind and degree of dirt as well as the hardness and resistance to wear of the covering material. While unglazed vitrified floor tiles can be used practically anywhere, glazed floor tiles have to be categorized according to stress groups. Scrapers, mats and the like help to remove dirt and abrasives and to protect glazed floor coverings. Something of this kind has to be provided especially in rooms with direct access from outside or from the garden. Extreme Stress For such areas we recommend the use of integrally coloured, unglazed tiles, which are available in a wide range of colours and sizes. Examples: floors subject to high traffic loads, e.g. in supermarkets, hotels, schools, administrative buildings, railway stations, hospitals, passageways, etc., taking into account the mechanical load. 7. Coefficient of Expansion, DIN EN ISO 10545-8 The coefficient of expansion is ascertained between room temperature and 100C. The measured values are at around 6 x 106/K in the case of vitrified materials. At 8 m length and 50 temperature difference the result is an expansion of 2.4 mm (in the case of screed/concrete 4.6 mm and steel 5.6 mm). 8. Thermal Shock Resistance, DIN EN ISO 10545-9 The thermal shock resistance is tested between 15 and 145C. 9. Moisture Expansion, DIN EN ISO 10545-10 The moisture expansion is determined between tempered and water-saturated samples.

10. Resistance to Glaze Cracking, DIN EN ISO 10545-11 This test takes place in the autoclave at 500 KPa with subsequent colour control. Glazes with hair cracks/crazes are marked as such and require the wetting of the covering prior to pointing to avoid deposits of fine particles of the pointing mortar in the hair cracks. Coloured pointing compounds are not suitable in the case of these glazes. The glaze surfaces must not be marked with felt-tip pen and the like. 11. Thermal Conductivity etc. Thermal conductivity, heat radiation and storage capacity as well as the thermal resistance are not standardized. Vitrified material produces the following approximate values:

Thermal conductivity: Heat radiation: 1 W/m K 5.3 W/m2K4 Heat storage capacity: Thermal resistance: 0.8 kJ/kgK 0.01 m 2 K/W

These are excellent values compared to other building materials. 12. Electrical Leakage Resistance With normally > 1010 Ohm, ceramics is antistatic and insulating in dry condition. With the series Eladuct and KerAion ELA 10.6 (electrical leakage resistance 106 Ohm), however, we also offer conductive ceramic materials. The derivation ability for electrostatic charges of the floors according to DIN EN 1081 is measured locally. 13. Steam Diffusion Resistance According to DIN EN ISO 12572 the steam diffusion resistance is approx. 120,000 in the case of vitrified material/split tiles and 100,000 in the case of earthenware (excluding joints). 14. Resistance to Frost, DIN EN ISO 10545-12 The test for frost resistance is carried out on 10 samples or > 0.25 m2 samples. After water saturation under vacuum the samples are checked for defects after 100 frost-thaw alternations. The resistance to frost of an outdoor flooring, however, does not only depend on the quality of the ceramic tiles used. Professional construction and laying are essential. For this, please refer to our specifications and the notice of the umbrella organization of the German building and construction industry Outdoor Tiled and Paved Coverings. 15. Light and Colour Fastness Both glazed and unglazed ceramics are light- and colour-fast according to DIN 51094. 16. Luminance The lightness value of a tile describes the brightness of the surface as perceived by the human eye. The measuring value Y = 100 corresponds to the brightness of an absolutely white surface, and Y = 0 to that of an absolutely black surface. The lightness value is determined for mono-coloured tiles. 17. Behaviour in Fire Ceramic tiles are classified A 1 according to DIN 4102. Therefore, they are generally non-combustible and thus fire-resistant. Also in the case of fire they do not release any toxic emissions.

Technical Information

Price list 2010, status December 2009

Technical Information

7.07

Chemical Properties

1 Resistance to Chemicals, DIN EN ISO 10545-13 Resistance to Household Chemicals and Bath Water Additives Household chemicals Ammonium chloride solution 100g/l Bath salts Sodium hypochlorite solution 20g/l Classes unglazed: UA/UB/UC* glazed: GA/GB/GC* Resistance to Acids and Alkalis Low concentration (L) a) Hydrochloric acid solution 3% b) Citric acid solution 100g/l c) Potassium hydroxide solution 30g/l High concentration (H) a) Hydrochloric acid solution 18% b) Lactic acid solution 5% c) Potassium hydroxide solution 100g/l Classes unglazed: ULA/ULB/ULC or UHA/UHB/UHC* glazed: GLA/GLB/GLC or GHA/GHB/GHC* Acid Protection and Apparatus Engineering The resistance for acid protection engineering DIN EN 993-16 or chemical apparatus engineering DIN 28062 is subject to individual tests.

* Class A shows the highest resistance to chemicals, which decreases more and more towards C.

2 Stain Resistance, DIN EN ISO 10545-14 Stain Forming Substances Stain forming substances, leaving traces Green stain forming substances in oil Red stain forming substances in oil Chemical stain forming substances Iodine, 13g/l in alcohol Stain forming substances, forming a film Olive oil Cleaning (within the framework of the test) Cleaning agent Hot water (+55 C) Weak cleaning agent Strong cleaning agent Solvent Hydrochloric acid solution 3% Potassium hydroxide 200g/l Acetone Classes Cl. 5 / Cl. 4 / Cl. 3 / Cl. 2 / Cl. 1* 3 Lead and Cadmium Delivery The glazed surfaces are exposed to an acetic acid solution. Then, the quantity of the delivered lead and cadmium is determined.

* Class 5 shows the highest stain resistance, which decreases more and more towards 1.

Price list 2010, status December 2009

Technical Information

7.08

Technical Information

Surface Coatings and Upgradings

HYDROTECT Hydrotect is a highly effective and durable surface coating of tiles and panels of Deutsche Steinzeug. The coating baked onto the surface on the base of titanium dioxide uses the principle of photocatalysis. It offers the user the following advantages: A) HYDROTECT decomposes bacteria and germs The surface is activated by sunlight or artificial lighting. Activated oxygen forms, which decomposes microorganisms. B) HYDROTECT eliminates disagreeable odours Disagreeable or even unhealthy odours in the air are also eliminated by Hydrotect. C) HYDROTECT reduces the cleaning efforts The hydrophilic surface makes it possible for water to get under the dirt. In this way the quantity of cleaning agents is considerably reduced, which means a contribution to environmental protection and the saving of time for manual works at the same time. HYDROTECT surfaces are odourless, non-poisonous, meet the requirements for food and are completely harmless for persons suffering from allergies. Laying and pointing are carried out by the usual techniques. The conventional agents (without hydrofluoric acid and its compounds) are applicable for cleaning. All additives forming a film, leaving fat on the surface or impregnating are excluded, which impair the surface activation by light. Renowned institutes in Germany and abroad have confirmed us the corresponding effects of Hydrotect. Hygiene Deutsche Steinzeug tiles ensure the best possible hygiene conditions. They are densely sintered and offer no possibility for germs to proliferate. Tests of institutes for hygiene confirm the suitability for the covering of drinking water reservoirs. Hyper-sensitive people such as those suffering from allergies make the best experiences with tiles. Cleaning On principle, claddings and coverings must be protected by appropriate measures against heavy soiling which may be caused in particular by subsequent construction works (painting etc.) Our tiles can generally be cleaned with water and a neutral or alkaline cleaning agent. In the case of hard water, the sporadic use of acid cleaning agents is required. In the case of stains, cleaning depends on the type of stains and has to be carried out with suitable chemicals. In the case of a higher concentration of the cleaning agent used, subsequent wiping with clear water is required. Rinsing with clear water is absolutely necessary when carrying out a basic cleaning. Cleaning agents containing maintenance additives are not recommended by us. They usually reduce the slip resistance and cause a negative visual appearance of the floor covering by forming layers! Important: the use of cleaning machines with pads containing abrasive grain has a polishing effect by which the slip resistance of the tiles is considerably reduced. We therefore expressly disapprove of such methods. Hydrofluoric acid or its compounds attack the ceramics and cause irreversible damage! You will find detailed cleaning instructions for ceramic tiles on the Internet at www.agrob-buchtal.de Architectural Ceramics Download Cleaning Instructions. Impregnation Unglazed stoneware as well as polished surfaces except for our products of the series Quantum, Reflex and Life and with ceramic Protecta upgrading must be impregnated. The penetration of coloured liquids, fats and oils is prevented and cleaning is facilitated. The impregnating agent must be applied on the clean and dry floor; excess material must be removed immediately. Better Beats Good Unglazed vitrified tiles are hard-wearing and resistant by nature. Thanks to the Protecta surface upgrading, the stain and dirt resistance could be improved considerably: during the firing process, the coating applied in-plant is ceramically bonded to the biscuit and closes the existing micropores quite natural for unglazed ceramics. In this way, the penetration of substances forming stains is prevented. The subsequent impregnation recommended so far is no longer required. Products with Protecta surface upgrading are marked with PT . Resista Resista is a surface upgrading applied in-plant. It is used for unglazed split tiles and durably prevents the penetration of coloured liquids, fats and oils in the pores existing by nature. An impregnation after laying is thus no longer required.

Protecta Surface Upgrading

Technical Information

Price list 2010, status December 2009

Technical Information

7.09

Slip Resistance

1. Coefficient of Friction/Slip Resistance Workshop rules as well as accident prevention regulations require floors to be smooth, slip-resistant and easy to clean. Special protective measures against slipping are necessary where there is a risk as a result of the use of water, oil, slush, grease or waste. This should be taken into consideration when choosing the surface material. This clear requirement is based on investigations carried out by the insurance companies, which proved that slipping is the primary cause of accidents. 1.1. Industrial Areas Competent authority: Main organization of the Trade Associations, Central Office for Accident Prevention and Industrial Medicine, Alte Heerstrae 111, 53754 St. Augustin, Technical Committee Building Fittings. Test standard: DIN 51130 Code of practice: BGR 181 Floors in work rooms and work areas with high risk of slipping. Test procedure: Inclined plane, safety footwear worn, test medium oil. The surface finish can be smooth, fine-rough, rough or profiled. Valuation Groups In a detailed table (see next page) the required valuation groups are assigned to work areas where there is a high risk of slipping. Information is available from the trade associations and Deutsche Steinzeug.

Test on inclined plane

Valuation groups Angle of inclination > 6- 10 R9 low static friction Industrial + commercial areas

> 10- 19 R 10 normal static friction

> 19- 27 R 11 increased static friction

Displacement space Walked-on surface Displacement space Drainage level Tile Displacement space/Minimum volume: Displacement space/Minimum volume:

> 27- 35 R 12 high static friction

> 35 R 13 very high static friction

V4 V8

4 cm3 / dm2 8 cm3 / dm2

V6 V 10

6 cm3/ dm2 10 cm3/ dm2

The displacement space (V4-V10) is the open space between the upper walked-on surface and the drainage level of profiled surfaces.

The indicated angles of inclination exclusively serve for the assignment of the valuation groups and can not be equated with the angles of inclination of slopes/ramps.

Price list 2010, status December 2009

Technical Information

7.10

Technical Information

Legal Basis Workshop rules as well as accident prevention regulations require floors to be smooth, slip-resistant and easy to clean. The result of these requirements is the code of practice: BGR 181 Code of practice for floors in work rooms and work areas with high risk of slipping. Publisher: Deutsche Gesetzliche Unfallversicherung, Alte Heerstrae 111, 53754 St. Augustin, telephone 02241/231-0, www.hvbg.de, info@hvgb.de Available at: Download at www.arbeitssicherheit.de 0 0.1 0.2 0.3 0.4 0.5 General work rooms and areas*) Entrance areas, indoors**) R9 Entrance areas, outdoors R11 (or R10 V4) Stairs, indoors***) R9 Outdoor stairs R11 (or R10 V4) Social facilities (e.g. toilets, changing rooms and washrooms) R10 Break rooms (e.g. recreation room, company canteens) R9 Medical rooms R9 Manufacture of margarine, edible fats and oils Melting of fat Cooking oil refinery Margarine production and packaging Cooking fat production and packing, oil bottling Milk processing, cheese production Fresh milk processing and butter production Cheese production, storage and packaging Icecream manufacturing Chocolate and confectionery production Sugar processing Cocoa production Production of raw mixtures Fabrication of chocolate bars and shells and filled chocolates Production of bread, cakes and pastries (bakeries, cake shops, production of long-life bakery products) Dough preparation Rooms in which predominantly fats or liquid mixtures are processed Washing-up rooms Slaughtering, meat processing Slaughter-house Tripe processing room Meat sectioning Sausage kitchen Boiled sausage unit Raw sausage unit Sausage drying room Gut store Salting and curing rooms, smoking establishments Poultry processing Cold cuts and packaging unit Workshop with sales area Fish processing, production of delicatessen Fish processing Production of delicatessen Manufacture of mayonnaise Processing of vegetables Production of sauerkraut Vegetable tinning Sterilizing rooms Rooms in which vegetables are prepared for processing Wet areas in food and beverage production (if not specifically mentioned) Storage cellars Beverage bottling, fruit juice production Catering establishments Kitchens in the catering trade (restaurant kitchens, hotel kitchens) up to 100 meals per day more than 100 meals per day Kitchens catering for homes, schools kindergartens, sanatoria Kitchens catering for hospitals, clinics Large kitchens catering for industrial and university canteens, and contract catering Food preparation kitchens (fast food kitchens, snack bars) R13 V6 R13 V4 R12 R12 R12 R11 R12 R12 R12 R11 R11

9.6 9.7 9.8 9.8.1 9.8.2 9.8.3 9.9 10 10.1 10.2 11 11.1 11.1.1 11.1.2 11.2 11.3 11.3.1 11.3.2 11.4 11.5 11.6 11.6.1 11.6.2 11.7 11.8 11.8.1 11.8.2 11.9 11.10 11.10.1 11.10.2 11.11 11.12 11.13 11.14 11.15 12 12.1 12.2 12.3 12.4 12.5 12.6 12.7 12.8 12.9 12.10 12.11 12.12 12.13 12.14 13 13.1 13.2

Kitchens for heating up frozen meals Coffee and tea kitchens, hotel garni kitchens and ward kitchens Washing-up rooms Washing-up rooms for 9.1, 9.4, 9.5 Washing-up rooms for 9.2 Washing-up rooms for 9.3 Dining rooms, guest rooms, canteens including serving counters Cold stores, deep freeze stores for unpacked goods for packed goods

R10 R10 R12 V4 R11 R12 R9 R12 R11

1 1.1 1.2 1.3 1.4 2 2.1 2.2 2.3 3 3.1 3.2 3.3 3.4 4 4.1 4.2 4.3 5 5.1 5.2 5.3 5.4 5.5 5.6 5.7 5.8 5.9 5.10 5.11 5.12 6 6.1 6.2 6.3 7 7.1 7.2 7.3 7.4 8

Sales outlets, shops Reception of goods, meat for unpacked goods R11 for packed goods R10 Reception of goods, fish R11 Serving counters for meat and sausage for unpacked goods R11 for packed goods R10 Serving counters for bread, cakes and pastries, unpacked goods R10 Serving counters for dairy products and delicatessen, unpacked goods R10 Serving counters for fish for unpacked goods R12 for packed goods R11 Serving counters, except for nos. 11.3 to 11.6 R9 Meat preparation rooms for meat preparation, except for no. 5 R12 V8 for meat processing, except for no. 5 R11 Florists shops R11 Sales areas with stationary ovens for the production of bread, cakes and pastries R11 for the warming up of prefabricated bread, cakes and pastries R10 Sales areas with stationary chip pans or grills R12 V4 Shops, customer rooms R9 Preparation areas for food for self-service shops R10 Cash register areas, packing areas R9 Outdoor sales areas R11 (or R10 V4) Health service rooms Disinfection rooms (wet) Pre-cleaning areas of sterilization Faeces disposal rooms, discharge rooms, unclean nursing work rooms Pathological facilities Rooms for medical baths, hydrotherapy, fango preparation Washrooms of operating theatres, plastering rooms Sanitary rooms, ward bathrooms Rooms for medical diagnosis and therapy, massage rooms Operating theatres Wards with hospital rooms and corridors Medical practices, day clinics Pharmacies Laboratories Hairdressing salons Laundry Rooms with continuous-flow washing machines or with spin-drier Rooms with washing machines at which the clothes are taken out dripping wet Ironing rooms Fodder concentrate production Dried fodder production Fodder concentrate production using fat and water Leather production, textiles Wet areas in tanneries Rooms with fleshing machines Areas where leather scraps accumulate Rooms for making leather impermeable by means of grease Dye mills for textiles Paint shops Wet grinding areas Ceramics industry Wet grinding mills (processing of ceramic raw materials) Mixers; handling of materials like tar, pitch, graphite and synthetic resins Presses (shaping); handling of materials like tar, pitch, graphite and synthetic resins Moulding areas Glazing areas R11 R10 R10 R10 R11 R10 R10 R9 R9 R9 R9 R9 R9 R9

R11 R12 R12 V4

R13 V10 R13 V10 R13 V8 R13 V8 R13 V8 R13 V6 R12 R12 R12 R12 V6 R12 R12 V8 ****) R13 V10 R13 V6 R13 V4 R13 V6 R13 V6 R11 R12 V4

R9 R11 R9 R11 R11 V4 R13 R13 V10 R13 V10 R12 R11 R12 V10 R11 R11 V6 R11 V6 R12 R12

13.3 14 14.1 14.2 15 15.1 15.2 15.3 15.4 15.5 16 16.1 17 17.1 17.2 17.3 17.4 17.5

Technical Information

8.1 8.2 9 9.1 9.1.1 9.1.2 9.2 9.3 9.4 9.5

R10 R11

R11 V4 R12 V4 R11 R12 R12 V4 R12 V4

Price list 2010, status December 2009

Technical Information

7.11

18 18.1 18.2 18.3 18.4 18.5 18.6 19 19.1 20 20.1 20.2 20.3 21 21.1 21.2 21.3 22 22.1 22.2 22.3 22.4 23 23.1 23.2 23.3 24 24.1 24.2 24.3 25 25.1 25.2 25.3 25.4 26 26.1 26.2 27 27.1 28 28.1 28.2 28.3 29 29.1 29.2 29.3 29.4 29.5 29.6 29.7 29.8 29.9 30 30.1 30.2 30.2.1 30.2.2 30.3 30.4.1 30.4.2

Glass and stone processing Stone cutting, stone grinding Glass shaping of hollow glass ware, container ware, glass for building purposes Grinding areas for hollow glass ware, flat glass Insulating glass manufacture; handling of drying agents Packaging, shipping of flat glass; handling of anti-adhesive agents Etching and acid polishing facilities for glass Cast concrete factories Concrete washing areas Storage areas Storage areas for oils and fats Storage areas for packed food Outdoor storage areas Chemical and thermal treatment of iron and metal Pickling plants Hardening shops Laboratory rooms Metal processing, metal workshops Galvanizing shops Grey cast iron processing Mechanical processing areas (turnery, milling shop), punching room, pressroom, drawing shop (pipes, wires) and areas exposed to increased stress by oil and lubricants Parts cleaning areas, exhaust steam areas Vehicle repair workshops Repair and servicing bays Working and inspection pits Car washing halls, washing areas Aircraft repair workshops Aircraft hangars Repair hangars Washing halls Sewage treatment plants Pump rooms Rooms for sludge draining facilities Rooms for screening equipment Stands of workplaces, scaffolds and maintenance platforms Fire brigade buildings Vehicle parking places Rooms for hose maintenance equipment Financial institutions Counter areas Parking areas Garages, car-parks not exposed to weather influences*****) Garages, car-parks exposed to weather influences Open-air parking areas Schools and kindergartens Entrance areas, corridors, assembly halls Class rooms, group rooms Stairs Toilets, washrooms Instructional kitchens in schools (also see no. 9) Kitchens in kindergartens (also see no. 9) Machine rooms for wood processing Special rooms for handicrafts Schoolyards

R11 R11 R11 R11 V6 R11 V6 R11 R11

*) For floors in wet areas walked on barefoot, see the GUV information Floor coverings in wet barefoot areas (GUV-I 8527, previous GUV 26.17). **) Entrance areas according to number 0.1 are all areas with direct access from outside and in which moisture from outside can be brought. For adjoining areas or other rooms with large surfaces, paragraph 3.4 of this Code of practice has to be considered. ***) Stairs according to number 0.3 are those possibly exposed to moisture brought in from outside. For adjoining areas, paragraph 3.4 of this Code of practice has to be observed. ****) If the same floor covering was laid in all areas, the displacement space can be lowered down to V4 after a risk analysis (taking into consideration the cleaning method, the working processes and the quantity of slippery substances on the floor). *****) The pedestrian areas which are not subject to a risk of slipping because of weather influences such as driving rain or moisture brought in. In connected work places with differing slip risks, where employees move from one work place to the other, the same floor covering of the higher valuation group should be used for the entire area. If floor coverings of different slip resistance are used in connected work rooms or areas, only floor coverings of two consecutive valuation groups should be used next to each other, e.g. valuation groups R10 and R11 or R11 and R12 etc. This also applies to corridors and stairs adjoining wet areas such as e.g. sanitary rooms. The floors must be even to avoid stumbling and pools of water. This can be achieved by letting the floors slope gently towards the floor drains. To facilitate cleaning it may be useful to use smooth, non-profiled floor coverings along the walls up to a distance of 15 cm, in corners and under machines which are firmly fixed to the floor. A rounded edge carried out by a cove skirting between the walls and floor is easier to clean than a rectangular edge.

R12 V6 R10 R11 (or R10 V4) R12 R12 R11 R12 R11 V4 R11 V4 R12 R11 R12 V4 R11 V4 R11 R12 R11 V4 R12 R12 R12 R12 R12 R12 R9

R10 R11 (or R10 V4) R11 (or R10 V4) R9 R9 R9 R10 R10 R10 R10 R10 R11 (or R10 V4)

Price list 2010, status December 2009

Technical Information

Plant traffic routes in outdoor areas Footpaths R11 (or R10 V4) Loading platforms R11 (or R10 V4) covered not covered R12 V4 Sloping ramps (e.g. for wheel-chairs, loading platforms) R12 Tank-up areas R12 Tank-up areas, covered R11

7.12

Technical Information

1.2. Barefoot Areas Competent authority: Deutsche Gesetzliche Unfallversicherung, Fockensteinstrae 1, 81539 Munich, www.unfallkassen.de Floors in wet barefoot areas, e. g. swimming pools, hospitals as well as dressing rooms, washrooms and showers in sports and work facilities. Test standard: DIN 51097. Code of practice: GUV-I 8527 (GUV 26.17) Floor coverings in wet barefoot areas. Testing method: Inclined plane, walked on barefoot, wetting agent solution as test medium. The surfaces are smooth, micro-rough or slightly profiled. Nonslip glazes with their micro-rough surfaces have proved excellently in practice. The various areas are assigned to the valuation groups. Information can be obtained from the German National Association of Accident Insurance Companies and Deutsche Steinzeug.

Test on inclined plane

Valuation groups Angle of inclination Barefoot area

> 12 _

_ > 18

> _ 24

Valuation Group A Barefoot passages (nearly dry) Individual and common dressing rooms Pool floors in non-swimmer areas if the water depth is between 80 cm and 1.35 m in the entire area Sauna and relaxation areas (nearly dry) Valuation Group B Barefoot passages not classified in group A Showers and pool surrounds Area of disinfecting spray facilities Pool floors in non-swimmer areas if the water depth is less than 80 cm in certain areas Non-swimmer sections of wave-action pools Movable floors and paddling pools Ladders leading into the water Stairs leading into the water with a max. width of 1 m and handrails on both sides Ladders and stairs outside the pool area Relaxation steps and underwater ledges Sauna and relaxation areas if not classified in group A Valuation Group C Stairs leading into the water, not classified in group B Walk-through pools Inclined pool edge designs

The indicated angles of inclination exclusively serve for the assignment of the valuation groups and can not be equated with the angles of inclination of slopes/ramps.

1.3. Private Areas With regard to slip resistance, ceramic floor coverings in private areas are not subject to standard regulations. Independent of that, however, it is recommended to choose slip-resistant tiles according to your personal safety requirements.

Technical Information

Price list 2010, status December 2009

Technical Information

7.13

List of Addresses

DIN/EN/ISO Standards Sheets Beuth Verlag GmbH, Burggrafenstrae 6, 10787 Berlin Tel. 0049 (0) 30/2601-2260, www.beuth.de KOK Directives for Swimming Pool Construction Construction Directives for Medical Baths RK-List of Tested Cleaning Agents DGfdB Notices Deutsche Gesellschaft fr das Badewesen e.V., Alfredstrae 73, 45130 Essen Tel. 0049 (0) 201/87969-0, www.boeb.de ZDB Notices Professional Association for Tiles and Natural Stone in the Central Association of the German Construction Industry, Berlin Available from: Verlagsgesellschaft R. Mller GmbH, Stolberger Strae 84, 50933 Kln Tel. 0049 (0) 221/5497-0, www.rudolf-mueller.de BG Notices on Slip Resistance Deutsche Gesetzliche Unfallversicherung Alte Heerstrae 111, 53754 St. Augustin Tel. 0049(0)2241/231-0, www.hvbg.de Available from: C. Heymanns Verlag KG, Luxemburger Strae 449, 50939 Kln Tel. 0049 (0) 221/94373-0, download at www.arbeitssicherheit.de GUV Notices on Slip Resistance Deutsche Gesetzliche Unfallversicherung Fockensteinstrae 1, 81539 Mnchen Tel. 0049 (0) 89/62272-0, download at www.unfallkassen.de Deutscher Industrieverband Keramische Fliesen und Platten e.V. Luisenstrae 44, 10177 Berlin Tel. 0049 (0) 30/27 59 59 74-0, www.fliesenverband.de Quality Controls Quality controls are carried out by: manufacturers themselves with strict sorting controls and special tests by the Deutsche Steinzeug laboratories individual and batch testing by external material testing institutions in Germany and abroad

Certificates

The characteristics and the quality of our products are constantly tested by acknowledged material testing institutions. The corresponding test certificates are available.

Register number: P1B017/01

Price list 2010, status December 2009

Technical Information

7.14

Special Pieces for Barrier-free Building

Shower Tub System - System Plural plus

The shower tub system consists of special tiles for realizing a shower tub integrated in the tile covering. The shower tub system is a registered design. It meets the requirements of DIN 18024 Barrier-free building and DIN 18025 Barrier-free living and has been awarded the Barrier-free. DIN tested test symbol (Register number: P1B017/01). In Germany, the 10 mm lip means that it is possible to take full advantage of various housing grants. The 100 mm modular dimension inclusive of a 3 mm wide joint guarantees perfectly hygienic tile coverings with a narrow joint width and accurately sized tiles. In the case of this system, no movement joint (maintenance joint) between the shower tub and the surface covering is required, which would be necessary in the case of other variants (prefabricated shower tub elements). The screed (according to DIN 18560) is only by 10 mm lower in the area of the shower tub. The minimum nominal thickness of the screed must be complied with. As with all slip-resistant surfaces of the System Plural, the surfaces of both the glazed and the ceramically upgraded unglazed tiles are very easy to clean. The shower tub system is predestined for wet areas in hospitals, sanatoriums, rehabilitation centres, old peoples and nursing homes, but also for showers in commercial areas, swimming pool, sauna and sports facilities, hotel and private bathrooms.

Register number: P1B017/01

1. The shower tub is a module with the necessary slope that can be integrated in the joint grid of the tile covering as required.

2. In combination with the cove skirting laid horizontally, a rounded transition between floor and wall covering is possible.

Plural plus 2, honeycomb structure

Plural plus 3, Softcorn

Corner

97 97

Corner

97 97

16,5

20,5

6,5

10,5

Strip

97 97

Strip

97 97

16,5

20,5

Technical Information

6,5

10,5

10 6,5

16,5

10 10,5

20,5

Price list 2010, status December 2009

Special Pieces for Barrier-free Building

7.15

The Shower Tub System of the Series Marino, Capestone, Quantum and Rovere

This shower tub system consists of only two components: the strip and the one-piece corner belonging to it. A peculiarity of the system is the special form of the slope which provides a difference in height of 10 mm. The edge of the shower tub designed in this manner is easy to pass on foot and with a wheel-chair. The relevant requirements (e.g. DIN 18024 or 18025) with regard to barrier-free construction taking into account the needs of senior and handicapped persons are effectively supported in this way. Thanks to the integrated slope the time-consuming execution of the edge of the shower tub on site is no longer required, and together with the even lower side facilitating laying the processing of these tiles is absolutely simple: It is sufficient to lay an appropriate substitute material (chip board or the like) in the screed and to remove it after hardening. Prefabricated substructure elements are not required. In the case of this system, no movement joint (maintenance joint) between the shower tub and the surface covering is required, which would be necessary in the case of other variants (prefabricated shower tub elements). The screed (according to DIN 18560) is only by 10 mm lower in the area of the shower tub. The minimum nominal thickness of the screed must be complied with.

Register number: P1B017/01

The shower tub system is perfectly completed by the series Marino, Capestone, Quantum and Rovere.

The shower tub system is based on a grid size of 12.5 x 12.5 cm. This permits a very variable dimensioning of the shower tub independent of standard dimensions and a harmonious integration in the shower installation or sanitary block.

Strip

Door casing

Door leaf

119

119

1 3 2 6 5 7 8

Floor structure with base-bonded, composite sealing layer 1 AGROB BUCHTAL ceramics 2 Thin-bed mortar 3 Base-bonded, compos. sealing layer 4 Screed CT, C20 (ZE 20) 5 Sliding layer, PE foil 6 Heat insulation, rigid plastics 7 Footfall sound insulation, soft 8 Reinforced concrete ceiling/floor

18

Strip

119 4 2 4

18120

e.g. model sizes 12.5 x 12.5, 25 x 12.5 or 25 x 25 cm

Cove skirting, (model no. 37080)

Skirting, (model no. 17190)

Corner

119 119

Wall connection variants

The shower tub systems of AGROB BUCHTAL are laid on a continuous cement screed and therefore do not require a highmaintenance movement joint between shower tub and adjoining areas.

Price list 2010, status December 2009

Technical Information

37070

17190

18

Slope

-0.010

0.000

Slope

18

7.16

Orientation Aid for the Blind

Floor Markings as Guide and Tactile Strip for the Blind

Standards DIN 18352 DIN 32984 Tile laying works Ground surface indicators in public traffic areas Surface Covering Stoneware tiles from AGROB BUCHTAL, 30 x 30 x 1.0 cm, smooth surface, slip-resistance valuation group R11, in a colour contrasting with the guide tiles. Bases a) Raw concrete surfaces C 25/30 b) Cement screed surfaces CT- C25 Laying Thin-bed laying Combined method (buttering-floating) according to DIN 18157 with flexible mortar, porcelain stoneware bonding agent or floating-bed mortar. Pointing By the grouting method In the case of chemical, hygienic and mechanical stress: with Epoxi for joints, joint widths according to the tile module. Movement Joints Field sizes as required or according to the ZDB code of practice.

Other guide tiles corresponding to the current regulations can be supplied. Available upon request. Applications Ground surface indicators as orientation aid for blind and visually impaired persons in public institutions, public transport systems and roads. Guide Strip Guide tile from AGROB BUCHTAL, 30 x 30 x 1.0 cm, unglazed with special surface grooves to be felt by means of the cane. Slip-resistance valuation group R11/A.

18 5

18 5

18 5

10 5

22

29 7

2 9 7

Technical Information

Price list 2010, status December 2009

Orientation Aid for the Blind

7.17

Arrangement of the Guide Strips for the Blind analogous to DIN 32984

Kerb 30 cm 60 90 cm 30 cm 30 cm 60 90 cm Stair landings

Pedestrian crossing

90 cm 60 cm

Road Demarcation strip 50 cm Pavement area

90 x 90 cm 60 200 cm Platform edge Platform edge Zone of attention Guide strip

Platform edge

Interception strip

Price list 2010, status December 2009

Technical Information

7.18

Details

Cove Skirting 10 x 10, 10 x 15 and 10 x 20 cm (details)

Cove Skirting 10 x 10 cm Plural plus 2, smooth and slip-resistant, 10 x 10 cm Basis 2, smooth, 10 x 10 cm glazed, length 97 mm

6,5 13,5

100

3 r1

7

Cove Skirting 10 x 10, 10 x 15 and 10 x 20 cm Fitting to:

102

5 r 2

6,5

Plural plus 3, smooth or Softcorn 10 x 10, 10 x 15, 10 x 20 cm, unglazed

7,5

14

Basis 2+, 10 x 10, 10 x 20 cm, unglazed Industria, 10 x 15 cm unglazed

Internal Corner

External Corner

24

Mould Fitting to cove skirting:

r = 3,5

r = 10

r = 3,5

Plural plus 2, 10 x 10 cm, glazed

100

6,5 6,5

18

Internal Corner Fitting to cove skirting:

17

100

97

External Corner

22 9

Fitting to cove skirting: Plural plus 3, 10 x 10, 10 x 15 and 10 x 20 cm, unglazed Basis 2 +, 10 x 10 and 10 x 20 cm, glazed

102 6

Technical Information

Plural plus 3, 10 x 10, 10 x 15 and 10 x 20 cm, unglazed Basis 2 +, 10 x 10 and 10 x 20 cm, glazed

102

Basis 3, 10 x 15 and 10 x 20 cm, unglazed Industria, 10 x 15 cm, unglazed

Basis 3, 10 x 15 and 10 x 20 cm, unglazed Industria, 10 x 15 cm, unglazed

6 38

Price list 2010, status December 2009

Glazed edges, natural stone and glass decoration elements

7.19

Glazed edges earthenware tiles (10 % per delivery)

Longit. edge Short edge 15 x 15 cm yes no 15 x 20 cm yes no 20 x 20 cm yes no 20 x 25 cm yes no 25 x 33 cm yes yes 25 x 44 cm yes yes 30 x 45 cm yes yes 30 x 60 cm yes yes

Natural stone decoration elements

Every natural stone is a naturally grown material. Consequently, each individual granite tile and natural stone decoration element becomes a unique piece. Different structures and colour shades underline the character of this natural material and have always been typical of the appearance of a natural stone covering. As a result, we can not assume liability for differences with regard to colour, structure and other natural characteristics. The natural stone articles do not meet the chemical and physical requirements of DIN EN 14411. For cleaning, only acid-free, non-caustic cleaning agents may be used. The illustrations of the natural stone decoration elements in this price list/programme of delivery convey only a general impression. For reasons of printing, however, they have to be regarded as non-binding.

Glass decoration elements

The glass decoration elements offered by us are, for the most part, hand-made design elements. Each piece is unique. As a result of the manufacturing process, slight variations with regard to the size, the colour and the structure may occur, which lend this special product its individual character. For cleaning, we recommend a commercially available glass cleaning agent, which should be applied by means of a clean and soft cloth. To avoid permanent damage on the surface, it is absolutely necessary to make sure that the glass elements do not come into contact with scratching (mortar and bonding agent residues) and abrasive materials (cleaning powder). The illustrations of the glass decorations in this price list/programme of delivery convey only a general impression. For technical reasons of printing, however, they can not be considered as binding.

Price list 2010, status December 2009

Technical Information

7.20

CE marking

CE marking according to the description in the obligatory annexes Q, ZA and ZB of the harmonized standard EN 14411 Ceramic tiles. From the 1st December 2005, products for which the application of the Directive for construction products 89/106/EEC is relevant must be provided with the CE marking. With the CE marking, the compliance with the essential requirements of this directive is declared. Our products of course meet the conditions of the EC directive in force and are provided with the CE marking accordingly. Further explanations / background information concerning the CE marking: 1. CE marking as condition for the commercialization of products From the 1st December 2005, manufacturers and importers themselves are obliged to mark products subject to the European Directive for construction products either directly or their packaging or the accompanying documents with the CE marking. The CE marking is a condition for the distribution within the EU and thus required for the first commercialization of a product. The target of the Directive for construction products 89/106/EEC is to harmonize laws, regulations and administrative provisions of the member states in order to make sure that structural and civil engineering projects are constructed and realized in such a way that the safety of persons and goods is not at risk and that at the same time other essential requirements in the interest of the public welfare are taken into account. Construction products are only authorized for the free movement of goods within the Community if they are suitable for their intended utilization, which presupposes that they meet the essential requirements defined in the Directive for construction products with regard to the health and safety of the users, which include the following fields: mechanical resistance and stability; fire protection; hygiene, health and environment; safety of utilization; sound insulation and energy saving as well as thermal insulation.

2. The CE marking is an administrative mark The CE marking is an administrative mark exclusively addressed to the governmental supervising authorities. The CE marking indicates to these authorities that the marked product corresponds to the European legislation at the time of its commercialization. 3. Declaration / certificate of conformity The declaration of conformity is the act by which the manufacturer himself declares that a product, process or service corresponds to a specific standard or any other set of regulations. The manufacturer is responsible for the certificate of conformity of the product. In addition to the CE marking and for each CE-marked product, the manufacturer must draw up a declaration of conformity based on the tasks which were carried out on his own responsibility or by a named laboratory. 4. Commerce and consumers have no right of inspection of certificates of conformity of the manufacturers The right to demand and inspect certificates of conformity is exclusively reserved to the market supervising authorities in charge of supervising the compliance with the legal safety requirements of construction products. 5. The CE marking is no quality or test mark The CE marking only refers to the compliance with the fundamental requirements stipulated by law of certain directives. Thus, is does not at all imply any statement concerning the quality of the marked products. As an administrative mark prescribed by law without any value for consumers and users, the CE marking should not be mixed up with the test marks issued by independent test institutes (such as e.g. MPA NRW, NF UPEC). These test institutes also do not check whether a product is provided with the CE marking in accordance with the law.

Technical Information

Price list 2010, status December 2009

7.21

Price list 2010, status December 2009

Technical Information

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Wiring Matters Full File PDFDokument35 SeitenWiring Matters Full File PDFKhay SaadNoch keine Bewertungen

- HSG202 - VentilationDokument22 SeitenHSG202 - Ventilationmichael_george291616Noch keine Bewertungen

- Facts About Soil ImprovementDokument4 SeitenFacts About Soil ImprovementCarina GhitaNoch keine Bewertungen

- KoshinoSlides PDFDokument18 SeitenKoshinoSlides PDFHuy DeathlyNoch keine Bewertungen

- Chassidut VishnitzDokument17 SeitenChassidut VishnitzCarina GhitaNoch keine Bewertungen

- Construction & MaterialityDokument178 SeitenConstruction & MaterialityHugh Rolland80% (5)

- Revit Keyboard Shortcuts Guide PDFDokument9 SeitenRevit Keyboard Shortcuts Guide PDFMohit KohliNoch keine Bewertungen

- Focus No2 2012 Mineral ResourcesDokument2 SeitenFocus No2 2012 Mineral ResourcesCarina GhitaNoch keine Bewertungen

- Library BooklistDokument18 SeitenLibrary BooklistCarina GhitaNoch keine Bewertungen

- Erasmus Orade ADokument792 SeitenErasmus Orade ACarina GhitaNoch keine Bewertungen

- Folding ArchitectureDokument74 SeitenFolding Architecturebobhartry100% (6)

- Architecture Is Participation - Susanne HofmanDokument130 SeitenArchitecture Is Participation - Susanne HofmanCarina GhitaNoch keine Bewertungen

- Participative Design&PlanningDokument123 SeitenParticipative Design&PlanningrasmussenchristinaNoch keine Bewertungen

- Rhino Level1Dokument268 SeitenRhino Level1han_solo_the_firstNoch keine Bewertungen

- Cup RinsDokument1 SeiteCup RinsCarina GhitaNoch keine Bewertungen

- ArtlantisDokument220 SeitenArtlantisBrainerd Rein DatumbanuaNoch keine Bewertungen

- Rhino Level 2 v4 (ENGLISH)Dokument0 SeitenRhino Level 2 v4 (ENGLISH)Baris AkgülNoch keine Bewertungen

- The Future For ArchitectsDokument24 SeitenThe Future For ArchitectsmellacrousnofNoch keine Bewertungen

- The Future For ArchitectsDokument24 SeitenThe Future For ArchitectsmellacrousnofNoch keine Bewertungen

- Home 201201 XDokument67 SeitenHome 201201 XCarina GhitaNoch keine Bewertungen

- Library BooklistDokument18 SeitenLibrary BooklistCarina GhitaNoch keine Bewertungen

- AC Training Series Vol.1Dokument62 SeitenAC Training Series Vol.1Michael RogersNoch keine Bewertungen

- Home 201202 XDokument67 SeitenHome 201202 XCarina GhitaNoch keine Bewertungen

- Introduction To History of ArchitectureDokument41 SeitenIntroduction To History of ArchitectureDR-Eiman El-IskandaraniNoch keine Bewertungen

- Poker Player UK 2013-02 PDFDokument68 SeitenPoker Player UK 2013-02 PDFCarina GhitaNoch keine Bewertungen

- Poker Player UK 2013-02 PDFDokument68 SeitenPoker Player UK 2013-02 PDFCarina GhitaNoch keine Bewertungen

- Photoshop User - February 2013Dokument108 SeitenPhotoshop User - February 2013Vasilis PolykarpidisNoch keine Bewertungen

- Ng4k0 Detail Magazine 2012 SpaiDokument51 SeitenNg4k0 Detail Magazine 2012 SpaiCarina Ghita0% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- SG-05 Safety Guideline For Illumination at WorkplaceDokument5 SeitenSG-05 Safety Guideline For Illumination at WorkplacebsrchandruNoch keine Bewertungen

- High Carbon Steel Shot GritDokument2 SeitenHigh Carbon Steel Shot Gritabdulaziz mohammedNoch keine Bewertungen

- T2 Homework 2Dokument3 SeitenT2 Homework 2Aziz Alusta OmarNoch keine Bewertungen

- Chemistry, Intermediate II Year Model Question PapersDokument3 SeitenChemistry, Intermediate II Year Model Question PapersAkshay PandeyNoch keine Bewertungen

- 115 Test Out Study GuideFeb2017Dokument16 Seiten115 Test Out Study GuideFeb2017Ashish MalikNoch keine Bewertungen

- ORT ReportDokument71 SeitenORT ReportNaveen ChodagiriNoch keine Bewertungen

- Agc-4 DRH 4189340686 UkDokument222 SeitenAgc-4 DRH 4189340686 UkGiangDoNoch keine Bewertungen

- EVI DC Inverter Technical Manual 2 Capacity TableDokument67 SeitenEVI DC Inverter Technical Manual 2 Capacity TableMouyed Al QasemNoch keine Bewertungen

- Lec8 SecondOrder PDFDokument61 SeitenLec8 SecondOrder PDFPhan Phuong NgocNoch keine Bewertungen

- Differential Calculus Assignment No.3Dokument20 SeitenDifferential Calculus Assignment No.3Agerico FunelasNoch keine Bewertungen

- Astm D3212.380331 1Dokument3 SeitenAstm D3212.380331 1anish_am2005Noch keine Bewertungen

- Tech. Specs. For 11 KV DP StructureDokument7 SeitenTech. Specs. For 11 KV DP StructureSaraswatapalitNoch keine Bewertungen

- Gestrast 6Dokument3 SeitenGestrast 6iran1362Noch keine Bewertungen

- Pso MPPTDokument10 SeitenPso MPPTDileep GNoch keine Bewertungen

- Final ProjectDokument4 SeitenFinal Projectsajad soleymanzadeNoch keine Bewertungen

- STK412 150 Sanyo PDFDokument4 SeitenSTK412 150 Sanyo PDFroger.Noch keine Bewertungen

- A Business Intelligence Framework For The FutureDokument10 SeitenA Business Intelligence Framework For The Futuremcalbala100% (1)

- Batteries and Primitive Survival Ebook 2008+ PDFDokument333 SeitenBatteries and Primitive Survival Ebook 2008+ PDFOceanNoch keine Bewertungen

- M2.2.9 Critical Review and Selection of NDT MethodsDokument13 SeitenM2.2.9 Critical Review and Selection of NDT MethodsAldy Bagus PratamaNoch keine Bewertungen

- Unit 16Dokument35 SeitenUnit 16api-334267616Noch keine Bewertungen

- LSV-08-2 NCPDokument2 SeitenLSV-08-2 NCPishtiaqNoch keine Bewertungen

- Tem 3413354 0101Dokument67 SeitenTem 3413354 0101Kolawole KehindeNoch keine Bewertungen

- Hitachi EX3600 Hydraulic Excavator PDFDokument11 SeitenHitachi EX3600 Hydraulic Excavator PDFChaerul Umami100% (1)

- Chapter 1 Introduction: U V U U V X y yDokument56 SeitenChapter 1 Introduction: U V U U V X y ywithyou100% (1)

- Guide To Using In-Situ Tensile Pull-Off Tests To Evaluate Bond of Concrete Surface MaterialsDokument12 SeitenGuide To Using In-Situ Tensile Pull-Off Tests To Evaluate Bond of Concrete Surface MaterialsMauricio Javier León TejadaNoch keine Bewertungen

- f77 f55 User ManualDokument36 Seitenf77 f55 User ManualGabi GabrielNoch keine Bewertungen

- Honcha QT6 16 PDFDokument7 SeitenHoncha QT6 16 PDFSuhendra Amka PutraNoch keine Bewertungen

- Dual Draw/Dual Return Fuel System TroubleshootingDokument4 SeitenDual Draw/Dual Return Fuel System Troubleshootinginformer techNoch keine Bewertungen

- Pressure Switch/Reed Switch Type: SeriesDokument4 SeitenPressure Switch/Reed Switch Type: SeriesDaniel Mauro Inga SalazarNoch keine Bewertungen

- EnglishDokument6 SeitenEnglishThineswary Siva naiduNoch keine Bewertungen