Beruflich Dokumente

Kultur Dokumente

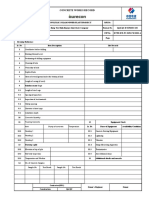

Troubleshooting Checklist

Hochgeladen von

Irma KnuttOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Troubleshooting Checklist

Hochgeladen von

Irma KnuttCopyright:

Verfügbare Formate

-EXTERIOR EXAMINATION -Unload the rifle and verify clear.

-Check the rifle for any damage from being dropped. Check the muzzle, front and rear sights, hand guards, barrel, buttstock, and sight alignment. -Ensure that the drain hole in the upper buttstock is clear. -Check steel parts for rust and porosity. -Check for any parts that may be loose on the rifle. Check the pistol grip, buttstock, front sight assembly, barrel, and the flash suppressor. -Pull charging handle back to check carrier for any binding or roughness. -Check the bolt catch tension and range of motion; depress bottom of bolt catch and retract carrier, check for binding of carrier on the bolt catch. -Check the magazine catch tension and range of motion. The magazine catch latch should sit flush in its slot and its threaded end should be flush with the surface of the magazine catch button. -Check that the ejection port cover functions in the open and closed positions. Make sure that the C clip is on the ejection port cover hinge pin and that the ejection port cover spring is properly installed. -Operate safety and check for proper function, tension, and range of motion. -Check the trigger pull and disconnector engagement; perform the function check. -Check that charging handle locks into upper receiver easily. -Check that the paddle of the bolt catch is not hitting the outside of the upper receiver. -Ensure that the gas tube roll pin is present. -With the bolt slightly out of battery, ensure that the forward assist fully closes the bolt. -INSPECTION OF UPPER -Pivot upper open/ shotgun, you should feel the buffer pushing against the carrier when you do this, check the takedown pin for ease of movement and fit. -Check that the bolt carrier moves easily from the locked position to the recoil position by moving it with your finger, not with the charging handle. -Check to make sure that the rear of the carrier is flush with the end of the upper receiver when the carrier is fully forward. -Separate the upper and lower receivers. Make sure the pivot pin moves easily and is secure. -Remove the bolt carrier and the charging handle. -Ensure that the auto sear clearance cut is present. -On A2, sights make sure that the drain hole under the elevation wheel lock screw is clear. -Ensure that the takedown pin lug has the proper bevels and facets and that the pinhole is chamfered and oblong. -Check the charging handle for damage and straightness, check for damage to the upper where the charging handle locks in place. -Clean and inspect the bore, look for excessive wear, rings, scratches, or other damage. Look for evidence of chrome plating around the muzzle and chamber. -Check the crown of the barrel for burrs and wear. -Check the end of the gas tube for excessive wear or damage. -Inspect the inside of the upper for damage, such as cracks or wear around the cam pin

clearance cut. -Check the gap between the receiver and the barrel extension; it should be no more than 0.012. -Inspect the feed ramps for smoothness and completeness. -On A2, sights make sure that the rear sight base hits the receiver on the last whole click of the elevation wheel. Check the alignment of the 3/8 or 3/6 with the index mark on the receiver. -On A2 sights, run the rear sight base to its highest elevation, ensure that it does not rock back, or twist more that it does in its lowest position. -INSPECTION OF BOLT CARRIER -Check the carrier key. Make sure that the key is tight, the screws are tight and staked in, and thee is no damage to the front of the key. Use a wrench to make sure the carrier key screws are not broken. -Operate the bolt to make sure it moves smoothly in the carrier. -Remove the firing pin retaining pin, the firing pin, and the cam pin, with the bolt in the unlocked position stand the bolt carrier on end. The bolt should not slip into the bolt carrier. -Remove and inspect the bolt, inspect the locking lugs for damage or excessive wear, ensure that there is a swage on the cam pin hole. -Check the firing pin retaining pin for damage and straightness. If the firing pin retaining pin is bent, then the hammer may be dragging on the firing pin. -Check the cam pin, firing pin, and the gas rings for damage and wear. -Check the firing pin protrusion. Use a gauge or calibrated eyeball. -Depress the ejector to check its tension and to make sure the ejector goes flush with or below the bolt face. -Check the extractors tension and range of motion using a cartridge case. Check it in both the locked and unlocked positions in the bolt carrier. -Remove the extractor. Check the pin and hook for damage, and check the spring and bumper. -Check to make sure that the gas tube does not bind in the carrier key and for proper gas tube alignment. -Clean and inspect the chamber, look for scratches, rings or other damage. -Reassemble the bolt carrier; make sure that the head of the firing pin retaining pin is flush or below the surface of the bolt carrier. -Slide the carrier and charging handle back into the upper receiver, lock the charging handle in place, and hold the bolt carrier to the rear. -With the upper at a 40 angle to the ground release the bolt carrier and check that it locks fully into the barrel extension under its own weight. -Check the headspace. The barrel must take a civilian or military GO gage; most military barrels will also accept the civilian NOGO gage.

-INSPECTION OF LOWER -Trigger guard should not protrude into the magazine well. -Insert a magazine into the magazine well and ensure that it drops free. -Check the pivot pin, and takedown pin for wear and fit, they should be snug but slide easily. -Check disconnector engagement: with the trigger forward, rotate the hammer to just short of the cocked position; the tip of the disconnector should almost touch the middle hammer hook. Holding the trigger to the rear, cock the hammer and release the trigger, the trigger should catch the hammer, and the hammer should smoothly slide out from under the disconnector hook. -Do not allow the hammer to strike the lower receiver or the bolt catch. -Remove the hammer and check the hammer spring for proper placement and tension. Inspect the middle hammer hook, lower hammer hook, and the J spring for damage. Ensure that stake retaining the J spring is present. -Remove the trigger and disconnector. Check for proper installation of the trigger spring and that the disconnector spring is present. -Check the hook of the disconnector for damage. -Inspect the trigger, check the tension of the trigger and disconnector spring, and look for wear or damage on the sear face of trigger. -Ensure that the disconnector slides easily in the trigger slot. -Check the inside of the lower for foreign matter, such as a primer in the pistol grip hole. -Remove the buffer and spring and inspect them for damage; such as small indents in the face of the buffer caused by the buffer retaining pin. Check the buffer spring for proper length; 11 -13 for rifles 10 1/16-11 for carbines. -Check the buffer retaining pin for function and range of motion. -Check the buttstock screws and lower receiver extension for tightness. -Reinstall the buffer and spring. -Reinstall the trigger, disconnector, and hammer. -When installing the hammer the hammer spring legs must be on top of the trigger pin and in the outside annular groove on the trigger pin. Failure to do so will allow the trigger pin to move. The wide end of the disconnector spring goes into the hole in the trigger. -Reassemble the upper and lower receivers. -Check to make sure that the charging handle does not drag on the bridge of the lower receiver. -Look into the magazine well to ensure that the upper receiver does not overhang the magazine well. -Insert an empty magazine and check for fit and function of magazine catch and bolt stop. The magazine should release smoothly and insert without undue force. Pull the bolt to the rear with the charging handle. The bolt should lock to the rear.

-THE RIFLE IS READY TO BE TEST FIRED-TEST FIRING PROCEDURE-Unload the rifle and verify that it is clear. -Check the bore for obstructions. -Load the rifle with one round from the magazine. Use quality ammunition and a proven magazine for this. -Aim downrange and fire, the bolt should catch on the bolt stop. Hold the rifle as loosely as possible. -Reload and repeat the process if the rifle does not lock open. Depress the bottom of the bolt stop before firing this time. This allows for weak magazine springs, sticky followers, or an overly strong bolt catch spring. -If the bolt does not lock open then there is a gas system problem. Investigate and repair the problem. -If it only locks open with the bolt stop depressed, repeat the process with a different magazine. If the rifle still fails to function then look at the bolt stop as a probable culprit. -If it does lock open then continue to the grouping phase. -At your favorite zero distance, fire a group. Three, six, ten rounds it doesnt matter. Look for center wind and mechanical zero on the front sight. The rifle should shoot somewhere near those settings. Adjust the windage if it is excessive, from the front sight, with a rawhide mallet. If the elevation or windage is greater than can be adjusted for at close range, there could be serious problems with the rifle. The barrel may be bent or the sights may be crooked or mounted too high. -Your windage zero should be within five clicks of center wind/mechanical zero at 100 yards/91.4 metres. I prefer my rear sight to be a centered as possible as it allows me to get on the sights faster. -ADDENDUM-The Army considers groups of four centimeters at twenty-five meters to be good enough. Your opinion will vary. Four centimeters at 25 meters is equivalent to nearly 5.5MOA. -The Army zeros their rifles at 25 meters; they also believe that a scared kid knee deep in mud, using his dead friend as a rifle rest can detect and effectively engage an enemy squad at 800 meters. Use your own discretion where your life is concerned. Look at your area of operations and determine what distances and targets you will encounter, work backwards from there. -The only way to know if your rifle works is to shoot the hell out of it using the same kind of ammunition and magazines each time. The brand name, the origin of the parts does not matter one bit. All that matters is function. Rifles that do not work one hundred percent are a liability and only a moron would keep one that doesnt. I would take a functioning gun show special over a broken Colt any day of the week. -This rifle is one piece of your life support equipment treat it as such. -This rifle is a piece of your life support equipment; I will treat it as such.

Das könnte Ihnen auch gefallen

- 16950s01 HV Testing ProceduresDokument1 Seite16950s01 HV Testing ProceduresVICTOR JOSE VILORIANoch keine Bewertungen

- Substation Earth System Injection Testing SWP: 1. Purpose and ScopeDokument10 SeitenSubstation Earth System Injection Testing SWP: 1. Purpose and ScopeJarrett MathewsNoch keine Bewertungen

- SG3125HV: Turnkey Station For SystemDokument2 SeitenSG3125HV: Turnkey Station For SystembajrangNoch keine Bewertungen

- ITP Transformer Testing and CommissioningDokument1 SeiteITP Transformer Testing and CommissioningguspriyNoch keine Bewertungen

- DOD-RGX-F427 - FIBRE OPTIC CABLE Splice Termination Test ReportDokument2 SeitenDOD-RGX-F427 - FIBRE OPTIC CABLE Splice Termination Test ReportBharathiNoch keine Bewertungen

- Attachment 3 - Bolt Tensioning Task PlanDokument4 SeitenAttachment 3 - Bolt Tensioning Task Planchancele nguepdjopNoch keine Bewertungen

- Anchr Bolt RefDokument9 SeitenAnchr Bolt ReferleosNoch keine Bewertungen

- Anchor Bolt MSDokument7 SeitenAnchor Bolt MSGaneshNoch keine Bewertungen

- MHI Electrical 1st Comment RSAE-MTS-QA-EL-009 MTS For MotorsDokument17 SeitenMHI Electrical 1st Comment RSAE-MTS-QA-EL-009 MTS For MotorskamilNoch keine Bewertungen

- Transformer Method StatementDokument13 SeitenTransformer Method StatementHareesh R IyerNoch keine Bewertungen

- Overhead Lines Andy PMDokument3 SeitenOverhead Lines Andy PMengrandyNoch keine Bewertungen

- SPI HSE FR 03 Stringing ChecklistDokument1 SeiteSPI HSE FR 03 Stringing ChecklistChandan KumarNoch keine Bewertungen

- Schneider Automatic Circuit Recloser SWP: 1. Purpose and ScopeDokument7 SeitenSchneider Automatic Circuit Recloser SWP: 1. Purpose and ScopeJairo WilchesNoch keine Bewertungen

- Inspection and Test Plan For Steel StructureDokument1 SeiteInspection and Test Plan For Steel Structureeva maniceNoch keine Bewertungen

- KBR Inspection Test Plan For Bus Duct: NO. Inspection Activity 1 Pre-Inspection Meeting 2 Documentation ReviewDokument2 SeitenKBR Inspection Test Plan For Bus Duct: NO. Inspection Activity 1 Pre-Inspection Meeting 2 Documentation ReviewkamlNoch keine Bewertungen

- ITP For Testing and Commissioning of ACSDokument1 SeiteITP For Testing and Commissioning of ACSRommel Espinosa ParasNoch keine Bewertungen

- QM Plan ProcedureDokument13 SeitenQM Plan ProcedureHans JonesNoch keine Bewertungen

- 04-2-TS vOL-II, Sec-IV, FQP R1 PDFDokument20 Seiten04-2-TS vOL-II, Sec-IV, FQP R1 PDFsanjeevchhabraNoch keine Bewertungen

- Inspection Test Plan For Fabrication PDF FreeDokument4 SeitenInspection Test Plan For Fabrication PDF Freesam paulNoch keine Bewertungen

- Checklist CablesDokument2 SeitenChecklist CablesSourav RanaNoch keine Bewertungen

- Elcometer 456 User Manual PDFDokument76 SeitenElcometer 456 User Manual PDFchaparal100% (1)

- 5 Formwork ChecklistDokument81 Seiten5 Formwork ChecklistAlphaNoch keine Bewertungen

- Inspection & Test Plan For Control Valve: Project: PP Pe Pilot PlantDokument3 SeitenInspection & Test Plan For Control Valve: Project: PP Pe Pilot PlantzsmithNoch keine Bewertungen

- IQ347-300-EL-CHL-00007 LV Cable Drum Test Report SheetDokument1 SeiteIQ347-300-EL-CHL-00007 LV Cable Drum Test Report SheetkamilNoch keine Bewertungen

- ChecklistDokument8 SeitenChecklistSrikar Reddy GummadiNoch keine Bewertungen

- Right Factorz Projects PVT LTD Checklist For Cable InstallationDokument9 SeitenRight Factorz Projects PVT LTD Checklist For Cable InstallationRajesh RaghunathanNoch keine Bewertungen

- RFI TempleteDokument6 SeitenRFI TempleteAshadi Amir100% (1)

- Bolt Tensioners CatalogDokument8 SeitenBolt Tensioners CatalogAdrian StoicescuNoch keine Bewertungen

- Method Statement For Electrcial Work Construc1Dokument69 SeitenMethod Statement For Electrcial Work Construc1herene7621Noch keine Bewertungen

- ITP - Fiber Optic CableDokument2 SeitenITP - Fiber Optic CableRamy AiadNoch keine Bewertungen

- Ms For Indoor Ligthing InstallationDokument6 SeitenMs For Indoor Ligthing InstallationJoe_AverageNoch keine Bewertungen

- Overhead Conductor Installation Guide: Recommended PracticesDokument20 SeitenOverhead Conductor Installation Guide: Recommended PracticesCarlos PlaceresNoch keine Bewertungen

- Draft QPADokument3 SeitenDraft QPASams Romantiz S'bontothlzNoch keine Bewertungen

- Sheet 1 of 1 Rev 1 Equipment Grounding Installation and Connection ChecklistDokument1 SeiteSheet 1 of 1 Rev 1 Equipment Grounding Installation and Connection ChecklistnayumNoch keine Bewertungen

- ITR For Electrical Instrument PDFDokument4 SeitenITR For Electrical Instrument PDFCokro YudhaNoch keine Bewertungen

- Inspection and Test Plan: Project NameDokument2 SeitenInspection and Test Plan: Project NameehteshamNoch keine Bewertungen

- Booster Pump Foundation Excavation ProcedureDokument9 SeitenBooster Pump Foundation Excavation ProcedurekbldamNoch keine Bewertungen

- QA&QC-DT-FRMC-020 Foundation Work of Transmission LineDokument2 SeitenQA&QC-DT-FRMC-020 Foundation Work of Transmission LineTariq Ali SialNoch keine Bewertungen

- Dokgoro K1785 Method StatementDokument6 SeitenDokgoro K1785 Method StatementJackie van SchalkwykNoch keine Bewertungen

- API System Inspection ChecklistDokument2 SeitenAPI System Inspection ChecklistYasir ArafatNoch keine Bewertungen

- Strat Plan For CIACDokument18 SeitenStrat Plan For CIACJonathan DavidNoch keine Bewertungen

- ITP-Line Hardware - Sample Test PDFDokument3 SeitenITP-Line Hardware - Sample Test PDFPrabhakar Sv100% (1)

- Prosedur Penangkal PetirDokument3 SeitenProsedur Penangkal Petirhendra silalahiNoch keine Bewertungen

- Transformer 1 MosDokument5 SeitenTransformer 1 MosMohamedAhmedFawzyNoch keine Bewertungen

- M R C Remarks Agency SL - No Componant & Operation Characteristcs Class Type of Check Quantum of Check Referance Documents Acceptance Norms Formats of RecordsDokument1 SeiteM R C Remarks Agency SL - No Componant & Operation Characteristcs Class Type of Check Quantum of Check Referance Documents Acceptance Norms Formats of Recordsmohan babuNoch keine Bewertungen

- PQP Flow ChartDokument1 SeitePQP Flow ChartFIRMANSYAHNoch keine Bewertungen

- Elec Foreman CVDokument4 SeitenElec Foreman CVhitanshu0% (1)

- Testing Procedures For HV Voltage TransformersDokument4 SeitenTesting Procedures For HV Voltage TransformersZeeshanNoch keine Bewertungen

- 150619110614e31-33-132-220kv Xlpe Cable Spec 12042019 PDFDokument81 Seiten150619110614e31-33-132-220kv Xlpe Cable Spec 12042019 PDFعريب صالح الروسانNoch keine Bewertungen

- Pre Commiss. Check List Chilled Water PumpsDokument3 SeitenPre Commiss. Check List Chilled Water PumpsARUL SANKARAN100% (1)

- Saudi Aramco Pre-Commissioning Form: Outdoor SubstationsDokument2 SeitenSaudi Aramco Pre-Commissioning Form: Outdoor SubstationsHaleem Ur Rashid BangashNoch keine Bewertungen

- Focus Dimension Target Purpose Action Persons Involve Estimate Budget Time Frame Production ResultsDokument4 SeitenFocus Dimension Target Purpose Action Persons Involve Estimate Budget Time Frame Production ResultsEsh YoNoch keine Bewertungen

- The Earthing System: Sometimes Simply Called Earthing', Is The Total Set ofDokument10 SeitenThe Earthing System: Sometimes Simply Called Earthing', Is The Total Set ofDaily FunNoch keine Bewertungen

- CHECKLIST For Installation of MICC CableDokument2 SeitenCHECKLIST For Installation of MICC CableTHEOPHILUS ATO FLETCHERNoch keine Bewertungen

- Construction Standard FOR Electrical Installation Original Edition DEC. 1997Dokument9 SeitenConstruction Standard FOR Electrical Installation Original Edition DEC. 1997cherif yahyaouiNoch keine Bewertungen

- MOS-Construction of OHTL From SS 8768 Layla PVDokument45 SeitenMOS-Construction of OHTL From SS 8768 Layla PVEngr Muhammad Azam ThaheemNoch keine Bewertungen

- Mossberg 151k PDFDokument6 SeitenMossberg 151k PDFmikey_tipswordNoch keine Bewertungen

- Winchester 1400Dokument7 SeitenWinchester 1400James517Noch keine Bewertungen

- Basic Rifle Marksmanship: Instructor NameDokument42 SeitenBasic Rifle Marksmanship: Instructor NameVitorMoreiraNoch keine Bewertungen

- JW-15 ManualDokument13 SeitenJW-15 ManualmetaalhoofdNoch keine Bewertungen

- 3energy Balance Approach - Griffith TheoryDokument39 Seiten3energy Balance Approach - Griffith TheoryMohd_Safuan_Ma_4863Noch keine Bewertungen

- Cuegis Essay On AmazonDokument3 SeitenCuegis Essay On AmazonKolimarla Sanchit Jaikumar75% (4)

- PTE Academic: Test Overview: Content Time AllowedDokument23 SeitenPTE Academic: Test Overview: Content Time Allowedrcpuram01Noch keine Bewertungen

- R 2 KyDokument3 SeitenR 2 KyJorge AzurduyNoch keine Bewertungen

- Sony Kv-29cl10k Chassis Fe2 (ET)Dokument52 SeitenSony Kv-29cl10k Chassis Fe2 (ET)khafjiNoch keine Bewertungen

- GUIA Inglés 2 ADV ExtraordinarioDokument2 SeitenGUIA Inglés 2 ADV ExtraordinarioPaulo GallegosNoch keine Bewertungen

- Otomobil Terimler SözlüğüDokument528 SeitenOtomobil Terimler Sözlüğüyakupagis1100% (2)

- 7-501142 RevA OmniClass Credentials Datasheet PDFDokument2 Seiten7-501142 RevA OmniClass Credentials Datasheet PDFGustavo LoboNoch keine Bewertungen

- Honeywell Question 1&2Dokument6 SeitenHoneywell Question 1&2anon_909027967Noch keine Bewertungen

- Changes in Ownership Interest: Multiple ChoiceDokument19 SeitenChanges in Ownership Interest: Multiple ChoicepompomNoch keine Bewertungen

- OFF2328 - Project - Travel ItineraryDokument3 SeitenOFF2328 - Project - Travel Itineraryalisaoud55555Noch keine Bewertungen

- SIP As A Stability Builder For A Retail InvestorDokument84 SeitenSIP As A Stability Builder For A Retail InvestorprathamNoch keine Bewertungen

- Leps202 PDFDokument20 SeitenLeps202 PDFSoma NaikNoch keine Bewertungen

- JTMK JW Kelas Kuatkuasa 29jan2024Dokument20 SeitenJTMK JW Kelas Kuatkuasa 29jan2024KHUESHALL A/L SRI SHANKAR LINGAMNoch keine Bewertungen

- SHPB2012 Barras de Cromsteel PDFDokument24 SeitenSHPB2012 Barras de Cromsteel PDFEdgar Rojas EspejoNoch keine Bewertungen

- Unit 6Dokument32 SeitenUnit 6May Thant SinNoch keine Bewertungen

- Ekanade Et Al - NigeriaDokument9 SeitenEkanade Et Al - NigeriammacmacNoch keine Bewertungen

- Black Box Testing TechniquesDokument28 SeitenBlack Box Testing TechniquesAshish YadavNoch keine Bewertungen

- MAPEH - 10 Semi Final EXAMDokument2 SeitenMAPEH - 10 Semi Final EXAMGlendle OtiongNoch keine Bewertungen

- H170HD, H190HD, H210HD, H230HD, H250HD, H280HD (H007) : 1660374 ©2009 Hyster Company 07/2009Dokument794 SeitenH170HD, H190HD, H210HD, H230HD, H250HD, H280HD (H007) : 1660374 ©2009 Hyster Company 07/2009Manutenção Base Anápolis100% (2)

- Consumer S Behaviour Regarding Cashless Payments During The Covid-19 PandemicDokument13 SeitenConsumer S Behaviour Regarding Cashless Payments During The Covid-19 PandemicAesthetica MoonNoch keine Bewertungen

- Ksa 2211 Kiswahili Sociolinguisticscu 4CH 60Dokument2 SeitenKsa 2211 Kiswahili Sociolinguisticscu 4CH 60Akandwanaho FagilNoch keine Bewertungen

- Service Manual: M PL Ifi EdDokument18 SeitenService Manual: M PL Ifi EdTecnico GenioNoch keine Bewertungen

- BJT SummaryDokument4 SeitenBJT SummaryPatricia Rossellinni GuintoNoch keine Bewertungen

- Breast UltrasoundDokument57 SeitenBreast UltrasoundYoungFanjiensNoch keine Bewertungen

- Macro Project (Pak Economic Survey)Dokument30 SeitenMacro Project (Pak Economic Survey)fiza majidNoch keine Bewertungen

- Methyl Isocyanate (MIC) Rundown & Storage System: The Bhopal Gas Tragedy Technical Series Part 1 of 4Dokument3 SeitenMethyl Isocyanate (MIC) Rundown & Storage System: The Bhopal Gas Tragedy Technical Series Part 1 of 4Jesse Haney IIINoch keine Bewertungen

- Algebra 2 and Trigonometry: English Bengali Problem SolvingDokument13 SeitenAlgebra 2 and Trigonometry: English Bengali Problem SolvingHasan AsifNoch keine Bewertungen

- Assetto Corsa Modding Manual 3.0 - 0.34revdDokument702 SeitenAssetto Corsa Modding Manual 3.0 - 0.34revdmentecuriosadejimmy100% (1)

- Basic Marketing Research 4th Edition Ebook PDFDokument61 SeitenBasic Marketing Research 4th Edition Ebook PDFrita.ayers590100% (44)

- The Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceVon EverandThe Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceNoch keine Bewertungen

- Endure: How to Work Hard, Outlast, and Keep HammeringVon EverandEndure: How to Work Hard, Outlast, and Keep HammeringBewertung: 4.5 von 5 Sternen4.5/5 (285)

- Well Integrity for Workovers and RecompletionsVon EverandWell Integrity for Workovers and RecompletionsBewertung: 5 von 5 Sternen5/5 (3)

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterVon EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterNoch keine Bewertungen

- Renewable Energy: Physics, Engineering, Environmental Impacts, Economics and PlanningVon EverandRenewable Energy: Physics, Engineering, Environmental Impacts, Economics and PlanningBewertung: 5 von 5 Sternen5/5 (4)

- Si-cology 1: Tales and Wisdom from Duck Dynasty's Favorite UncleVon EverandSi-cology 1: Tales and Wisdom from Duck Dynasty's Favorite UncleBewertung: 4.5 von 5 Sternen4.5/5 (16)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesVon EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesBewertung: 4.5 von 5 Sternen4.5/5 (21)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialVon EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNoch keine Bewertungen

- Endure: How to Work Hard, Outlast, and Keep HammeringVon EverandEndure: How to Work Hard, Outlast, and Keep HammeringBewertung: 5 von 5 Sternen5/5 (1)

- Happy, Happy, Happy: My Life and Legacy as the Duck CommanderVon EverandHappy, Happy, Happy: My Life and Legacy as the Duck CommanderBewertung: 5 von 5 Sternen5/5 (39)

- The Grid: The Fraying Wires Between Americans and Our Energy FutureVon EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureBewertung: 3.5 von 5 Sternen3.5/5 (48)

- Shorting the Grid: The Hidden Fragility of Our Electric GridVon EverandShorting the Grid: The Hidden Fragility of Our Electric GridBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Introduction to Power System ProtectionVon EverandIntroduction to Power System ProtectionBewertung: 5 von 5 Sternen5/5 (1)

- Electric Motor Control: DC, AC, and BLDC MotorsVon EverandElectric Motor Control: DC, AC, and BLDC MotorsBewertung: 4.5 von 5 Sternen4.5/5 (19)

- The Homeowner's DIY Guide to Electrical WiringVon EverandThe Homeowner's DIY Guide to Electrical WiringBewertung: 5 von 5 Sternen5/5 (2)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsVon EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNoch keine Bewertungen

- Concealed Carry Class: The ABCs of Self-Defense Tools and TacticsVon EverandConcealed Carry Class: The ABCs of Self-Defense Tools and TacticsNoch keine Bewertungen

- Gunsmithing Made Easy: Projects for the Home GunsmithVon EverandGunsmithing Made Easy: Projects for the Home GunsmithBewertung: 3 von 5 Sternen3/5 (2)

- DIY GUNS: Recoil Magazine's Guide to Homebuilt Suppressors, 80 Percent Lowers, Rifle Mods and More!Von EverandDIY GUNS: Recoil Magazine's Guide to Homebuilt Suppressors, 80 Percent Lowers, Rifle Mods and More!Bewertung: 4 von 5 Sternen4/5 (4)

- SuppressorsVon EverandSuppressorsEditors of RECOIL MagazineNoch keine Bewertungen

- Building Energy Management Systems and Techniques: Principles, Methods, and ModellingVon EverandBuilding Energy Management Systems and Techniques: Principles, Methods, and ModellingNoch keine Bewertungen

- Death in the Long Grass: A Big Game Hunter's Adventures in the African BushVon EverandDeath in the Long Grass: A Big Game Hunter's Adventures in the African BushBewertung: 4.5 von 5 Sternen4.5/5 (59)

- Solar Energy: Survive Easily on Solar Power Off the GridVon EverandSolar Energy: Survive Easily on Solar Power Off the GridNoch keine Bewertungen