Beruflich Dokumente

Kultur Dokumente

Manufacturing Production Manager or Manufacturing Operations Man

Hochgeladen von

api-121411744Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Manufacturing Production Manager or Manufacturing Operations Man

Hochgeladen von

api-121411744Copyright:

Verfügbare Formate

BARRY S. KING 5683 Douglas Way Anderson, IN. 46013 765-778-4624 bk12eeb50@westpost.

net SKILLS SUMMARY Professional recognized for: Specialized expertise in manufacturing management and Production Control and Logistics with education, skills and experience in le an enterprise systems. PROFESSIONAL EXPERIENCE U.S. Census Bureau, Muncie, IN Mar 2010 -Sep 2010 Office Clerk Responsible for a wide variety of clerical operations such as preparing enumerat or assignments, preparing crew leader assignment control records data keying an d preparing training materials. Plant Closing Retired - Aug 2007

DELPHI CORP., Anderson, IN Jun 2005 - Aug 2007 Production Control Value Stream Manager - Plant 20 Responsible for entire product flow from suppliers, to mfg. floor, to customers * 20% reduction in overall direct goods inventory $'s * Employed the use of seven material tugger routes with a supermarket using onehour routes. * Improved inventory turns to 31 * Maintained customer shipments and built bridge banks for all customers to main tain customer requirements during transition of business and plant shut down. DELPHI CORP., Anderson, IN Jun 2003 - Jun 2005 General Operations Supervisor - Plant 11 Responsible for operations while preparing for and shutting down Plant 11 * Actually averaged a 16.5% productivity improvement quarter over quarter and ye ar over year * Had zero customer quality complaints and won the Delphi quality award two year s in a row. * Maintained 100% on time shipments for two years * Achieved 6.5 million hours without a lost workday accident DELPHI CORP., Anderson, IN Jun 2001 - Jun 2003 Operations Manager - Plant 20 Responsible for all manufacturing operations & Lean Mfg, implementation * Implemented visual pull system scheduling systems throughout plant * Implemented preventive maintenance teams as well as a maintenance dispatch sys tem to improve response time for unscheduled downtime * Improved plant equipment uptime from 63% to 85% * Improved Avg. Annual Inventory Turns from 12 to 25 * Reduced overtime by 59% * Reduced scrap 33% * Quality defects reduced 66% as measured in PPM * Improved productivity 15% year over year in units per employee-hour * Selected as model plant for Automotive Holdings Group for lean implementation

DELPHI CORP., Anderson, IN Jun 1999 - Jun 2001 Manager Lean Implementation - Plant 20 Responsible for the development and implementation of lean principles in Plant 2

0 * Train all staff and employees in lean manufacturing principles * Changed 60% of the plant into product cells * 24 product cells created and supported through ergonomics, safety, error proof ing and point of use material delivery * Began tying scheduling systems from customer, through manufacturing and to sup pliers * Hosted two day workshop and display of lean tools and processes throughout ent ire plant for 80 Delphi plant managers and operations staffs * Implemented product cell scoreboards and coached on their proper use. * Began implementing standardized work practices to support lean activities * 100% of value streams flow-mapped and Tpct calculated with an average reductio n of 28% and some as high as 90+% DELCO REMY DIV. GMC, Anderson, IN Jan 1993 - Jun 1999 Project Manager Responsible for the incorporation of all new products into Plant 20 * Manufacturing Project Manager for the introduction of five new business produc t lines into the plant * The last product line was implemented with a start of production in January of 1999 and incorporated all the latest know lean principles. It was under the con sultation and oversight of two lean Sensis from the initial design phase, equipm ent and machine build and procurement to the manufacturing design system impleme ntation DELCO REMY DIV. GMC, Anderson, IN Mar 1981 - Nov 1982 Labor Relations Representative Responsible for Plants 5 and 10 during the 1982 local contract negotiations DELCO REMY DIV. GMC, Anderson, IN Jan 1971 - Jan 1993 Manufacturing Supervisor and General Supervisor Responsible for various assignments in a variety of product areas

EDUCATION/TRAINING Indiana State University, Terre Haute, IN Industrial Management World Wide Flow College, Denver CO. Graduate in both products flow technology and Understanding Finances of Flow

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 5 Managing Employee RedeploymentDokument4 Seiten5 Managing Employee Redeploymenthoney08priyaNoch keine Bewertungen

- The Impact of A Dual Career Path IIDokument1 SeiteThe Impact of A Dual Career Path IISrishti MathurNoch keine Bewertungen

- Project Title HARSHITADokument63 SeitenProject Title HARSHITAHarshita RajeNoch keine Bewertungen

- Management Case Study - Module 7 - IPM Sri LankaDokument15 SeitenManagement Case Study - Module 7 - IPM Sri LankaShan Anjana Jayasinghe100% (1)

- MotivationDokument5 SeitenMotivationVijaya BanuNoch keine Bewertungen

- Total Strength of EmployeesDokument22 SeitenTotal Strength of EmployeeszakirdecentNoch keine Bewertungen

- Termination Letter 154Dokument2 SeitenTermination Letter 154shiprapathaniaNoch keine Bewertungen

- HRM Performance ManagementDokument13 SeitenHRM Performance ManagementRishabh VijayNoch keine Bewertungen

- Office of The Human Resource Management Officer Organizational ChartDokument1 SeiteOffice of The Human Resource Management Officer Organizational ChartMark Andrew FernandezNoch keine Bewertungen

- Impact of Employees Motivation On Organizational EffectivenessDokument5 SeitenImpact of Employees Motivation On Organizational EffectivenessChudhary JunaidNoch keine Bewertungen

- Employee Scheduling Methods Using A CalculatorDokument6 SeitenEmployee Scheduling Methods Using A CalculatorMohd Nazri SalimNoch keine Bewertungen

- TugasDokument4 SeitenTugasendang wahyuniNoch keine Bewertungen

- Types of ProstitutionDokument4 SeitenTypes of ProstitutionAbhilash AggarwalNoch keine Bewertungen

- Case Study 2 Dick SpencerDokument3 SeitenCase Study 2 Dick Spencerakpe1234Noch keine Bewertungen

- Differences Between Cuepacs and Mtuc AimanDokument7 SeitenDifferences Between Cuepacs and Mtuc AimanfatinNoch keine Bewertungen

- Self Learning KitDokument39 SeitenSelf Learning KitWacks VenzonNoch keine Bewertungen

- Snapshot Industries CaseDokument20 SeitenSnapshot Industries CaseMusaShukry0% (1)

- Employment LawDokument51 SeitenEmployment LawNorainah Abdul GaniNoch keine Bewertungen

- IFFCO ProjectDokument95 SeitenIFFCO ProjectVidisha Khandelwal50% (2)

- Cast StudyDokument7 SeitenCast StudyEdelyn De la CruzNoch keine Bewertungen

- Subjunctive: Verbs Followed by The SubjunctiveDokument3 SeitenSubjunctive: Verbs Followed by The SubjunctiveMinh Chanh NguyenNoch keine Bewertungen

- Nursing Management Is Performing Leadership Functions of Governance and DecisionDokument4 SeitenNursing Management Is Performing Leadership Functions of Governance and DecisionLhen Vegas CagahastianNoch keine Bewertungen

- Trade UnionsDokument36 SeitenTrade Unionspankaj51281100% (1)

- California Child and Spousal Support Bench GuideDokument96 SeitenCalifornia Child and Spousal Support Bench GuideAnonymous oY5Dk8c5u100% (2)

- Service Failure and Recovery in The Airline Industry: Evidence From The TRNCDokument116 SeitenService Failure and Recovery in The Airline Industry: Evidence From The TRNCSukesh SethiNoch keine Bewertungen

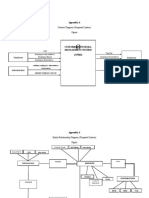

- Context Diagram (Proposed System) : Appendix ADokument3 SeitenContext Diagram (Proposed System) : Appendix Aiver127Noch keine Bewertungen

- QEEW2.0 42 Short Scales For Survey ResearchDokument96 SeitenQEEW2.0 42 Short Scales For Survey Researchcaca ramadhaniNoch keine Bewertungen

- Case Study 1Dokument3 SeitenCase Study 1kathNoch keine Bewertungen

- Workplace Violence ChecklistDokument2 SeitenWorkplace Violence ChecklistPatricia GeraldesNoch keine Bewertungen