Beruflich Dokumente

Kultur Dokumente

Metal Detector Revised

Hochgeladen von

Mpu WantoOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Metal Detector Revised

Hochgeladen von

Mpu WantoCopyright:

Verfügbare Formate

A simple, sensitive metal detector

This is a implementation of a project 561 from a Electronics Today International.

Schematics in PDF format PCB in Protel Easyedit 2.06 format PCB in Protel Easyedit 2.06 format (as above) WinZipped Parts list in ascii text

The Protel MS-DOS freeware software can be downloaded as ZIP-File from Protel Site.

ETI Project 561 Simple, Sensitive Metal Detector Phil Wait Electronics Today International

The Search Coil (abbreviated from the original article)

The greater the coil diameter the greater the penetration depth, but the less sensitive it is to small objects. As a general rule the penetration is about equal to the search coil diameter, while the sensitivity is roughly proportional to the cube of the object diameter. Sensitivity is also inversely proportional to the sixth power of the distance. The chosen coil has 150 mm diameter to give good sensitivity to small objects giving about 100 150 mm penetration. Remember that if the coil diameter is increased the number of turns have to be reduced to maintain constant frequency.

Faraday Shield

To remove the effect of capacitance to the search coil it is enclosed in a Faraday shield. The field consists of a wrapping of aluminium foil around the coil but broken at one point so it does not make a shorted turn. This shield is then connected to the ground potential of the detector.

Construction

The search coil is mounted on a 165 mm diameter plastic pot stand. The connection to the search coil is via a length of shielded cable. The search coil is wound so that it can be tucked inside the rim of the up-turned plastic pot stand. First make a cardboard former of the appropriate diameter. Wind then the coil into this former. The coil contains 70 turns of 0.4 mm enameled wire. Wind two layers of insulation tape around the coil leading the ends out at the same place. Next wind the Faraday shield. Cut some aluminium kitchen foil into 15 mm wide strips and wind over the coil to make two layers but leaving a small gap about 5 mm to 10 mm wide where the coil ends come out. Wind a length of tinned copper wire around the shield. Wind it tight with around 10 mm between successive turns. The end of this wire is taken out at the same place as the coil connections. Now wind another two layers of insulation tape around the whole assembly. Drill a hole in the side of the pot stand and the press the coil down into the rim. Pass the wires thru the hole. Pour epoxy over the coil to hold it in place. Solder the coil connections to the twin shielded cable, the Faraday shield connecting to the cable's shield, and glue the cable and wires underneath the pot stand to hold them rigid.

METAL DETECTOR ETI Project 561 Pekka Ala-Mayry pam(at)iki.fi

Revised: September Revision: A

9, 1998

Bill Of Materials

September

9, 1998

23:17:11

Page

Item Quantity Reference Part ____________________________________________________________ 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 2 4 1 1 1 1 2 2 1 2 1 1 1 2 1 1 1 1 1 2 1 1 1 BT2,BT1 C1,C4,C6,C8 C2 C3 C5 C7 IC2,IC1 IC4,IC3 L1 Q1,Q2 RV1 RV2 RV3 R5,R1 R2 R3 R4 R6 R7 R8,R9 SP1 S1 Y1 9V IEC 6F22 100nF 1nF polystyrene 4.7nF polystyrene 47pF 10p 4001 4013 80r 0.5mm BC548 10k LIN 100k LIN 100k LOG 100 1k 100k 1M 10M 22k 4.7k 8 ohm SWITCH 3.2768MHz

"Gary's Pulse Induction Metal Detector"

Go Back to My "Home Page" Or "Projects Page"

Origonally Created: Mar 16 2002 Latest Revision, Aug 6, 2010

Go Back to My

EFFECTIVE AUG 1, 2010:

I NO LONGER will give Any help to persons that did Not Buy at least the Basic Kit of parts from me.

As Too many persons make Substitutions or Errors, than expect me to solve there mistakes.

IMPORTANT NOTE:

Due to Variations between using the TL071's

instead of TL081's, I have found some detectors Won't adjust propery with VR1, using the Current Resistor values. So I have changed R18 to 4K7 and R19 to 1K. This will correct this problem for Both these IC's. But if your using the TL081, there is no reason to make this change. Also Changing R26 to a 33K will give a better adjustment range for VR2.

This detector Features Either a Single Coil Metal Detector, Or 2 possible Dual Coil Configurations! You Choose which you want. *Click Here, Pictures of My Metal Detector Project, Built by Others *Click Here, Some Comparison Test Results, by Dave in Australia Warning: I Do Not Recommend this project for the "Beginner",

It definately Requires Good Soldering Skills and at least a basic working knowledge of electronics is Needed. Before Testing the Completed Unit Wash the board to Remove All Flux Residue. IT WILL NOT WORK CORRECTLY IF YOU DON'T! It is Also Recommended to use a Current Regulated Power Supply when first testing this unit. (Less than 300 Ma. is quite satisfactory) Excessive Current, generating heat, will Distroy the REG1117A. Failing a Regulated Supply, a 60 Watt/110 volt standard light bulb can be placed in series with the positive battery lead. This should limit current to a reasonable level, preventing any damage to parts.

(Where only 220 volt bulbs are available, use a 150 watt bulb or two 75 watts in parallel works well.)

I Repeat, Good Soldering is a Must!

However, If you build this project and have problems, I will offer you as much assistance as possible in e-mails, Even to the extent of Free Repairs, Not Including Postage Charges and Possibly subject to replacement parts cost. (No parts charges will be made, without prior confirmation from that person, and most I haven't even charged for the parts.)

NOTE: It is Important to use a Good Soldering Iron, Rated at 15 to 25 Watts

and having a Small Clean Tip! Note also the Revision Dates on All My Articles. Always check for changes, I update most articles quite regularly.

Note: This metal Detector was Not specifically designed to Detect Gold Nuggets.

Additionally, The only metal that I have found that my metal detector will NOT DETECT is some Better Qualities of "Stainless Steel". I Didn't know why! Here is a Much Appreciated explaination from one of my readers: Well the reason why you can't detect it is because the conductivity of Stainless is very low. This is true for all pulse induction metal detectors. Because of the low conductivity, the eddy currents have disipated by the time the pulse delay has ended and you begin to sample the signal. The lower the conductivity of the metal, the faster the eddy currents disipate. If I remember right the conductivity of copper is 100, the conductivity of stainless steel is about 1.3 or so. The conductivity of silver is 108 so its the best on range. Gold is in the 60 to 80 range depending on the alloy. The longer the pulse delay on your detector is, the less likely you will be able to pick up lower conductive metals. Hope this helps. Good luck, Charles

A Note from me: Well I was aware of the Delay times, I didn't realize that stainless was so low in conductivity. Thanks Charles!

If You Have PROBLEMS when you build this Unit? Don't Overlook Anything! Some Guys Problems Click Here to read them

**This project is offered totally Free for those who are interested in it. I have tried to make this article as complete as possible, but I will Not assume any liability for any "Errors or Omissions" in this article. If Needed, I will attempt to help you as much as possible with any problems. However I have no control of your abilities or skills, so build it totally at your own risk! This unit is Extremely Stable, and features three possible configurations with the coils, as listed below. I can supply a small Pizo Transducer that works Excellent well on this unit.

The 3 possible coil Configurations are:

1) First configuration is just a single coil. Good for most applications! 2) Second is a dual coil, with noise and ground effects cancellation. 3) Third is a dual coil, one for transmit and one for recieve.

Here is A Very Simple Coil that Will Work, At least for testing purposes.

Here is a Pretty Good Coil, and reasonably easy to make.

Decades ago this style of coil was used for AM Antennas in some Old Tube Type Radios.

My Recommended: "Optium Flat Coil Sizes".

Depending on my current Stock, I may use a 20, 21 or 22 AWG Wire. And I can Supply these Flat Coils, Up to about 13 Inches OD: For Really Small Objects: ID = 2.62 inches & OD = 6 inches with 52 turns. Coils wound on Ferrite Rods are also good. For Medium Objects: ID = 5.8 inches & OD = 8 inches with 34 turns. Its Best to use this size coil for finding Coins. For Larger Objects: ID = 8.2 inches & OD = 10 inches with 28 turns ID = 10.4 inches & OD = 12 inches with 25 turns. Or "YOU" can make even Larger Coils: ID = 13.6 inches & OD = 15 inches with 21 turns. ID = 39.2 inches & OD = 40 inches with 12 turns. For Really Large Objects: A 48 inch Square Coil = 8 to 10 turns.

**A Convential Kit of parts Is Available if you want it.

Other than the PCB and coils, most parts are supplied at my Landed Cost.

Click Here for Detector Prices

It would be Greatly Appreciated to recieve Feedback

from ALL persons building this Detector. Reguardless weither you purchase

the Circuit board from me or not! As of May 2003, Well over 200 units have been built with boards from me, and From Replies recieved none have been unsatisified with it. I am also aware of a few who have built this detector using boards they made themselves.

"Want a More Sensitive Meter, Do This"

These values are for a 200 uA Meter, but if you double the two resistor values for a 100 Ua meter or Quadruple these values for a 50 Ua meter, this should also work fine.

Latest Update: Feb 23 2007

I can Now Supply this Vu Meter

These Meters are Rated at 100 uA at the -3 Db and about 240 uA at the + 3Db. Reasonably Priced at $8.00 each.

"Click on the Titles below to open them"

***********************************************************************

Facts about Gold and its detection.

I now have some Coils for sale!

A Very Detailed Picture Overlay of the Assembled PCB.

This should print OK, horizontally on a 8.5 x 14 paper.

NOTE: On this Newest Circuit Board, R32 is above the IC, Not beside it as shown here.

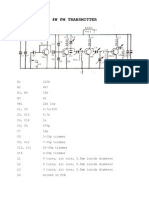

A Large Printable Schematic.

Corrections & Re-Drawn as of Dec 2009, But a Newer Design is coming.

The Printed Circuit Board

A New Circuit Board design is coming, But it will only be available through me.

Calibration and Setup Procedures (Revised Mar 15 2010 Parts List (Revised Mar 6 2006) Updated Coil Winding Info "UPDATED"Some technical Info and coil pics,

Revised April 5 2004

Additional Pictures and More Info on my Pulse Induction Metal Detector.

A HELP File, if you have problems. IMPORTANT NOTE

The only claims I will make as to the sensitivity of this unit is: The one I made for myself does detect a Canadian Quarter (made of Nickel) and also an American Quarter at a distance of 12 inches in free air and at a good 10 inches in the soil in my yard. Additionally, If built correctly: This Metal detector should detect a "Pop Can" at an "Absolute Minimum Distance" of 15 Inches. AND it could get depths to 25 Inches or More, depending on the meter used. However there are too many Variables in Coil Construction, as well as materials, shapes, sizes and soil conditions to try to predict exact ally

what other units will do under various conditions.

ADDITIONALLY, Remember This:

THE MOST IMPORTANT THING WITH ANY METAL DETECTOR, IS THE OPERATORS "ABILITIES", "SKILLS" AND "PATIENTS" in using it PROPERLY! All Imformation in this Article is "Copyright protected".

Chemelec

*Copyright 2002 & 2009*

Das könnte Ihnen auch gefallen

- Build your own simple metal detectorDokument21 SeitenBuild your own simple metal detectorMădălin George IonescuNoch keine Bewertungen

- A Simple Inverter For Flour..Dokument8 SeitenA Simple Inverter For Flour..Daniel Vladimir MaciucaNoch keine Bewertungen

- Crystal Radio CircuitsDokument11 SeitenCrystal Radio CircuitsSubimal BawaliNoch keine Bewertungen

- Winding Instrctions DEVICE2Dokument3 SeitenWinding Instrctions DEVICE2Bones MacGyver-RichNoch keine Bewertungen

- How To Build An Alpha Particle Spark DetectorDokument6 SeitenHow To Build An Alpha Particle Spark Detectorjuan9gonzalez_9100% (1)

- Bio BatteryDokument4 SeitenBio BatteryVasundhara Srinivas50% (2)

- Double Shielded PD Lab Attenuates Noise 57dBDokument1 SeiteDouble Shielded PD Lab Attenuates Noise 57dBMuthuraj74Noch keine Bewertungen

- Plasma Thermal Gun: Theory of OperationDokument9 SeitenPlasma Thermal Gun: Theory of OperationBirdy MadNoch keine Bewertungen

- Crystal Radio LampDokument4 SeitenCrystal Radio LampJim100% (2)

- Nanocoating Best Method - TutorialDokument9 SeitenNanocoating Best Method - Tutorialmutzunache2001100% (1)

- Plasma Capacitor - Sheet 03A v3 12-29-15Dokument2 SeitenPlasma Capacitor - Sheet 03A v3 12-29-15radiocatifea100% (2)

- The Smith Generator BlueprintsDokument36 SeitenThe Smith Generator BlueprintsZoran AleksicNoch keine Bewertungen

- DIY Coil WinderDokument7 SeitenDIY Coil WinderWilson F SobrinhoNoch keine Bewertungen

- ECE Bubble Power PDFDokument15 SeitenECE Bubble Power PDFsachinsdurgadNoch keine Bewertungen

- Building A Solid State Tesla CoilDokument24 SeitenBuilding A Solid State Tesla CoilWar machinesNoch keine Bewertungen

- Jacksons Tesla Wireless Coil Instructions Apr 21 2011Dokument50 SeitenJacksons Tesla Wireless Coil Instructions Apr 21 2011zunder12100% (1)

- Ferrite T PuDokument4 SeitenFerrite T PunanarNoch keine Bewertungen

- TCL Series Solid State Tesla CoilDokument20 SeitenTCL Series Solid State Tesla CoilNayanka SpringerNoch keine Bewertungen

- Stator Generator EolianDokument40 SeitenStator Generator EolianCatalin BordeiNoch keine Bewertungen

- Magnetron: Operating PrincipleDokument6 SeitenMagnetron: Operating PrincipleAbdullah WalidNoch keine Bewertungen

- The "Forgotten" Coil and Its Variations: Home Coil Info Products OrderingDokument6 SeitenThe "Forgotten" Coil and Its Variations: Home Coil Info Products Orderingmatej100% (1)

- Amazing All-Band ReceiverDokument8 SeitenAmazing All-Band ReceiverjhonkayNoch keine Bewertungen

- How Make Wifi Feed HornDokument5 SeitenHow Make Wifi Feed HornRajesh Punia100% (2)

- Plasma Generator Kit ManualDokument6 SeitenPlasma Generator Kit ManualJayam SonaniNoch keine Bewertungen

- Mobius Coils by LoohanDokument16 SeitenMobius Coils by Loohangabriel_danut100% (3)

- Stun GunsDokument6 SeitenStun Gunsdefensetechs100% (1)

- Simple FM Transmitter With A Single TransistorDokument3 SeitenSimple FM Transmitter With A Single TransistordzambieNoch keine Bewertungen

- Simple Arduino Inverter CircuitDokument11 SeitenSimple Arduino Inverter CircuitPramillaNoch keine Bewertungen

- Slayer Exciter: by Ivan WilbergDokument7 SeitenSlayer Exciter: by Ivan Wilbergapi-408463795Noch keine Bewertungen

- Tesla CoilDokument5 SeitenTesla CoilREYMAXNoch keine Bewertungen

- Tesla CoilsDokument4 SeitenTesla CoilsPankaj SharmaNoch keine Bewertungen

- Build a Tesla coil that produces spectacular electrical fireworksDokument5 SeitenBuild a Tesla coil that produces spectacular electrical fireworksmad10000Noch keine Bewertungen

- Simple Free-Energy Devices: Chapter 2: The "Joule Thief"Dokument5 SeitenSimple Free-Energy Devices: Chapter 2: The "Joule Thief"Rafat KashoomNoch keine Bewertungen

- Build a radiant battery charger using negative energyDokument9 SeitenBuild a radiant battery charger using negative energysuso73100% (2)

- Tesla coil investigatory projectDokument15 SeitenTesla coil investigatory projectG Sunanda100% (1)

- The TransformerDokument21 SeitenThe TransformerAshok KumarNoch keine Bewertungen

- Induction heating circuit built by Daniel from Melnik, CzechDokument6 SeitenInduction heating circuit built by Daniel from Melnik, Czechnangkarak8201Noch keine Bewertungen

- Make A 3 Phase GeneratorDokument12 SeitenMake A 3 Phase GeneratorLaterNoch keine Bewertungen

- Simple Digital Geiger CounterDokument9 SeitenSimple Digital Geiger CounterAnonymous Kti5jq5EJINoch keine Bewertungen

- 4w FM TransmitterDokument9 Seiten4w FM TransmitterMantas PauliukonisNoch keine Bewertungen

- Large Loop AntennasDokument3 SeitenLarge Loop AntennasBenjamin DoverNoch keine Bewertungen

- Tesla Coil Project: V1 Cprobe 15p CP 9.3p L1 19.5m R1 1megDokument9 SeitenTesla Coil Project: V1 Cprobe 15p CP 9.3p L1 19.5m R1 1megNISHANT KumarNoch keine Bewertungen

- Transformers PDFDokument6 SeitenTransformers PDFVasileSpireaNoch keine Bewertungen

- Wireless DoorbellDokument8 SeitenWireless DoorbellnicklingatongNoch keine Bewertungen

- 1.5V Double Layer Gans Cell (DLGC) : Alekz SystemDokument10 Seiten1.5V Double Layer Gans Cell (DLGC) : Alekz Systemhallo1234100% (3)

- History of Radiation DetectorsDokument25 SeitenHistory of Radiation DetectorsAli AlhaikNoch keine Bewertungen

- Twelve Plant Hydroponic Flood and Drain System: Parts ListDokument7 SeitenTwelve Plant Hydroponic Flood and Drain System: Parts Listtraj17Noch keine Bewertungen

- REPLICAS of MEYER - Qiman13 Posts 1 - WATER As FUEL - Review of Available Technologies - MDG 2006-2007Dokument22 SeitenREPLICAS of MEYER - Qiman13 Posts 1 - WATER As FUEL - Review of Available Technologies - MDG 2006-2007Steve MolkeNoch keine Bewertungen

- The Resonance Energy Device Explained: PrefaceDokument39 SeitenThe Resonance Energy Device Explained: PrefaceR. K GuptaNoch keine Bewertungen

- Circuits Hight VoltajeDokument45 SeitenCircuits Hight VoltajeRICHIHOTS2Noch keine Bewertungen

- The Single Cure: Human Life Extension to 300+ YearsVon EverandThe Single Cure: Human Life Extension to 300+ YearsNoch keine Bewertungen

- Induction Coils - How To Make, Use, And Repair Them: Including Ruhmkorff, Tesla, And Medical Coils, Roentgen, Radiography, Wireless Telegraphy, And Practical Information On Primary And Secodary BatteryVon EverandInduction Coils - How To Make, Use, And Repair Them: Including Ruhmkorff, Tesla, And Medical Coils, Roentgen, Radiography, Wireless Telegraphy, And Practical Information On Primary And Secodary BatteryBewertung: 5 von 5 Sternen5/5 (2)

- Inventions, Researches and Writings of Nikola Tesla: Including Tesla's AutobiographyVon EverandInventions, Researches and Writings of Nikola Tesla: Including Tesla's AutobiographyNoch keine Bewertungen

- Build your own metal detectorDokument10 SeitenBuild your own metal detectorVaibhav MhatreNoch keine Bewertungen

- How To Make A Metal DetectorDokument12 SeitenHow To Make A Metal Detectorhassan saadatpoorNoch keine Bewertungen

- Coil WindingDokument11 SeitenCoil WindingGeorge LucianNoch keine Bewertungen

- Simple BFO Metal DetectorDokument6 SeitenSimple BFO Metal DetectorKireNoch keine Bewertungen

- Metal Simple and Powerful Detector - ElettroAmiciDokument6 SeitenMetal Simple and Powerful Detector - ElettroAmiciAbdelmalek BaaliNoch keine Bewertungen

- A Self-Sustaining Electric Generator - Orgone Flux CapacitorDokument9 SeitenA Self-Sustaining Electric Generator - Orgone Flux Capacitor1357531100% (2)

- CaterDokument20 SeitenCaterCesare Di Girolamo0% (1)

- Baticorrometro Polatrak Deepwater-Manual de OperacionDokument15 SeitenBaticorrometro Polatrak Deepwater-Manual de OperacionemilidiverNoch keine Bewertungen

- Sa 423Dokument6 SeitenSa 423Widya widyaNoch keine Bewertungen

- Section & Steel PropertiesDokument5 SeitenSection & Steel PropertiesKory EstesNoch keine Bewertungen

- ASTM F 467m-03aDokument9 SeitenASTM F 467m-03aJORGE ARTURO TORIBIO HUERTANoch keine Bewertungen

- MS.50002Dokument28 SeitenMS.50002Alanevh Alanevh100% (1)

- Astm A671 2004 PDFDokument9 SeitenAstm A671 2004 PDFDevarajanRamasamyNoch keine Bewertungen

- Crosby® Jaw & Jaw Galvanized TurnbucklesDokument7 SeitenCrosby® Jaw & Jaw Galvanized TurnbucklesLazzarus Az GunawanNoch keine Bewertungen

- Item EdpDokument487 SeitenItem Edpyusfadillah100% (1)

- AWS - Welding of Cast Iron - Papers PDFDokument365 SeitenAWS - Welding of Cast Iron - Papers PDFCarlos Guanipa100% (5)

- Case Study On Truck VehicalDokument7 SeitenCase Study On Truck VehicalPratik KadamNoch keine Bewertungen

- The Universal Grinding Machine Guide to Grinding Wheels and Tool SharpeningDokument40 SeitenThe Universal Grinding Machine Guide to Grinding Wheels and Tool SharpeningmrjkopelNoch keine Bewertungen

- Steel Bars, Alloy, Standard GradesDokument4 SeitenSteel Bars, Alloy, Standard GradesGian SennaNoch keine Bewertungen

- Carding MachineDokument29 SeitenCarding MachineAnisul IslamNoch keine Bewertungen

- RVC 05 FLG PDFDokument5 SeitenRVC 05 FLG PDFengp3077Noch keine Bewertungen

- Is 4049 Part 1Dokument7 SeitenIs 4049 Part 1Otavio123Noch keine Bewertungen

- Aro Electrodes enDokument44 SeitenAro Electrodes endandolea75Noch keine Bewertungen

- Social Icons: C-80 GradeDokument3 SeitenSocial Icons: C-80 GradeEdward OropezaNoch keine Bewertungen

- EnclosurecatalogueDokument153 SeitenEnclosurecatalogueTomuta StefanNoch keine Bewertungen

- Czujniki KCCDokument11 SeitenCzujniki KCCDinhnamsgpNoch keine Bewertungen

- 2.TENSA GRIP Silent Tensa Grip Silent enDokument6 Seiten2.TENSA GRIP Silent Tensa Grip Silent enAlexandra SanduNoch keine Bewertungen

- Zoeller x292Dokument2 SeitenZoeller x2922009tamerNoch keine Bewertungen

- M601-2004 (Welding and Inspection of Piping-NORSOK) ut-MT-RT-VT-PT AND ACCEPTANCE CRITERIADokument20 SeitenM601-2004 (Welding and Inspection of Piping-NORSOK) ut-MT-RT-VT-PT AND ACCEPTANCE CRITERIAarash59_4u100% (1)

- BS en 439-94 PDFDokument12 SeitenBS en 439-94 PDFAhmet Memiş100% (2)

- Grades 6056 Comparison Vs 6061 2024 7075Dokument2 SeitenGrades 6056 Comparison Vs 6061 2024 7075Vinoth Kumar100% (1)

- Composition of Abrasive Wheels - Novovodolazhsky Abrasive PlantDokument3 SeitenComposition of Abrasive Wheels - Novovodolazhsky Abrasive PlantpercydziksNoch keine Bewertungen

- 03 04 Faradays Laws of Electrolysis and ApplicationsDokument12 Seiten03 04 Faradays Laws of Electrolysis and ApplicationsPavan ReddyNoch keine Bewertungen

- L13-Rolling of MetalsDokument32 SeitenL13-Rolling of MetalsAbirHasan100% (1)

- Get 8va EdicionDokument820 SeitenGet 8va EdicionPlaneamiento MecanicoNoch keine Bewertungen

- Damascus SteelDokument3 SeitenDamascus SteelAli HassanNoch keine Bewertungen

- Manufacturing Processes For Engineering Materials: Sixth EditionDokument61 SeitenManufacturing Processes For Engineering Materials: Sixth EditionEthan StoneNoch keine Bewertungen