Beruflich Dokumente

Kultur Dokumente

20 SDMS 01

Hochgeladen von

tapas_jituOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

20 SDMS 01

Hochgeladen von

tapas_jituCopyright:

Verfügbare Formate

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

20-SDMS-01 REV. 01 SPECIFICATIONS FOR

OCTAGONAL STEEL POLES

This specification is property of SEC and subject to change or modification without any notice

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

TABLE OF CONTENTS

PAGE

1.0 2.0 3.0 4.0 5.0

SCOPE CROSS REFERENCES APPPLICABLE CODES AND STANDARDS SERVICE AND SYSTEM CONDITIONS DESIGN, MATERIALS AND FABRICATION 5.1 5.2 5.3 5.4 5.5 General Design Materials Fabrication Marking

3 3 3 6 7 7 7 13 14 15 16 19 19 20 21 33

6.0 7.0 8.0 9.0

INSPECTION AND TESTING PACKING AND SHIPPING GUARANTEE SUBMITTALS

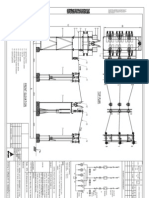

10.0 DATA SCHEDULE 11.0 STEEL POLE DRAWINGS

Page 2 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

1.0

SCOPE This SEC Distribution Material Specification (SDMS) specifies the minimum technical requirement for design, engineering, manufacturing, inspection, testing and performance of Octagonal Steel Poles intended to be used in the medium and low voltage system (MV/LV) of Saudi Electricity Company (SEC).

2.0

CROSS REFERENCES The Material Standard Specification shall be read in conjunction with SEC General Specification No. 01-SDMS-01 (latest revision) for General Requirement for all Equipment/Materials as an integral part of this SDMS. This SDMS shall also be read in conjunction with SEC purchase order requirements.

3.0

APPLICATION CODES AND STANDARDS The latest revision of the following codes and standards shall be applicable for the equipment/materials covered in this SDMS. In case of any deviation, the vendor/manufacturer may propose equipment/materials conforming to alternate codes or standards. However, the provisions of this specification shall supersede the provisions of these alternate standards in case of any difference. 3.1 3.2 3.3 3.4 3.5 3.6 SASO/SSA 39 SASO/SSA 107 Mechanical testing of welded joints Tensile steel testing

SASO/SSA 157 Charpy method of impact test on metals ASTM ASTM A123 ASTM A143 A36MStandard Specification for Carbon Structural Steel Standard Specification for Zinc (Hot-Dip Galvanized) Coatings of Iron and Steel Products Standard Practice for Safeguarding Against Embrittlement of Hot-Dip Galvanized Structural Steel Products and Procedure for Detecting Embrittlement

Page 3 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

3.7 3.8

ASTM A153 ASTM A215

Standard Specification for Zinc Coating (Hot-Dip) on Iron and Steel Hardware Martensitic Stainless Steel and Alloy Steel Castings for Pressure Containing Parts Suitable for High Temperature Service Standard Test Method for Locating the Thinnest Spot in a Zinc (Galvanized) Coating on Iron or Steel Articles by the Preece Test (Copper Sulfate Dip) Standard Specification for Carbon Steel Bolts and Studs, 60000 PSI Tensile Strength Alloy-Steel Bolting Materials for Low Temperature Austenitic Steel Castings for High Temperature Service Standard Specification for Structural Bolts, Steel, HeatTreated, 120/105 PSI Minimum Tensile Strength Standard Specification for Quenched and Tempered Alloy Steel Bolts, Studs and Other Externally Threaded Fasteners Standard Test Methods and Definitions for Mechanical Testing of Steel Products Standard Practice for Safeguarding Against Warpage and Distortion During Hot-Dip Galvanizing of Steel Assemblies Standard Practice for Providing High Quality Zinc Coatings (Hot-Dip) Standard Specification for Carbon and Alloy Steel Nuts Quenched and Tempered Alloy Steel Bolts for Structural Steel Joints

3.9

ASTM A239

3.10 3.11 3.12 3.13 3.14

ASTM A307 ASTM A320 ASTM A351 ASTM A325 ASTM A354

3.15 3.16

ASTM A370 ASTM A384

3.17 3.18 3.19

ASTM A385 ASTM A394 ASTM A490

Page 4 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

3.20 3.21 3.22

ASTM A537 ASTM A572 ASTM A588

Pressure Vessel Plates, Heat Treated, Carbon-ManganeseSilicon High-Strength Low-Alloy Columbium-Vanadium Steels of Structural Quality Standard Specification for High-Strength Low-Alloy Structural Steel with 50 ksi (345 MPa) Minimum Yield Point to 4-inch (100 mm) Thick Standard Specification for Normalized High-Strength Low-Alloy Structural Steel Plates Standard Specification for Sampling Procedure for Impact Testing of Structural Steel Standard Specification for High-Strength Non-Headed Steel Bolts and Studs

3.23 3.24 3.25 3.26 3.27

ASTM A633 ASTM A673 ASTM A687

ASTM A577M Standard Specification for Ultrasonic Angle Beam Examination of Steel Plates ASTM A578M Standard Specification for Ultrasonic Straight Beam Examination of Plain and Clad Steel Plates for Special Application ASTM E165 ASTM E709 ASCE 72 AISC AWS AWS D1.1 D10.9 Standard Test Method for Liquid Penetrant Examination Standard Guide for Magnetic Particle Examination Guide for Design of Steel Transmission Pole Structures Manual of Steel Construction, 9th Edition Structural Welding Code, Steel Specification for Qualification of Welding Procedures and Welders for Piping and Tubing

3.28 3.29 3.30 3.31 3.32 3.33

Page 5 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

3.34 3.35 3.36 3.37 3.38

NEMA TT-1 ISO ISO ISO ISO 630 R657 1459 1460

Tapered Tubular Steel Structures Standards for Structural Steels Recommendation for Hot-Rolled Steel Sections Metallic Coatings - Protection Against Corrosion by Hot Dip Galvanizing - Guiding Principles Metallic Coatings - Hot-Dip Galvanized Coatings on Ferrous Materials - Gravimetric Determination of the Mass per Unit Area Metallic Coatings - Hot Dip Galvanized Coatings on Fabricated Ferrous Products - Requirements Continuous Hot-Dip Zinc-Coated Carbon Steel Sheet of Commercial, Lock-Forming and Drawing Qualities Cold-Reduced Steel Sheet of Structural Quality Continuous Hot-Dip Zinc-Coated Carbon Steel Sheet of Structural Quality Hexagon Nuts for Structural Bolting, Style 1, Hot-Dip Galvanized (Oversize Tapped) - Product Grades A and B Property Classes 5, 6 and 8 Hexagon Nuts for Structural Bolting - Style 2, Hot-Dip Galvanized (Oversize Tapped) - Product Grade A Property Class 9

3.39 3.40 3.41 3.42 3.43

ISO ISO ISO ISO ISO

1461 3575 4997 4998 7413

3.44

ISO

7417

4.0

SERVICE AND SYSTEM CONDITIONS The poles shall be suitable for operation under the service conditions given in the latest revision of SEC General Specification No. 01-SDMS-01.

Page 6 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

5.0

DESIGN, MATERIALS AND FABRICATION

5.1 General 5.1.1 The galvanized steel poles shall be in a single piece of required length. Their cross sectional shapes shall be tapered octagonal and conform to dimensions given in the tables and drawings in this specification. Poles shall satisfy the dimensional length and pole top loading requirements as per the design parameters listed in this specification. The dimensions across flats for top and bottom for all poles are listed in this specification as a preferred design to utilize one dimension for each type of pole length in so far as design criteria is met. Poles shall be pre-drilled and supplied complete with pole top cap and base plate.

5.1.2

5.1.3 5.2 Design 5.2.1 5.2.2 5.2.3 5.2.4

Types, dimensions and characteristics of standard steel poles included in this specification are given in Table 1. Applications of the standard steel poles are given in Tables 2 and 3. The standard poles shall be suitable for the specified applications based on the design parameters given in Tables 4 and 5. Poles are designed to withstand the worst possible combination of simultaneous loading of: Lateral loads consisting of wind forces on conductors corresponding to wind spans, wind force on insulators, wind force on pole and maximum conductor tension. Vertical loads consisting of pole self-weight, weights of conductors, insulators, cross-arm, additional equipment, lineman and compressive force due to reaction of stays wherever applicable. The maximum design unit stress shall not exceed the minimum yield stress as stated in this specification for the particular application and types of loads, including overload capacity factors.

Page 7 of 43

5.2.5

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

Table 1 Types, Dimensions and Characteristics of Standard Octagonal Steel Poles

Top Across Flat Dia. (mm) 100 155 155 155 155 155 Bottom Across Flat Dia. (mm) 345 390 410 430 600 450 Shaft Thickness (mm) 4 4 4 4 4 4 Shaft Weight (kg) 227 335 377 420 544 466 Ultimate Load (Kg) 803 1509 1530 1564 2431 1545 Color Code (No. of Bands) White (1) Black (1) Red (1) Yellow (1) Yellow (2) Green (1) White (3) Black (3) Red (3) Yellow (3) Green (3)

Pole Type OC10 OC12S OC13S OC14S OC14D

OC15S/D

Brief Description 10m Steel Pole, Low Voltage 12m Steel Pole, Medium. Voltage, Single Circuit 13m Steel Pole, Medium. Voltage, Single Circuit 14m Steel Pole, Medium. Voltage, Single Circuit 14m Steel Pole, Medium. Voltage, Double Circuit 15m Steel Pole, Medium. Voltage, Single & Double Circuit 10m Steel Pole, Self Support, Single Circuit 12m Steel Pole, Self Support, Single Circuit 13m Steel Pole, Self Support, Single Circuit 14m Steel Pole, Self Support, Single Circuit 15m Steel Pole, Self Support, Single Circuit

OC10SFS

230 230 230 230 230

590 710 750 790 830

5 7 7 7 7

527 1012 1143 1282 1429

4968 8517 8781 8874 8898

OC12SFS

OC13SFS

OC14SFS

OC15SFS

Page 8 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

Table 2 Applications of Standard Octagonal Steel Poles For Single Circuit Lines

Pole Type Pole Structure Angle Deviation (Degrees) 0 - 15 16 - 60 61 - 90 05 6 15 16 60 61 90 0 - 90 No. of Stays/Location From Top (mm) N/A 1 @ 150 1 @ 150 1 @ 150 N/A 1 @ 250 1 @ 250 & 1 @ 350 1 @ 250 & 1 @ 350 2 @ 250 along the line 1 @ 250 & 1 @ 350 N/A Buried Depth (mm) 1500 1500 1500 1500 2000 2000 2000 2000 2000 2000 1500 Crossarm Location From Top (mm) N/A N/A N/A N/A 50 50 50 50 50 50 N/A

Intermediate, LV OC10 Medium Angle, LV Heavy Angle, LV Terminal, LV Intermediate, MV Light Angle, MV OC12S OC13S OC14S OC15S/D Medium Angle, MV Heavy Angle, MV Section, MV Terminal, MV OC10SFS OC12SFS OC13SFS OC14SFS OC15SFS Self-Support, LV

Self-Support, MV

0 - 90

N/A

2000

50

Page 9 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

Table 3 Applications of Standard Octagonal Steel Poles For Double Circuit Lines

Pole Type Pole Structure Intermediate, MV Light Angle, MV Medium Angle, MV Heavy Angle, MV Section, MV Terminal, MV Intermediate, MV Light Angle, MV OC15S/D Medium Angle, MV Heavy Angle, MV Section, MV Terminal, MV 1 @ 250, 1 @ 350, 1 @ 2650 & 1 @ 2750 2000 50, 1250 & 2450 1 @ 250, 1 @ 350, 1 @ 2650 & 1 @ 2750 0 1 15 16 60 61 90 2 @ 250 & 2 @ 2650 along the line 2000 50, 1250 & 2450 N/A 1 @ 250 & 1 @ 350 1 @ 250, 1 @ 350, 1 @ 2650 & 1 @ 2750 1 @ 250, 1 @ 350, 1 @ 2650 & 1 @ 2750 2000 2000 2000 2000 2000 50, 1250 & 2450 50, 1250 & 2450 50, 1250 & 2450 50, 1250 & 2450 50, 1250 & 2450 Angle of Deviation (Degrees) 05 6 15 16 60 61 90 2 @ 250 & 2 @ 2650 along the line 2000 50, 1250 & 2450 No. of Stays/Location From Top (mm) Buried Depth (mm) 2000 2000 2000 2000 Crossarm Location From Top (mm) 50, 1250 & 2450 50, 1250 & 2450 50, 1250 & 2450 50, 1250 & 2450

N/A 1 @ 250 & 1 @ 350 1 @ 250, 1 @ 350, 1 @ 2650 & 1 @ 2750 1 @ 250, 1 @ 350, 1 @ 2650 & 1 @ 2750

OC14D

Page 10 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

Table 4 Design Parameters for Single Circuit LV and MV (with Earth Wire) Line

Description Span (m) Wind Pressure (N/m) Basic Wind Weight On Pole On Conductors at 10C Vertical Loads Transverse Loads Longitudinal Loads Ultimate Load Conductor Minimum Breaking Strength 10m 50 55 75 1200 600 1.5 1.5 1.5 1.5 3.0 1.5 Intermediate (0-15) Med. Angle (16-60) Heavy Angle (61-90) Terminal Self-Support (90) 5% of exposed length 120 mm Quadruplex Cable (3 - Insulated AAC for Phase & 1 Bare ACSR/AW Messenger-Neutral) N/A 65 kN 90 % of Min. Breaking Load 37 -2C +80C 12m, 13m, 14m and 15m 100 110 150 1200 600 1.5 1.5 1.5 1.5 3.0 2.0 Intermediate (0-5) Light Angle (6-15) Med. Angle (16-60) Heavy Angle (61-90) Section Terminal Self-Support (90) 5% of exposed length 170 mm ACSR/AW (Merlin) in horizontal configuration 70 mm ACSR/AW (Quail) for Branch 70 mm ACSR/AW (Quail) below crossarm 101 kN 90 % of Min. Breaking Load 37 -2C +80C

Factor of Safety

Planting Depth (m) Unstayed Stayed Stayed Type of Stayed Structure Stayed Stayed Unstayed Allowable Deflection at Pole Top Phase Conductors Earth Wire Minimum Breaking Load Stay Wires Max. Tension Minimum Angle to the Pole Minimum Maximum

Temperature

Page 11 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

Table 5 Design Parameters for Double Circuit MV (with Earth Wire) Line

Description Basic Wind Weight On Pole On Conductors at 10C 14m 100 110 150 1200 600 1.5 1.5 1.5 1.5 3.0 2.0 Intermediate (0-5) Light Angle (6-15) Med. Angle (16-60) Heavy Angle (61-90) Section Terminal 5% of exposed length 170 mm ACSR/AW (Merlin) in vertical configuration 70 mm ACSR/AW (Quail) below crossarm 101 kN 90 % of Min. Breaking Load 37 -2C +80C 15m 100 110 150 1200 600 1.5 1.5 1.5 1.5 3.0 2.0 Intermediate (0) Light Angle (1-15) Med. Angle (16-60) Heavy Angle (61-90) Section Terminal 5% of exposed length 170 mm ACSR/AW (Merlin) in vertical configuration 70 mm ACSR/AW (Quail) below crossarm 101 kN 90 % of Min. Breaking Load 37 -2C +80C

Span (m) Wind Pressure (N/m)

Vertical Loads Transverse Loads Longitudinal Loads Factor of Ultimate Load Safety Conductor Minimum Breaking Strength Planting Depth (m) Unstayed Stayed Stayed Type of Stayed Structure Stayed Stayed Allowable Deflection at Pole Top Phase Conductors Earth Wire Minimum Breaking Load Stay Wires Max. Tension Minimum Angle to the Pole Minimum Maximum

Temperature

Page 12 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

5.3 Materials 5.3.1 Structural steel for pole shaft shall comply with the applicable requirements of ASTM A572 or equivalent with mechanical properties as given below: Minimum yield strength Minimum ultimate tensile strength Max. ultimate tensile strength - 355 N/mm - 490 N/mm - 620 N/mm

5.3.2 Structural steel for bearing plate and top cap shall comply with the applicable requirements of ASTM A36 or equivalent with minimum yield strength of 250 N/mm. 5.3.3 Pole shaft, bearing plate and top cap shall be hot-dipped galvanized after fabrication, including all drilling, cutting and welding. Galvanizing shall be done in accordance with the requirement of 01-SDMS-01 and the minimum average thickness of coating shall be 0.086 mm, equivalent to 610 g/m. 5.3.4 Bolts, nuts and locknuts for top cap, bearing plate and earthing nut shall be steel Grade 4.6 and shall comply with the applicable requirements of ASTM A307 and ASTM A 563 or equivalent and hot-dipped galvanized in accordance with the requirement of 01-SDMS-01 with minimum average coating thickness of 0.053 mm, equivalent to 381 g/m. 5.3.5 Weld material shall be compatible with the material of the pole as defined by American Welding Society. 5.3.6 Poles shall be provided with factory-applied extra anti-corrosion coating of coal tar epoxy applied over galvanization on embedded portion plus 300 mm and suitable barrier coating shall be applied over the coal tar epoxy 300 mm above and below ground line. Complete details of the coating and procedures for application shall be submitted for review/approval by SEC.

Page 13 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

5.4 Fabrication 5.4.1 Shearing and cutting shall be performed carefully and all portions of the work shall be finished neatly. Copes and re-entrant cuts shall be filleted before cutting. All forming and bending during fabrication shall be done by method that will prevent embrittlement or loss of strength in the material being worked. All welding operations shall be done in accordance with the American Welding Society, AWS D1.1. Boltholes as specified in the applicable drawings shall be punched or drilled. Holes may be punched when the material thickness does not exceed the diameter of the hole. Holes of any diameter may be drilled. Holes shall be cylindrical, perpendicular to the pole shaft, free of burrs, and clean cut without torn or ragged edges. The use of burning torch for cutting holes will not be permitted. Extra holes for the purpose of lifting or other than those specified in the drawings shall not be permitted. All pre-drilled holes shall be provided with durable ultra-violet resistant, plastic plugs. Steel pole shall be provided with M12 earthing nut at the location specified in applicable drawing. Hot-dipped galvanized M12 x 30 mm long hexagonal bolt with washer shall be screwed on to the earthing nut. Steel poles shall be provided with detachable top cap and base bearing plate. Flat bar with drilled and tapped hole to suit M12 bolt shall be welded to the top and bottom of the pole for attaching the top cap and base bearing plate, respectively. Hot-dipped galvanized M12 x 30 hexagonal bolts and washers shall be provided for attaching the top cap and base plate.

5.4.2

5.4.3 5.4.4

5.4.5 5.4.6 5.4.7

5.4.8

Page 14 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

5.4.9 The following tolerances shall apply: +/-0.5 % for overall length +/- 5 mm for A/F diameter +/- 2 mm for center-to-center distance between holes +/- 0.5 mm for diameter of pre-drilled holes 5.4.10 Straightness of the pole shaft shall be within 1 mm/m and without any twist. 5.5 Marking 5.5.1 Each pole shall be provided with 80 mm x 80 mm nameplate riveted to the shaft at the location specified in applicable drawing. All markings shall be legible and so applied to remain legible under normal handling and installation practices. Nameplate shall include, but not limited to the following information: SEC Monogram Pole Type Pole Ultimate Load Pole Dimension (A/F Top/Bottom/Thickness) Pole Weight SEC Purchase Order Number SEC Stock Number Manufacturers Name or trademark, place and year of manufacturing.

SAUDI ELECTRICITY CO. SEC-BRANCH

Pole Type: Pole Ultimate Load: Pole Dimensions: Shaft Weight: SEC P.O. No. SEC Stock No. Manufacturer: Year of Manufacture: Made in:

Page 15 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

5.5.2

Each pole shall be provided with color coding consisting of 50 mm wide band with the following color painted to the pole at the location specified in applicable drawing: 10 m Single Circuit - White 12 m Single Circuit - Black 13 m Single Circuit - Red 14 m Single Circuit - Yellow 15 m Single Circuit - Green Double Circuit Same color as the above except double band 50 mm apart. Self-Support Same color as the above except triple band 50 mm apart.

6.0

INSPECTION AND TESTING In addition to the requirements specified in 01-SDMS-01, the following shall be fulfilled: 6.1 The Supplier shall make adequate tests and inspections to determine the conformity of material furnished under this Specification with the requirements invoked. SEC or its designated representative will conduct acceptance inspection and witness testing at the manufacturer's plant. 6.2 Inspection/Routine Test Requirements 6.2.1 Inspection / routine tests shall be in accordance with NEMA Standard TT-1 for Tapered Tubular Steel Structure. 6.2.2 Visual inspection shall include checks for satisfactory workmanship, materials, freedom from surface defects and for compliance with the Purchase Order and the General Specifications.

Page 16 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

6.2.3

SEC designated representative shall have free access at all times while work is being carried on, to all areas of the Supplier's plant which concern the work. Inspection/routine tests may be made during all stages of manufacturing, testing and shipping. Inspection may be at the point of shipment or delivery site at SEC option. However, inspection and acceptance shall not relieve the Supplier of his responsibility for conformance with this specification. Proof Load Test (Horizontal Testing) The tubular steel poles shall be proof tested in accordance with applicable standards. One pole of each design for every consignment shall be tested as per the manufacturers testing procedure approved by SEC. Manual application of load during testing shall not be allowed. Digital dynamometer shall be used to obtain accurate readings. The proof test will verify the adequacy of steel pole to withstand the static design loads specified for that structure as an individual entity under controlled conditions. In the event of any one pole not fulfilling the test requirements, further two shall be tested. Should either of these fail, the whole order of the particular type of pole shall be deemed to have failed to comply with this specification.

6.2.4

6.2.5

6.3 Type Testing Requirements All materials shall be type tested in accordance with the latest standards in this specification. Following the completion of all tests, two certified copies of the test reports shall be submitted to SEC for review and approval.

Page 17 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

6.3.1

Full-scale Loading Test (Vertical Testing) When SEC desires full scale loading tests, it shall be as stated in the Data Schedule. The Supplier shall then include in his proposal, as a separate item, the cost of the tests. Full scale loading test shall be in accordance with the applicable standards. The Supplier shall submit for approval by SEC diagrams showing the proposed scheme for applying and measuring loads and determining deflections of critical points.

. 6.3.2 Deflections (During Pole Test) Pole deflections under load shall be measured and recorded. Deflection readings shall be recorded for the before-load, load-on and load-off conditions as well as at all intermediate holds during loading. All deflections shall be performed to common base readings, such as the initial positions, taken before any test loads are applied. A no-load deflection reading shall be taken five minutes after the removal of the maximum test load, the reading shall not exceed the allowable deflection (5% of the exposed length). 6.3.3 Test Reports The Supplier shall furnish a full and comprehensive report of each pole test and shall include detailed diagrams and tabulation showing values and methods of load application and deflection records of each load test, photographs of test set up and description (with photographs) of all failures, if any. Include mill test reports of the material used and the results of any tensile tests of specimens cut from any members, which failed during the testing program. Particular emphasis shall be placed on the determination of the mechanical properties of the material. 6.3.4 Test Acceptance The Supplier, upon receipt of written acceptance from SEC for the satisfactory performance of the pole loading tests, may start fabrication of the steel poles.

Page 18 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

7.0

PACKING AND SHIPMENT In addition to the packing and shipping requirements specified in 01-SDMS-01, the following shall be fulfilled:

7.1 The poles shall be stacked with spacers and blocks in order to avoid damages of zinc coating during the loading and transportation. 7.2 Poles shall be delivered in bundles of 6 poles with the arrangement of 2 layers, with 3 poles per layer, and strapped at four (4) locations of equal distances with the use of steel straps size 31 mm x 0.8 mm (min.) and necessary wood separators, padding or cushion material underneath the steel straps. 7.3 Wooden separators shall be provided between the horizontal and vertical layers of poles to avoid scratches and to facilitate slinging. 7.4 Bundled poles shall be so arranged such that the earthing hardwares are not disturbed during normal handling. 7.5 Reasonable care shall be exercised in the handling and shipment of steel poles. Any expense incurred due to the careless handling and shipment of steel poles shall be considered as a legitimate back charge against the Supplier. 8.0 GUARANTEE

8.1 The vendor shall guarantee the steel pole against all defects arising out of faulty design or workmanship or defective material for a period of one year from the date of installation or two years from date of delivery. SEC certificates for date of commissioning shall be accepted. 8.2 If no exceptions to this specification is taken and no list of deviations is submitted, it shall be deemed that, in every respect, steel pole offered shall conform to this Specification. SEC interpretation of this Specification shall be accepted.

Page 19 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

9.0

SUBMITTALS 9.1 In addition to documentations specified in 01-SDMS-01, the following shall be submitted by the vendor/manufacturer: 9.1.1 Design information and drawings to be supplied with the proposals: a) Detailed drawings of steel pole showing the complete dimensions identification marks, number and location of pre-drilled bolt holes, details of pole top cap, bearing plate, hole plastic plug, earthing nut and marking plate. b) Detailed drawing/procedure for bundling of poles. c) Details of anti-corrosion coating 9.1.2 Submittals required following award of contract: a. Drawings for final SEC approval shall be submitted prior to start of manufacturing. Supplier shall furnish all final drawings in original or Mylar tracings as well as on digital format. b. Manufacturing schedule, progress report and test schedules. c. Test reports including, but not limited to, the following: Certified mill test reports for all material. Certified welding reports. Impact property test reports showing that the materials used in the structures meet the impact properties. Test reports on coating thickness, nuts & bolts and reports on dimensional checks. Report of all structure testing, when required, including photos, diagrams, loading trees, etc.

Page 20 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

10.0 DATA SCHEDULE OCTAGONAL STEEL POLE (Sheet 1 of 12) SEC Inquiry No. ______________________________ SEC Stock No. __________ REF. SECTION

5.2.1

DESCRIPTION Pole type

Length, m Top A/F diameter, mm Bottom A/F diameter, mm Shaft thickness, mm

SEC VALUES

OC10 10 100 345 4 1368 * * 355 610 As specified As specified As specified As specified As specified As specified As specified As specified As specified White (1) As specified

VENDOR PROPOSED VALUES

5.2.1 5.2.1 5.2.1 5.2.1 5.2.1 5.3.1 5.3.1 5.3.3 5.3.4 5.3.6 5.4.6 5.4.7 5.4.8 5.4.9 5.4.10 5.5.1 5.5.1 5.5.2

9.0

Pole ultimate load, kg Total weight (after galvanization), kg

Standard designation/grade of steel for pole shaft Minimum yield stress of steel material for pole shaft, N/mm Minimum coating weight of hot-dip galvanizing of pole shaft, g/m2 Hot-dipped galvanized steel Grade 4.6 for bolts, nuts & locknuts of top cap, bearing plate and earthing nuts With factory-applied anti-corrosion coating over galvanization on embedded portion plus 300 mm above ground line

All pre-drilled holes provided with U.V. resistant, plastic plugs M12 x 30 mm bolt and washer for earthing nut M12 x 30 mm bolt with washer for attaching top cap and bearing plate Tolerances Straightness of the pole

Name plate with complete information Name plate affixed to the pole by rivets Color Code (Number of bands) Submittals as per this specification enclosed

* Values to be provided/proposed by Vendor

Page 21 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

10.0 DATA SCHEDULE OCTAGONAL STEEL POLE (Sheet 2 of 12) SEC Inquiry No. ______________________________ SEC Stock No. __________ REF. SECTION

5.2.1

DESCRIPTION Pole type

Length, m Top A/F diameter, mm Bottom A/F diameter, mm Shaft thickness, mm

SEC VALUES

OC12S 12 155 390 4 1509 * * 355 610 As specified As specified As specified As specified As specified As specified As specified As specified As specified Black (1) As specified

VENDOR PROPOSED VALUES

5.2.1 5.2.1 5.2.1 5.2.1 5.2.1 5.3.1 5.3.1 5.3.3 5.3.4 5.3.6 5.4.6 5.4.7 5.4.8 5.4.9 5.4.10 5.5.1 5.5.1 5.5.2

9.0

Pole ultimate load, kg Total weight (after galvanization), kg

Standard designation/grade of steel for pole shaft Minimum yield stress of steel material for pole shaft, N/mm Minimum coating weight of hot-dip galvanizing of pole shaft, g/m2 Hot-dipped galvanized steel Grade 4.6 for bolts, nuts & locknuts of top cap, bearing plate and earthing nuts With factory-applied anti-corrosion coating over galvanization on embedded portion plus 300 mm above ground line

All pre-drilled holes provided with U.V. resistant, plastic plugs M12 x 30 mm bolt and washer for earthing nut M12 x 30 mm bolt with washer for attaching top cap and bearing plate Tolerances Straightness of the pole

Name plate with complete information Name plate affixed to the pole by rivets Color Code (Number of bands) Submittals as per this specification enclosed

* Values to be provided by Vendor

Page 22 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

10.0 DATA SCHEDULE OCTAGONAL STEEL POLE (Sheet 3 of 12) SEC Inquiry No. ______________________________ SEC Stock No. __________ REF. SECTION

5.2.1

DESCRIPTION Pole type

Length, m Top A/F diameter, mm Bottom A/F diameter, mm Shaft thickness, mm

SEC VALUES

OC13S 13 155 410 4 1530 * * 355

VENDOR PROPOSED VALUES

5.2.1 5.2.1 5.2.1 5.2.1 5.2.1 5.3.1 5.3.1 5.3.3 5.3.4 5.3.6 5.4.6 5.4.7 5.4.8 5.4.9 5.4.10 5.5.1 5.5.1 5.5.2

9.0

Pole ultimate load, kg Total weight (after galvanization), kg

Standard designation/grade of steel for pole shaft Minimum yield stress of steel material for pole shaft, N/mm Minimum coating weight of hot-dip galvanizing of 610 pole shaft, g/m2 Hot-dipped galvanized steel Grade 4.6 for bolts, nuts As specified & locknuts of top cap, bearing plate and earthing nuts With factory-applied anti-corrosion coating over As specified galvanization on embedded portion plus 300 mm above ground line As specified All pre-drilled holes provided with U.V.

resistant, plastic plugs M12 x 30 mm bolt and washer for earthing nut M12 x 30 mm bolt with washer for attaching top cap and bearing plate Tolerances Straightness of the pole

Name plate with complete information Name plate affixed to the pole by rivets Color Code (Number of bands) Submittals as per this specification enclosed

As specified As specified As specified As specified As specified As specified Red (1) As specified

* Values to be provided by Vendor

Page 23 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

10.0 DATA SCHEDULE OCTAGONAL STEEL POLE (Sheet 4 of 12) SEC Inquiry No. ______________________________ SEC Stock No. __________ REF. SECTION

5.2.1

DESCRIPTION Pole type

Length, m Top A/F diameter, mm Bottom A/F diameter, mm Shaft thickness, mm

SEC VALUES

OC14S 14 155 430 4 1564 * * 355 610 As specified As specified As specified As specified As specified As specified As specified As specified As specified Yellow (1) As specified

VENDOR PROPOSED VALUES

5.2.1 5.2.1 5.2.1 5.2.1 5.2.1 5.3.1 5.3.1 5.3.3 5.3.4 5.3.6 5.4.6 5.4.7 5.4.8 5.4.9 5.4.10 5.5.1 5.5.1 5.5.2

9.0

Pole ultimate load, kg Total weight (after galvanization), kg

Standard designation/grade of steel for pole shaft Minimum yield stress of steel material for pole shaft, N/mm Minimum coating weight of hot-dip galvanizing of pole shaft, g/m2 Hot-dipped galvanized steel Grade 4.6 for bolts, nuts & locknuts of top cap, bearing plate and earthing nuts With factory-applied anti-corrosion coating over galvanization on embedded portion plus 300 mm above ground line

All pre-drilled holes provided with U.V. resistant, plastic plugs M12 x 30 mm bolt and washer for earthing nut M12 x 30 mm bolt with washer for attaching top cap and bearing plate Tolerances Straightness of the pole

Name plate with complete information Name plate affixed to the pole by rivets Color Code (Number of bands) Submittals as per this specification enclosed

* Values to be provided by Vendor

Page 24 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

10.0 DATA SCHEDULE OCTAGONAL STEEL POLE (Sheet 5 of 12) SEC Inquiry No. ______________________________ SEC Stock No. __________ REF. SECTION

5.2.1

DESCRIPTION Pole type

Length, m Top A/F diameter, mm Bottom A/F diameter, mm Shaft thickness, mm

SEC VALUES

OC14D 14 155 600 4 2431 * * 355 610 As specified As specified As specified As specified As specified As specified As specified As specified As specified Yellow (2) As specified

VENDOR PROPOSED VALUES

5.2.1 5.2.1 5.2.1 5.2.1 5.2.1 5.3.1 5.3.1 5.3.3 5.3.4 5.3.6 5.4.6 5.4.7 5.4.8 5.4.9 5.4.10 5.5.1 5.5.1 5.5.2

9.0

Pole ultimate load, kg Total weight (after galvanization), kg

Standard designation/grade of steel for pole shaft Minimum yield stress of steel material for pole shaft, N/mm Minimum coating weight of hot-dip galvanizing of pole shaft, g/m2 Hot-dipped galvanized steel Grade 4.6 for bolts, nuts & locknuts of top cap, bearing plate and earthing nuts With factory-applied anti-corrosion coating over galvanization on embedded portion plus 300 mm above ground line

All pre-drilled holes provided with U.V. resistant, plastic plugs M12 x 30 mm bolt and washer for earthing nut M12 x 30 mm bolt with washer for attaching top cap and bearing plate Tolerances Straightness of the pole

Name plate with complete information Name plate affixed to the pole by rivets Color Code (Number of bands) Submittals as per this specification enclosed

* Values to be provided by Vendor

Page 25 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

10.0 DATA SCHEDULE OCTAGONAL STEEL POLE (Sheet 6 of 12) SEC Inquiry No. ______________________________ SEC Stock No. __________ REF. SECTION

5.2.1

DESCRIPTION Pole type

Length, m Top A/F diameter, mm Bottom A/F diameter, mm Shaft thickness, mm

SEC VALUES

OC15S/D 15 155 450 4 1545 * * 355 610 As specified As specified As specified As specified As specified As specified As specified As specified As specified Green (1) As specified

VENDOR PROPOSED VALUES

5.2.1 5.2.1 5.2.1 5.2.1 5.2.1 5.3.1 5.3.1 5.3.3 5.3.4 5.3.6 5.4.6

Pole ultimate load, kg Total weight (after galvanization), kg

Standard designation/grade of steel for pole shaft Minimum yield stress of steel material for pole shaft, N/mm Minimum coating weight of hot-dip galvanizing of pole shaft, g/m2 Hot-dipped galvanized steel Grade 4.6 for bolts, nuts & locknuts of top cap, bearing plate and earthing nuts With factory-applied anti-corrosion coating over galvanization on embedded portion plus 300 mm above ground line

All pre-drilled holes provided with U.V. resistant, plastic plugs 5.4.7 M12 x 30 mm bolt and washer for earthing nut 5.4.8 M12 x 30 mm bolt with washer for attaching top cap and bearing plate 5.4.9 Tolerances 5.4.10 Straightness of the pole 5.5.1 Name plate with complete information 5.5.1 Name plate affixed to the pole by rivets 5.5.2 Color Code (Number of bands)

9.0 Submittals as per this specification enclosed

* Values to be provided by Vendor

Page 26 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

10.0 DATA SCHEDULE OCTAGONAL STEEL POLE (Sheet 7 of 12) SEC Inquiry No. ______________________________ SEC Stock No. __________ REF. SECTION

5.2.1

DESCRIPTION Pole type

Length, m Top A/F diameter, mm Bottom A/F diameter, mm Shaft thickness, mm

SEC VALUES

OC10SFS 10 230 590 5 4968 * * 355 610 As specified As specified As specified As specified As specified As specified As specified As specified As specified White (3) As specified

VENDOR PROPOSED VALUES

5.2.1 5.2.1 5.2.1 5.2.1 5.2.1 5.3.1 5.3.1 5.3.3 5.3.4 5.3.6 5.4.6 5.4.7 5.4.8 5.4.9 5.4.10 5.5.1 5.5.1 5.5.2

9.0

Pole ultimate load, kg Total weight (after galvanization), kg

Standard designation/grade of steel for pole shaft Minimum yield stress of steel material for pole shaft, N/mm Minimum coating weight of hot-dip galvanizing of pole shaft, g/m2 Hot-dipped galvanized steel Grade 4.6 for bolts, nuts & locknuts of top cap, bearing plate and earthing nuts With factory-applied anti-corrosion coating over galvanization on embedded portion plus 300 mm above ground line

All pre-drilled holes provided with U.V. resistant, plastic plugs M12 x 30 mm bolt and washer for earthing nut M12 x 30 mm bolt with washer for attaching top cap and bearing plate Tolerances Straightness of the pole

Name plate with complete information Name plate affixed to the pole by rivets Color Code (Number of bands) Submittals as per this specification enclosed

* Values to be provided by Vendor

Page 27 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

10.0 DATA SCHEDULE OCTAGONAL STEEL POLE (Sheet 8 of 12) SEC Inquiry No. ______________________________ SEC Stock No. __________ REF. SECTION

5.2.1

DESCRIPTION Pole type

Length, m Top A/F diameter, mm Bottom A/F diameter, mm Shaft thickness, mm

SEC VALUES

OC12SFS 12 230 710 7 8517 * * 355 610 As specified As specified As specified As specified As specified As specified As specified As specified As specified Black (3) As specified

VENDOR PROPOSED VALUES

5.2.1 5.2.1 5.2.1 5.2.1 5.2.1 5.3.1 5.3.1 5.3.3 5.3.4 5.3.6 5.4.6 5.4.7 5.4.8 5.4.9 5.4.10 5.5.1 5.5.1 5.5.2

9.0

Pole ultimate load, kg Total weight (after galvanization), kg

Standard designation/grade of steel for pole shaft Minimum yield stress of steel material for pole shaft, N/mm Minimum coating weight of hot-dip galvanizing of pole shaft, g/m2 Hot-dipped galvanized steel Grade 4.6 for bolts, nuts & locknuts of top cap, bearing plate and earthing nuts With factory-applied anti-corrosion coating over galvanization on embedded portion plus 300 mm above ground line

All pre-drilled holes provided with U.V. resistant, plastic plugs M12 x 30 mm bolt and washer for earthing nut M12 x 30 mm bolt with washer for attaching top cap and bearing plate Tolerances Straightness of the pole

Name plate with complete information Name plate affixed to the pole by rivets Color Code (Number of bands) Submittals as per this specification enclosed

* Values to be provided by Vendor

Page 28 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

10.0 DATA SCHEDULE OCTAGONAL STEEL POLE (Sheet 9 of 12) SEC Inquiry No. ______________________________ SEC Stock No. __________ REF. SECTION

5.2.1

DESCRIPTION Pole type

Length, m Top A/F diameter, mm Bottom A/F diameter, mm Shaft thickness, mm

SEC VALUES

OC13SFS 13 230 750 7 8781 * * 355 610 As specified As specified As specified As specified As specified As specified As specified As specified As specified Red (3) As specified

VENDOR PROPOSED VALUES

5.2.1 5.2.1 5.2.1 5.2.1 5.2.1 5.3.1 5.3.1 5.3.3 5.3.4 5.3.6 5.4.6

Pole ultimate load, kg Total weight (after galvanization), kg

Standard designation/grade of steel for pole shaft Minimum yield stress of steel material for pole shaft, N/mm Minimum coating weight of hot-dip galvanizing of pole shaft, g/m2 Hot-dipped galvanized steel Grade 4.6 for bolts, nuts & locknuts of top cap, bearing plate and earthing nuts With factory-applied anti-corrosion coating over galvanization on embedded portion plus 300 mm above ground line

All pre-drilled holes provided with U.V. resistant, plastic plugs 5.4.7 M12 x 30 mm bolt and washer for earthing nut 5.4.8 M12 x 30 mm bolt with washer for attaching top cap and bearing plate 5.4.9 Tolerances 5.4.10 Straightness of the pole 5.5.1 Name plate with complete information 5.5.1 Name plate affixed to the pole by rivets 5.5.2 Color Code (Number of bands)

9.0 Submittals as per this specification enclosed

* Values to be provided by Vendor

Page 29 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

10.0 DATA SCHEDULE OCTAGONAL STEEL POLE (Sheet 10 of 12) SEC Inquiry No. ______________________________ SEC Stock No. __________ REF. SECTION

5.2.1

DESCRIPTION Pole type

Length, m Top A/F diameter, mm Bottom A/F diameter, mm Shaft thickness, mm

SEC VALUES

OC14SFS 14 230 790 7 8874 * * 355 610 As specified As specified As specified As specified As specified As specified As specified As specified As specified Yellow (3) As specified

VENDOR PROPOSED VALUES

5.2.1 5.2.1 5.2.1 5.2.1 5.2.1 5.3.1 5.3.1 5.3.3 5.3.4 5.3.6 5.4.6 5.4.7 5.4.8 5.4.9 5.4.10 5.5.1 5.5.1 5.5.2

9.0

Pole ultimate load, kg Total weight (after galvanization), kg

Standard designation/grade of steel for pole shaft Minimum yield stress of steel material for pole shaft, N/mm Minimum coating weight of hot-dip galvanizing of pole shaft, g/m2 Hot-dipped galvanized steel Grade 4.6 for bolts, nuts & locknuts of top cap, bearing plate and earthing nuts With factory-applied anti-corrosion coating over galvanization on embedded portion plus 300 mm above ground line

All pre-drilled holes provided with U.V. resistant, plastic plugs M12 x 30 mm bolt and washer for earthing nut M12 x 30 mm bolt with washer for attaching top cap and bearing plate Tolerances Straightness of the pole

Name plate with complete information Name plate affixed to the pole by rivets Color Code (Number of bands) Submittals as per this specification enclosed

* Values to be provided by Vendor

Page 30 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

10.0 DATA SCHEDULE OCTAGONAL STEEL POLE (Sheet 11 of 12) SEC Inquiry No. ______________________________ SEC Stock No. __________ REF. SECTION

5.2.1

DESCRIPTION Pole type

Length, m Top A/F diameter, mm Bottom A/F diameter, mm Shaft thickness, mm

SEC VALUES

OC15SFS 15 230 830 7 8898 * * 355 610 As specified As specified As specified As specified As specified As specified As specified As specified As specified Green (3) As specified

VENDOR PROPOSED VALUES

5.2.1 5.2.1 5.2.1 5.2.1 5.2.1 5.3.1 5.3.1 5.3.3 5.3.4 5.3.6 5.4.6

Pole ultimate load, kg Total weight (after galvanization), kg

Standard designation/grade of steel for pole shaft Minimum yield stress of steel material for pole shaft, N/mm Minimum coating weight of hot-dip galvanizing of pole shaft, g/m2 Hot-dipped galvanized steel Grade 4.6 for bolts, nuts & locknuts of top cap, bearing plate and earthing nuts With factory-applied anti-corrosion coating over galvanization on embedded portion plus 300 mm above ground line

All pre-drilled holes provided with U.V. resistant, plastic plugs 5.4.7 M12 x 30 mm bolt and washer for earthing nut 5.4.8 M12 x 30 mm bolt with washer for attaching top cap and bearing plate 5.4.9 Tolerances 5.4.10 Straightness of the pole 5.5.1 Name plate with complete information 5.5.1 Name plate affixed to the pole by rivets 5.5.2 Color Code (Number of bands)

9.0 Submittals as per this specification enclosed

* Values to be provided by Vendor

Page 31 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

10.0 DATA SCHEDULE OCTAGONAL STEEL POLE (Sheet 12 of 12) A. ADDITIONAL TECHNICAL INFORMATION OR FEATURES SPECIFIED BY SEC:

B.

ADDITIONAL SUPPLEMENTARY DATA OR FEATURES PROPOSED BY BIDDER/VENDOR/SUPPLIER:

C.

OTHER PARTICULARS TO BE FILLED UP BY BIDDER/VENDOR/ SUPPLIER:

D.

LIST OF DEVIATIONS & CLAUSES TO WHICH EXCEPTIONS ARE TAKEN BY THE BIDDER/VENDOR/SUPPLIER: (USE SEPARATE SHEET IF NECESSARY)

MANUFACTURER Name of Company Location and Office Address Name and Signature of Authorized Representative Official Seal / Stamp

VENDOR / SUPPLIER

Page 32 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

Page 33 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

Page 34 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

Page 35 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

Page 36 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

Page 37 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

Page 38 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

Page 39 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

Page 40 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

Page 41 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

Page 42 of 43

Saudi Electricity Company

SEC DISTRIBUTION MATERIALS SPECIFICATION

20-SDMS-01, Rev. 01 DATE: 04-06-1423 H

Page 43 of 43

Das könnte Ihnen auch gefallen

- Sans10123 PDFDokument65 SeitenSans10123 PDFMpho Michael Raphulu0% (1)

- License Kalpataru Power Transmission Limited/IN-885-t Not For Resale, 2/11/2017 12:59:48 PM Saudi TimeDokument28 SeitenLicense Kalpataru Power Transmission Limited/IN-885-t Not For Resale, 2/11/2017 12:59:48 PM Saudi Timechand saigv100% (1)

- 12-TMSS-01-R1 Line HardwareDokument25 Seiten12-TMSS-01-R1 Line HardwareNauman Habib KhanNoch keine Bewertungen

- ManualDokument1 SeiteManualmicajecicNoch keine Bewertungen

- 14 Samss 533 PDFDokument14 Seiten14 Samss 533 PDFMudabbir HussainNoch keine Bewertungen

- S-TR-CORR (Rev.0-2015)Dokument19 SeitenS-TR-CORR (Rev.0-2015)Abhinav SinhaNoch keine Bewertungen

- Sdcs-03 Part 1 (Distribution Network Grounding) Rev01Dokument107 SeitenSdcs-03 Part 1 (Distribution Network Grounding) Rev01Haytham BafoNoch keine Bewertungen

- Materials System SpecificationDokument23 SeitenMaterials System SpecificationFAPM1285Noch keine Bewertungen

- 20 TMSS 02 R1Dokument26 Seiten20 TMSS 02 R1Anonymous NrBbhHuZyiNoch keine Bewertungen

- 12 TMSS 10Dokument19 Seiten12 TMSS 10Fouad AliNoch keine Bewertungen

- 20PKSA001-LNT-SPV-G-DBR-0041 - R5 Design Basis Report PV Plant - ADokument53 Seiten20PKSA001-LNT-SPV-G-DBR-0041 - R5 Design Basis Report PV Plant - ASamkonaya BitomNoch keine Bewertungen

- Vitreous China Plumbing Fixtures 75SMSS2Dokument25 SeitenVitreous China Plumbing Fixtures 75SMSS2Pageduesca RouelNoch keine Bewertungen

- June 30, 2010Dokument41 SeitenJune 30, 2010TTPL ProjectsNoch keine Bewertungen

- 11-TMSS-10-R1 Control CablesDokument14 Seiten11-TMSS-10-R1 Control CablesNauman Habib KhanNoch keine Bewertungen

- 16 Samss 518Dokument10 Seiten16 Samss 518adnanmppNoch keine Bewertungen

- 53TMSS02R1Dokument57 Seiten53TMSS02R1Abdulaziz AlmutiriNoch keine Bewertungen

- 46TMSS04R0 Valve Regulated Lead Acid (VRLA) Stationary Battery BankDokument15 Seiten46TMSS04R0 Valve Regulated Lead Acid (VRLA) Stationary Battery BankMohamed NasrNoch keine Bewertungen

- Tes P 122 181213130429Dokument31 SeitenTes P 122 181213130429Ahmed AboelgoodNoch keine Bewertungen

- Saes P 119Dokument17 SeitenSaes P 119drbabithameringeorgemdsorthoNoch keine Bewertungen

- Saes P 107Dokument18 SeitenSaes P 107bilal hussain qureshiNoch keine Bewertungen

- Materials System SpecificationDokument18 SeitenMaterials System SpecificationEagle SpiritNoch keine Bewertungen

- BS 5212 - 2 Cold Applied Joint Sealant Systems For ConcreteDokument14 SeitenBS 5212 - 2 Cold Applied Joint Sealant Systems For ConcreteTom YeeNoch keine Bewertungen

- TCS Q 113.03 Rev 00Dokument44 SeitenTCS Q 113.03 Rev 00chand saigvNoch keine Bewertungen

- 12-SDMS-02 REV. 02: Saudi Electricity CompanyDokument20 Seiten12-SDMS-02 REV. 02: Saudi Electricity CompanyMichael Camit EsoNoch keine Bewertungen

- Current, Voltage, Resistance, Impedance, Circuit, Ohm Laws. Kirchaff LawDokument40 SeitenCurrent, Voltage, Resistance, Impedance, Circuit, Ohm Laws. Kirchaff LawMonica CarrollNoch keine Bewertungen

- 10-Tmss-05-Bare, Copper-Clad Grounding Conductor and Ground Rod-R2Dokument11 Seiten10-Tmss-05-Bare, Copper-Clad Grounding Conductor and Ground Rod-R2m3eenNoch keine Bewertungen

- 1-) 52-TMSS-01-Rev.00Dokument29 Seiten1-) 52-TMSS-01-Rev.00Orcun CalayNoch keine Bewertungen

- 20PKSA001-LNT-SPV-V-DSH-1903 - R3-SCADA System - Datasheet and Drawings BOM - ADokument68 Seiten20PKSA001-LNT-SPV-V-DSH-1903 - R3-SCADA System - Datasheet and Drawings BOM - ASamkonaya BitomNoch keine Bewertungen

- Saes B 063Dokument6 SeitenSaes B 063hasanmnhNoch keine Bewertungen

- CHAPTER 1 M.V. NETWORK Part 1 Design Standards 01-04-2019Dokument23 SeitenCHAPTER 1 M.V. NETWORK Part 1 Design Standards 01-04-2019Ahmed Aboelgood100% (1)

- Inspection Checklist PDFDokument7 SeitenInspection Checklist PDFBennyNoch keine Bewertungen

- TES-P-119-12-R0-Application Criteria For Electrical EquipmentDokument22 SeitenTES-P-119-12-R0-Application Criteria For Electrical EquipmentZain-Ul- AbdeenNoch keine Bewertungen

- Saudi Electricity Company PDFDokument25 SeitenSaudi Electricity Company PDFDP DianaNoch keine Bewertungen

- September 07, 2010Dokument12 SeitenSeptember 07, 2010Suhaib ObeidatNoch keine Bewertungen

- M 504 Saudi 230kV OHTL JRSD BSP TO SWCC 2B - JSW (PORTION-2 LINE-3 G) Tower Schedule 03.10.2019Dokument2 SeitenM 504 Saudi 230kV OHTL JRSD BSP TO SWCC 2B - JSW (PORTION-2 LINE-3 G) Tower Schedule 03.10.2019Prabhakar SvNoch keine Bewertungen

- Meter Inspection and Maintenance: Distribution Maintenance Manual FORDokument10 SeitenMeter Inspection and Maintenance: Distribution Maintenance Manual FORAmmar Lateef GakharNoch keine Bewertungen

- SAIC-P-3007 Rev 7 FinalDokument20 SeitenSAIC-P-3007 Rev 7 FinalEnginerShahzadGhaffarNoch keine Bewertungen

- 16 Samss 514Dokument17 Seiten16 Samss 514HatemS.MashaGbehNoch keine Bewertungen

- Ses H 001.01Dokument28 SeitenSes H 001.01skmd87100% (1)

- 11 TMSS 02 R0Dokument0 Seiten11 TMSS 02 R0renjithas2005Noch keine Bewertungen

- Indices of Approved Transmission Standards and SpecificationsDokument10 SeitenIndices of Approved Transmission Standards and SpecificationsSiva KumarNoch keine Bewertungen

- 16 Samss 521Dokument8 Seiten16 Samss 521Eagle SpiritNoch keine Bewertungen

- 10 TMSS 02 R0Dokument0 Seiten10 TMSS 02 R0renjithas2005Noch keine Bewertungen

- Vol V KFW TR 107 16112017 PDFDokument376 SeitenVol V KFW TR 107 16112017 PDFramesh seerviNoch keine Bewertungen

- 01TMSS01R2Dokument22 Seiten01TMSS01R2Badhur Zaman100% (1)

- 01-TMSS-01 (Rev 03)Dokument23 Seiten01-TMSS-01 (Rev 03)GardellNoch keine Bewertungen

- TES-P-122-07-R1-Transmission Structure SpottingDokument18 SeitenTES-P-122-07-R1-Transmission Structure SpottingMozammil AkhtarNoch keine Bewertungen

- 16 Samss 502 - PDFDokument12 Seiten16 Samss 502 - PDFShahraiz KhanNoch keine Bewertungen

- 15-SDMS-02 Overhead Line Polymer. Insulators PDFDokument26 Seiten15-SDMS-02 Overhead Line Polymer. Insulators PDFMehdi Salah100% (1)

- SATIP-P-113-01 Rev 8 Final Induction Motor PDFDokument3 SeitenSATIP-P-113-01 Rev 8 Final Induction Motor PDFSabheeh AliNoch keine Bewertungen

- ITP-Composite Insulator - Type Test PDFDokument4 SeitenITP-Composite Insulator - Type Test PDFPrabhakar SvNoch keine Bewertungen

- ITP-OPGW - Type Test PDFDokument4 SeitenITP-OPGW - Type Test PDFPrabhakar SvNoch keine Bewertungen

- Indx SaesDokument3 SeitenIndx SaeskhaledNoch keine Bewertungen

- BS 3G 210 PTFE Insulated Equipment Wires & Cables, Single - & Multi-Core PDFDokument30 SeitenBS 3G 210 PTFE Insulated Equipment Wires & Cables, Single - & Multi-Core PDFwaseem kausarNoch keine Bewertungen

- LM6 Alloy DetailDokument4 SeitenLM6 Alloy DetaildsoNoch keine Bewertungen

- 175 023400Dokument2 Seiten175 023400Abu Anas M.SalaheldinNoch keine Bewertungen

- 20 TMSS 02 R0Dokument0 Seiten20 TMSS 02 R0renjithas2005Noch keine Bewertungen

- 20-SDMS-01 R3 FinalDokument30 Seiten20-SDMS-01 R3 FinalFayyaz Ahmad KhanNoch keine Bewertungen

- 20-TMSS-02 R.1 (Not Applicable)Dokument26 Seiten20-TMSS-02 R.1 (Not Applicable)wastazoheb_700349353Noch keine Bewertungen

- 12-SAMSS-007 Fabrication Structural Miscellaneous Steel 2006Dokument29 Seiten12-SAMSS-007 Fabrication Structural Miscellaneous Steel 2006ymasedaNoch keine Bewertungen

- 90206-000-CV-SP-105 SPECIFICATION FOR Fabrication and Erection of Steel Structures IN ALL AREAS (Rev.A0) PDFDokument22 Seiten90206-000-CV-SP-105 SPECIFICATION FOR Fabrication and Erection of Steel Structures IN ALL AREAS (Rev.A0) PDFamini_mohiNoch keine Bewertungen

- Project Site Organisation Chart CONTRACTOR NO. - 21131142/00Dokument4 SeitenProject Site Organisation Chart CONTRACTOR NO. - 21131142/00tapas_jituNoch keine Bewertungen

- Shipment Release CetificateDokument1 SeiteShipment Release Cetificatetapas_jituNoch keine Bewertungen

- AB Chance MethodDokument2 SeitenAB Chance Methodtapas_jituNoch keine Bewertungen

- WO 800 Access Road ContractDokument1 SeiteWO 800 Access Road Contracttapas_jituNoch keine Bewertungen

- ADR111EDokument14 SeitenADR111Etapas_jituNoch keine Bewertungen

- First Manual - RA-01Dokument5 SeitenFirst Manual - RA-01tapas_jituNoch keine Bewertungen

- GA DRAWING FOR 3630 kVAr, 12 (1) .65 KV CAP - BANKDokument1 SeiteGA DRAWING FOR 3630 kVAr, 12 (1) .65 KV CAP - BANKtapas_jituNoch keine Bewertungen

- 260362main - NESC TECH UP 2007Dokument66 Seiten260362main - NESC TECH UP 2007tapas_jituNoch keine Bewertungen

- Metriso Prime M550TDokument4 SeitenMetriso Prime M550TnaveenNoch keine Bewertungen

- FusesDokument34 SeitenFusesOrlando RomaniNoch keine Bewertungen

- Electric Heat Tracing Rev1.0Dokument12 SeitenElectric Heat Tracing Rev1.0draftingisincNoch keine Bewertungen

- Choose Your Cable TraysDokument28 SeitenChoose Your Cable Trayskamal fularaNoch keine Bewertungen

- High Volteage EngineeringDokument5 SeitenHigh Volteage EngineeringSenthil NathanNoch keine Bewertungen

- Ieee STD c57!19!00 2004 Ieee StandardDokument27 SeitenIeee STD c57!19!00 2004 Ieee StandardEdison Villarruel CuchoNoch keine Bewertungen

- EFR EU27 Steel Scrap SpecificationDokument12 SeitenEFR EU27 Steel Scrap SpecificationAnonymous dIK4xERPNoch keine Bewertungen

- Electrician-Power Distribution CTS NSQF-5 0Dokument74 SeitenElectrician-Power Distribution CTS NSQF-5 0Jayant KoshtiNoch keine Bewertungen

- Heat Shrink Gas Torches For LV Cable JointsDokument6 SeitenHeat Shrink Gas Torches For LV Cable JointsRísês ÃfrözNoch keine Bewertungen

- BR Mersen NH Fuse SystemDokument136 SeitenBR Mersen NH Fuse SystemMasterGNoch keine Bewertungen

- Cable Ho5v KDokument2 SeitenCable Ho5v KAlicia AltamiranoNoch keine Bewertungen

- 'EX 6 Measurement of Insulation ResistanceDokument16 Seiten'EX 6 Measurement of Insulation ResistanceTejas ManeNoch keine Bewertungen

- LV PVC Cable Supreme PDFDokument39 SeitenLV PVC Cable Supreme PDFGus Win Ibnu SufjanNoch keine Bewertungen

- ABB - TechNotes - 2.2 - Overvoltages - Protective Distance 1HC0138872 EN AADokument11 SeitenABB - TechNotes - 2.2 - Overvoltages - Protective Distance 1HC0138872 EN AADeoudrafNoch keine Bewertungen

- Hfe Marantz nr1603 Service enDokument218 SeitenHfe Marantz nr1603 Service enPaulNoch keine Bewertungen

- Cigre 204Dokument17 SeitenCigre 204edwinoria100% (2)

- Jeppiaar SRR Engineering College: SyllabusDokument9 SeitenJeppiaar SRR Engineering College: SyllabusKeerthika VenkatesanNoch keine Bewertungen

- Root-Cause Diagnostics of Generator Service FailuresDokument9 SeitenRoot-Cause Diagnostics of Generator Service Failures賴明宏Noch keine Bewertungen

- Dielectrics: Unit V Dielectric MaterialsDokument20 SeitenDielectrics: Unit V Dielectric MaterialsSpyx MeniNoch keine Bewertungen

- Transformer Design AnalysisDokument6 SeitenTransformer Design AnalysisAkash VermaNoch keine Bewertungen

- Denon AVR-X4000 v.1 PDFDokument224 SeitenDenon AVR-X4000 v.1 PDFboroda2410Noch keine Bewertungen

- High Voltage Cable PDFDokument2 SeitenHigh Voltage Cable PDFDavid CharcapeNoch keine Bewertungen

- Model QuestionDokument2 SeitenModel QuestionkrishnandrkNoch keine Bewertungen

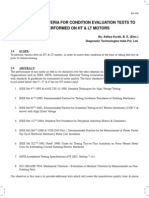

- Acceptance Criteria For Condition Evaluation Tests To Be Performed On HT & LT MotorsDokument13 SeitenAcceptance Criteria For Condition Evaluation Tests To Be Performed On HT & LT MotorsYogananda Madhava SettyNoch keine Bewertungen

- American National Standard Specifications For Distribution Fuse Disconnecting Switches, Fuse Supports, and Current-Limiting FusesDokument14 SeitenAmerican National Standard Specifications For Distribution Fuse Disconnecting Switches, Fuse Supports, and Current-Limiting FusesukritNoch keine Bewertungen

- Presentation On IEC 61439Dokument95 SeitenPresentation On IEC 61439Youwan Lee100% (1)

- Green Recloser: Chardon KoreaDokument6 SeitenGreen Recloser: Chardon KoreatusarNoch keine Bewertungen

- Borealis Ls4201sDokument3 SeitenBorealis Ls4201smanish450inNoch keine Bewertungen

- Astm D3487-2009 PDFDokument6 SeitenAstm D3487-2009 PDFRafael Cruz VazquezNoch keine Bewertungen