Beruflich Dokumente

Kultur Dokumente

Bench Seats and Table

Hochgeladen von

DorranOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Bench Seats and Table

Hochgeladen von

DorranCopyright:

Verfügbare Formate

Wooden Projects

for Outdoor Living

Beautiful

POPULAR WOODWORKING BOOKS

CINCINNATI, OHIO

www.popularwoodworking.com

JOHN MARCKWORTH

70723 front matterP1-P7_CTP.indd1 1 6/18/06 6:46:55 PM

22

70723 ch02 p22-33_CTP.indd 22 6/18/06 7:10:42 PM

23

A favorite landscape design feature of my backyard

is a small, compact deck. Its a great place to hang out with a

beverage, but the low square footage is easily overwhelmed by

a traditional garden table and four chairs. My solution to this

problem was to develop a design for a small table and four bench

seats that could be arranged in different seating configurations

or moved out of the way completely if necessary. They also func-

tion nicely as side tables for lawn chairs and are sturdy enough to

stand on to retrieve the cat from lower tree branches.

I chose to use teak for the tops and wenge for the frames and legs.

The wenge was an experiment. Its a durable tropical hardwood

and, when oiled, provides a striking contrast to the lighter teak.

I made all four benches as a single production run. This not only

made the construction process faster and more efficient but also

ensured that component sizing and dimensions were exactly the

same for all of the benches. Although the measurements are dif-

ferent, I also made the table part of the production run, utilizing

the same machine setups for the different steps.

2

bench seats

and table

70723 ch02 p22-33_CTP.indd 23 6/18/06 7:10:45 PM

24

'

!c'

2

!-'

'

'

!-'

'

!2'

'C

'

!c'

|NL| |L1^||

''

'

!-'

^

^

^

C

C

|

|

L

|

|

'c'

(:c c -|o:-)

!'C'

!-

2'

'-'

'

!-'

'

!c'

'C

'

!2'

-

'

!c'

'

'

!2'

LN /|L. ||| L|.

h

a

rd

w

a

re

a

n

d

s

u

p

p

lie

s

3

/

8" (10mm) 2" (50mm) gluing dowels

1

1

/

4" (30mm) stainless steel flathead screws

70723 ch02 p22-33_CTP.indd 24 6/18/06 7:10:46 PM

25

inches (millimeters)

R

E

F

E

R

E

N

C

E

Q

U

A

N

T

I

T

Y

P

A

R

T

S

T

O

C

K

C

O

M

M

E

N

T

S

A 2 apron sides wenge

3

4 (19) 2

1

2 (64) 20 (508)

B 2 apron ends wenge

3

4 (19) 2

1

2 (64) 14 (356)

C 4 legs wenge 1

3

4 (45) 1

3

4 (45) 16

5

8 (422)

D 2 leg cross braces wenge

3

4 (19) 2

1

2 (64) 10 (254)

E 1 stretcher wenge

3

4 (19) 2 (51) 15 (381)

F 8 top slats teak

3

4 (19) 1

3

8 (35) 18

1

8 (460)

3

16"

+

- (5mm) between slats and

between the slats, apron sides and ends

G 2 top slat cleats wenge

5

8 (16)

3

4 (19) 12

1

2 (318)

H 1 top slat center brace teak 1

1

2 (38)

3

4 (19) 12

1

2 (318)

(mm) (mm) (mm) L

E

N

G

T

H

W

I

D

T

H

T

H

I

C

K

N

E

S

S

C

U

T

T

I

N

G

L

I

S

T

b

e

n

c

h

s

e

a

t

(

t

h

i

s

i

s

f

o

r

o

n

e

s

e

a

t

)

1

Begin the bench by building the apron. Although a number of different joints

could be used at the corners, I chose to use through dovetails. This provides a

solid joint with lots of gluing surface and the interlocking design keeps the joint from

separating or racking. I used a template jig system to machine-cut the dovetails. The

only trick here was to be sure that the width dimension of the apron stock matched the

jigs layout pattern. Measure the jig carefully and adjust the stocks width accordingly.

TECH

tip

Building furniture for outdoor use requires

careful construction planning. Unlike the

loveseat, which relies exclusively on

mechanical fasteners, the bench seats are

assembled using a combination of glued

and mechanical joinery techniques. I was

careful to choose a waterproof glue with

some gap-filling capability and long-term

flexibility and used outdoor-rated or SS

screws. All countersunk screw holes that

might collect water were glued and plugged.

70723 ch02 p22-33_CTP.indd 25 6/18/06 7:10:57 PM

26

TECH

tip

dealing with router blowout

No matter how carefully I make router dove-

tail cuts in hardwoods, there is inevitably a

chance for blowout or chipping when the bit

catches the edge of the wood grain. Im not a

fan of putty or wood dough fillers because the

color is never the same as the wood, even with

stain and it doesnt hold up outdoors. I make

my own filler using glue and sawdust from the

wood Im using. In this case I mixed wenge saw-

dust with a dark-colored waterproof glue.

4

After setting the blade height on the tablesaw, youre ready to make

the first two shoulder cuts on each leg. Use the miter gauge and

the starter block for safety.

2

After applying glue to the

dovetail pins and tails with a

small brush, assemble the apron

using bar clamps. Although the

dovetail joints do a good prelimi-

nary job of squaring the assembly,

carefully equalize opposing cor-

ner-to-corner measurements.

3

Much of the strength of the bench seat re-

sults from way that the legs are attached

to the apron corners. Each leg has a shoulder

cut into the tops of two adjacent sides and a

corner of the apron rests on these shoulders.

This design provides solid support for the

apron-and-top assembly to supplement the

mechanical fasteners. After cutting the legs to

length, mark the faces to be cut with chalk. This

helps keep track of the cutting sequence and

prevents cutting errors.

70723 ch02 p22-33_CTP.indd 26 6/18/06 7:11:01 PM

27

5

Make the crosscuts on the two marked adjacent sides

on each leg. 6

Finish the shoulder cuts on the band saw using a stop clamped to

the table to limit the length of cut.

7

These legs are ready for

assembly.

Miter Gauge Safety

To prevent stock from pinching against the fence

and kicking back when you use the miter gauge,

use a starter block. This is simply a scrap of wood

clamped to the fence behind the leading edge of

the blade. Adjust the fence so that the distance

from the face of the block plus the blade kerf (in

this case) equals the length of cut you need to

make. With the stock held against the miter gauge,

move it over to just touch the side of the block.

Since the front edge of the block is behind the

blade, the stock will be clear of both the fence and

the block when the cut is made.

70723 ch02 p22-33_CTP.indd 27 6/18/06 7:11:05 PM

28

9

Use a doweling jig to drill holes for

3

8" (10mm) dowels in the ends

of the cross braces.

10

Drill holes in the legs to match the holes in the

cross braces.

8

Now youre ready to assemble the two, leg-and-cross-brace assem-

blies using glue and dowels. First, put two legs in place on one end

of the apron assembly. With the two legs firmly clamped in the apron end

corners, take a measurement between the legs and cut the cross braces

to length.

70723 ch02 p22-33_CTP.indd 28 6/18/06 7:11:08 PM

29

11

Using dowels and waterproof glue, assemble and clamp the leg-

and-cross-brace assemblies. 12

Use a spacer cut to the same length as the cross brace so the

legs will mate squarely to the brace.

13

The leg assemblies are now ready to be attached to the apron

corners.

14

Cut spacers to fit snugly between the legs around all four sides

of the inside of the apron. (These will hold the legs tightly

in place against the corners during installation.) Apply glue to the two

shoulder faces on each leg, set them into the corners and lock them

snugly in place with the temporary spacers.

70723 ch02 p22-33_CTP.indd 29 6/18/06 7:11:12 PM

30

18

The top slats are supported by cleats at each end. Glue and

screw the cleats to the insides of the end aprons and plug the

screw holes.

17

Install the stretcher using glue and countersunk screws. Plug

the screw holes.

15

Attach each leg using two screws through the outside corners

of the apron. Plug the screw holes. When the glue has dried,

remove the temporary spacers.

16

After cutting the stretcher to length, position it between

the leg cross braces, centering it on each cross brace

using spacer blocks.

70723 ch02 p22-33_CTP.indd 30 6/18/06 7:11:15 PM

31

19

Use spacers to hold equal spacing between the slats. Trim the

spacers if necessary until the slats fit between the side aprons. 20

So no fasteners will show on the finished bench top, attach

the slats from below. With the slats and spacers set loosely

in place on the cleats, lay a piece of

1

4" (6mm) plywood (slightly larger

than the bench) over the top, then flip the entire assembly upside down

on your work surface. If youre careful, the slats and spacers will all stay

together inside the apron, ready for installation! Predrill into the slats

through the cleats at each end and fasten the slats from below with

screws. Attach a brace across the center of the slats from below with

screws. Although probably not necessary, this brace adds stiffness and

strength to the top slat assembly.

inches (millimeters)

R

E

F

E

R

E

N

C

E

Q

U

A

N

T

I

T

Y

P

A

R

T

S

T

O

C

K

C

O

M

M

E

N

T

S

(mm) (mm) (mm) L

E

N

G

T

H

W

I

D

T

H

T

H

I

C

K

N

E

S

S

C

U

T

T

I

N

G

L

I

S

T

(

b

e

n

c

h

s

e

a

t

s

a

n

d

t

a

b

l

e

)

SMALL TABLE

J 4 apron sides wenge

3

4 (19) 2

1

2 (64) 25 (635)

K 4 legs wenge 1

3

4 (45) 1

3

4 (45) 26

5

8 (676)

L 2 leg cross braces wenge

3

4 (19) 2

1

2 (64) 21 (533)

M 2 stretchers wenge

3

4 (19) 2 (51) 22 (559)

N 1 center top slat teak

3

4 (19) 3

1

2 (89) 23

1

8 (587)

P 8 top slats teak

3

4 (19) 2

1

8 (54) 23

1

8 (587)

3

16"

+

- (5mm) between slats and

between the slats, apron sides and ends

Q 2 top slat cleats wenge

5

8 (16)

3

4 (19) 23

1

2 (597)

R 2 top slat center braces teak 1

1

2 (38)

3

4 (19) 23

1

2 (597)

patio umbrella. The design of the top

slats, slat supports and stretchers have

been modified to accommodate the

umbrella and umbrella base, but those

are the only structural differences.

Build the Matching Table

The table closely follows the design of

the bench seats. The material, joinery

and construction sequences are ex-

actly the same; only sizing and dimen-

sions are different. The table is square

and the top has a center hole for a

70723 ch02 p22-33_CTP.indd 31 6/18/06 7:11:19 PM

'

!c'

2''

2''

2c'

(:c c -|o:-)

2

'

!2'

'

!2'

-'

!-'

2'

'

!2'

'

'

!c' c|occ:cc |c|c

cc uc|cc||o -|o:

1^|L /|L. ||| L|.

'

!-' -oc|cj

|c:.ccc -|o:-

'

'

!-'

'

!2'

2C

'

!c'

2'

'

!-'

|

|

| |

|

|

6

6

|

|

6 |

|

|

N

|

6

|

h

a

rd

w

a

re

a

n

d

s

u

p

p

lie

s

3

/

8" (10mm) 2" (50mm) gluing dowels

1

1

/

4" (30mm) stainless steel flathead screws

70723 ch02 p22-33_CTP.indd 32 6/18/06 7:11:20 PM

33

1

The bench seats have a single stretcher, but the table needs two

with enough space between them for the umbrella shaft and

base. Using spacer blocks to hold the stretchers in position, attach the

the stretcher with screws through the outside of the leg cross braces.

Plug the screw holes.

2

The tabletop slats are proportionally wider than the bench seat

slats. Make the center slat wider to accomodate the umbrella hole.

Install two evenly-spaced teak braces below the slats for extra support.

3

Drill a small pilot hole in the center of the tabletop. Then, using a

sharp Forstner bit and drilling from both sides to avoid split-out,

drill a 1

5

8" (40mm)-diameter hole through the slat.

Apply Exterior Finish

As I said earlier, I like the contrast between the

two woods I used for the benches and table. To

protect against weathering and to keep the colors

looking fresh, I applied a brush-on, wipe-off exte-

rior oil sealer that I plan to reapply yearly.

4

Use a bearing-guided

1

8" (3mm)-radius roundover bit and sandpa-

per to clean and finish the edges of the hole.

70723 ch02 p22-33_CTP.indd 33 6/18/06 7:11:30 PM

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Department of Education Second Periodical TestDokument23 SeitenDepartment of Education Second Periodical TestcalindaganNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- A Project Report On: "Tissue Culture As Best Means of Horticulture"Dokument46 SeitenA Project Report On: "Tissue Culture As Best Means of Horticulture"Alok JainNoch keine Bewertungen

- Varieties of GrapesDokument9 SeitenVarieties of GrapesBilal ArshadNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Indigenous Breeds of CowDokument9 SeitenIndigenous Breeds of CowbruntigNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Muscle and Weight Gain Diet PDFDokument11 SeitenMuscle and Weight Gain Diet PDFCavalera Max100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Some Physical Properties of Gbafilo ( - I - Chrysobalanus Icaco - I - ) Fruits and Kernels Preparatory To Primary ProcessingDokument11 SeitenSome Physical Properties of Gbafilo ( - I - Chrysobalanus Icaco - I - ) Fruits and Kernels Preparatory To Primary ProcessingSNNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Soil Biology The Soil Biology Primer ChaDokument21 SeitenSoil Biology The Soil Biology Primer ChaRojotiana Marco RAKOTOMANANANoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- 11 Biology Revision Study Material Chapter 8Dokument8 Seiten11 Biology Revision Study Material Chapter 8Saurav SoniNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Orchid Review V.1Dokument437 SeitenThe Orchid Review V.1tobiasaxo5653Noch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Ravi CropDokument12 SeitenRavi CropRanjan Rashmi ParhiNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Percent and PercentagesDokument59 SeitenPercent and PercentagesJenn sayongNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- 1943 7714 Article p125Dokument6 Seiten1943 7714 Article p125Murat AquaNoch keine Bewertungen

- Physical Examination of MilkDokument7 SeitenPhysical Examination of Milkusamatayyab100% (2)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Spoken Hindi Language More Easy To LearnDokument41 SeitenSpoken Hindi Language More Easy To LearnAc RaviNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- IMD Hammermills GuideDokument8 SeitenIMD Hammermills GuideInternational Milling DirectoryNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Guide To Growing MangoDokument8 SeitenGuide To Growing MangoRhenn Las100% (2)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- September 2012 K-5 Lunch MenuDokument1 SeiteSeptember 2012 K-5 Lunch MenuMedford Public Schools and City of Medford, MANoch keine Bewertungen

- Toxic Woods PDFDokument6 SeitenToxic Woods PDFLoralie Evangeline Perez-MirandaNoch keine Bewertungen

- Fungi ClassificationDokument8 SeitenFungi ClassificationNAYAN JYOTI KALITA100% (1)

- Photosynthesis TestDokument2 SeitenPhotosynthesis TestKatrīna SimanovskaNoch keine Bewertungen

- Mon Livre D - Exercices 4Dokument214 SeitenMon Livre D - Exercices 4Enseignant Universiataire100% (1)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

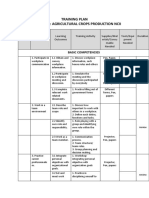

- Training Plan Qualification: Agricultural Crops Production NciiDokument4 SeitenTraining Plan Qualification: Agricultural Crops Production NciiLeonelyn Hermosa Gasco - CosidoNoch keine Bewertungen

- Strand Woven BambooDokument2 SeitenStrand Woven BambooJayan PrajapatiNoch keine Bewertungen

- Legno Home Catalogue WardrobeDokument64 SeitenLegno Home Catalogue WardrobeSheik HassanNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- English Language Arts TestDokument20 SeitenEnglish Language Arts TestYogi SANoch keine Bewertungen

- TÌM LỖI SAI trong đề thi THPT Quốc Gia (Phần 1)Dokument13 SeitenTÌM LỖI SAI trong đề thi THPT Quốc Gia (Phần 1)Bùi Hồng QuảngNoch keine Bewertungen

- Brochure HorticultureDokument46 SeitenBrochure HorticulturezulfiqaralimalikNoch keine Bewertungen

- The Genus Capparis in India - Web - Protected PDFDokument104 SeitenThe Genus Capparis in India - Web - Protected PDFMukesh BoobanaNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Culinary Herbs & Spices 1D100Dokument4 SeitenCulinary Herbs & Spices 1D100Radosław KwiecińskiNoch keine Bewertungen

- Australia Wheat Quality PDFDokument40 SeitenAustralia Wheat Quality PDFAlain DuretNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)