Beruflich Dokumente

Kultur Dokumente

Frame and Bumpers 13 - 1

Hochgeladen von

Sry SantosOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Frame and Bumpers 13 - 1

Hochgeladen von

Sry SantosCopyright:

Verfügbare Formate

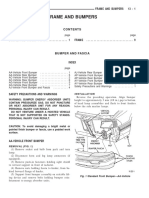

FRAME AND BUMPERS

13 - 1

FRAME AND BUMPERS

CONTENTS

page page

BUMPER AND FASCIA

.................... 1

FRAME

................................ 9

BUMPER AND FASCIA INDEX

page Front BumperAA-Vehicle Rear BumperAA-Vehicle Front BumperAC-Vehicle Rear BumperAC-Vehicle Front BumperAG-Vehicle Rear BumperAG-Vehicle Front BumperAJ-Vehicle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 5 2 6 3 7 4 Rear BumperAJ-Vehicle . . . . . Front BumperAP-Vehicle . . . . Rear BumperAP-Vehicle . . . . Front BumperAY-Vehicle . . . . Rear BumperAY-Vehicle . . . . Safety Precautions and Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page . . . . . . . . . . . . 7 4 8 5 8 1

SAFETY PRECAUTIONS AND WARNINGS

WARNING: BUMPER ENERGY ABSORBER UNITS CONTAIN PRESSURIZE GAS. DO NOT PUNCTURE OR HEAT ABSORBER UNIT FOR ANY REASON. PERSONAL INJURY CAN RESULT. DO NOT VENTURE UNDER A HOISTED VEHICLE THAT IS NOT SUPPORTED ON SAFETY STANDS. PERSONAL INJURY CAN RESULT. CAUTION: To avoid damaging a bright metal or painted finish bumper or fascia, use a padded work surface.

INSTALLATION Reverse the preceding operation. Align bumper height to approximately 3 mm (1/8 in.) gap to bottom of head lamp assemblies and flush to front fenders below the side marker lamps.

FRONT BUMPERAA-VEHICLE

BUMPER AND STANDARD FASCIA REMOVAL (FIG. 1) (1) Remove socket and bulb from park and turn lamp. (2) Disconnect horn and fog lamp connectors (if equipped). (3) Remove push-in fasteners holding sight shield to vertical support in front of radiator. (4) Remove nuts holding fascia to fender, from behind forward flange of fender. (5) Support front bumper assembly on suitable lifting device and remove bolts holding bumper reinforcement to energy absorber units.

Fig. 1 Standard Front BumperAA-Vehicle

13 - 2

FRAME AND BUMPERS

cia. Remove dam retaining channels and reinforcements from fascia (if equipped). (4) Remove park and turn signal lamp assemblies, see Group 8L, Lamps (5) Remove fog lamp bracket from bottom of bumper reinforcement (if equipped). (6) Remove horns from back of bumper reinforcement. (7) Remove lower air intake louver screws and push-in fastener and separate louver from fascia. (8) Remove upper reinforcement to fascia attaching bolts and separate reinforcement from fascia. (9) Straighten toy-tab fasteners holding horizontal moulding to fascia and separate moulding from two sided adhesive tape behind moulding. Remove moulding from fascia. To assemble, reverse the preceding operation.

BUMPER AND WRAP-AROUND FASCIA REMOVAL (FIG. 2) (1) Remove socket and bulb from park and turn lamp. (2) Disconnect horn and fog lamp connectors (if equipped). (3) Remove push-in plastic fasteners at forward edge of front wheel opening. (4) Remove pal-nut fasteners from behind front fenders rearward of the side marker lamp. (5) Remove push-in, fasteners holding sight shield to vertical support in front of radiator. (6) Remove nuts holding fascia to fender, from behind forward flange of fender. (7) Support front bumper on suitable lifting device and remove bolts holding bumper reinforcement to energy absorber units. INSTALLATION Reverse the preceding operation. Align bumper height to approximately 3 mm (1/8 in.) gap to bottom of head lamp assemblies and flush to front fenders below the side marker lamps.

Fig. 3 Front Bumper OverhaulAA-Vehicle

FRONT BUMPERAC VEHICLE

FRONT BUMPER AND STANDARD FASCIA REMOVALAC/D OR AC/C-H-BODY (FIG. 4) (1) Remove nuts holding fascia to fender, from behind forward flange of fender. (2) Support front bumper assembly on suitable lifting device and remove bolts holding bumper reinforcement to energy absorber units. (3) Separate bumper from vehicle.

Fig. 2 Wrap-around Front BumperAA-Vehicle

BUMPER OVERHAUL (FIG. 3) (1) Position bumper assembly on a suitable padded work surface to avoid damage to painted fascia. (2) Remove sight shield push-in, fasteners and separate shield from assembly. (3) Remove air dam screws and push-in fasteners and lift dam out of retaining channels at ends of fasINSTALLATION Reverse the preceding operation. Align bumper height to fit flush to bottom of head lamp assemblies and grille. FRONT BUMPER OVERHAULAC\ OR AC/C-HBODY(FIG. 4) (1) Position bumper assembly on a suitable padded

FRAME AND BUMPERS

13 - 3

BUMPER OVERHAULAC/C-BODY (1) Position bumper assembly on a suitable padded work surface to avoid damage to painted fascia. (2) Remove bolts holding bumper face bar to reinforcement. (3) Remove push-in fasteners holding fascia to reinforcement. (4) Separate reinforcement from fascia. To assemble, reverse the preceding operation.

FRONT BUMPERAG-VEHICLE

FRONT BUMPER FASCIA REMOVAL (FIG. 6) (1) Remove headlamp and fog lamp (if equipped) assemblies, refer to Group 8L, Lamps. (2) Raise vehicle and support on safety stands. (3) Remove radiator closure panel sight shield. (4) Remove push-in fasteners holding fascia to front fender wheel opening flange. (5) Remove nuts holding fascia to fender from above side marker reflectors. Remove fender splash shields if necessary. (6) Remove nuts holding front fascia headlamp mounting panel to forward edge of fenders. (7) Remove bolts holding fascia headlamp mounting panel to radiator closure panel brace. (8) Remove push-in fasteners holding fascia to bottom of bumper reinforcement. (9) Separate front bumper fascia and headlamp mounting panel from vehicle. INSTALLATION Reverse the preceding operation. If headlamps require aiming, refer to Group 8L, Lamps.

Fig. 4 Front BumperAC\ or AC/C-H-Body

work surface to avoid damage to painted fascia. (2) Remove push-in fasteners holding fascia to reinforcement. (3) Remove upper reinforcement to fascia attaching bolts and separate reinforcement from fascia. To assemble, reverse the preceding operation.

FRONT BUMPER AND FASCIA REMOVAL AC/C-BODY (FIG. 5) (1) Raise vehicle and support on safety stands. (2) Remove push-in fasteners holding bumper fascia to front wheel opening lip. (3) Support bumper on a suitable lifting device. (4) Remove nuts holding bumper reinforcement to energy absorbers. (5) Separate bumper from vehicle. INSTALLATION Reverse the preceding operation.

Fig. 6 Front Bumper FasciaAG-Vehicle Fig. 5 Front BumperAC/C-Body

13 - 4

FRAME AND BUMPERS

HEADLAMP MOUNTING PANEL REMOVALAG-VEHICLE (FIG. 7) (1) Remove all lamp assemblies, refer to group 8L, Lamps. (2) Remove front bumper fascia. (3) Remove bolts holding fascia to headlamp mounting panel ends. (4) Remove push-in fasteners holding fascia to headlamp mounting panel. (5) Separate headlamp mounting panel from fascia. INSTALLATION Reverse the preceding operation

Fig. 8 Front Bumper Reinforcement and Energy Absorber UnitAG-Vehicle

FRONT BUMPERAJ-VEHICLE

REMOVAL (FIG. 9) (1) Remove socket and bulb from park and turn lamp. (2) Remove nuts holding fascia to fender, from behind forward flange of fender. (3) Support front bumper assembly on suitable lifting device and remove bolts holding bumper reinforcement to energy absorber units. INSTALLATION Reverse the preceding operation. Align bumper height to approximately 5 mm (0.200 in.) gap to bottom of grille and flush to front fenders on the sides.

Fig. 7 Headlamp Mounting PanelAG-Vehicle

FRONT BUMPER REINFORCEMENT REMOVALAG-VEHICLE (FIG. 8) (1) Remove bumper fascia as necessary to gain clearance to remove bumper reinforcement. (2) Remove nuts holding bumper reinforcement to energy absorber units. (3) Separate bumper reinforcement from vehicle. carriage INSTALLATION Reverse the preceding operation FRONT BUMPER ENERGY ABSORBER REMOVALAG-VEHICLE (FIG. 8) (1) Remove front fascia and bumper reinforcement as necessary to remove absorber unit. (2) Remove bolts holding energy absorber unit to front closure panel. (3) Separate energy absorber from vehicle. INSTALLATION Reverse the preceding operation.

Fig. 9 Front Bumper and FasciaAJ-Vehicle

FRONT BUMPERAP-VEHICLE

REMOVAL (FIG. 10) (1) Raise vehicle and support on safety stands.

FRAME AND BUMPERS

(2) Disconnect front park and turn signal lamp wire connector. (3) Remove front side marker lamp socket from lamp assembly and position socket out of the way. (4) Remove bolt holding front bumper fascia to wheelhouse splash shield. (5) Remove nuts holding fascia to front fender. (6) Support front bumper on lifting device. (7) Remove bolts holding front bumper reinforcement to energy absorber units. (8) Separate front bumper from vehicle.

13 - 5

INSTALLATION Reverse the preceding operation.

Fig. 11 Front Bumper and FasciaAY/P-Body

(4) Remove nuts holding bumper reinforcement to energy absorbers. (5) Separate bumper from vehicle.

INSTALLATION Reverse the preceding operation.

Fig. 10 Front BumperAP-Vehicle

FRONT BUMPERAY-VEHICLE

BUMPER AND FASCIA REMOVALAY/P-BODY (FIG. 11) (1) Remove wheel house splash shields as necessary to gain access to fascia attaching nuts. (2) Remove lower fascia bottom extension cover. (3) Remove nuts holding fascia to fender, from behind forward flange of fender. (4) Support front bumper assembly on suitable lifting device. (5) Remove nuts holding bumper to energy absorber units. (6) Separate bumper from vehicle. INSTALLATION Reverse the preceding operation. Align bumper height to fit flush to bottom of filler panel. FRONT BUMPER AND FASCIA REMOVALAY/ S-BODY (FIG. 12) (1) Raise vehicle and support on safety stands. (2) Remove push-in fasteners holding bumper fascia to front wheel opening lip. (3) Support bumper on a suitable lifting device.

Fig. 12 Front BumperAY/S-Body

BUMPER OVERHAULAY/S-BODY (1) Position bumper assembly on a suitable padded work surface to avoid damage to painted fascia. (2) Remove bolts holding bumper face bar to reinforcement. (3) Remove push-in fasteners holding fascia to reinforcement. (4) Separate reinforcement from fascia. To assemble, reverse the preceding operation.

REAR BUMPERAA-VEHICLE

REAR BUMPER AND STANDARD FASCIA REMOVAL (FIG. 13) (1) Open trunk lid and separate quarter panel liners (if equipped) from tail panel area. (2) Remove rear fascia attaching nuts at rear of inner quarter panel drop-down wells.

13 - 6

FRAME AND BUMPERS

(3) Remove lower fascia push-in fasteners holding fascia to bottom of bumper reinforcement. (4) Remove fascia nuts holding fascia to trunk opening panel. (5) Remove fascia bolts holding fascia to ends of bumper reinforcement. (6) Separate fascia from reinforcement and separate fascia from vehicle. (7) Support bumper reinforcement. Remove reinforcement attaching bolts and separate assembly from energy absorbers.

INSTALLATION Reverse the preceding operation.

Fig. 14 Wrap-around Rear BumperAA-Vehicle

(3) Support bumper assembly on suitable lifting device and remove bolts holding bumper reinforcement to energy absorber units. (4) Separate bumper from vehicle.

INSTALLATION Reverse the preceding operation. Align bumper height to fit flush to bottom of tail lamp.

Fig. 13 Standard Rear BumperAA-Vehicle

REAR BUMPER AND WRAP-AROUND FASCIA REMOVAL (FIG. 14) (1) Remove push-in fasteners holding rear fascia to rearward edge of wheel opening. (2) Open trunk lid and separate quarter panel liner from tail panel area ,if equipped. (3) Remove pal-nut fasteners located behind quarter panel, holding fascia to quarter panel. (4) Perform steps 2 through 7 of Rear Bumper and Standard Fascia Removal/Installation procedure. INSTALLATION Reverse the preceding operation.

Fig. 15 Rear BumperAC/D-Body

REAR BUMPER OVERHAULAC/D-BODY (FIG. 16) (1) Position bumper assembly on a suitable padded work surface to avoid damage to painted fascia. (3) Remove push-in fasteners holding fascia to bottom of reinforcement. (4) Remove bolts holding fascia to reinforcement and separate fascia from reinforcement. (5) Remove bolts holding bumper guards to fascia and separate guards from fascia. To assemble reverse the preceding operation.

REAR BUMPERAC-VEHICLE

REMOVALAC/D-BODY (FIG. 15) (1) Disconnect license plate lamps wire connectors. (2) Remove nuts holding fascia to quarter panel ends.

FRAME AND BUMPERS

13 - 7

(3) Remove nuts holding fascia ends to quarter panel end flanges. (4) Remove pop-rivets holding bumper fascia to wheel lip flanges. (5) Remove nuts holding bumper fascia to quarter panel along belt line. (6) Support rear bumper assembly on lifting device. (7) Remove nuts holding rear bumper reinforcement to energy absorbers. (8) Separate bumper from vehicle.

INSTALLATION Reverse the preceding operation.

Fig. 16 Rear Bumper OverhaulAC/D-Body

REAR BUMPER REMOVALAC/C-BODY (FIG. 17) (1) In luggage compartment, separate liners from quarter panels to gain access to fascia nuts. (2) Remove nuts holding bumper fascia to quarter panels. (3) Remove fasteners holding bumper fascia to wheel opening flange. (4) Disconnect license plate lamp wire connectors. (5) Remove bolts holding bumper to rear closure panel. (6) Remove nuts holding bumper to energy absorber units. (7) Separate bumper from vehicle. INSTALLATION Reverse the preceding operation.

Fig. 18 Rear Bumper Fascia and ReinforcementAG-Vehicle

REAR BUMPERAJ-VEHICLE

REMOVAL (FIG. 19) (1) Remove nuts holding rear fascia to quarter panel ends. (2) Remove push-in fasteners holding fascia to bottom of bumper reinforcement. (3) Remove nuts holding fascia to trunk tail panel. (4) Remove bolts holding fascia to ends of bumper reinforcement. (5) Separate fascia from reinforcement and separate fascia from vehicle. (6) Support bumper reinforcement on a lifting device. Remove bolts holding reinforcement to energy absorbers. Separate reinforcement from energy absorbers. INSTALLATION Reverse the preceding operation.

Fig. 17 Rear BumperAC/C-Body

REAR BUMPERAG-VEHICLE

REMOVAL (FIG. 18) (1) Raise vehicle and support on safety stands. (2) Remove nuts holding rear fascia to luggage compartment tail panel.

13 - 8

FRAME AND BUMPERS

(2) Support bumper assembly on suitable lifting device and remove bolts holding bumper reinforcement to energy absorber units. (3) Separate bumper from vehicle.

INSTALLATION Reverse the preceding operation. Align bumper height to fit flush to bottom of tail lamp. REAR BUMPER OVERHAULAY/P-BODY (1) Position bumper assembly on a suitable padded work surface to avoid damage to painted fascia. (2) Remove bolts holding bumper face bar to reinforcement and separate face bar from assembly. (3) Remove push-in fasteners holding fascia to reinforcement. (4) Remove upper reinforcement to fascia attaching bolts and separate reinforcement from fascia. To assemble, reverse the preceding operation.

Fig. 19 Rear Bumper and FasciaAJ-Vehicle

REAR BUMPERAP-VEHICLE

REMOVAL (FIG. 20) (1) Raise vehicle and support on safety stands. (2) Support rear bumper on lifting device. (3) Remove bolts holding rear bumper reinforcement to energy absorber units. (4) Pull rear bumper assembly rearward to disengage retainers from quarter panel. (5) Separate front bumper from vehicle. INSTALLATION Reverse the preceding operation.

Fig. 21 Rear BumperAY/P-Body

REAR BUMPER REMOVALAY/S-BODY (FIG. 22) (1) In luggage compartment, separate liners from quarter panels to gain access to fascia nuts.

Fig. 20 Rear Bumper

REAR BUMPERAY-VEHICLE

REAR BUMPER REMOVALAY/P-BODY (FIG. 21) (1) Remove nuts holding fascia to quarter panel ends.

Fig. 22 Rear BumperAC/S-Body

FRAME AND BUMPERS

(2) Remove nuts holding bumper fascia to quarter panels. (3) Remove fasteners holding bumper fascia to wheel opening flange. (4) Disconnect license plate lamp wire connectors. (5) Remove bolts holding bumper to rear closure panel.

13 - 9

(6) Remove nuts holding bumper to energy absorber units. (7) Separate bumper from vehicle.

REAR BUMPER INSTALLATION Reverse the preceding operation.

FRAME INDEX

page Crossmember . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 Frame Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . 9 General Information page ........................ 9

GENERAL INFORMATION

In this section, references are made to Vehicle Family (Body) codes. To determine the vehicle family identification code, refer to the Introduction Group at the front of this manual.

FRAME DIMENSIONS

Frame dimensions are listed in metric scale then converted to inch scale listed in parenthesis. Engine compartment charts include front suspension upper strut damper mounting tower location. All dimensions are from center to center of Principal Locating Point (PLP), or from center to center of PLP and fastener location.

VEHICLE PREPARATION Position the vehicle on a level work surface. Using screw or bottle jacks, adjust the vehicle height to the specified PLP dimension above the Datum Line (work surface). Vertical dimensions can be taken from the datum line to the PLP.

ENGINE COMPARTMENT DIMENSIONS Refer to Fig. 1, 2, 3, 4 or 5. FRONT FRAME DIMENSIONS Refer to Fig. 6 REAR FRAME DIMENSIONS Refer to Fig. 7, 8, 9, 10 or 11.

Fig. 1 Engine Compartment DimensionsAA-Body

13 - 10

FRAME AND BUMPERS

Fig. 2 Engine Compartment DimensionsAC-Body

Fig. 4 Engine Compartment DimensionsAJ-Body

Fig. 3 Engine Compartment DimensionsAG-Body

Fig. 5 Engine Compartment DimensionsAP-Body

FRAME AND BUMPERS

13 - 11

Fig. 6 Front Frame DimensionsAll

13 - 12

FRAME AND BUMPERS

Fig. 7 Rear Frame DimensionsAA-Body

FRAME AND BUMPERS

13 - 13

Fig. 8 Rear Frame DimensionsAC, AY-Body

13 - 14

FRAME AND BUMPERS

Fig. 9 Rear Frame DimensionsAG-Body

FRAME AND BUMPERS

13 - 15

Fig. 10 Rear Frame DimensionsAJ-Body

13 - 16

FRAME AND BUMPERS

Fig. 11 Rear Frame DimensionsAP-Body

FRAME AND BUMPERS

13 - 17

Fig. 12 Crossmember

CROSSMEMBER

REMOVAL (FIG. 12) (1) Hoist vehicle and support on safety stands. Refer to Group 0, Lubrication and Maintenance for proper procedures. (2) Remove front wheels. (3) Disconnect lower ball joints from the knuckle assembly. Refer to Group 2, Suspension for proper procedures. (4) Disconnect power steering hose tie-down from rear upper edge of crossmember, if equipped. (5) Remove bolts holding steering gear to crossmember. Refer to Group 19, Steering for proper procedures.

(6) Remove bolt holding engine damper strut to crossmember, if equipped with manual transaxle. (7) Support crossmember on a suitable lifting device. (8) Remove nuts holding rear of crossmember to the frame. (9) Remove bolts holding crossmember to frame from above lower control arms. (10) Separate the crossmember from the vehicle. (11) Transfer lower control arms and sway eliminator shaft to new crossmember, if crossmember is being replaced. Refer to Group 2, Suspension for proper procedure.

CROSSMEMBER INSTALLATION Reverse the preceding operation. delete this line

Das könnte Ihnen auch gefallen

- 93FWD 13Dokument18 Seiten93FWD 13Christian MartinezNoch keine Bewertungen

- Frame and BumpersDokument16 SeitenFrame and BumpersMike KrothNoch keine Bewertungen

- Frame and BumpersDokument12 SeitenFrame and BumpersAshif IqubalNoch keine Bewertungen

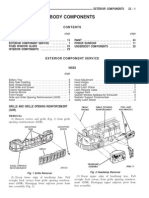

- Body ComponentDokument44 SeitenBody ComponentZamrizal ZakariaNoch keine Bewertungen

- 32sPACE WAGONDokument8 Seiten32sPACE WAGONrafaelcruzgjaNoch keine Bewertungen

- Body Panels SystemDokument62 SeitenBody Panels Systemmika DataNoch keine Bewertungen

- Exterior: Click On The Applicable Bookmark To Selected The Required Model YearDokument33 SeitenExterior: Click On The Applicable Bookmark To Selected The Required Model Yearruanm_1Noch keine Bewertungen

- Removing and Installing Moulded Headliner: Special Tools and Workshop Equipment RequiredDokument13 SeitenRemoving and Installing Moulded Headliner: Special Tools and Workshop Equipment RequiredNurm LevunoNoch keine Bewertungen

- BMW E39 TIS Blower Motor ReplacementDokument24 SeitenBMW E39 TIS Blower Motor Replacementmnbvqwert100% (2)

- Rear Suspension Jl14843Dokument10 SeitenRear Suspension Jl14843Omar MarianiNoch keine Bewertungen

- Desarmado & Armado Eje Trasero 426BDokument14 SeitenDesarmado & Armado Eje Trasero 426BAbelardo Pina100% (1)

- Aa c6 InstructionsDokument45 SeitenAa c6 InstructionsezzezzezzeNoch keine Bewertungen

- Windshield Washer Nozzle Adjustment: Ac5uuw00006811Dokument26 SeitenWindshield Washer Nozzle Adjustment: Ac5uuw00006811chí công lêNoch keine Bewertungen

- Workshop Manual R51 3 and R67 Including ToolsDokument208 SeitenWorkshop Manual R51 3 and R67 Including ToolsOswaldo Gabriel Aponte PelayoNoch keine Bewertungen

- 61SNC01 - 05 - Engine Mechanical - AssemblyDokument23 Seiten61SNC01 - 05 - Engine Mechanical - AssemblyangelvalladaresNoch keine Bewertungen

- Toothed Belt, Remove and Install - 17959 Astra Motor Ecotec Z18XEDokument7 SeitenToothed Belt, Remove and Install - 17959 Astra Motor Ecotec Z18XESaulo CastroNoch keine Bewertungen

- 2007 ACCORD HYBRID - Headliner Removal/Installation: Special Tools RequiredDokument6 Seiten2007 ACCORD HYBRID - Headliner Removal/Installation: Special Tools RequiredriztechNoch keine Bewertungen

- Doors and LiftgateDokument25 SeitenDoors and Liftgateiobeam1Noch keine Bewertungen

- PDI SVS Can AmDokument13 SeitenPDI SVS Can Ambapal1986Noch keine Bewertungen

- Transmission Removal and Installation at PDFDokument4 SeitenTransmission Removal and Installation at PDFOskars ŠtālsNoch keine Bewertungen

- Service Brakes - RemoveDokument5 SeitenService Brakes - RemovealonsoNoch keine Bewertungen

- Rocker Panel Cover, Removing and Installing (S4) : 1 - Hex NutDokument6 SeitenRocker Panel Cover, Removing and Installing (S4) : 1 - Hex Nutmefisto06cNoch keine Bewertungen

- Interior Trim Location Index: Ac5uuw00007540Dokument260 SeitenInterior Trim Location Index: Ac5uuw00007540chí công lêNoch keine Bewertungen

- Honda CR V 2007 2009 Engine Mechanical Service Repair ManualDokument10 SeitenHonda CR V 2007 2009 Engine Mechanical Service Repair Manuallisa100% (39)

- Remove & Install Travel Motor & Final DrivesDokument49 SeitenRemove & Install Travel Motor & Final DrivesAngelica VergaraNoch keine Bewertungen

- 950f 2 3 - Sisweb - Sisweb - Techdoc - Techdoc - Print - Page - JSPDokument18 Seiten950f 2 3 - Sisweb - Sisweb - Techdoc - Techdoc - Print - Page - JSPMehdi ChakrouneNoch keine Bewertungen

- Engine AssemblyDokument26 SeitenEngine Assemblysled novaNoch keine Bewertungen

- Engine Assembly Engine Assembly Removal and Installation: (QR25DE)Dokument33 SeitenEngine Assembly Engine Assembly Removal and Installation: (QR25DE)Ioana BocaniciuNoch keine Bewertungen

- Master Mf6400 WSM 02 enDokument214 SeitenMaster Mf6400 WSM 02 enSelmirije2Noch keine Bewertungen

- 5L ENGINE REMOVALlDokument11 Seiten5L ENGINE REMOVALlTobi AlakeNoch keine Bewertungen

- Power System Location Index: Ac5uuw00007216Dokument51 SeitenPower System Location Index: Ac5uuw00007216chí công lêNoch keine Bewertungen

- Chapt 02Dokument144 SeitenChapt 02Tony LoweNoch keine Bewertungen

- P250-250S Cap 05 (ENGINE REMOVALINSTALLATION)Dokument7 SeitenP250-250S Cap 05 (ENGINE REMOVALINSTALLATION)Minh ChuNoch keine Bewertungen

- Mercedes - 220 - Workshop Manual - 1994 - 1995 - 2Dokument13.111 SeitenMercedes - 220 - Workshop Manual - 1994 - 1995 - 2Juan Harmond Bambang WirawanNoch keine Bewertungen

- 72-24 Recaro Seats PDFDokument35 Seiten72-24 Recaro Seats PDFmefisto06cNoch keine Bewertungen

- Reparacion Cortina SunroofDokument20 SeitenReparacion Cortina SunroofLuis De la hozNoch keine Bewertungen

- Piaggio MP3 400 I.E Service Station Manual-17Dokument20 SeitenPiaggio MP3 400 I.E Service Station Manual-17H. KeithNoch keine Bewertungen

- RF PDFDokument10 SeitenRF PDFJessica EdwardsonsNoch keine Bewertungen

- Super X Transmission RemovalDokument29 SeitenSuper X Transmission RemovallNoch keine Bewertungen

- Section 10 - Power Take-OffDokument19 SeitenSection 10 - Power Take-OffMiller Andres ArocaNoch keine Bewertungen

- WRX STI 2004 SR SunroofDokument10 SeitenWRX STI 2004 SR Sunroofinterlo100% (1)

- BMW F 800 R K73 Bajar-Subir MotorDokument7 SeitenBMW F 800 R K73 Bajar-Subir MotorGustavo FajardoNoch keine Bewertungen

- Lamps: Lamp DiagnosisDokument10 SeitenLamps: Lamp DiagnosisDalton WiseNoch keine Bewertungen

- Electrico UrvanDokument32 SeitenElectrico UrvanEdgar SolisNoch keine Bewertungen

- 2014 Mazda 6 Fog Lamp InstallDokument17 Seiten2014 Mazda 6 Fog Lamp Installksuth100% (1)

- BMW F 800 R K73 Desmontaje-Montaje CulataDokument18 SeitenBMW F 800 R K73 Desmontaje-Montaje CulataGustavo FajardoNoch keine Bewertungen

- Exterior Trim Location Index: Ac5uuw00006865Dokument50 SeitenExterior Trim Location Index: Ac5uuw00006865chí công lêNoch keine Bewertungen

- Ear Axle 35Dokument108 SeitenEar Axle 35donnieee77Noch keine Bewertungen

- Hyundai HD78 Suspension SystemDokument26 SeitenHyundai HD78 Suspension SystemBigfair HD78Noch keine Bewertungen

- Ws 3503000 WMDokument43 SeitenWs 3503000 WMPABLO ANDRES RODRIGUEZ FARIASNoch keine Bewertungen

- Removal: 2Az-Fe Engine Mechanical - Engine AssemblyDokument8 SeitenRemoval: 2Az-Fe Engine Mechanical - Engine AssemblyViệt Anh PhạmNoch keine Bewertungen

- Daewoo Matiz 2000-2013 Bumpers and FacialsDokument8 SeitenDaewoo Matiz 2000-2013 Bumpers and FacialssheoNoch keine Bewertungen

- 04 1955 CAD-Chassis Sheet MetalDokument4 Seiten04 1955 CAD-Chassis Sheet MetalLuis Fernando ZampieriNoch keine Bewertungen

- 2009 FIT - Ignition Coil and Spark Plug Removal/InstallationDokument8 Seiten2009 FIT - Ignition Coil and Spark Plug Removal/Installationbcr888Noch keine Bewertungen

- Wheel Bearing Removal & InstallationDokument3 SeitenWheel Bearing Removal & Installationkaushik_rajan_2Noch keine Bewertungen

- Drive Axle FrontDokument23 SeitenDrive Axle Frontcarloslopez85Noch keine Bewertungen

- Phaeton. Pillar TrimDokument13 SeitenPhaeton. Pillar TrimKarl Hubel100% (1)

- Blower - Blower UnitDokument13 SeitenBlower - Blower UnitTrường ThiNoch keine Bewertungen

- Rear Axle 966cDokument10 SeitenRear Axle 966cHector VallesNoch keine Bewertungen

- Chevy Differentials: How to Rebuild the 10- and 12-BoltVon EverandChevy Differentials: How to Rebuild the 10- and 12-BoltBewertung: 5 von 5 Sternen5/5 (8)

- Linear MK II 6kVA Service ManualDokument31 SeitenLinear MK II 6kVA Service ManualSry SantosNoch keine Bewertungen

- 2ul02r02 PDFDokument57 Seiten2ul02r02 PDFSry SantosNoch keine Bewertungen

- Aeroflex Communication Test EquipmentDokument265 SeitenAeroflex Communication Test EquipmentSry SantosNoch keine Bewertungen

- Kung Fu Tai Chi - 2018Dokument100 SeitenKung Fu Tai Chi - 2018Sry Santos100% (2)

- Radar SpectrumDokument18 SeitenRadar SpectrumSry SantosNoch keine Bewertungen

- Ctu+rwy ManualDokument68 SeitenCtu+rwy ManualSry SantosNoch keine Bewertungen

- How Battery WorksDokument6 SeitenHow Battery WorksSry SantosNoch keine Bewertungen

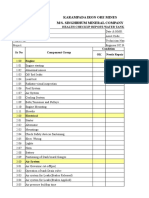

- Salary SurveyDokument15 SeitenSalary SurveySry SantosNoch keine Bewertungen

- Remote Control & Status Equipment Rcse443Dokument129 SeitenRemote Control & Status Equipment Rcse443Sry Santos100% (2)

- Brazilian Room 2018-2019 Rental Fees: Tilden Regional Park Wildcat Canyon at Shasta Road, Berkeley, CA 94708Dokument2 SeitenBrazilian Room 2018-2019 Rental Fees: Tilden Regional Park Wildcat Canyon at Shasta Road, Berkeley, CA 94708Sry SantosNoch keine Bewertungen

- 2N Easy Gate PRO User Guide en 1.4Dokument78 Seiten2N Easy Gate PRO User Guide en 1.4Sry SantosNoch keine Bewertungen

- Constitution and by LawsDokument28 SeitenConstitution and by LawsSry SantosNoch keine Bewertungen

- LetterAuthorizationConfirmation PDFDokument1 SeiteLetterAuthorizationConfirmation PDFSry Santos100% (1)

- LetterAuthorizationConfirmation PDFDokument1 SeiteLetterAuthorizationConfirmation PDFSry Santos100% (1)

- Current Electricity and MagnetismDokument5 SeitenCurrent Electricity and MagnetismSry SantosNoch keine Bewertungen

- Providers ManualDokument30 SeitenProviders ManualSry SantosNoch keine Bewertungen

- No Insurance? High Deductible? No Problem!: Comprehensive Care For $35 Per VisitDokument2 SeitenNo Insurance? High Deductible? No Problem!: Comprehensive Care For $35 Per VisitSry SantosNoch keine Bewertungen

- 2N Easy Gate PRO User Guide en 1.4Dokument78 Seiten2N Easy Gate PRO User Guide en 1.4Sry SantosNoch keine Bewertungen

- Cables & WiresDokument2 SeitenCables & WiresSry SantosNoch keine Bewertungen

- Letter Authorization ConfirmationDokument1 SeiteLetter Authorization ConfirmationSry SantosNoch keine Bewertungen

- Alternating Current MeasurementsDokument1 SeiteAlternating Current MeasurementsSry SantosNoch keine Bewertungen

- Electricity: Electricity Is A General Term Applied To Phenomena Involving A Fundamental Property ofDokument12 SeitenElectricity: Electricity Is A General Term Applied To Phenomena Involving A Fundamental Property ofSry SantosNoch keine Bewertungen

- 3 Way Switch Diagram 4Dokument1 Seite3 Way Switch Diagram 4Sry SantosNoch keine Bewertungen

- Alternator: From Wikipedia, The Free EncyclopediaDokument3 SeitenAlternator: From Wikipedia, The Free EncyclopediaSry SantosNoch keine Bewertungen

- Circuit Breaker: o o o o oDokument11 SeitenCircuit Breaker: o o o o oSry Santos100% (1)

- JP Selecta IncubatorDokument5 SeitenJP Selecta IncubatorAhmed AlkabodyNoch keine Bewertungen

- Rubric For Aet570 BenchmarkDokument4 SeitenRubric For Aet570 Benchmarkapi-255765082Noch keine Bewertungen

- Ubi Caritas Guitar Solo Arrangement by Patrick Glenn BalanzaDokument8 SeitenUbi Caritas Guitar Solo Arrangement by Patrick Glenn BalanzaPatrick Glenn BalanzaNoch keine Bewertungen

- Oracle SOA Suite 11g:buildDokument372 SeitenOracle SOA Suite 11g:buildMohsen Tavakkoli100% (1)

- Dissertation 7 HeraldDokument3 SeitenDissertation 7 HeraldNaison Shingirai PfavayiNoch keine Bewertungen

- Packet Unit 3 - Atomic Structure-Answers ChemistryDokument11 SeitenPacket Unit 3 - Atomic Structure-Answers ChemistryMario J. KafatiNoch keine Bewertungen

- Liquid Chlorine SdsDokument7 SeitenLiquid Chlorine SdsIPKL RS BHAYANGKARA KEDIRINoch keine Bewertungen

- Particle BoardDokument1 SeiteParticle BoardNamrata RamahNoch keine Bewertungen

- BRAND AWARENESS Proposal DocumentDokument11 SeitenBRAND AWARENESS Proposal DocumentBuchi MadukaNoch keine Bewertungen

- Restaurant Report Card: February 9, 2023Dokument4 SeitenRestaurant Report Card: February 9, 2023KBTXNoch keine Bewertungen

- NHM Thane Recruitment 2022 For 280 PostsDokument9 SeitenNHM Thane Recruitment 2022 For 280 PostsDr.kailas Gaikwad , MO UPHC Turbhe NMMCNoch keine Bewertungen

- WinCC Control CenterDokument300 SeitenWinCC Control Centerwww.otomasyonegitimi.comNoch keine Bewertungen

- LavazzaDokument2 SeitenLavazzajendakimNoch keine Bewertungen

- AstmDokument5 SeitenAstmyanurarzaqaNoch keine Bewertungen

- Fire Technical Examples DIFT No 30Dokument27 SeitenFire Technical Examples DIFT No 30Daniela HanekováNoch keine Bewertungen

- N2 V Operare ManualDokument370 SeitenN2 V Operare Manualramiro0001Noch keine Bewertungen

- Water Tanker Check ListDokument8 SeitenWater Tanker Check ListHariyanto oknesNoch keine Bewertungen

- Nuclear Power Engineering (MEE 2027) : Fall Semester (2020-2021)Dokument13 SeitenNuclear Power Engineering (MEE 2027) : Fall Semester (2020-2021)AllNoch keine Bewertungen

- Asan Visa Ae102901499Dokument2 SeitenAsan Visa Ae102901499hardeep ranaNoch keine Bewertungen

- Linear Dynamic Analysis of Free-Piston Stirling Engines OnDokument21 SeitenLinear Dynamic Analysis of Free-Piston Stirling Engines OnCh Sameer AhmedNoch keine Bewertungen

- Planning EngineerDokument1 SeitePlanning EngineerChijioke ObiNoch keine Bewertungen

- A Junk Project - An Income Generating ProjectDokument2 SeitenA Junk Project - An Income Generating ProjectHercules Verdeflor ValenzuelaNoch keine Bewertungen

- Ginger Final Report FIGTF 02Dokument80 SeitenGinger Final Report FIGTF 02Nihmathullah Kalanther Lebbe100% (2)

- Contoh Assignment PDFDokument18 SeitenContoh Assignment PDFSiti Fatimah A Salam67% (3)

- Amp DC, OaDokument4 SeitenAmp DC, OaFantastic KiaNoch keine Bewertungen

- Antibiotics MCQsDokument4 SeitenAntibiotics MCQsPh Israa KadhimNoch keine Bewertungen

- Hetal Patel: Team Leader - SalesDokument2 SeitenHetal Patel: Team Leader - SalesPrashant kumarNoch keine Bewertungen

- 100 20210811 ICOPH 2021 Abstract BookDokument186 Seiten100 20210811 ICOPH 2021 Abstract Bookwafiq alibabaNoch keine Bewertungen

- CSEC SocStud CoverSheetForESBA Fillable Dec2019Dokument1 SeiteCSEC SocStud CoverSheetForESBA Fillable Dec2019chrissaineNoch keine Bewertungen

- Bài Tập Từ Loại Ta10Dokument52 SeitenBài Tập Từ Loại Ta10Trinh TrầnNoch keine Bewertungen