Beruflich Dokumente

Kultur Dokumente

A21. Recomnad Japonia-Generalitati

Hochgeladen von

Cornel TatuOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

A21. Recomnad Japonia-Generalitati

Hochgeladen von

Cornel TatuCopyright:

Verfügbare Formate

1

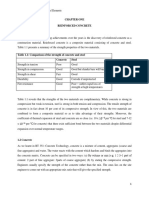

Chapter 1

1.1 Scope of Application

General

(1) The Draft recommendations in this document (hereafter called the recommendations) provide the basic principles of design and construction of a structure using the ultra high strength fiber reinforced concrete (hereafter called UFC) in order that the guidelines will meet the performance requirements for safety, serviceability, durability, and fatigue resistance. (2) The UFC is a type of cementitious composites reinforced by fiber with characteristic values in excess of 150 N/mm2 in compressive strength, 5 N/mm2 in tensile strength, and 4 N/mm2 in first cracking strength. The matrix of the UFC is as follows: it should be composed of aggregates, whose maximum particle sizes are less than 2.5 mm, cement, and pozzolans and the water-cement ratio is less than 0.24. It contains reinforcing fibers of more than 2% by volume, whose tensile strength exceeds 2103 N/ mm2 , ranging 10 to 20 mm in length and 0.1 to 0.25 mm in diameter. If materials outside the conditions above are used, it should be verified that the physical properties of the materials are either equivalent or exceed the values stated in this guide in respect to strength, durability, and efficiency in construction as required for the UFC. (3) The UFC requires heat curing as the standard method of curing.

[Comments] (1) The recommendations provide general requirements for the design and construction of structures made with UFC with high-performance in strength, toughness, and durability. (2) The hardened state of the UFC is evaluated by characteristic values described in Section 3.2. A concrete with less than 150 N/mm2 in the compressive strength and 5 N/mm2 in the tensile strength is outside the scope of the recommendations, as it requires reinforcing steel and makes the construction non-economical. The recommendations are applied to the matrix (except the portion of fiber reinforcement) consisting of aggregates, cement, and pozzolans. Special care is necessary to arrange particle size distribution of the materials in order to achieve a high dense as filler and provide the excellent self-compacting ability at the time of casting and molding. The particle size of the pozzolans shall be less than 1m. Silica fumes and other pozzolanic materials

may be used. A higher density can be achieved by adding quartz particles, whose size is intermediate between cement and pozzolans, to the matrix. The silica flour, a type of quartz particles ranging from 2m to 20m, may be used for the purpose of increasing the dense. Adequate tensile strength may not be achieved if the size of the aggregates exceeds 2.5 mm, as it makes it difficult to attain the desired compression strength, and fibers are not uniformly dispersed within the concrete. In addition, if the W/C ratio exceeds 0.24, the desired compression strength and tensile strength will not be achieved. It may also lower the durability. The standard application of the fiber reinforcement is the use of fibers 10 to 20 mm in length and 0.1 to 0.25 mm in diameter, with a tensile strength of 2103 N/ mm2 or more and 2% volume fraction. Other than these conditions, the target effect of reinforcement may not be achieved since the fibers will not be homogeneously dispersed in the concrete. The recommendations stipulate that, in case of the use of materials outside the conditions above, it should be verified that the physical properties of the materials are either equivalent or exceed the values stated in this document in respect to strength, durability, and efficiency in construction as required for UFC. (3) Heat curing is applied to achieve a high-density in the hardened concrete. There are steam curing and other methods for this purpose. The effects of heat curing on UFC are as follows. It accelerates the development of strength. It decreases the effect of shrinkage and creep after completion of the curing. It increases durability by achieving higher dense of the concrete.

Considering the above, it was determined that the use of heat curing is the standard curing operation for UFC. The details of the heat cure are described in Section 12.8. Anything not documented in the recommendations shall be addressed in accordance with the Standard Specifications for Concrete Structures prepared by the Japan Society of Civil Engineers in 2002 (hereafter called Standard Specifications" ) and related documents.

1.2 Definition of Terms The terminologies in the recommendations are as follows. UFC: The concrete that satisfies the conditions described in 1.1 (2). Reinforcing fiber: The fiber that satisfies the conditions described in 1.1 (2), which is added to the concrete matrix for reinforcement. First Cracking Strength: A stress level with which the first crack occurs on UFC when subjected to tensile stress. It is a stress where the assumption of linear elasticity is no longer applicable in the stress-strain curve, a point at which the shape of the curve becomes nonlinear. Tensile Strength: The maximum tensile strength of UFC. Premix Method: A method to produce UFC using the matrix grain blended in advance by a special mixer, using the materials individually examined and procured. Non-premix Method: A method to produce UFC using the materials individually examined, procured, stored, and then measured immediately before mixing. Standard Mixed Ingredients: The matrix grain confirmed of its conformity to the recommendations with respect to strength, durability and efficiency of construction required for the UFC. The premix method shall be employed for production Heat Curing: A curing method applied after hardening of the UFC, for the purpose of improving strength and durability.

1.3 Notations The symbols used in the recommendations are as follows. fcr: The first cracking strength of UFC. ft: The tensile strength of UFC. fv: The averaged tensile strength perpendicular to the diagonal crack of UFC. Leq: Equivalent specific length. Vf: The shear strength provided by reinforcing fibers. Vrpc: The shear strength of a beam or a column that has no shear reinforcement, excluding the strength that is provided by fiber reinforcement. w1k: In the tension softening curve, a range of CMOD (crack mouth opening displacement) for which the concrete can still maintain a certain level of tensile stress after the first crack has occurred. w2k: In the tension softening curve, the point of CMOD where tensile stress becomes zero.

u: An angle of a diagonal crack.

All other symbols shall comply with the notations of the Standard Specifications.

Das könnte Ihnen auch gefallen

- 1Ch1-Properties of Conc1Dokument9 Seiten1Ch1-Properties of Conc1yimamNoch keine Bewertungen

- Kurz 2012 Paper EnglishDokument14 SeitenKurz 2012 Paper EnglishPrayush RajbhandariNoch keine Bewertungen

- 04-Recommendation For Design and Construction-ConstructionDokument22 Seiten04-Recommendation For Design and Construction-Construction孙飞Noch keine Bewertungen

- Rahul SirDokument8 SeitenRahul SirSandeep_AjmireNoch keine Bewertungen

- Control Joints For Concrete Masonry Walls - Alternative Engineered MethodDokument8 SeitenControl Joints For Concrete Masonry Walls - Alternative Engineered Methodmiguel fuentesNoch keine Bewertungen

- Design of Structures.hDokument95 SeitenDesign of Structures.hAsiimwe Moses KasirikaNoch keine Bewertungen

- Dramix ShotcreteDokument13 SeitenDramix ShotcreteMiguel Eulufi VillenaNoch keine Bewertungen

- Learning Material RCDDokument18 SeitenLearning Material RCDChristian John BiolNoch keine Bewertungen

- Chapter 1 - Introduction: 1.1 Brief HistoryDokument17 SeitenChapter 1 - Introduction: 1.1 Brief HistoryRicky RickxNoch keine Bewertungen

- CE2404 QB PDFDokument20 SeitenCE2404 QB PDFresha bhatiaNoch keine Bewertungen

- Important Questions PDFDokument20 SeitenImportant Questions PDFresha bhatiaNoch keine Bewertungen

- Reinforced Concrete Design by Professor Anthony Kwame DansoDokument131 SeitenReinforced Concrete Design by Professor Anthony Kwame DansoBadu Evans NyiayeNoch keine Bewertungen

- CRSI Manual To Design RC Diaphragms - Part3Dokument4 SeitenCRSI Manual To Design RC Diaphragms - Part3Adam Michael GreenNoch keine Bewertungen

- DPSC Mod 1 IntroductionDokument12 SeitenDPSC Mod 1 IntroductionKajalNoch keine Bewertungen

- Adcs 1Dokument38 SeitenAdcs 1Phanendra Kumar AttadaNoch keine Bewertungen

- Losses in Prestress ConcreteDokument41 SeitenLosses in Prestress ConcreteourebooksNoch keine Bewertungen

- Fiber-Reinforced - Concrete Power Point PresentationDokument27 SeitenFiber-Reinforced - Concrete Power Point Presentationusama anterNoch keine Bewertungen

- FerrocementDokument4 SeitenFerrocementAhmed MohammedNoch keine Bewertungen

- Lecture 10Dokument28 SeitenLecture 10atholNoch keine Bewertungen

- Effects - of - trapezoidal - cross-section - dimensions - on مفيد PDFDokument15 SeitenEffects - of - trapezoidal - cross-section - dimensions - on مفيد PDFMajid AlzubadyNoch keine Bewertungen

- Steel Structures 3 - Composite Structures - Lecture Notes Chapter 10.7Dokument29 SeitenSteel Structures 3 - Composite Structures - Lecture Notes Chapter 10.7iSoK11Noch keine Bewertungen

- Concrete Mix DesignDokument6 SeitenConcrete Mix DesignSriram DiwanaNoch keine Bewertungen

- Ridged PavementDokument4 SeitenRidged Pavementgetanna07Noch keine Bewertungen

- Novel Cement-Based Composites For Strengthening and Repair of PDFDokument8 SeitenNovel Cement-Based Composites For Strengthening and Repair of PDFrjdgNoch keine Bewertungen

- Chapter 3 Design Values of MaterialsDokument23 SeitenChapter 3 Design Values of MaterialsMashfiqul IslamNoch keine Bewertungen

- Composite Structures Full Notes Part 7 PDFDokument25 SeitenComposite Structures Full Notes Part 7 PDFsvnNoch keine Bewertungen

- PSC Mod1eDokument43 SeitenPSC Mod1eNani RujaNoch keine Bewertungen

- AMK30103 L1-3 MaterialsDokument8 SeitenAMK30103 L1-3 Materialsadeliene 25Noch keine Bewertungen

- Fibre Reinforced ConcreteDokument21 SeitenFibre Reinforced ConcreteAnand PradhanNoch keine Bewertungen

- FRCFRCDokument11 SeitenFRCFRCdhananjay kumarNoch keine Bewertungen

- UntitledDokument65 SeitenUntitledA 1002 Alfrid AdnanNoch keine Bewertungen

- Effect of Embedded Length On Bond Behaviour of SteelDokument7 SeitenEffect of Embedded Length On Bond Behaviour of SteelAvish GunnuckNoch keine Bewertungen

- Experimental Tests On Tunnel Precast Segmental Lining With Fiber Reinforced ConcreteDokument8 SeitenExperimental Tests On Tunnel Precast Segmental Lining With Fiber Reinforced ConcretemetropodikasNoch keine Bewertungen

- Ferrocement-BNBC Presentation-Final - Copy (30147073)Dokument37 SeitenFerrocement-BNBC Presentation-Final - Copy (30147073)Asif RaihanNoch keine Bewertungen

- Prestress Concrete (17-23)Dokument40 SeitenPrestress Concrete (17-23)anon_57992799Noch keine Bewertungen

- Final PDF frc1-2Dokument23 SeitenFinal PDF frc1-2Sherif FodaNoch keine Bewertungen

- Tek 10-03 PDFDokument8 SeitenTek 10-03 PDFJUAN JOSE LariosNoch keine Bewertungen

- Durability Stability and Serviceability (Part 1)Dokument57 SeitenDurability Stability and Serviceability (Part 1)Johnson116Noch keine Bewertungen

- Studying Flexural Behavior of Reinforced Fibrous Self-Compacted Concrete T - Beams Strengthened With CFRP SheetsDokument11 SeitenStudying Flexural Behavior of Reinforced Fibrous Self-Compacted Concrete T - Beams Strengthened With CFRP SheetsAarohiShirkeNoch keine Bewertungen

- Irjet V2i985Dokument8 SeitenIrjet V2i985sheikNoch keine Bewertungen

- Special Concretes: Assignment ON February-2002 Question PaperDokument19 SeitenSpecial Concretes: Assignment ON February-2002 Question PapersyedNoch keine Bewertungen

- Section 1.5Dokument10 SeitenSection 1.5Jayson J. PagalNoch keine Bewertungen

- Activity 1 in Pre-StressedDokument3 SeitenActivity 1 in Pre-StressedFrancis Prince ArtiagaNoch keine Bewertungen

- YokotaDokument14 SeitenYokotaUDDOM CHHENGNoch keine Bewertungen

- Sefi e Conference 2012-1-255Dokument11 SeitenSefi e Conference 2012-1-255vsnagarjunreddyNoch keine Bewertungen

- Advantages of PrestressedDokument3 SeitenAdvantages of PrestressedLarete PaoloNoch keine Bewertungen

- SFS in TunnellingDokument5 SeitenSFS in TunnellingwjzabalaNoch keine Bewertungen

- CHAPTER 1: Introduction: 1.1 General ReviewDokument9 SeitenCHAPTER 1: Introduction: 1.1 General ReviewKubaNoch keine Bewertungen

- Basis of Design & Analysis - 04Dokument102 SeitenBasis of Design & Analysis - 04Ashraf Ali Hafeel AhamedNoch keine Bewertungen

- A Case Study On Pre-Tensioning & Post Tensioning Systems of A Prestressed ConcreteDokument6 SeitenA Case Study On Pre-Tensioning & Post Tensioning Systems of A Prestressed ConcreteSHEKHARNoch keine Bewertungen

- 002 RCM Chapter 2 - LoadingDokument19 Seiten002 RCM Chapter 2 - LoadingMossSkosanaNoch keine Bewertungen

- Prestressed Concrete: 1) Pre-Tensioned Beam ConstructionDokument6 SeitenPrestressed Concrete: 1) Pre-Tensioned Beam ConstructionSoham BanerjeeNoch keine Bewertungen

- En-1680769140-Concrete Blocks - BCDC 2 (283) DTZSDokument15 SeitenEn-1680769140-Concrete Blocks - BCDC 2 (283) DTZSEmil ElkinNoch keine Bewertungen

- Fibre Reinforced Concrete - PPTXDokument32 SeitenFibre Reinforced Concrete - PPTXEr Anindya GhoshNoch keine Bewertungen

- Reinforced Concrete Buildings: Behavior and DesignVon EverandReinforced Concrete Buildings: Behavior and DesignBewertung: 5 von 5 Sternen5/5 (1)

- Lecture Notes on Reinforced Concrete DesignVon EverandLecture Notes on Reinforced Concrete DesignNoch keine Bewertungen

- Structural Concrete: Materials; Mix Design; Plain, Reinforced and Prestressed Concrete; Design TablesVon EverandStructural Concrete: Materials; Mix Design; Plain, Reinforced and Prestressed Concrete; Design TablesBewertung: 3.5 von 5 Sternen3.5/5 (13)

- Time and Costs IP AustraliaDokument7 SeitenTime and Costs IP AustraliaBehzad NematollahiNoch keine Bewertungen

- Flexural Behavior of Prestressed Girder With High Strength ConcreteDokument24 SeitenFlexural Behavior of Prestressed Girder With High Strength ConcreteBehzad NematollahiNoch keine Bewertungen

- Application Product Code : Timber-Concrete Composite Construction VB 8. 3Dokument4 SeitenApplication Product Code : Timber-Concrete Composite Construction VB 8. 3Behzad NematollahiNoch keine Bewertungen

- Wisconsin's Experience With HPC Bridge Decks: James M. ParryDokument12 SeitenWisconsin's Experience With HPC Bridge Decks: James M. ParryBehzad NematollahiNoch keine Bewertungen

- UHPC Reference ListDokument8 SeitenUHPC Reference ListBehzad NematollahiNoch keine Bewertungen

- The Journal of Commerce OnlineDokument2 SeitenThe Journal of Commerce OnlineBehzad NematollahiNoch keine Bewertungen

- Precast Prestressed Concrete Retaining Wall Designed by A New Method of Earth Pressure EstimationDokument1 SeitePrecast Prestressed Concrete Retaining Wall Designed by A New Method of Earth Pressure EstimationBehzad NematollahiNoch keine Bewertungen