Beruflich Dokumente

Kultur Dokumente

Din 00127

Hochgeladen von

Tathagat KoleyOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Din 00127

Hochgeladen von

Tathagat KoleyCopyright:

Verfügbare Formate

Spring lock washers with square ends or tang ends F&cringe; aufgebogen

oder glatt mit rechteckigem Querschnitt Supersedes December

DIN 127

1970 edition.

/n keeping with current practice in standards published has been used ihroughout as the. decimal marker.

by the lnlernalional

OrganizaUon

for Standardizalion

(/SO). a comma

it is recommended that DIN 128 be used instead of the present standard, (see Explanatory notes).

which

is to be withdrawn

by 1 January

1992

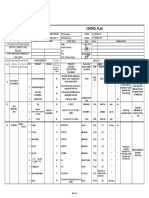

Dimensions

in mm

1 scope and field of application

Spring lock washers covered in this standard are deemed to be spring washers designed for use with bolt/nut assemblies involving fasteners of property class 5.8 or less, as specified in IS0 898 Pan 1. They are intended to counteract the effect of setting which results in bolt/nut assemblies working loose (see DIN 267 Part 26). They do not effectively prevent loosening of the assembly under varying radial load and are designed for use with short bolts predominantly subject to thrust. 2 Dimensions Type 8, with square ends

Type A, with tang ends (size 3 and larger)

Z (

I

Tang ends for type A. Washer cross section (enlarged)

The tang ends shall be produced to dimension of the circumference from either end.

k without

kinking

by bending thread,

both ends in a zone extending the position

one-tenth

The illustrations show spring lock washers for screws with right-hand versa for bolts with left-hand thread.

of the tang ends being vice

Continued

on pages 2 and 3

Page 2

DIN

127

dl

Vominal size m*x. ,2.4 2.6 2.9 3.4 3.9 4.4 5.4 6.5 7.5 8.5 10.7 12.7 14.7 17 19 21.2 23.5

d2

b

limit dcvir(ionr 0.9 1 1 1.3 1.3 I\,5 1.8 2.5 2.5 3 3.5 4 4.5 5 5 6 6 7 7

fO.l 0.5

,;$&

"'i.:.,h

m;yym#

'

(::g:

t&

"tn. 2.1 23 2.6 3.1 3.6 4.1 5.1

mu. 4.4 4.8 5.1 6.2 6.7 7.6 9.2 11.8 12.8 14.8 18.1 21.1 24,l 27.4 29,4 33.6 35.9 40 43

2)

2,2')2)

2,s)

fO.l

1.2 1.4 1.4 1,9 1,9 2.1 2.8 3.8 3.8 4,7 5.2 5.9 7.1 8.3 8.3 9.4 9,4 11.8 11.8

0.15 0.15 0.15 0.15 0.2 0.2 0.3 0,3 0,4 0,4 0.4 0.4 0.4 0.4 0.5 0.5

0.1 0.1 0.1 0.2 02 0.2 0.2 0.3 0.3 0.5 0.5 1 1 1 1 1 1 1.6 1,6

0.033 0.050 O&3 0,ll 0.12 0.18 0.36 0.83 0,93 1.6

2 22 2.5 ' 3 3.5 4 5 6 7 8 10 12 14 16 18 20 22 24 27

f 0.1

f 0.1

0.6 0.6 0.8 0.8 0.9 1.2 1.6 1,6 2 2.2 2.5 3 3.5 3.5 4 4 5 5

* 0.1 io.1 f0.1 fo.1

f 0.1

1.9 1.9 2.1 2.7 3.6 3.6 4,6 5 5.8 6,8 7,8 7,8 8,8 8.8 , 11 11

21. 2.2 2.5 3.2 4.2 4,2 5.4 5.9 6.8 8 9.2 9,2 10.4 10.4 13 13 .

1.2 1.2 1.6 1.6 1.8 2.4 3.2 3.2 4 4,4 5 6 7 7 8 8 10 10

3') 3,5') 4 5 6 7') 8 10 12 14 16 18 20 22 24 27

ko0.t 20.1

f 0.1

~~0.1 fo,15 zto.15

* 0.15 io.2 +02

20.1 ~~0.1 20.1

f 0.1

6.1

7.1

8.1

10.2 12.2 14.2 16.2 18.2 20.2 22.5

f0.15.

f 0.15

2.53

3.82 6,Ol 8.91 9.73 15.2 16,5 26.2 28.7

f02

t 02 5 0.2 t 0.2 t 0.2 -co25 2 0.25

t 0.15

i0.2 f0.2 f 0.2 + 0.2

24.5 , 25.5, 27.5 28.5

*02

It 0.2

36 30 39')2) 42')2)

36.5 39.5 30,5 42.5

37.7 31.7 40.7 43.7

58.2 48.2 61,2 68.2

10 10 8 12

2 0.25 r 0.25 -co25 ~025

6 6 7

f 0.2 -c 0.25 f2 0.2

13.6

16.1

12

14,2

0,8

1.6

67.3 44.3 , ;

15.6 13.6 I 16.1 I 12 18.4 14

14.2 , 0.8 :;4; ;;;

: il:: 1.6

2 2 2 2 2 2 2 2 2

45')2) 48')2) 52')2) 561)2) 60')2) WI21 68')2) 72')2) 801)2) 90')2) I 00')2)

1)

45.5 49 53 57 61 65 69 73 81 91 101

46.7 50.5 54.5 58.5 62.5 66.5 70.5 74.5 82,5 92.5 I 102,5

71.2 75 83 87 91 95 99 103 111 121 131

12 12 14 14 14 14 14 14 14 14 14 I

2 0.25 f 0.25 -c 0.25

7 7 8 8 8 8 8 8 8 8 8

+ 0.25 f 0.25 zt 0.25 -co25 to25 rt 0.25 2 0.25 5 0.25 it 0.25 &ozs 2 0.25

15.6 15.6 18 18 I 18 18 18 18 18 18 I 18

18,4 18.4 21.2 21.2 21.2 21.2 21.2 21,2 21.2 21.2 21.2

14 14 16 16 16 16 16 16 16 16 I 16

16,5 16.5 18.9 18.9 18.9 18.9 18.9 18,9 18,9

0.8 0.8 l 1 1 1 1 1 1

117 123 182 193 203 218 228 240 262

45 48 52 56 60 64 68 72

ztozs

t 0.25 3~025 rf: 0.25 f 0.25 + 0.25 r 0.25 zt 0.25

:::i

1:

i:;

1:

Testvaluesforthespringforcetestasdescribedin

DIN 267Part26have described

notasyetbeenspecifiedforthisnominalsize. for this

2) Test values for the test for permanentsetas nominal size.

in DIN 267 Part 26 have not as yet been specified

DIN 127

Page 3

Technical

delivery

conditions

8s

DIN 267 Part 26 shall apply with regard to the technical delivery conditions, Material: f St = spring steel specified in 0 IN 267 Part 26.

4 Designation

Designation of a type A spring lock washer of nominal size 8, made of spring steel (FSt) 1):

Spring lock washer DIN 127 - A 8 - FSt

Where spring lock washers for left-hand thread bolts are required, the letter symbol LH shall be included in the designation:

Spring lock washer DIN 127 - A 8 - LH - FSt

The DIN 4000 - 3 - 3 tabular layout of article characteristics shall apply for spring lock washers covered in this standard.

Standards

DIN DIN

referred to

Curved and wave spring lock washers Fasteners; technical delivery conditions; steel spring washers for bolt/nut Tabular layout of article characteristics for washers and lock washers Mechanical properties of fasteners; bolts, screws and studs assemblies

128 267 Part 26

DIN 4000 Part 3 IS0 898 Part 1

Previous editions

DIN 127 Supplement: 02.37; DIN 127: 04.21,07.23,07.29,01.4l, 04.43,02.56,01.61,12.?0.

Amendments

The following amendments have been made to the December 1970 edition. a) The field of application has been modified. b) A note on the period of validity of this standard has been included; see Explanatory c) d) e) f) Nominal sizes 2,3,2,6 and 33 have been deleted. The technical delivery conditions have been summarized in DIN 267 Part 26. The designation now includes a reference to the material to be used. The standard has been editorially revised.

notes.

Explanatory

notes

By maintaining a sufficiently high preloading in a bolt/nut assembly, spring washers are designed to prevent loosening of the assembly, which may be caused, for instance, by the effect of setting. The specification of residual spring forces given in DIN 267 Part 26 has made it possible for the first time to assessthe performance of spring washers. Spring lock washers complying with DIN 128 are suitable for bolt/nut assemblies involving fasteners of a property class less than 8.8, whilst spring lock washers complying with the present standard are only to be used for bolts of property class 5.8 or less. As there is no real demand for DIN 127 spring lock washers, DIN 128 washers being more suitable for the proposed application, the responsible committee has decided to withdraw DIN 127 in due course, the proposed transitional period of five years being intended to give manufacturers and users the opportunity to convert to spring lock washers complying with DIN 128.

International

F 16639124

Patent Classification

1) FSt shall also apply where no material has been specified in existing documentation.

Das könnte Ihnen auch gefallen

- GMW3359Dokument4 SeitenGMW3359lev501Noch keine Bewertungen

- Steel Rivets and Bars For Rivets, Pressure VesselsDokument4 SeitenSteel Rivets and Bars For Rivets, Pressure VesselsxaviereduardoNoch keine Bewertungen

- Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and ShapesDokument8 SeitenHot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and ShapesradziNoch keine Bewertungen

- Astm F837M-16Dokument8 SeitenAstm F837M-16arcadioscoNoch keine Bewertungen

- FORD WX200 Rev2014Dokument4 SeitenFORD WX200 Rev2014Amandeep SinghNoch keine Bewertungen

- AA Standards and Tolerances For Aluminum Extrusions PDFDokument48 SeitenAA Standards and Tolerances For Aluminum Extrusions PDFShibnathLahiri100% (1)

- AS400 BASIC User's Guide and ReferenceDokument673 SeitenAS400 BASIC User's Guide and Referencedhany PNoch keine Bewertungen

- A320 MetaDokument284 SeitenA320 MetaPacoNoch keine Bewertungen

- Astm F 1941-00 PDFDokument11 SeitenAstm F 1941-00 PDFJORGE ARTURO TORIBIO HUERTANoch keine Bewertungen

- Foreword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BDokument4 SeitenForeword: ISO 7044:2012 (En) Prevailing Torque Type All-Metal Hexagon Nuts With Flange, Style 2 - Product Grades A and BMarcelo KleinNoch keine Bewertungen

- 024 - Mechanical Properties of Fasteners Made of Carbon Steel and Alloy Steel PDFDokument1 Seite024 - Mechanical Properties of Fasteners Made of Carbon Steel and Alloy Steel PDFRonak RanaNoch keine Bewertungen

- Din71802 PDFDokument2 SeitenDin71802 PDFjudas1432Noch keine Bewertungen

- Hotel BillDokument2 SeitenHotel BillSipri TkgNoch keine Bewertungen

- Material Specification: Specification: Revision Date: Revision LevelDokument2 SeitenMaterial Specification: Specification: Revision Date: Revision LevelReginaldo Santos100% (1)

- Al Busbar 6060 DatasheetDokument1 SeiteAl Busbar 6060 DatasheetpiirsaluNoch keine Bewertungen

- Surface Vehicle Recommended Practice: 400 Commonwealth Drive, Warrendale, PA 15096-0001Dokument5 SeitenSurface Vehicle Recommended Practice: 400 Commonwealth Drive, Warrendale, PA 15096-0001Leonardo Gonçalves GomideNoch keine Bewertungen

- TL245 English 2004Dokument8 SeitenTL245 English 2004Elliott RussellNoch keine Bewertungen

- Ford 970Dokument4 SeitenFord 970amanNoch keine Bewertungen

- M6x1.0x23 Long HHS Control PlanDokument2 SeitenM6x1.0x23 Long HHS Control PlanDhanluxmi AutomaticsNoch keine Bewertungen

- Ansi b17 2 Woodruff Keys Flat Bottom Type 1Dokument3 SeitenAnsi b17 2 Woodruff Keys Flat Bottom Type 1rbagriNoch keine Bewertungen

- WSS M1P94 ADokument9 SeitenWSS M1P94 AAleks SenaNoch keine Bewertungen

- Drill Size Recommended For TapDokument4 SeitenDrill Size Recommended For Tapnithin83aNoch keine Bewertungen

- Iso 8734Dokument7 SeitenIso 8734Anderson MarimNoch keine Bewertungen

- Three Grades of Rivets and Bolts Used in Building ConstructionDokument4 SeitenThree Grades of Rivets and Bolts Used in Building ConstructiontheDLordP15Noch keine Bewertungen

- JIS B 1186 1995 PDFDokument23 SeitenJIS B 1186 1995 PDFJellyn CamiñaNoch keine Bewertungen

- A493 00 PDFDokument3 SeitenA493 00 PDFJohano AraújoNoch keine Bewertungen

- Domex 100 XF Data SheetDokument2 SeitenDomex 100 XF Data Sheetzubblwump5063Noch keine Bewertungen

- ASTM A686 T72301 W1A 9.5 Steel Plate, ASTM T72301 W1A 9.5 Tool SteelDokument2 SeitenASTM A686 T72301 W1A 9.5 Steel Plate, ASTM T72301 W1A 9.5 Tool SteelBernice JohnsonNoch keine Bewertungen

- Calculation of Retaining RingsDokument7 SeitenCalculation of Retaining RingsDobrica PetrovicNoch keine Bewertungen

- MildSteel AISI 1018Dokument2 SeitenMildSteel AISI 1018ramanamurtytv7176Noch keine Bewertungen

- 2012-005 RWG-WEB RodEnd SphericalBearingsDokument14 Seiten2012-005 RWG-WEB RodEnd SphericalBearingskamaleshaiahNoch keine Bewertungen

- Acrylonitrile Butadiene Styrene - UV Stabilized and General Purpose, Heat StabilizedDokument7 SeitenAcrylonitrile Butadiene Styrene - UV Stabilized and General Purpose, Heat StabilizedJefferson CruzNoch keine Bewertungen

- Ford-WSS-M1A365-A11A23 - (2017-09) - (Steel-CR-HR-Low Carbon) 9pgDokument9 SeitenFord-WSS-M1A365-A11A23 - (2017-09) - (Steel-CR-HR-Low Carbon) 9pgdpfloresNoch keine Bewertungen

- WSS-M1A346-A - Calidad de ChapaDokument12 SeitenWSS-M1A346-A - Calidad de ChapaDANIEL DIAZNoch keine Bewertungen

- En 10140-2006Dokument14 SeitenEn 10140-2006KaanMertNoch keine Bewertungen

- Jis.g.3507.2.e.2005 Carbon Steel For Cold Heading Part 2 WiresDokument11 SeitenJis.g.3507.2.e.2005 Carbon Steel For Cold Heading Part 2 WiresAnonymous gQyrTUHX38Noch keine Bewertungen

- Araymond Tinnerman Catalog IndustrialDokument137 SeitenAraymond Tinnerman Catalog IndustrialG.L. HuyettNoch keine Bewertungen

- Geomet 321Dokument2 SeitenGeomet 321Satnam Rachna FastenersNoch keine Bewertungen

- Techincal Data For PCD Dia & Torque ChartDokument1 SeiteTechincal Data For PCD Dia & Torque ChartTuff quality100% (1)

- Microindentation Hardness of Materials: Standard Test Method ForDokument28 SeitenMicroindentation Hardness of Materials: Standard Test Method ForSarvesh MishraNoch keine Bewertungen

- Metric DIN 127 SpecDokument5 SeitenMetric DIN 127 SpecmahfuzNoch keine Bewertungen

- Zinc Plating InformationDokument4 SeitenZinc Plating Informationankur panwarNoch keine Bewertungen

- ARNOLD - Thread Forming ScrewDokument4 SeitenARNOLD - Thread Forming ScrewgirishawantiNoch keine Bewertungen

- Evaluating Coatings For High Temperature Service: Standard Test Methods ForDokument3 SeitenEvaluating Coatings For High Temperature Service: Standard Test Methods ForFernando Berrospi Garay100% (1)

- Iso 4162Dokument2 SeitenIso 4162Guillermo TorresNoch keine Bewertungen

- Iso 4162 1990Dokument9 SeitenIso 4162 1990lokesh prakashNoch keine Bewertungen

- A153a153m - 16 PDFDokument5 SeitenA153a153m - 16 PDFHéctor BrunaNoch keine Bewertungen

- A354 PDFDokument7 SeitenA354 PDFDeen ewNoch keine Bewertungen

- Geomet 500 PDFDokument2 SeitenGeomet 500 PDFKaran Chadha100% (1)

- D1056-14 - Standard Specification For Flexible Cellular Materials - Sponge or Expanded RubberDokument15 SeitenD1056-14 - Standard Specification For Flexible Cellular Materials - Sponge or Expanded RubberFrancoNoch keine Bewertungen

- Astm A325m PDFDokument8 SeitenAstm A325m PDFDastaggir KarimiNoch keine Bewertungen

- Metric Fasteners PDFDokument28 SeitenMetric Fasteners PDFzainudinNoch keine Bewertungen

- ASTM A580 2006 Standard Specification For Stainless Steel WireDokument5 SeitenASTM A580 2006 Standard Specification For Stainless Steel WireEidrish Shaikh100% (2)

- Imds Recommendation 001 Annex IDokument33 SeitenImds Recommendation 001 Annex IAnjali DeshpandeNoch keine Bewertungen

- ASTM F 467-03aDokument10 SeitenASTM F 467-03aJORGE ARTURO TORIBIO HUERTANoch keine Bewertungen

- FastenerDokument46 SeitenFastenerTechproNoch keine Bewertungen

- Electrodeposited Coatings of Tin: Standard Specification ForDokument9 SeitenElectrodeposited Coatings of Tin: Standard Specification ForFelipeMoriNoch keine Bewertungen

- Is 3063-Spring WashersDokument11 SeitenIs 3063-Spring Washerspbp2956Noch keine Bewertungen

- Is 3063Dokument11 SeitenIs 3063Sumit ShyamalNoch keine Bewertungen

- Structural CalculationsDokument112 SeitenStructural Calculationsmechpandian100% (1)

- Indian Standard On Hex Bolts - IS 1363 Part 2Dokument12 SeitenIndian Standard On Hex Bolts - IS 1363 Part 2Debasis_De_scribdNoch keine Bewertungen

- 2870 Amd3Dokument12 Seiten2870 Amd3duckman2009Noch keine Bewertungen

- Firmware Functional Description MPH-, MPB-, MPD-, MPC-08 R911332643 - 01 PDFDokument1.186 SeitenFirmware Functional Description MPH-, MPB-, MPD-, MPC-08 R911332643 - 01 PDFCristopher Entena100% (1)

- 8051 TutorialDokument88 Seiten8051 Tutorialanon-596672100% (1)

- Epson EH-TW490 3LCD HD Gaming / Home Theatre ProjectorDokument2 SeitenEpson EH-TW490 3LCD HD Gaming / Home Theatre ProjectorWebAntics.com Online Shopping StoreNoch keine Bewertungen

- NV DS QUADRO K5000 For Mac US NV LRDokument2 SeitenNV DS QUADRO K5000 For Mac US NV LRAbdôüTitöûNoch keine Bewertungen

- Hpc301 User ManualDokument25 SeitenHpc301 User ManualRonaldo Faria da SilvaNoch keine Bewertungen

- Cubieboard Serial Conection TTLDokument4 SeitenCubieboard Serial Conection TTLsaladfingers8989Noch keine Bewertungen

- ReadmeDokument3 SeitenReadmeHector Lacasta BorderasNoch keine Bewertungen

- PIR Motion Sensor TutorialDokument10 SeitenPIR Motion Sensor Tutorialsuman kumarNoch keine Bewertungen

- La-6591 Pal5x - Uma - Macallan - 14 - Uma - A00 - 0110 - Final Dell E6420 Uma PDFDokument66 SeitenLa-6591 Pal5x - Uma - Macallan - 14 - Uma - A00 - 0110 - Final Dell E6420 Uma PDFJoselo LópezNoch keine Bewertungen

- Midterm PracticeDokument7 SeitenMidterm PracticeZhang YoudanNoch keine Bewertungen

- Foxconn 865a05 Rev BDokument39 SeitenFoxconn 865a05 Rev BAngel DiazNoch keine Bewertungen

- Replacement Parts For RyobiDokument13 SeitenReplacement Parts For RyobiSorin80% (5)

- ASK2Dokument5 SeitenASK2Tala JaberNoch keine Bewertungen

- Chapter5ExceptionHandling IIDokument30 SeitenChapter5ExceptionHandling IISaya WaniNoch keine Bewertungen

- Orangehrm Open Source: Quick Start Guide V-3.3.2Dokument6 SeitenOrangehrm Open Source: Quick Start Guide V-3.3.2tituspermadiNoch keine Bewertungen

- DCS Thyristor Power Converters For DC DriveDokument48 SeitenDCS Thyristor Power Converters For DC DriveArulrajNoch keine Bewertungen

- 17CS44 Module-3 Part-A NotesDokument21 Seiten17CS44 Module-3 Part-A Notesvishwa darshiniNoch keine Bewertungen

- Hunter X CoreDokument32 SeitenHunter X Coretennis5luvNoch keine Bewertungen

- SE110 Transistor de PotenciaDokument8 SeitenSE110 Transistor de PotenciajoseNoch keine Bewertungen

- NoticeBoard 1990Dokument350 SeitenNoticeBoard 1990मौर्यवंशी सम्राट आकाशNoch keine Bewertungen

- 1.1 Benefits of Desktop VirtualizationDokument15 Seiten1.1 Benefits of Desktop VirtualizationMishal FathimaNoch keine Bewertungen

- ELS Pricelist 1 September 2018Dokument9 SeitenELS Pricelist 1 September 2018Patrisedi 42Noch keine Bewertungen

- A837 Disassembly & ReassemblyDokument11 SeitenA837 Disassembly & ReassemblySimon JohnsonNoch keine Bewertungen

- KDC-W5641U 00 EnglishDokument24 SeitenKDC-W5641U 00 EnglishsciroccoNoch keine Bewertungen

- LogDokument2 SeitenLogATS TLNoch keine Bewertungen

- Lab Manual For CCNPDokument180 SeitenLab Manual For CCNPblck bxNoch keine Bewertungen

- Operating System FinalDokument14 SeitenOperating System FinaljayaNoch keine Bewertungen

- Dell Precision R5500 Server Spec SheetDokument2 SeitenDell Precision R5500 Server Spec SheetTim ChegeNoch keine Bewertungen