Beruflich Dokumente

Kultur Dokumente

MASIBUS

Hochgeladen von

khandelwalaOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

MASIBUS

Hochgeladen von

khandelwalaCopyright:

Verfügbare Formate

Ref. No.: m83/om/403 Issue No.

: 17

masibus

Operators Manual

S C A NNE R - 85 X X

Masibus Automation & Instrumentation Pvt. Ltd. B/30, GIDC Electronics Estate, Sector-25, Gandhinagar-382044, Gujarat, India. Ph: 91-079-23287275--79 Fax: 91-079-23287281/82 Email: support@masibus.com Web: www.masibus.com

Page 1 of 52 Operators manual Date: 04/05/2009

Ref. No.: m83/om/403 Issue No.: 17

masibus

CONTENTS

1. TECHNICAL DETAILS. 2. SPECIFICATIONS. 3. KEY OPERATION. 4. CONNECTIONS DETAILS. 5. USER GUIDE. 6. MODE OF OPERATION. 7. FINAL OUTPUT TABLE. 8. RELAY TABLE. 9. AUXILLAY OPTIONS TABLE. 10. TROUBLE SHOOTING. 11. MODBUS DETAIL (OPTIONAL). 12. OPEN COLLECTOR PIN DETAILS.

Page 2 of 52

Operator Manual Date: 04/05/2009

Ref. No.: m83/om/403 Issue No.: 17

masibus

Latching for LED Status of alarm limit 1 and alarm limit 2 is programmable. Scan time is programmable up to 99 seconds. Provision for zero and span setting is made to restrict range of usage and programming. This restricts accidental wrong setting of set point beyond the range of interest. Outside this range the unit will indicate data as 'OVER' towards span side up to 5% more than programmed span and UNDR towards zero side up to 5% less then programmed zero. This zero and span setting is more useful for linear inputs for setting the range between 1999 to 9999 counts. Digital input is mapped on 0-5V input and printing output and display is as ON if input voltage is less than 2.5v DC and OFF if input voltage is greater than 2.5v DC. The reverse feature can be obtained on using UPSCALE/DOWN SCALE of open sensor. There is no relay or any output action for digital input. Number of optional features provided including Relay output, Open collector output, Isolated Retransmission output, Serial printer output or Centronics printer output which can be easily set through front panel keys under Auxiliary Slot1 and Slot2 configuration. Full relay mapping possible. Any channel can be assigned to any group. For each group two relays are given for one alarm limit 1 and second alarm limit 2 if relay group mode is selected as 2rELy. For each group one relay is given for alarm limit 1 if relay group mode is selected as 1rELy. Isolated Retransmission output (420mA) can be configured for either Minimum or Maximum of channels selected in a group. Serial Communication with RS 232 / RS 485 is also provided for using the scanner as backend for Supervisory Control or for P.C. connectivity. Standard protocol for communication used is MODBUS-RTU. Serial or parallel printer interface is also provided for online Data printing application with Real Time Clock in

Page 3 of 52

1. TECHNICAL DETAILS

This is a versatile micro-controller based Scanner with a very high performance to price ratio. The features offered in this product are better than any other Scanner available in similar price range. The instrument is made in 96x192x208 mm size with standard cut out of 92x188 mm. Front is sealed membrane type to withstand dusty environment. On back plate PCB soldered flat terminals of very good quality are used. The programming, calibration and operation of the instrument are by nine simple keys with two independent displays for channel no. and data value for that channel. Channel display is of two digits to differentiate it from data display of four digits, each of 0.56" seven segments LED. Status of Run/ Program/Verify mode, Fault, Auto/Manual mode and status of each channel for programmed set point limits are displayed by 3 mm red LEDs. Operation of the instrument is menu driven with user understandable prompts. Provision for PASS WORD is kept for unauthorized access to critical configuration and program parameters. The product is made to accept all 7 standard thermocouple, PT100 RTD, CU-53, PT46, Linear voltage and current inputs and digital input. The type of input can be changed in field also. The calibration of the unit is done without trim-pots. The unit can be calibrated in installed condition itself by front panel keys at any given point i.e. user do not required to feed a fixed signal. RTD inputs are linear for 0.1 deg. as well as 1 deg. resolution. Also incorporating Self check feature for stand alone verification of hardware of the device of input section. Set point type (LL, HL or HH), abnormal status (Alarm or Trip) for alarm limit1 and alarm limit 2 as well as Relay action type (ON or OFF) for alarm limit 1 and alarm limit 2 are programmable if group mode is selected as 2rELy. Relay action type (ON or OFF) for alarm limit 1 are programmable if group mode is selected as 2rELy. if group mode is selected as 1rELy, then Relay action type ( ON or OFF ) for alarm limit 1 is only programmable.

Operators manual Date: 04/05/2009

Ref. No.: m83/om/403 Issue No.: 17 built. Print time is settable from 0-99 minutes. Also PC based configuration software is available for configuration of data through PC.

masibus

2.3. RANGE

E -200 to 1000 Deg C J -200 to 1200 Deg C K -200 to 1372 Deg C T -200 to 400 Deg C B 400 to 1820 Deg C R 0 to 1768 Deg C S 0 to 1768 Deg C Cu-53 -210 to 210 Deg C PT46 -200 to 600 Deg. C PT100(RTD 1) -199 to 850 Deg. C PT100 (RTD 0) -199.0 to 200.0 Deg C 4-20mA- Field scaleable-1999 to 9999 0-5 V - Field scaleable -1999 to 9999

2. SPECIFICATIONS

2.1. DISPLAY

2 digit 0.56" Red seven segment LEDs for channel no. 4 digit 0.56" Red seven segment LEDs for data of current channel. Power ON and Mode Selection discrete Red LEDs. Individual discrete Red LEDs to indicate channel status.

2.4. CALIBRATION

Ambient, Zero and span adjusted by digital calibration through front panel keys. No trim- pots. Zero Span Calibration of output through front panel keys. One shot Calibration of both input and output. Self check calibration through front panel keys.

2.2. INPUT

Universal Input. No. of inputs 8,16 or 24. Thermocouple type E, J, K, T, B, R, S (ANSI Standard). RTD Pt 100, Pt-46, CU-53 3-wire. 4-20 mA* / 1-5 V DC / 0-20 mA* / 05 V DC (*250 ohm/0.1% external Resistor required). Digital I/P wetted internally. Digital input is mapped on 0-5V input and display is as ON if input voltage is less than 2.5v DC and OFF if input voltage is greater than 2.5v DC. The reverse feature can be obtained on using UPSCALE/DOWN SCALE of open sensor. There is no relay or any output action for digital input. Cold junction compensation automatic for thermocouple types. Three wire cancellation for RTD I/P automatic by software. Accuracy: +/- 0.1% of full span +/- 1 Count Sampling Speed 250 msec per channel for T/C & Linear Input. 450 msec per channel for RTD Input. Display Scan Rate Settable 1 to 99 seconds. CMRR CMRR > 120 db @ 50Hz. NMRR NMRR > 40 db @ 50Hz.

2.5. CONTROLS

Vfy, Increase, Decrease, Auto/Man, Next/Group Check, Skip/Self Check, Al1/Al2, Scan Time/Print Time and Enter/ ACK keys for operation, programming & calibration.

2.6. Serial Communication

Isolated RS232/485 Serial Communication Protocol Standard MODBUS RTU HEX. OR Standard Serial Printer Output.

Page 4 of 52

Operator Manual Date: 04/05/2009

Ref. No.: m83/om/403 Issue No.: 17

masibus

2.7. OPTIONS FOR AUXILLARY OUTPUTS (Maximum Two Auxiliary Outputs are possible under SLOT-1 and SLOT-2 Input):

Relay card 2relay/1relay(per group) 3 groups(1 to 3 ) with 2 set points/ Slot 1 6 groups(1 to 6) with 1 set point Two Isolated Retransmission groups (Gr. No.: 1 and 2) 24 Open Collector Outputs Analog Card Output Open Card Collector Printer Card

3 groups(4 to 6) with 2 set points Slot 2 6 groups(7 to 12) with 1 set point 2A@230V A.C. with N.O./C/N.C. Relay Mapping possible with number of channels

Two Isolated Retransmission groups (Gr. No.: 3 and 4) Groups:- MAX or MIN Outputs:- 4-20mA Accuracy:- 0.25% of Range Load:- 250 Ohms

24 Open Collector Outputs

Centronics Printer Port interface

Common Description

24V D.C. @ 100mA externally wet Contacts

Parallel port

printer

NOTE: The possible combinations are explained in the operational manual in Topic no. 8. Parallel Printer Port: 1 No ( See Special Note 2) o Centronics Printer Port Interface Special note 1: If OR type Logic is selected or Scanner Type is 8508 and INDIVIDUAL logic is used, user can configure SLOT-2 for any other Output. (Refer to Operation manual for detail description of OR type and INDIVIDUAL type Logic). If INDIVIDUAL Logic is used and Scanner Type 8516 or 8524 both Slots require Open Collector Output by default. Special note 2: If serial Printer is selected then Parallel Printer Selected on Slot-1 and Slot-2 will not be active. If Parallel

Operators manual Date: 04/05/2009

Printer is selected as Option on Both Slots, Parallel Printer on Slot-1 will only be active.

2.8. GENERAL

power supply - selectable 85V to 265V AC 50 Hz and 125V to 280 VDC. 22V to 30V DC, (optional),110V DC(optional). Ambient - 0 to 55 deg C. Humidity - up to 95% RH (Noncondensing) Power consumption - Less than 20 VA Scanning time 1) For T/C and Linear - 250 mSec. 2) For Rtd - 450 mSec.

Page 5 of 52

Ref. No.: m83/om/403 Issue No.: 17

masibus

Key 9 push button keys for front access.

2.9.

PHYSICAL

Case M.S. powder coated with ABS molded bezel Terminals Screw type, can accept up to 2.5 sq. mm wire Bezel size - 96 X 192 mm Depth behind panel - 208 mm / 250mm (with terminal plate) Panel cutout - 92 X 188 mm

2.11. OTHER OPTIONS

1. Channel to channel online isolation up to 125V AC and 300V DC and off-line isolation up to 500VDC is available for Critical Applications. 2. Horizontal Scanner: Bezel size - 192 X 96 mm Depth behind panel -208 mm / 250mm (with terminal plate) Panel cutout - 188 X 92 mm

2.10. SPECIAL FEATURES:

Real time RTC interface for Serial or parallel printer output. Print on Time and Hot printing feature. Print Time settable from 0-99 minutes. 85xx-WP Case-Material:- 1.6 MM THK. M.S SHEET METAL FABBRICATIED. Painted Shade 631,IS:5. Dimension320 (H) x 350 (W) x 420(D)

85xx-EXP Case-Material:- Cast Al. LM6(A6-M).Paint-Epoxy, Light Grey Shade 631,IS:5. Dimension560 (H) x 275 (W) x 210(D)

Page 6 of 52

Operator Manual Date: 04/05/2009

Ref. No.: m83/om/403 Issue No.: 17

masibus

3.1.1.5. NEXT /GCHK

This key is used to move into next parameter in a current mode. In MAN mode it is used to select next channel for fixed channel display. Also during RUM Mode this key is used as Relay map check key. On pressing NEXT /GCHK key for at least 3 sec the Relay map display feature is enabled and display shows set point type , group number and channels mapped to it is shown by LEDs AL1 and AL2 glowing.

3. Key Operation

There are nine keys for operation of the instrument. For understanding the operation first let us see the operation of keys.

3.1.1.1. VFY

This key is used to select desired parameter in configuration, program, verify configuration and verify program modes. On first press of this key, it will display

By pressing INC or DEC key you can select the desired mode (VPGM, PRGM, VCFG, and CNFG) of operation. Now if you again press the vfy key then the instrument will come in Run mode. The corresponding mode LED will glow on pressing this key.

Md upgm

Verify program mode

Press VFY to exit from this mode or will come out after time out of at least 20 seconds. Check those Leds which are on at this prompt indicated that the channel is in this group.

hh Grp1

3.1.1.2. ENTER/ACK

This key is used to enter the value of the selected parameter. After setting the data to proper value, if ENTER key is pressed, the data will be permanently stored in non-volatile memory. On pressing of ENTER key, the decimal point on last digit disappears to indicate that data is entered. Now, the data change is not allowed until ENTER key is pressed once again. On pressing of ENTER key once again, decimal point on last digit will glow and allow change in the data. This key when pressed during RUN MODE will be considered as an ACK key which is used to acknowledge the relays and LED status as per logic selected.

3.1.1.6. AUTO/MAN

This key is used to set the unit in either auto mode or manual mode. This is a toggle key. i.e. if it is pressed in auto mode, the unit is switched into MAN mode and channel display will become fixed. MAN LED will glow in MAN mode to indicate the same. This key is also used for individual zero/span, individual input type, individual decimal point position, Relay mapping, Retransmission mapping and Retransmission configuration setting for each channel.

3.1.1.7. SCN /PRN TIME

This key is used to set the scan time for display of channels and its reading. It can be incremented up to 99 using INC key or decremented up to 1 using DEC key. The same key is also used for print time setting for online printing of data. Print time is settable from 0-99 minutes. This key is also used to enter in calibration mode from configuration mode.

3.1.1.3. INC ()

This key will increment the selected parameter value by one count in program, configuration or calibration mode. if you keep pressed the key then value will be incremented by 10 times faster up to the maximum value of that particular parameter.

3.1.1.4. DEC ()

This key will decrement the selected parameter value by one count in program or configuration mode. If you keep pressed the key then value will be decremented by 10 times faster up to the minimum value of that particular parameter.

3.1.1.8. SKIP / SCHK KEY

This key is used to skip / un-skip the channel in program mode. This is also a toggle key. i.e. if key is pressed while channel is skipped, it will un-skip the channel. On pressing this key in program mode, skip / un-skip message will be displayed in Data window and channel

Page 7 of 52

Operators manual Date: 04/05/2009

Ref. No.: m83/om/403 Issue No.: 17 no. will be displayed in Channel window. Self check feature can also be invoked by this key during Run Mode.

masibus

3.1.1.9. AL1 / AL2

This key is used to change from alarm limit 1 to alarm limit 2 and vice-versa. This is also a toggle key.

Page 8 of 52

Operator Manual Date: 04/05/2009

Ref. No.: m83/om/403 Issue No.: 17

masibus

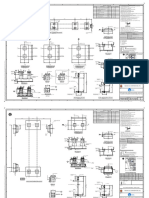

4. CONNECTION DETAILS:

Back plate Detail. (Standard back plate)

C C NO NC C C NO NO RL NC C RL

C NO RL NC C NO RL NC C C RL NO NC RL NO RL NC RL RL

RELAY OUTPUT

NO NC C NO

RL

RL NO RL NC 2 NC 1 +Ve C +Ve C NO -Ve RL -Ve NO RL NC RL NC

3

+Ve -Ve

4

+Ve -Ve

NC

C CH

RL

+ C

+ C

C CH

CH

+ C

+ CH C

SENSOR CONNECTION

1. FOR RTD INPUT : 2. FOR T/C : 3. FOR DIGITAL I/P :

+ C

CH

+ C

CH

INPUT SIGNAL

+ C

CH

+ CH C

4. FOR VOLT :

5. FOR CURRENT :

+ C

CH

+ C

CH

+ C

CH

+ CH C

250Ohms,0.1%,Externally.

+ C

CH

+ C

CH

+ AMB.SENSOR

CH

+ CH C

+ C

CH

+ C

CH

PIN 1

+ C

CH

+ CH C

+ -

CH

+ -

CH

SERIAL COMMUNICATION

+ 4

CH

+ CH POWER CONNECTION

2 L/+ 3 N/4 E

NC L/+ N/- E

FU SE

MAINS

Page 9 of 52 Operators manual Date: 04/05/2009

Ref. No.: m83/om/403 Issue No.: 17

masibus

Back plate Detail of OPEN COLLECTOR (OPTIONAL)

DG OC13 OC1 OC14 OC2 OC15 OC3 OC16 OC4 OC17 OC5 OC18 OC6 OC19 OC7 OC20 OC8 OC21 OC9 OC22 OC10 OC23 OC11 OC24 OC12

OPEN COLLECTOR OUTPUT

OC36 OC48 OC35 OC47 OC34 OC33 OC46 OC45 OC32 OC44 OC31 OC30 OC43 OC29 OC42 OC41 OC28 OC40 OC27 OC26 OC39 OC38 OC25 OC37 DG

C CH

+ C

+ C

C CH

C CH

+ C

+ CH C

SENSOR CONNECTION

1. FOR RTD INPUT : 2. FOR T/C :

+ C

CH

+ C

CH

INPUT SIGNAL

+ C

CH

+ CH C

3. FOR VOLT :

4. FOR CURRENT :

+ C

CH

+ C

CH

+ C

CH

+ CH C

250Ohms,0.1%,Externally.

+ C

CH

+ C

CH

+ AMB.SENSOR

CH

+ CH C

+ C

CH

+ C

CH

PIN 1

+ C

CH

+ CH C

+ -

CH

+ -

CH

SERIAL COMMUNICATION

+ 4

CH

+ CH POWER CONNECTION

2 3 4 E

NC L/+ N/- E

FU SE

MAINS

L/+ N/-

Page 10 of 52

Operator Manual Date: 04/05/2009

Ref. No.: m83/om/403 Issue No.: 17

masibus

Back plate Detail of PARALLEL PRINTER (optional).

RELAY OUTPUT

C NO RL NO RL NC 2 NC 1 +Ve C +Ve C NO -Ve RL -Ve NO RL NC RL NC

C C NO NC NO RL NC RL

C CH

RL

+ C

+ C

C CH

C CH

+ C

+ CH C

SENSOR CONNECTION

1. FOR RTD INPUT : 2. FOR T/C : 3. FOR DIGITAL I/P :

+ C

CH

+ C

CH

INPUT SIGNAL

+ C

CH

+ CH C

- +

4. FOR VOLT :

5. FOR CURRENT :

+ C

CH

+ C

CH

+ C

CH

+ CH C

250Ohms,0.1%,Externally.

+ C

CH

+ C

CH

+ AMB.SENSOR

CH

+ CH C

+ C

CH

+ C

C

PIN 1

CH

+ C

CH

+ CH C

+ -

CH

+ -

CH

SERIAL COMMUNICATION

+ E 4

CH

+ CH POWER CONNECTION

2 L/+ 3 N/4 E

NC L/+ N/FUSE

MAINS

Page 11 of 52 Operators manual Date: 04/05/2009

masibus

Back plate Connection Detail of Weather Proof and FLP Scanner (optional).

RL-7 to 12

TOP VIEW

RL-1 to 6

CH-2

CH-4

CH-6

CH-8

CH-10

CH-12

CH-14

CH-16

CH-18

CH-20

CH-22

CH-24

Ref. No.: m83/om/403

CH-1

CH-3

CH-5

CH-7

CH-9

CH-11

CH-13

CH-15

CH-17

CH-19

CH-21

CH-23

Issue No.: 17

C + - C + -

C + - C + - C + - C + - C + - C + - C + - C + - C + - C + RTD T/C VOLTS + CURRENT + - 250 ohm 0.1% MA

CH-17 to 24

CH-9 to 16

CH-1 to 8

Page 12 of 52

Operator Manual Date: 04/05/2009

L/+N/- E

MAINS SUPPLY

RL-2 RL-1 RL-4 RL-3 RL-6 RL-5

C NO NC C NO NC C NO NC C NO NC C NO NC C NO NC RL-8 RL-7 RL-10 RL-9 RL-12 RL-11

Rx O/P-1 Rx O/P-2 RS-485 MODBUS

+ + D+ D-

Ref. No.: m83/om/403 Issue No.: 17

masibus

Relay cable (25 pin D type (Female)

Back plate connection detail of Weather Proof & FLP SCANNER (25 PIN D TYPE Female) connector) CHANNEL CH-1 PIN NO 16 14 CH-2 15 19 17 18 20 22 21 23 25 24 3 1 2 6 4 5 8 10 9 11 13 12 7 Common +/Hi -/Lo Common +/Hi -/Lo Common +/Hi -/Lo Common +/Hi -/Lo Common +/Hi -/Lo Common +/Hi -/Lo Common +/Hi -/Lo Common +/Hi -/Lo Common CH-10 CH-18 CHANNE L CH-9 CHANNEL CH-17

PIN NO 1 2 3 4 12 13 14 15 16 17 18 19 20 21 22 23 24 25

CHANNEL C-3 NO-3 NC-3 C-4 NO-6 NC-6 C-1 NO-1 NC-1 C-2 NO-2 NC-2 NO-4 NC-4 C-5 NO-5 NC-5 C-6

CH-3

CH-11

CH-19

CH-4

CH-12

CH-20

CH-5

CH-13

CH-21

CH-6

CH-14

CH-22

CH-7

CH-15

CH-23

CH-8

CH-16

CH-24

NC

Page 13 of 52 Operators manual Date: 04/05/2009

Ref. No.: m83/om/403 Issue No.: 17

masibus

SCANNER

MAN POWER CHANNEL RUN VFY PRG FLT DATA AL1 1 AL2 AL1 2 3 4 5 6 7 8 9 10 11 12

5. USER GUIDE

5.1. INTRODUCTION

This is a single chip micro-controller based scanner designed for universal input type. Instrument is operated by nine user friendly keys. These keys are used for operation, programming and calibration. There are four levels of protections in the instrument. The four levels decide access to verify settings (operator level), access to set points & control parameters (supervisor level), configuration and calibration. The manual covers all aspects of operation of the instrument. Please read instructions carefully before altering any programming or configuration information. Vertical Scanner: Bezel size - 96 X 192 mm Depth behind panel - 208 250mm (with terminal plate) Panel cutout - 92 X 188 mm

13 14 15 16 17 18 19 20 21 22 23 24 AL2

mm

ENT ACK AUTO MAN AL1 AL2

VFY

NEXT

SKIP SCHK

SCN TIME

masibus

85XX

Page 14 of 52

Operator Manual Date: 04/05/2009

Ref. No.: m83/om/403 Issue No.: 17

masibus

Horizontal Scanner: Bezel size - 192 X 96 mm Depth behind panel -208 mm / 250mm (with terminal plate) Panel cutout - 188 X 92 mm

FLP Scanner:

WEATHER PROOF Scanner:

Page 15 of 52 Operators manual Date: 04/05/2009

Ref. No.: m83/om/403 Issue No.: 17

masibus

Configuration mode. Also refer relay logic table There is a facility for latching of alarm status. Even when the channel comes back to normal mode, LED will be ON till acknowledged to indicate past alarms. The relay will be self clearing in this mode. For currently selected calibration channel decimal point on units digit of channel no. will glow. In this mode self check feature through SKIP/SCHK key and Relay map summary through NEXT/GCHK key are also accessible.

5.2. OPERATION

5.2.1. POWER SUPPLY Always be sure that you are connecting right input supply voltage to right power terminal of the instrument. On application of proper power, the instrument will display Scanner type for 2 seconds and then configuration type for another two seconds. Now, if the input signal is connected, scanner will display value of input in DATA window and channel no. in channel window on display along with appropriate mode LED.

6.2

MANUAL MODE

6. MODES OF OPERATIONS

There are seven modes of operations. 6.1 6.2 6.3 6.4 6.5 6.6 6.7 Run mode Manual mode Program mode Configuration mode Verify configuration mode Verify Program mode Calibration mode

Manual mode is same as normal run mode except for displaying only one channel continuously. The channel number can be changed by NEXT key. This mode is entered by pressing AUTO/MAN key in RUN/AUTO mode. Pressing this key once again brings back to AUTO mode. In this mode self check feature through SKIP/SCHK key and Relay map summary through NEXT/GCHK key are also accessible.

Each are described in detail in individual chapter

6.3

PROGRAM MODE

6.1 RUN MODE

This mode is indicated by RUN LED glowing. In this mode, channel window will display current channel number and DATA window will show its temperature. In AUTO mode, it will keep on displaying successive un-skipped channels at the programmed scan rate. In case of MAN mode, only one channel will be displayed continuously. For manual mode separate LED indication of mode is provided on front. In RUN mode, alarm status of channels is indicated by discrete LEDs for both AL1 and AL2 limits. If the LED is on, the channel has crossed that limit. If the LED is flashing, the alarm is not acknowledged. When ENTER/ACK key is pressed, the LED will become steady to indicate acknowledged alarm. The relay of that channel will be turned OFF, on acknowledging the alarm, if the alarm type is not configured for trip logic, where relay is not turned OFF until it actually comes within limit. The type of action and normal status of relay is programmable and described in

Page 16 of 52

This mode is used to display / change alarm limits, scan time, print time and skip status of channels. For entering in this mode, press VFY key in RUN mode and VFY LED will glow to indicate the mode selection and display will ask to select the mode. By pressing increment and decrement key select PRGM option and press ENTER key. By pressing the ENTER key it will ask for Password. Select your password by using INC and DEC keys. If the Password is correct then it will go in to Program mode and PRG LED will start glowing to indicate the current mode of operation. Then press NEXT key to enter in program mode. Pressing VFY key will take you out of this mode. Factory set password is '00'. If the user has programmed password in configuration mode, go to correct password using INC key and DEC keys and then press ENT key. 6.3.1 CHANNEL 1 SET ALARM TRIP VALUE

01

Operator Manual Date: 04/05/2009

Ref. No.: m83/om/403 Issue No.: 17

masibus St 001

500

First parameter is alarm limit 1 for channel 1. The upper row LED (for AL1) for channel 1 will be flashing to indicate channel affected by this limit. Also a decimal point on last digit of data will glow. Change the limit as per requirement by INC and DEC key and press ENTER. The LEDs will stop flashing. For changing the entry once again, press ENTER key. The decimal point on last digit of data indicates, whether changing of data is allowed or not. If decimal point is off and LEDs are steady data changing is not allowed. Pressing NEXT key will bring display to channel 02 limits. CHANNEL 2

Displays scan time for updating the channel on display. Maximum Scan Time is 99 Sec. Minimum Scan Time is 1 Sec. Change Scan Time by INC and DEC keys and press ENTER when correct value is set. On pressing NEXT key, print time menu appears if printing feature is selected (Either serial or parallel printer Interface). Display will show:

Alarm limit for 1 for channel 2. The upper row LED (for AL1) for channel 2 will be flashing to indicate channels affected by this limit. Other operations are identical to channel 1. Pressing NEXT key will bring display to channel 03 limits. CHANNEL 3

02 600

Print Time can be set between 0-99 minutes. Setting print time equals to 0 disables printing. Change Print Time by INC and DEC keys and press ENTER when correct value is set. Printing at regular interval of set time is available on printer output (Serial or Parallel printer Interface). Also hot printing can be obtained through SCN/PRN key in Run mode. I.e. Print on Demand feature. SKIPPING / UNSKIPPING OF CHANNEL For changing the skip status of channels, press SKIP key in program mode. The display will show channel skip status. If Ch-1 is skipped, display will be 6.3.2

05 PrNt

Alarm limit 1 for Channel 3. The upper row LED (for AL1) for channel 3 will be flashing to indicate channel affected by this limit. Other operations are identical to channel 1. Pressing NEXT key will bring display to channel 04 limits. Thus you can set AL1 limit for each individual channel. For programming AL2 limit for all channels, press AL1/AL2 key to change to AL2 limits. Now, the lower row LEDs for AL2 will start flashing for the particular channel. Other operations are identical to AL1 programming. SCAN TIME/PRINT TIME For programming Scan Time or Print Time, press SCN/PRN key in program mode. Display will show:

Operators manual Date: 04/05/2009

03 700

If Ch-1 is un-skipped, display will be

1 S-ch 1 U-ch

Channel can be selected by pressing NEXT key. SKIP key works as a toggle key, i.e. if channel is skipped, by pressing SKIP key status will change to un-skip and vice-versa. After changing the skip status, press ENTER key to store the status. Skipping of all channels is not allowed. At least one channel has to be un-skipped for

Page 17 of 52

Ref. No.: m83/om/403 Issue No.: 17 operation of unit. When user tries to skip the last un-skipped channel, it will not allow. In program mode, user can select any parameter by using NEXT, SKIP, AL1/AL2 and SCAN TIME keys and can abort from this mode by pressing VFY key. For Verify mode all the parameter sequences are same except for password entry and decimal point in last digit is 'off'. 6.4.2

masibus

CONFIGURATION TYPE

In this configuration type different input type can be set for individual channel. 6.4.3 INPUT TYPE

FI CNfg

6.4

CONFIGURATION MODE

Configuration mode is used to change basic configuration of unit. The program is same for all options and all options are configurable from front only by using various keys. No hardware changes are necessary for changing input type. It can be changed by just using front keys. For entering Configuration mode, press VFY key in RUN mode and VFY LED will glow to indicate the mode selection and display will ask to select the mode. By pressing increment and decrement key select CNFG option and press ENTER key. Now it will ask for Password. After setting correct Password with the help of INC and DEC keys press ENTER. If the Password is correct then only you can enter in Configuration mode. PRG LED starts glowing which indicates the mode of operation. Then press NEXT key to go ahead in Configuration mode. Pressing VFY key will take you out of this mode. By entering in Configuration mode, the scanner will display scanner type. The parameters in sequence are described below. User can go to next parameter in sequence by pressing NEXT key. 6.4.1 SCANNER TYPE

For changing of input type, no internal hardware changes are required. If input type is 4-20mA then you are required to connect the 250ohm Resistors supplied between the INHI and INLOW terminals of the terminal plate. This will be treated as common i/p type for all the channels. When an input type is selected its corresponding zero and span range is automatically adjusted as per its table. However if user wants to change zero and span as required he can move to the zero or span prompt and can change . With this facility if the same input is selected (ie.ENTER key is pressed on the same input), its zero and span range is kept as it is. For setting the range as per the table one has to change the input first and then change back to same input as required. Refer corresponding range as per the inputs. There is provision for setting input type for each channel individually. By pressing AUTO/MAN key here, you can enter individual input type for all the channels provided that configuration type is selected as mix. Display will show as:

No 8508

OR OR

No 8516

IP E-tc

Discrete LED 1 of AL1 will start flashing .By pressing INC/DEC keys; you can set the input type for channel 1. By pressing NEXT key here you can go to next channel and similarly set the input type of other channels. If you want to come at channel 1 from any other channel then use SCN TIME key. VFY key will bring you back to the configuration mode (i.e. one level up) at common input type setting. From here you can go to the next parameters setting. Each type is displayed by prompt as follows.

There are three options 8508 or 8516 or 8524 for this parameter. Pressing INC and DEC key you can make it 8508 or 8516 or 8524.

Page 18 of 52

No 8508

Operator Manual Date: 04/05/2009

Ref. No.: m83/om/403 Issue No.: 17

masibus

6.4.4 SETPOINT TYPE

E-tc J-tc K-tc T-tc B-tc R-tc S-tc CU53 Pt46 Rtd

-200 to 1000

E - type thermocouple

-200 to 1200

hh

OR

J - type thermocouple

hL SPtY

OR

LL

K - type thermocouple -

-200 to 1372

Where HH - high, very high AL1 high AL2 - very high HL - high, Low AL1 - low

AL2 high

T - type thermocouple

-200 to 400

LL - low, very low AL1 - very low AL2 - low This setting is common for all groups if the relay group mode is configured as 2rELy. If the relay group mode is selected as 1rELy, then only two set points types will be available. i.e.

400 to 1820

B - type thermocouple

0 to 1768

R - type thermocouple

0 to 1768

S - Type thermocouple

hi

Where,

OR

Lo

-210 to 210

RTD CU-53, 1 deg. Resolution

-200 to 600

SptY hi - high AL1 high Lo - low AL1 - low

RTD PT-46, 1 deg. Resolution

For exact understanding of relay and LED operation please refers the relay logic table given at the end of manual.

-199 to 850 6.4.5 ABNORMAL STATUS OF AL1

RTD PT-100, 1 deg. Resolution

Rtd.1 4-20 0-5v dIgt

-

RTD PT-100, 0.1 deg. Resolution -199.0 to 200.0

AL

OR

TR

CAL1

Configuration of abnormal status for AL1 limit. It will toggle between ALRM and TRIP by INC and DEC keys. In alarm type, discrete LEDs and relays are self-clearing. In trip type, both are latched. They will go off only by pressing ACK key and returning to normal status. Even if the reading has come to normal, relay will not be turned off until ACK key is pressed. This is useful when the relay is used for tripping the plant or device and it

Page 19 of 52

4-20 mA or 1-5 V input

-1999 to 9999

-1999 to 9999

0-5 V input or 0-20 mA

on or off

Digital input(0-5 v)

Operators manual Date: 04/05/2009

Ref. No.: m83/om/403 Issue No.: 17 is not to be started once again until operator has set up for starting once again. Open condition will be treated as normal condition in trip type. This is common for all groups if the relay group mode is configured as 2rELy. NOTE: If the relay group mode is selected as 1rELy, then only AL1 limit will be available which can be configured as alarm or trip. 6.4.9

masibus

HYSTERESIS

6.4.6

ABNORMAL STATUS OF AL2

Hysteresis for relay operation on alarm limits. This parameter is common for all groups. Minimum value can be '0' and maximum value can be 100. Use INC or DEC keys for changing the value. Hysteresis is treated as per count basis depending on display value. For RTD Pt100; 0.1 deg. resolution, maximum setting will be 10.0 deg. 6.4.10 ZERO

h 010

AL

OR

TR

This is for configuration of abnormal status for AL2. Other description is same as AL1. NOTE: This parameter will be available only if relay group mode is selected as 2rELy. 6.4.7 LATCHING OF ALARM

CAL2

no Ltch

OR

This is used to enable latching of discrete LEDs when alarm limit is crossed. This option will keep discrete LEDs latched even after the channel has come to normal status until ACK key is pressed. This option can be changed to Yes or no for enabling and disabling respectively. When CAL1 and CAL2 are of trip type, this parameter will be skipped from display. 6.4.8 OPEN SENSOR UP/DOWN

Zero value or minimum value for selected input. Upto 5% below of the total zero and span value OVER will be indicated on display. For out of range value, OPEN will be indicated on display. Minimum value is decided by input type. Maximum value will be span value. For linear inputs, this is the zero setting for range programming. This will be treated as common Zero value for all the channels. There is provision for setting zero/ span/ dp position (dp position is zero for t/cs, 1 for RTD0.1) for each channel individually. By pressing AUTO/MAN key here, you can enter individual zero value for all the channels. Display will show as:

Z -1999

01 100

Discrete LED 1 of AL1 will start flashing .By pressing INC/DEC keys; you can set the zero value for channel 1. If you press AUTO/MAN key here then Discrete LED 1 of AL2 will start flashing. Now display will show span of channel 1.By pressing INC/DEC keys, you can set the span value for channel 1. AUTO/MAN key here works as toggle key between AL1 & AL2 (i.e. Zero and Span). By pressing NEXT key here you can go to next channel and similarly set the zero and span values of other channels. If you want to come at channel 1 from any other channel then use SCN TIME key. VFY key will bring you back to the configuration mode (i.e. one level up) at

Operator Manual Date: 04/05/2009

This is used to define the state of the alarms in open sensor condition. It can be configured as UP or DOWN by pressing INC and DEC keys. If it is configured as UP then open condition will be treated as alarm / abnormal condition. If it is configured as DOWN then open condition will be treated as normal condition.

UP OPEN

Page 20 of 52

Ref. No.: m83/om/403 Issue No.: 17 common zero value setting. From here you can go to the next parameters setting. 6.4.11 SPAN

masibus

channel 1 from any other channel then use SCN TIME key. VFY key will bring you back to the configuration mode (i.e. one level up) at common DP value setting. From here you can go to the next parameters setting. For the channels having input types t/c and rtd, dp position value is fixed (zero). If you are using the instrument with individual scaling of zero/span and dp then dont press ENTER key at the main zero/span and dp parameters in the configuration mode after setting individual values. Main zero/span and dp values are common values for all the channels. After setting individual values if you will press ENTER key at main zero/span/dp then this will make zero, span and dp values same or common for all the channels. 6.4.13 PASSWORD

Span value or maximum value for selected input. Up to 5% above of the total zero and span value OVER will be indicated on display. For out of range value, OPEN will be indicated on display. Maximum or minimum value is decided by input type. For linear inputs, this is the span setting for range programming. Ey pressing AUTO/MAN key here, you can enter individual zero/ span values for all the channels. Display will show as:

S 2000

Discrete LED 1 of AL2 will start flashing. All the functions described in the previous description of zero value setting are applicable here. 6.4.12 DECIMAL POINT POSITION

01 1000

Password for entering to Program mode and Configuration mode. The value of password can be programmed anywhere between '0' to '99'. Factory set password is 00. 6.4.14 SERIAL OUTPUT CONFIGURATION: This parameter is used for configuration of serial output either as Serial Modbus or Serial Printer. Display will show:

0 PASS

Decimal point position is applicable only to 420 mA or 0-5V i/p. It can be set 0 to 3 as per requirement. If i/p type is selected as linear (4 to 20mA, 0 to 5V) then only by pressing AUTO/MAN key here, you can enter individual dp position value for all the channels. If configuration type is selected as mix then you can enter in individual DP position setting but you can change DP position of channels only which has I/P type as 0-5V or 4 20. Display will show as:

dP 000

When serial configuration parameter is set as print (PRINT), baud rate is print fixed 9600 and is not changeable; also serial printer should have a default baud rate of 9600. 6.4.15 SERIAL NUMBER

S0 PrNt

01 001

Discrete LED 1 of AL1 will start flashing .By pressing INC/DEC keys; you can set the dp position value for channel 1. By pressing NEXT key here you can go to next channel and similarly set the dp position values of other channels. If you want to come at

Operators manual Date: 04/05/2009

This parameter is required while using the Serial Communication facility. It represents the serial number or the ID number of the Unit. It can be configured between 1 and 99 by using INC/DEC keys.

Page 21 of 52

1 SrNo

Ref. No.: m83/om/403 Issue No.: 17 6.4.16 BAUD RATE

masibus

6.4.19 RELAY OUTPUT: To set Slot 1 or Slot 2 configuration as Relay output, select Relay card on slot 1 prompt, display shows:

This parameter is used to set the BAUD RATE for serial communication. Different baud rates can be selected by using INC/DEC keys. Baud rate can be set from 4800, 9600 and 19.2KB. In case of Serial printer interface as serial output baud rate is fixed to 9600 and cannot be modified. 6.4.17 SLOT 1CONFIGURATION: 6.4.18 SLOT 2CONFIGURATION:

bd 9600

S1 RELC

Press ENTER on this prompt, on pressing next key a Relay Mapping Menu appears wherein channels can be mapped to groups. Relay configuration menu appears on display as:

GROUP RELAY:

Scanner is equipped with two auxiliary slots whose function of operation can be defined and configured through Slot 1 and Slot 2 configurations parameters. Each slot is programmed independently for required output and their configurations are configured per slot. I.e. Slot wise configuration is carried out. (Refer Auxiliary options table for detail information) These slots can be configured for number of outputs and there combinations are as defined in Auxiliary options chart. Five available options are: Relay output ---Relay Card

1rLy

GP or

2rLy

The relay settings can be configured as 1 relay (1rELy) for settings of total of 12 groups. Or as 2 relay(2rELy) for settings of total 6 groups. 1rELy group1 - 6 for Slot1 and group7 12 for slot2. 2rELy group1 -3 for Slot1 and group4 6 for slot2.

RELAY MAPPING:

relC opeC rtrC prNc

No Output.

Open Collector Output ---Open collector card ----

Retransmission Output Retransmission card

Parallel Printer Output ---Centronics Printer card ---No card placed in slot

Press Auto/Man key to enter into mapping configuration. Individual channels are displayed with there mapping onto groups. If both the slots are selected as Relay card and the group settings are selected as 2rELy in GP mode, a total of 6 groups are available, 3 groups per card where as if only single slot is configured as Relay card, only 3 groups are available. If both the slots are selected as Relay card and the group settings are selected as 1rELy in GP mode, a total of 12 groups are available, 6 groups per card where as if only single slot is configured as Relay card, only 6 groups are available. Display appears as:

Rl mapp

NoNe

Page 22 of 52

01

Operator Manual Date: 04/05/2009

Ref. No.: m83/om/403 Issue No.: 17

masibus RELC

The Same sequence is followed for Slot 2 Configuration as Relay card: Note: Refer the Back plate details for Relay output connections. For full fledge details of Relay operation refer the Relay Logic Table attached. 6.4.20 OPEN COLLECTOR CARD: 24 open collector outputs are available per card and can be configured as: 1 outputs per channel -- Common output of AL1 and Al2 (OR Type) 2 output per channel output Al1 and Al2 (IND- Type) -- Individual configuration

Discrete LED 1 of AL1 will start flashing .By pressing INC/DEC keys; you can set the required group for channel 1. By pressing NEXT key here you can go to next channel and similarly the group for any channel can be set. Also one can select No group prompt for avoiding the channel in any group.

Grp1

All relay operations are based on grouping of channels. On pressing VFY key menu will shift back to upper level and on pressing NEXT key Relay configuration parameter appears:

01 NGrp

RELAY STATUS OF AL1:

OF

OR

on

CrL1

Configures normal relay status as ON or OFF for AL1 Relay. This is common for all groups. If GP mode is selected as 1rELy, then only CrL1 will be displayed. If GP mode is selected as 2rELy, then both CrL1 and CrL2 will be displayed.

When the output is selected as OR Type, one open collector output is available per channel and is activated when any of AL1 or AL2 alarm limit is crossed. When the output is selected as IND Type, two open collector output is available per channel corresponding to AL1 and AL2 limits. In order to configure Slot 1 as Open collector output , Select Open collector output on display prompt,

RELAY STATUS OF AL2:

OF

OR

on

Configures normal relay status as ON or OFF for AL2 Relay. This is common for all groups. If it is configured as ON, relay will remain ON when all channels of that group are in clear status. This is useful for specific applications where Scanner ON is used for making a contact for failsafe operation, i.e. user wants to sound buzzer or annunciator when Scanner is turned OFF or it is not working. NOTE: This parameter will be displayed only if 2rELy mode is selected. Pressing NEXT key displays the configuration for Slot 2:

CrL2

By pressing NEXT key a parameter for Open collector output type can be configured (IND or OR type)

S1 oPEC

Note: Open collector type options is common for both Slot 1 and Slot 2 configuraiton . An open collector output follows the Led Indication as seen on Front panel. Refer back plate details for Open collector output connections.

Page 23 of 52

In or oCty

OR

S2

Operators manual Date: 04/05/2009

Ref. No.: m83/om/403 Issue No.: 17 6.4.21 RETRANSMISSION OUTPUT: Two Isolated 4-20mA with 0.25% accuracy of full scale & Loading up to 250, Retransmission output is available per card. Slot1 or Slor2 can be configured for Retransmission output. When both the slots are configures as Retransmission card, a total of 4 Isolated Retransmission output is available with two auxiliary cards. Retransmission output can be configured as either Minimum or Maximum of channels mapped to Retransmission groups. Any channel can be mapped to any Retransmission group. (2 in case of one Retransmission card and 4 in case of two Retransmission card). When Output configuration is set as Maximum, channel whose output is maximum in that group will be transmitted as 4-20mA equivalent. When Output configuration is set as Minimum, channel whose output is minimum in that group will be transmitted as 4-20mA equivalent. Channels those are OPEN or skipped are not considered for Retransmission output. As for an Example: Analog o/p of 4 to 20mA. Analog O/P will follow as the below indication: Set zero = 0. Set span = 500. mA Min/Max 4 4 Process open UNDER -25 (5%) value on display mA Process value on display 4 0 20 500 20 525(5%)

masibus rt mapp

Press Auto/Man key to enter into mapping configuration. Individual channels are displayed with there mapping onto groups. If both the slots are selected as Retransmission output a total of 4 Retransmission groups are available, 2 groups per card where as if only single slot is configured as Retransmission output, only 2 groups are available. Display appears as:

Discrete LED 1 of AL1 will start flashing .By pressing INC/DEC keys; you can set the required group for channel 1. By pressing NEXT key here you can go to next channel and similarly the group for any channel can be set. Also one can select No group prompt for avoiding the channel in any group.

01 Rgp1

On pressing VFY key menu will shift back to upper level and on pressing NEXT key Retranmission group configuration parameter appears:

01 NGrp

mA 20 Min/Max Process value OVER OPEN on display In order to select Retransmission output, enter Retransmission card at display prompt,

Press Auto/Man key to enter into output configuration. In this Menu output group can be configured as either Maximum or Minimum output of channels of that group.

rt cnfg

On pressing NEXT key a menu for Retransmission mapping is displayed wherein any channel can be mapped to any Retransmission group.

S1 RtrC

Discrete LED 1 of AL1 will start flashing .By pressing INC/DEC keys; you can set the required output configuration for Group1. By pressing NEXT key here you can go to next output group. Same Menu appears for Slot 2Configuration.

g1 Max OR mIN

Page 24 of 52

Operator Manual Date: 04/05/2009

Ref. No.: m83/om/403 Issue No.: 17 6.4.22 PRINTER OUTPUT: Centronics (Parallel) printer can be interface through a parallel printer card. Slot 1 or Slot 2 can be set for Printer output. In order to configure the slot for printer output selected Printer card on display prompt,

masibus

3. Seconds: This prompt is used to set Seconds (0-59)for Real Time RTC. Display will show:

Online printing at regular interval (Print time as set in Program mode) is available on printer output. Also Hot printing facility is available through SCN/PRN key in run mode. In order to reset the printing sequence printer page reset option is used (Page Reset parameter in program mode) Note: Only one printer output can be available at a time. Since scanner is equipped with both serial and parallel printer interface following priority of operations are defined: Serial printer is given highest priority if configured serial printing and then parallel Centronics output. Only one at a time. If both Slot 1 and Slot 2 are configured as Printer output Slot 1 is given highest priority . Pressing NEXT key displays the Date and Time setting of Real Time Clock (RTC) specifically used for Printer output. Time stamp setting is common for both Slot 1 or Slot 2.

S1 PRNC

4. Day: This prompt is used to set day (17)(Sunday = 1)for Real Time RTC. Display will show:

24 seC

5. Date: This prompt is used to set date (131)for Real Time RTC. Display will show:

4 day

6. Month: This prompt is used to set Month (1-12)for the Real Time RTC. Display will show:

28 date 12 mth

7. Year: This prompt is used to set Year (099)for the Real Time RTC. Display will show:

TIME STAMP SETTINGS:

Press INC or parameters. DEC key to set following

7 YEAr

6.5 VERIFY CONFIGURATION MODE

Example: 15:12:24 28/12/05 Wednesday 1. Hour: This prompt is used to set Hour (023)for Real Time RTC.Display will show: This mode is to verify all the configuration parameters like scanner type, input type, no. of groups, no. of channels in each group, decimal point, zero, span etc. User can view the data but cant change the data in this mode. For entering into verify configuration mode, press VFY key in RUN mode and VFY LED will glow to indicate the mode selection and display will ask to select the mode. By pressing increment and decrement key select VCFG option and press ENTER key. Then press NEXT key to enter in verify configuration mode. Pressing VFY key will take you out of this mode.

Page 25 of 52 Operators manual Date: 04/05/2009

2. Minutes: This prompt is used to set Minutes (0-59)for Real Time RTC.Display will show:

15 hour 12 mIN

Ref. No.: m83/om/403 Issue No.: 17

masibus

This gives selection for Input, Output or Self check calibration. Press INC or DEC key to select the calibration type. If retransmission output is selected then, by pressing ENT key output calibration is selected. On pressing INC key Retransmission output Calibration prompt appears:

6.6

VERIFY PROGRAM MODE

This mode is to verify the alarm limits, scan time and channel skip information. User can view the data but can not change it in this mode. For entering into verify program mode, press VFY key in RUN mode and VFY LED will glow to indicate the mode selection and display will ask to select the mode. By pressing increment and decrement key select VPGM option and press ENTER key. Then press NEXT key to enter in verify program mode. Pressing VFY key will take you out of this mode.

Op CLch

If retransmission output is not selected then, their calibrations prompt will not appear. For input calibration, On pressing next key following prompt appears:

6.7

CALIBRATION MODE

You can calibrate instrument after entering in configuration mode, press SCN TIME key to enter into Calibration mode. Here there are 5 groups of calibration. Group 1: E-t/c, Jt/c, Kt/c, Tt/c. Group2: Bt/c, Rt/c, St/c. Group3: RTD0, Group4: RTD1, PT46, CU53 Group4: 0-5V, 4-20mA. Calibration can be done in any one channel only for each group. Calibration done in any one channel will hold for all the channels that has I/P type of that group only. For the first group the calibration done is of I/P type Kt/c. For the second group the calibration type is Rt/c. For the third group the calibration type is RTD0. For the fourth group the calibration type is RTD1 and for the fifth group the calibration type is 0-5V. i.e. if you want to use any channel in Jt/c then first you have to calibrate any channel as per any I/P type of group: 1. This calibration will hold for all the four types of first group. Similar is the case with all the groups. One shot calibration feature is implemented for both input as well as output. For one shot calibration calibrate zero and Span sequentially. There is no need of calibration for digital input. In calibration mode following values are displayed and programmed as follows. When you press SCN TIME key display will be as follows:

I ChNo

Select your channel for calibration by using INC/DEC keys. After selecting calibration channel press enter to change calibration parameter. It is mandatory to press enter if you want to change calibration parameter of particular channel. 6.7.1 AMBIENT CALIBRATION

CA 027

It will display current reading of ambient temperature. Use INC or DEC key to bring it to correct value and press ENTER key to store ambient temperature. To come out of calibration mode press VFY key. 6.7.2 ZERO CALIBRATION

CZ 054

It will display current reading of calibration channel. Use INC or DEC key to bring it to desired value and press ENTER key to store zero calibration. Display will shoe Wait message during calibration. On both sides 10% of total span is allowed for adjustment.

Operator Manual Date: 04/05/2009

Ip CLch

Page 26 of 52

Ref. No.: m83/om/403 Issue No.: 17 To come out of calibration mode press VFY key. 6.7.3 SPAN CALIBRATION

masibus

Display will show Wait message during calibration. On both sides 10% of total span is allowed for adjustment. To come out of calibration mode press VFY key. 6.7.5 RETRANMISSION SPAN CALIBRATION

It will display current reading of calibration channel. Use INC or DEC key to bring it to desired value and press ENTER key to store span calibration. On both sides 10% of total span is allowed for adjustment. After pressing ENTER at span, unit under goes one shot Calibration (in case of sequentially calibration of zero and span) with a WAIT message on display. Calibration is completed then after.

CS 1000

Cs 2. 0.800

It will display current reading of calibration channel. Use INC or DEC key to set the mA value exactly same as at Ampere-meter reading connected at output. Now Press ENTER key to calibrate O/P for 20 mA. Display will show Wait message during calibration. On both sides 10% of total span is allowed for adjustment. To come out of calibration mode press VFY key.

If output calibration is selected then, On pressing next key following appears:

prompt

I ChNo

Select your channel for calibration by using INC/DEC keys. After selecting calibration channel press enter to change calibration parameter. It is mandatory to press enter if you want to change calibration parameter of particular channel. 6.7.4 RETRANSMISSION ZERO CALIBRATION

CZ 3.200

It will display current reading of retransmission output. Use INC or DEC key to set the mA value exactly same as at Amperemeter reading connected at output. Now Press ENTER key to calibrate O/P for 4 mA.

Page 27 of 52 Operators manual Date: 04/05/2009

Ref. No.: m83/om/403 Issue No.: 17

masibus

Final Output Table

Input: RTD Range: -200 deg C to 850 deg C Retransmission o/p: 4 to 20mA. Retransmission o/p will follow as the below indication. Set zero= 0, Set span = 500

Open sensor UNDER UP mA O/P Retrasmission DOWN 3.2 mA 3.2 mA 4 mA 4mA<O/P <20mA 20 mA 20.8 mA 20.8 mA 3.2m A 3.2 mA

Process value on display

-25 (5%) 3.2 mA

0 4 mA

0<PV< 500 4mA<O/P <20mA

500 20 mA

525 (5%) 20.8 mA

OVER 20.8 mA

OPEN 20.8 mA

Note: 1. For above table default I/P type is RTD. 2. For TC I/P above table is also applicable. 3. For Linear input type 5% of input range, over and under conditions of above table are not applicable.

Page 28 of 52

Operator Manual Date: 04/05/2009

Ref. No.: m83/om/403 Issue No.: 17

masibus

Relay logic table

ALARM AL1 MOMEMTARY ALARM (when in abnormal condition ack not pressed) ACK NORMAL * *** FLASH OFF OFF OFF FLASH ON FLASH OFF OFF OFF FLASH ON FLASH OFF OFF OFF FLASH ON OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF

For 2 relay settings:

CONDITION ALARM LATCH = LAMP YES HIGH ***** TRIP NO RELAY RELAY LAMP RELAY ALARM LATCH = LAMP YES LOW ***** TRIP NO RELAY RELAY LAMP RELAY ALARM LATCH = LAMP YES VLOW NO TRIP RELAY RELAY LAMP RELAY ALARM AL2 MOMEMTARY ALARM ALARM LATCH = LAMP ALARM LATCH = LAMP ALARM LATCH = LAMP

NORMAL ABNORMAL UP (O/S) DOWN (O/S) ACK ** OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF FLASH ON FLASH ON FLASH ON FLASH ON FLASH ON FLASH ON FLASH ON FLASH ON FLASH ON FLASH ON FLASH ON OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF FLASH ON FLASH ON OFF OFF FLASH ON FLASH ON OFF OFF

(when in abnormal condition ack not pressed) ACK NORMAL * *** FLASH OFF OFF OFF FLASH ON FLASH OFF OFF OFF FLASH ON FLASH OFF OFF OFF FLASH ON OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF Page 29 of 52

CONDITION ALARM LATCH YES VHIGH ALARM LATCH NO TRIP LAMP RELAY LAMP RELAY LAMP RELAY ALARM LATCH YES HIGH ALARM LATCH NO TRIP LAMP RELAY LAMP RELAY LAMP RELAY ALARM LATCH YES LOW ALARM LATCH NO TRIP LAMP RELAY LAMP RELAY LAMP RELAY

NORMAL ABNORMAL UP (O/S) DOWN (O/S) ACK ** OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF FLASH ON FLASH ON FLASH ON FLASH ON FLASH ON FLASH ON FLASH ON FLASH ON FLASH ON FLASH ON FLASH ON OFF OFF FLASH ON FLASH ON OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF FLASH ON FLASH ON OFF OFF

Operators manual Date: 04/05/2009

Ref. No.: m83/om/403 Issue No.: 17

masibus

(when in abnormal condition ack is pressed) DOWN NORMAL ABNORMAL UP (O/S) (O/S) ACK ** OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF FLASH ON FLASH ON FLASH ON FLASH ON FLASH ON FLASH ON FLASH ON FLASH ON FLASH ON FLASH ON FLASH ON OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF FLASH ON FLASH ON OFF OFF FLASH ON FLASH ON OFF OFF STEADY ON STEADY OFF STEADY ON STEADY ON STEADY OFF STEADY ON STEADY ON STEADY OFF STEADY ON

ALARM AL1 MAINTAINED ALARM CONDITION ALARM LATCH = LAMP YES HIGH ***** TRIP NO RELAY RELAY LAMP RELAY ALARM LATCH = LAMP YES LOW ***** TRIP NO RELAY RELAY LAMP RELAY ALARM LATCH = LAMP YES VLOW NO TRIP ALARM AL2 MAINTAINED ALARM CONDITION ALARM LATCH YES VHIGH ALARM LATCH NO TRIP LAMP RELAY LAMP RELAY LAMP RELAY ALARM LATCH YES HIGH ALARM LATCH NO TRIP LAMP RELAY LAMP RELAY LAMP RELAY ALARM LATCH YES LOW ALARM LATCH NO TRIP Notes : * means normal condition after abnormal has occurred ** means ack pressed in abnormal condition *** means ack pressed in normal condition after abnormal has already occurred. ***** means this logic will also be apply for 1relay settings for HIGH & LOW respectively. LAMP RELAY LAMP RELAY LAMP RELAY (when in abnormal condition ack is pressed) DOWN ACK ** NORMAL ABNORMAL UP (O/S) (O/S) OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF FLASH ON FLASH ON FLASH ON FLASH ON FLASH ON FLASH ON FLASH ON FLASH ON FLASH ON FLASH ON FLASH ON OFF OFF FLASH ON FLASH ON OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF FLASH ON FLASH ON OFF OFF STEADY ON STEADY OFF STEADY ON STEADY ON STEADY OFF STEADY ON STEADY ON STEADY OFF STEADY ON RELAY RELAY LAMP RELAY ALARM LATCH = LAMP ALARM LATCH = LAMP ALARM LATCH = LAMP

NORMAL * ACK *** STEADY OFF OFF OFF STEADY ON STEADY OFF OFF OFF STEADY ON STEADY OFF OFF OFF STEADY ON OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF

NORMAL * ACK *** STEADY OFF OFF OFF STEADY ON STEADY OFF OFF OFF STEADY ON STEADY OFF OFF OFF STEADY ON OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF OFF

Page 30 of 52

Operator Manual Date: 04/05/2009

Ref. No.: m83/om/403 Issue No.: 17

masibus

Auxiliary options table

Auxiliary options available for scanner under Slot1 and Slot2 Configuration.

Sr. No 1 Output Type Relay output (3 Groups) SLOT: 1 Relay card (RELC) SLOT: 2 No card (NONE) Remarks

Relay output (6 Groups)

Relay card (RELC)

Relay card (RELC)

Retransmission output 2 channels Retransmission output 4 channels Relay output (3 Groups) & Retransmission output ( 2-channels)

Retransmission card (RTRC) Retransmission card (RTRC) Relay card (RELC) / Retransmission card (RTRC)

No card

(NONE)

Retransmission card (RTRC) Retransmission card (RTRC) / Relay card (RELC)

Open collector output 8516,8524 IND type Open collector output 8508 IND type Open collector output 8508,8516,8524 OR type Centronics Printer Output (Parallel printer Interface) Centronics Printer Output (Parallel printer Interface) No output

O/C card (OPEC)

O/C card (OPEC)

IND type configuration IND type configuration OR type configuration

O/C card (OPEC)

No card (NONE)

O/C card (OPEC)

No card (NONE)

No card (NONE)

Printer card (PRNC)

Relay output (3 Groups)

Printer card (PRNC)

No card (NONE)

No card (NONE)

Note:

For different combinations of output slot marked with No card (NONE) can be configured for other outputs as required as explained in above table. Only single printer output is available at a time. Serial printer is given highest priority if configured as serial printer and then printer of Slot 1 if both the slots are configured as printer output.

Page 31 of 52 Operators manual Date: 04/05/2009

Ref. No.: m83/om/403 Issue No.: 17

masibus

Check the calibration of the unit. Check that proper zero-span range is programmed or not.

10 Trouble shooting

Scanner does not Switch ON. Check the Mains Cord. I/P power may be not present. Check power supply voltage is it proper as per order Check fuse, if blown off replace it Check the Power ON Indication LED.

Reading indicated by scanner is unstable, wrong or open. Checks the process input and also check its connection are as per the back-plate supplied. Ensure the perfect EARTHING to the unit & also check that neutral should not be floating. Shielded cables should used for input. Shield should be EARTHED near the unit only. Check any of the sensor is not getting EARTHED or having weak insulation with respect to earth. If so, remove that sensor and check the cabling. Check the lead resistance of all the three arms of RTDs. All the three leads should have same lead resistance. If no, change the cables. Check that Input cables are properly tighten with back-plate Check that back-plate is not loose. Take separate earth wires for separate instruments, avoid looping of earth wires. If scanner is showing different reading in all channels for common I/P type and same Process vale then please enter I/P type again. Check for AC voltage pick up at the signal at scanner side All low-level input and output such as T/C, Rtd, Linear I/P and control signal wires must be kept separate from supply and relay output cabling. Communication Problem between the Unit and Host PC/Operator Terminal Check the cabling. Check the serial No. and baud rate settings at PC side and scanner side. Check the RS-485 to RS232 converter for 485 communications. Check the serial port of the computer by shorting 2 and 3 no

Calibration of the unit is doubted to have drifted. Check the O/P of sensor is as per the chart supplied to you by sensor manufacturer. Measure it with instrument with better then 0.1% accuracy. Standard multi-meter with 3 digit display may have poor accuracy then scanner. For temperature measurements check position of the sensor and check for the problem related to sensor first. Calibrate the unit as explained in the manual. Select the proper method according to your scanner input type.

In linear type input the unit shows false reading or OVER or UNDER. Check for the polarity of the I/p connections. Check that the 250 resistor is connected across the I/P terminals, if the I/P type is 4 20 mA. 250 resistor is mandatory for linear I/P type 4 to 20mA. Check the current I/P coming from the field, it may be below 4 or over 20 mA. Check for the proper range programmed in that channel. In thermocouple type input the reading indicated has got some error. Check for the proper I/p type selected. Ensure that the compensating cables used are of proper type and connected in proper direction Positive and negative.

Page 32 of 52

Operator Manual Date: 04/05/2009

Ref. No.: m83/om/403 Issue No.: 17 pin of PC comports with PROCOMM or any other available application. Check RS 232 RS 485 connection at PC and scanner side. For RS 485 sometimes terminating resistor of 120 at scanner and converter side. In most of the cases this is not required for scanner.

masibus

of channel no. display will glow, if the parameter data in EEPROM is disturbed. If you change any individual I/P type or common I/P type then please also adjust your particular channel span value, Zero value and alarm-trip setpoints.

Relay or open collector O/P Action problem Check power to the contactor operated by relay from scanner. If relay card or open collector card burns out frequently check for the rating of the relay driven by open collector card or rating of contactor driven by relay card. General It is mandatory to reset the Instrument by switching off the Power if the input type is changed. In Configuration, Program, Verify Configuration, Verify Program and Calibration modes, 20 Sec time out is provided i.e. if no key is pressed for 20 seconds; it will fall back into Run/Man mode. While programming value, if the INC or DEC key is kept pressed for more than 10 counts, the Speed of change will be increased by 5 times. It is the dual speed concept for changing value at faster rate. On power on scanner will first display model (8508/8516/8524), then configuration type for some time and then it will come to actual Run mode display. If there is any error in EEPROM data, it will display error message and halt.

SUPPLY VOLTAGE

Supply voltage should be given through a good isolation transformer. This being a microprocessor based instrument, a massive voltage spike can damage it. A good isolation transformer shields the instrument from such voltage spikes and surges. All supply connections to final control devices such as contactors, solenoids etc. must be taken directly from the supply and not from the supply terminals of the instrument. An effective earth is mandatory for the instrument. I n absence of proper earthing instrument body will float at half some part of the supply voltage and this may give shock to user. When power supply LED not glowing change fuse as per table FUSE selection. FUSE Selection:Supply Voltage FUSE 85V to 265V AC/125V to 280V DC 22V to 30V DC 110V DC 2A

2A 2A

The upper two digit display will show no. of parameters having errors and lower 4 digit display will show -err message. To see the parameter having error, scan through parameters Both in Program mode & Configuration mode. The decimal point of first digit

10 -Err

This is an electronics instrument it may have problem not listed above, in case of such fault while reporting to factory (Masibus area office or head office), mention exact nature of fault with sequence of events.

Page 33 of 52 Operators manual Date: 04/05/2009

Ref. No.: m83/om/403 Issue No.: 17

masibus

11. Modbus detail

11.1. INTRODUCTION

The scanner 85XX can be connected in RS-485/RS232 communication data link either in multi drop or repeat mode. Each scanner 85XX must have unique Serial Number. Two scanners may not have the same address. Entire range of addresses (1 to 99) may be used. Before starting any communication, choose a baud rate and protocol compatible to the host computer. Only two-pass protocol is available on scanners and hence when using the scanners, only two-pass protocol is assumed. This speeds up the total throughput.

11.2. COMMUNICATION PROTOCOL

The communication protocol is a HEX protocol. The host computer issues the commands to the scanners that in turn respond to each command. The entire protocol is based on the command/answer pr otocol. 11.3.1. How Characters are transmitted serially When messages are transmitted on standard Modbus serial networks, each character or byte is sent in this order (left to right): Least Significant Bit (LSB) ... Most Significant Bit (MSB) With RTU character framing, the bit sequence is:

i.e.

1 start bit, 2 Stop bit for none parity, . 11.3.2. MESSAGE QUERY:

Page 34 of 52

Operator Manual Date: 04/05/2009

Ref. No.: m83/om/403 Issue No.: 17

masibus

11.3.3. RTU Framing

11.3.4. START DELAY and ADDRESS: Always contains the start of message with 3.5 null char delay followed by the address of the scanner to be addressed. The address is represented by a HEX character ranges from 00 to 99. 11.3.5. FUNCTION: When a message is sent from a master to a slave device the function code field tells the slave what kind of action to perform. In scanner 85XX the functions implemented are 01 READ COIL STATUS (REFERENCE - 0x). 05. FORCE SINGLE COIL (REFERENCE - 0x). 03. READ HOLDING REGISTERS (REFERENCE- 4x). 06. PRESET SINGLE REGISTER (REFERENCE - 4x). Here Same Reference Functions are used for Reading and writing a parameter, so only one Variable Tag is required for reading and writing a parameter. 11.3.6. DATA FIELD: Read: The query message specifies the starting register and quantity of registers to be read. Registers are addressed starting at zero- registers 1 ... 12 are addressed as 0 ... 11. The quantity of channels must not exceed (total no of channels starting channel address). Write: The query message specifies the register address and the data to be written in that register. Registers are addressed starting at zero- register 1 is addressed as 0.

Page 35 of 52 Operators manual Date: 04/05/2009

Ref. No.: m83/om/403 Issue No.: 17 11.3.7. CHECKSUM COMPUTATION:

masibus

The error-checking field contains a 16-bit value implemented as two eight-bit bytes. The error check value is the result of a Cyclical Redundancy Check (CRC) calculation performed on the message contents. 11.3.8. CRC calculation: The CRC field checks the contents of the entire message. It is applied regardless of any parity check method used for the individual characters of the message. The CRC value is calculated by the transmitting device, which appends the CRC to the message. The receiving device recalculates a CRC during receipt of the message, and compares the calculated value to the actual value it received in the CRC field. If the two values are not equal, an error results. The CRC is started by first pre loading a 16-bit register to all 1's. Then a process begins of applying successive eight-bit bytes of the message to the current contents of the register. Only the eight bits of data in each character are used for generating the CRC. Start and stop bits, and the parity bit, do not apply to the CRC. During generation of the CRC, each eight-bit character is exclusive ORed with the register contents. Then the result is shifted in the direction of the least significant bit (LSB), with a zero filled into the most significant bit (MSB) position. The LSB is extracted and examined. If the LSB was a 1, the register is then exclusive ORed with a preset, fixed value. If the LSB was a 0, no exclusive OR takes place. This process is repeated until eight shifts have been performed. After the last (eighth) shift, the next eight-bit byte is exclusive ORed with the register's current value, and the process repeats for eight more shifts as described above. The final content of the register, after all the bytes of the message have been applied, is the CRC value. When the CRC is appended to the message, the low-order byte is appended first, followed by the high-order byte. 11.3.9. MESSAGE RESPONSE:

Page 36 of 52

Operator Manual Date: 04/05/2009

Ref. No.: m83/om/403 Issue No.: 17

masibus

11.3. COMMUNICATION PROTOCOL IN SCANNER

11.3.1. Process Value read and Alarm Trip Set-point value read write Data read Query = [0 x Sr.No.], [0 x Fun Code], [0 x ADD. High], [0 x ADD. Low], [0 x Data. High], [0 x Data. Low] [0 x CRC Low] [0 x CRC High] Fun code = 0X03 Data word - Address word < 73. Response = [Sr.No.], [0 x Fun Code], [Byte count], [Data High], [Data Low] ... [Data. High], [Data. Low] [0 x CRC Low] [0 x CRC High] Data write Query = [0 x Sr.No.], [0 x Fun Code], [0 x ADD. High], [0 x ADD. Low], [0 x Data. High], [0 x Data. Low] [0 x CRC Low] [0 x CRC High] Fun code = 0X06 Data word - Address word < 73. Response = [Sr.No.], [0 x Fun Code], [ADD High], [ADD Low], [Data. High], [Data. Low] [0 x CRC Low] [0 x CRC High] 11..3.1.

Sr.no 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. CH1 CH2 CH3 CH4 CH5 CH6 CH7 CH8 CH9 CH10 CH11 CH12 CH13

Process value Addresses

Absolute Address 40001 40002 40003 40004 40005 40006 40007 40008 40009 40010 40011 40012 40013 Type of Access Read Read Read Read Read Read Read Read Read Read Read Read Read only only only only only only only only only only only only only Parameter Type Int Int Int Int Int Int Int Int Int Int Int Int Int Values Applicable NA NA NA NA NA NA NA NA NA NA NA NA NA Page 37 of 52

Analog Parameters

Operators manual Date: 04/05/2009

Ref. No.: m83/om/403 Issue No.: 17

14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. CH14 CH15 CH16 CH17 CH18 CH19 CH20 CH21 CH22 CH23 CH24 40014 40015 40016 40017 40018 40019 40020 40021 40022 40023 40024 Read Read Read Read Read Read Read Read Read Read Read only only only only only only only only only only only Int Int Int Int Int Int Int Int Int Int Int

masibus

NA NA NA NA NA NA NA NA NA NA NA

Note: Display on scanner will show over when process value is higher then 5 % of individual span, at that time scanner will send process value fed to it to PC. Same way when process value is lower then 5 % of individual zero scanner will show under on its display but it will send process value fed to it to PC. If scanner process value is out of limit for particular I/P type then scanner will show Open on display but it will send 10000 to PC Skipped channel value will be zero, if scanner is restarted after channel is skip. If scanner is not restarted it will give OLD process value. 11..3.2.

Sr. No. 25. 26. 27. 28. 29. 30. 31. 32. 33. 34. 35. 36. 37. 38. 39. 40. 41. 42. 43. 44. 45. 46. 47. 48. Analog Parameters ALM1_1 ALM2_1 ALM3_1 ALM4_1 ALM5_1 ALM6_1 ALM7_1 ALM8_1 ALM9_1 ALM10_1 ALM11_1 ALM12_1 ALM13_1 ALM14_1 ALM15_1 ALM16_1 ALM17_1 ALM18_1 ALM19_1 ALM20_1 ALM21_1 ALM22_1 ALM23_1 ALM24_1

Alarm value addresses (AL1)

Absolute Address 40025 40026 40027 40028 40029 40030 40031 40032 40033 40034 40035 40036 40037 40038 40039 40040 40041 40042 40043 40044 40045 40046 40047 40048 Type of Access Read/ Write Read/ Write Read/ Write Read/ Write Read/ Write Read/ Write Read/ Write Read/ Write Read/ Write Read/ Write Read/ Write Read/Write Read/ Write Read/ Write Read/ Write Read/ Write Read/ Write Read/ Write Read/ Write Read/ Write Read/ Write Read/ Write Read/ Write Read/ Write Parameter Type Int Int Int Int Int Int Int Int Int Int Int Int Int Int Int Int Int Int Int Int Int Int Int Int Values Applicable Ind. zero to Ind. Span Ind. zero to Ind. Span Ind. zero to Ind. Span Ind. zero to Ind. Span Ind. zero to Ind. Span Ind. zero to Ind. Span Ind. zero to Ind. Span Ind. zero to Ind. Span Ind. zero to Ind. Span Ind. zero to Ind. Span Ind. zero to Ind. Span Ind. zero to Ind. Span Ind. zero to Ind. Span Ind. zero to Ind. Span Ind. zero to Ind. Span Ind. zero to Ind. Span Ind. zero to Ind. Span Ind. zero to Ind. Span Ind. zero to Ind. Span Ind. zero to Ind. Span Ind. zero to Ind. Span Ind. zero to Ind. Span Ind. zero to Ind. Span Ind. zero to Ind. Span

11..3.3.

Sr. No. 49. 50. 51. 52. 53. 54. Analog Parameters TRIP1_1 TRIP2_1 TRIP3_1 TRIP4_1 TRIP5_1 TRIP6_1

Trip Value Addresses (AL2)

Absolute Address 40049 40050 40051 40052 40053 40054 Type of Access Read/ Write Read/ Write Read/ Write Read/ Write Read/ Write Read/ Write Parameter Type Int Int Int Int Int Int Values Applicable Ind. Ind. Ind. Ind. Ind. Ind. zero zero zero zero zero zero to to to to to to Ind. Ind. Ind. Ind. Ind. Ind. Span Span Span Span Span Span Operator Manual Date: 04/05/2009

Page 38 of 52

Ref. No.: m83/om/403 Issue No.: 17

55. 56. 57. 58. 59. 60. 61. 62. 63. 64. 65. 66. 67. 68. 69. 70. 71. 72. TRIP7_1 TRIP8_1 TRIP9_1 TRIP10_1 TRIP11_1 TRIP12_1 TRIP13_1 TRIP14_1 TRIP15_1 TRIP16_1 TRIP17_1 TRIP18_1 TRIP19_1 TRIP20_1 TRIP21_1 TRIP22_1 TRIP23_1 TRIP24_1 40055 40056 40057 40058 40059 40060 40061 40062 40063 40064 40065 40066 40067 40068 40069 40070 40071 40072 Read/ Read/ Read/ Read/ Read/ Read/ Read/ Read/ Read/ Read/ Read/ Read/ Read/ Read/ Read/ Read/ Read/ Read/ Write Write Write Write Write Write Write Write Write Write Write Write Write Write Write Write Write Write Int Int Int Int Int Int Int Int Int Int Int Int Int Int Int Int Int Int

masibus

Ind. Ind. Ind. Ind. Ind. Ind. Ind. Ind. Ind. Ind. Ind. Ind. Ind. Ind. Ind. Ind. Ind. Ind. zero zero zero zero zero zero zero zero zero zero zero zero zero zero zero zero zero zero to to to to to to to to to to to to to to to to to to Ind. Ind. Ind. Ind. Ind. Ind. Ind. Ind. Ind. Ind. Ind. Ind. Ind. Ind. Ind. Ind. Ind. Ind. Span Span Span Span Span Span Span Span Span Span Span Span Span Span Span Span Span Span

11..3.4.

Sr. No. 73. 74. 75. 76. 77. 78. 79. 80. 81. 82. 83. 84. 85. 86. 87. 88. 89. 90. 91. 92. 93. 94. 95. 96.

Individual Scale Zero Addresses