Beruflich Dokumente

Kultur Dokumente

Selecting The Right Key Performance Indicators

Hochgeladen von

asifraza94Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Selecting The Right Key Performance Indicators

Hochgeladen von

asifraza94Copyright:

Verfügbare Formate

Selecting the Right Key Performance Indicators

An effective set of interlocking indicators provides feedback to individuals, groups, and the enterprise, directing the behavior of all. By Anthony McNeeney, Meridium Measures of performance have been used by management for centuries to review current operational capabilities. Such measures have been used to assess both departmental and corporate performance, as well as trend performance achieved against plan. In many industrial facilities, these measurements are related to safety (number of incidents), environmental (number of releases), costs (percentage of departmental budgets used), and production (comparison of actual vs targeted production output). These measures are needed in order to determine not only if resources and costs have been managed for the production achieved, but also whether the assets or plant remain in good health. Clearly, these measures provide assurance that asset policies in place today do not limit capabilities for tomorrow. In order to define a complete set of performance measures, companies must ensure that simple, workable measures are in place. The real challenge is not only to select those indicators that satisfy budgetary goals, but also to build the activities needed to meet the levels of asset performance required to meet strategic goals. Selecting the right measures is vital for effectiveness. Even more importantly, the metrics must be built into a performance measurement system that allows individuals and groups to understand how their behaviors and activities are fulfilling the overall corporate goals.

BUILDING AND TESTING PERFORMANCE INDICATORS

As with many management issues, it is often best to build a solution in stages. Suggested stages for performance indicators are: 1. Define the links between corporate goals and major operational perspectives. 2. Map these strategic links to required processes in each perspective area. 3. Define a set of near-term and medium-term metrics which drive the new outcomes in each perspective. 4. Define the gaps and dependencies across the organization which will need to be bridged to result in corporate success. 5. Implement the metrics as individual and group scorecards and monitor to secure the strategic results. Use the SMART test S = Specific: clear and focused to avoid misinterpretation. M = Measurable: can be quantified and compared to other data. A = Attainable: achievable, reasonable, and credible under conditions expected. R = Realistic: fits into the organization's constraints and is cost effective. T = Timely: doable within the time frame given. Key performance indicators should be trendable, observable, reliable, measurable, and specific. back to article

PERFORMANCE INDICATORS FOR MANAGING RISK AND IMPROVING PROFITABILITY

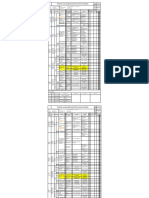

High level goal: Manage Risk and Improve Profitability of Chemical Plant Operations Perspective Reliability Perspective Work Management Perspective Safety and Environmental Perspective Goals: Controlled, audited environmental; safe, audited operational capabilities Strategic KPI Incident rate Safety performance index PHA/reviews completed, number PSM compliance audits, number Significant environmental aspects defined/quantified, number

Goals: Reduce operating Goals: Maximize uptime; Goals: Minimize costs and risks; preserve plant and asset corrective work; restore maximize output integrity asset condition

Strategic KPI Plant availability Number LPO events Time operatingoutside deterioration limits, percent Plant uptime, percent Production targetcompliance

Strategic KPI Plant availability Proactive work orders, percent Emergency work orders on high critical systems, percent Significant deterioration mechanisms improvements Inspection compliance Protective device schedule compliance Quantified reliability target, number Predictive maintenance compliance Operational KPI MTBF by equipment type, area MTBR by equipment type, area MTBM by equipment type, area MTBF growth Cumulative nonavailability of critical assets Unscheduled maintenance events, number Completed work order records on significant failures,

Strategic KPI Planning compliance Work order complete (within 20 percent of planned costs) Proactive work orders, percent Scheduling compliance Assessments of work order complete, number Quantified availability targets, number

Operational KPI Process availability variance Utility variance Product transfer indicator Quality limit excursions, number Actual counter measures, number Startup indicators Shutdown indicators Offspec product Scrap value Inventory

Operational KPI Emergency work orders, percent Reactive work orders, percent Backlog work orders, number Overtime hours, percent Work orders planned, number Cumulative maintenance costs for standing order Average direct cost per maintenance event Work orders

Operational KPI Outstanding items from monthly safety inspection report, number E&S A incidents, number E&S B incidents, number E&S C incidents, number Total days lost days due to injury PHA action items

number Bad actor count Current mechanical availability Mechanical availability trend

scheduled, number Rework, percent Closed work orders within 2 days of schedule, percent

Das könnte Ihnen auch gefallen

- AT&T General Practices: 002-290-459Dokument14 SeitenAT&T General Practices: 002-290-459c3149244Noch keine Bewertungen

- Boeing. Maintenance Reliability. An Overview PDFDokument700 SeitenBoeing. Maintenance Reliability. An Overview PDFJuan Javier Luna Muñoz67% (3)

- Bundle RBI Assessment Using API 581 Philip HenryDokument39 SeitenBundle RBI Assessment Using API 581 Philip Henrymohamedyoussef1100% (2)

- Criteo CLV Report 2019Dokument16 SeitenCriteo CLV Report 2019theghostinthepostNoch keine Bewertungen

- Managing Sales Team Ethics and Sales MoralityDokument2 SeitenManaging Sales Team Ethics and Sales MoralityOsama RasoolNoch keine Bewertungen

- A3 Problem Solving Training Course OutlineDokument1 SeiteA3 Problem Solving Training Course OutlineNedra DebbechNoch keine Bewertungen

- The Path To Operational Excellence Through OperationalDokument5 SeitenThe Path To Operational Excellence Through OperationalNESTOR DURANNoch keine Bewertungen

- Article On Effective Operational ExcellenceDokument4 SeitenArticle On Effective Operational Excellencealaissa cagubcobNoch keine Bewertungen

- VP Continuous Improvement in Chicago IL Resume Mike MicklewrightDokument4 SeitenVP Continuous Improvement in Chicago IL Resume Mike MicklewrightMikeMicklewrightNoch keine Bewertungen

- Understand What Is A Benchmark and How It Is UsedDokument8 SeitenUnderstand What Is A Benchmark and How It Is UsedSharah Del Tabudlong TudeNoch keine Bewertungen

- BPR MethodologiesDokument29 SeitenBPR MethodologiesOsamah S. Alshaya100% (1)

- Quality Element Previous State TQMDokument3 SeitenQuality Element Previous State TQMArdalan_mar2001Noch keine Bewertungen

- The 5 S'S: Japanese Transliterated EnglishDokument4 SeitenThe 5 S'S: Japanese Transliterated EnglishRishita TandonNoch keine Bewertungen

- Kaizen Event 2Dokument20 SeitenKaizen Event 2Elena CavedagnaNoch keine Bewertungen

- Engr. John Lumenick Peñas: Total Productive ManufacturingDokument54 SeitenEngr. John Lumenick Peñas: Total Productive ManufacturingXype LanderNoch keine Bewertungen

- Sustainability Measurement GINDokument36 SeitenSustainability Measurement GINEliasAyoubNoch keine Bewertungen

- Who Has The D Summary by AdeelDokument3 SeitenWho Has The D Summary by AdeelSadiaSadi0% (1)

- Forging New LinksDokument60 SeitenForging New Linkshiwale_sonalNoch keine Bewertungen

- UKFM QRMS 11EB02 Yuvanesan MuthukumaresanDokument27 SeitenUKFM QRMS 11EB02 Yuvanesan MuthukumaresanYuvanesh Yuvan100% (1)

- CSATDokument23 SeitenCSATisaiah khalidNoch keine Bewertungen

- An Instrument For Assessing Lean Service AdoptionDokument35 SeitenAn Instrument For Assessing Lean Service AdoptionRaider622Noch keine Bewertungen

- Continuous Improvement A Complete Guide - 2019 EditionVon EverandContinuous Improvement A Complete Guide - 2019 EditionNoch keine Bewertungen

- Six Sigma - A Case Study - Express Healthcare PDFDokument5 SeitenSix Sigma - A Case Study - Express Healthcare PDFmsulgadleNoch keine Bewertungen

- Iannone and Elena - 2013 - Managing OEE To Optimize Factory PerformanceDokument20 SeitenIannone and Elena - 2013 - Managing OEE To Optimize Factory PerformanceAndrey MatusevichNoch keine Bewertungen

- Lean Manufacturing PrinciplesDokument14 SeitenLean Manufacturing PrinciplesPavithraNoch keine Bewertungen

- Talk 09. Lean & Six SigmaDokument19 SeitenTalk 09. Lean & Six SigmaPhuc Linh100% (1)

- Reliability Software, Weibull Distribution, Test Design, Failure AnalysisDokument6 SeitenReliability Software, Weibull Distribution, Test Design, Failure AnalysisD ARUL KUMARESANNoch keine Bewertungen

- Main Components: Quality Planning, Quality Assurance, QualityDokument6 SeitenMain Components: Quality Planning, Quality Assurance, QualityJen gemudianoNoch keine Bewertungen

- Future of TQMDokument15 SeitenFuture of TQMGreeshma0% (1)

- Reliability Basics II Using FMRA To Estimate Baseline ReliabilityDokument10 SeitenReliability Basics II Using FMRA To Estimate Baseline ReliabilityNdomaduNoch keine Bewertungen

- Lean ManufacturingDokument66 SeitenLean Manufacturingmanpreetsodhi08Noch keine Bewertungen

- 1 Lean GlossaryDokument7 Seiten1 Lean GlossaryHilalAldemirNoch keine Bewertungen

- Conceptual Foundations of Strategic Planning in The Malcolm Baldrige Criteria For Performance ExcellenceDokument19 SeitenConceptual Foundations of Strategic Planning in The Malcolm Baldrige Criteria For Performance ExcellenceWiddiy Binti KasidiNoch keine Bewertungen

- Performance Improvement in Hospitals and Health Systems Managing Analytics and Quality in Healthcare (2nd Edition), Cap 5Dokument32 SeitenPerformance Improvement in Hospitals and Health Systems Managing Analytics and Quality in Healthcare (2nd Edition), Cap 5Daniela LópezNoch keine Bewertungen

- SumTotal Strategic HCM BrochureDokument4 SeitenSumTotal Strategic HCM BrochureSumTotal Talent ManagementNoch keine Bewertungen

- Operations Intelligence Complete Self-Assessment GuideVon EverandOperations Intelligence Complete Self-Assessment GuideNoch keine Bewertungen

- KPIs in ServiceDokument19 SeitenKPIs in ServiceBojan JanjatovicNoch keine Bewertungen

- FEIGENBAUM + Ishikawa + TaguchiDokument7 SeitenFEIGENBAUM + Ishikawa + Taguchiaulia rakhmawatiNoch keine Bewertungen

- MBA 6203 - Assessment 02 Document v3.0 (Group Report) - Group No 06Dokument14 SeitenMBA 6203 - Assessment 02 Document v3.0 (Group Report) - Group No 06andreamuthulakshmiNoch keine Bewertungen

- Fast Track Implementation Program 2015Dokument1 SeiteFast Track Implementation Program 2015rodrigoNoch keine Bewertungen

- Emotional IntelligenceDokument205 SeitenEmotional IntelligenceShashank GuptaNoch keine Bewertungen

- Developing Leaders in Your CompanyDokument2 SeitenDeveloping Leaders in Your CompanySyElfredGNoch keine Bewertungen

- Process Engineer Lean Manufacturing in Freeport TX Resume Douglas WilkinsDokument2 SeitenProcess Engineer Lean Manufacturing in Freeport TX Resume Douglas WilkinsDouglasWilkinsNoch keine Bewertungen

- What Is OEEDokument4 SeitenWhat Is OEEmarcovsouzaNoch keine Bewertungen

- Six Sigma in Healthcare Value ChainDokument30 SeitenSix Sigma in Healthcare Value ChainChowdhury Golam Kibria100% (2)

- L1 Supply Chain Strategy IntroductionDokument21 SeitenL1 Supply Chain Strategy IntroductionEma100% (1)

- Understanding Customer Requirements-CrmDokument47 SeitenUnderstanding Customer Requirements-CrmBenedict MuringakumweNoch keine Bewertungen

- Employee Engagement and Retention Survey in Ten CompanyDokument16 SeitenEmployee Engagement and Retention Survey in Ten CompanypujanswetalNoch keine Bewertungen

- Tests For One Poisson MeanDokument9 SeitenTests For One Poisson MeanJulyAntoNoch keine Bewertungen

- Improving SystemDokument1 SeiteImproving Systemavinash_k007Noch keine Bewertungen

- Cross 1988Dokument11 SeitenCross 1988deltanueveNoch keine Bewertungen

- Sustaining Success " Yash"Dokument30 SeitenSustaining Success " Yash"Kavya SaxenaNoch keine Bewertungen

- KaizenDokument10 SeitenKaizenSiddharth KarakotiNoch keine Bewertungen

- Strategic Management Chap012Dokument49 SeitenStrategic Management Chap012rizz_inkays100% (1)

- Slides of HRM ProjectDokument28 SeitenSlides of HRM ProjectNouman SafdarNoch keine Bewertungen

- Session 10. Discovering Profound Insights Into Operational Excellence (Watson, 2020)Dokument56 SeitenSession 10. Discovering Profound Insights Into Operational Excellence (Watson, 2020)taghavi1347Noch keine Bewertungen

- Lean Six Sigma White Belt Autor University of California San DiegoDokument31 SeitenLean Six Sigma White Belt Autor University of California San DiegoGoran SpasićNoch keine Bewertungen

- KPI For Lean Implementation in Manufacturing PDFDokument14 SeitenKPI For Lean Implementation in Manufacturing PDFHadee SaberNoch keine Bewertungen

- Review of The Regulation of Cosmetic InterventionsDokument67 SeitenReview of The Regulation of Cosmetic InterventionsplastaukNoch keine Bewertungen

- Total Cost Management Presentation PDFDokument18 SeitenTotal Cost Management Presentation PDFDeejaay2010Noch keine Bewertungen

- 3 Reasons Why Project Controls Are An Executive IssueDokument2 Seiten3 Reasons Why Project Controls Are An Executive IssueBrentNoch keine Bewertungen

- BS en 10204Dokument14 SeitenBS en 10204asifraza94100% (1)

- Energy Conservation Calculation Case: Geyser Comparison: Asif Raza Electrical Team LeaderDokument6 SeitenEnergy Conservation Calculation Case: Geyser Comparison: Asif Raza Electrical Team Leaderasifraza94Noch keine Bewertungen

- Man's Worldly GoodsDokument240 SeitenMan's Worldly GoodsHyeonwoo KimNoch keine Bewertungen

- Ghubaar-e-Khatir Urdu Book by Molana Abul Kalam Azad PDFDokument436 SeitenGhubaar-e-Khatir Urdu Book by Molana Abul Kalam Azad PDFasifraza9467% (3)

- India Wins Freedom by Abul Kalam Azad PDFDokument300 SeitenIndia Wins Freedom by Abul Kalam Azad PDFasifraza9467% (3)

- PowerDokument28 SeitenPowerasifraza94Noch keine Bewertungen

- Chapter 06Dokument39 SeitenChapter 06kNoch keine Bewertungen

- Aircraft Rules and Regulations Notes (Semester-5) PDFDokument158 SeitenAircraft Rules and Regulations Notes (Semester-5) PDFsatyam singhNoch keine Bewertungen

- SSAS ProDokument6 SeitenSSAS ProИван ПарлапановNoch keine Bewertungen

- 83-132550-000 Sa1 Ba - 1-54Dokument54 Seiten83-132550-000 Sa1 Ba - 1-54thiagoh179Noch keine Bewertungen

- Risk AssessmentDokument47 SeitenRisk AssessmentcblairNoch keine Bewertungen

- API-581 3rd Thinning Example 2Dokument42 SeitenAPI-581 3rd Thinning Example 2Javier Iglesias75% (4)

- IFB AutomotiveDokument13 SeitenIFB AutomotiveSrc Santhana KrishnanNoch keine Bewertungen

- ANRITSU MS610B DatasheetDokument4 SeitenANRITSU MS610B DatasheetBorut ViNoch keine Bewertungen

- API 580 QuestionsDokument4 SeitenAPI 580 QuestionsMohamed Abdul AzizNoch keine Bewertungen

- Reliability, Availability, MaintainabilityDokument76 SeitenReliability, Availability, MaintainabilityWilly K. Ng'etich100% (2)

- Plant Design White Paper (Cadworx vs. Autoplant)Dokument60 SeitenPlant Design White Paper (Cadworx vs. Autoplant)gustavoemirNoch keine Bewertungen

- Performing Effective MTBF Comparisons For Data Center InfrastructureDokument16 SeitenPerforming Effective MTBF Comparisons For Data Center Infrastructure(unknown)Noch keine Bewertungen

- GE 07-06-11 R002 V1R1 IEC 61508 AssessmentDokument25 SeitenGE 07-06-11 R002 V1R1 IEC 61508 AssessmentHeryanto SyamNoch keine Bewertungen

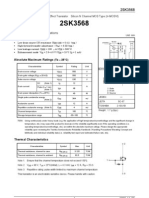

- 2 SK 3568Dokument6 Seiten2 SK 3568Angel De Dios RosoNoch keine Bewertungen

- SMRP Exam CMRP Certified Maintenance and PDFDokument5 SeitenSMRP Exam CMRP Certified Maintenance and PDFrenzo100% (1)

- Potential Failure Mode and Effects Analysis (Pfmea)Dokument3 SeitenPotential Failure Mode and Effects Analysis (Pfmea)aslamNoch keine Bewertungen

- Evaluation The Compressive Strength in CDokument4 SeitenEvaluation The Compressive Strength in CrameshkaaNoch keine Bewertungen

- INCOSE Benefits Limitations of Current Techniques For Measuring System ReadinessDokument36 SeitenINCOSE Benefits Limitations of Current Techniques For Measuring System ReadinesslcatarinoNoch keine Bewertungen

- Stair LiftDokument8 SeitenStair LiftVASNoch keine Bewertungen

- Type PRS Programmable Resettable Sectionalizer Single-Phase: SectionDokument9 SeitenType PRS Programmable Resettable Sectionalizer Single-Phase: SectionLuis MurilloNoch keine Bewertungen

- R5F64 DatasheetDokument103 SeitenR5F64 DatasheetWinston diaz valeraNoch keine Bewertungen

- Dependability and Security SpecificationsDokument42 SeitenDependability and Security SpecificationsYrreg GerryNoch keine Bewertungen

- International Gcse: Geography (9-1)Dokument14 SeitenInternational Gcse: Geography (9-1)Fahmy AbdiNoch keine Bewertungen

- HPD L15a7Dokument31 SeitenHPD L15a7pachara0032Noch keine Bewertungen

- Power Wizard Range PDFDokument6 SeitenPower Wizard Range PDFSayed Younis SadaatNoch keine Bewertungen

- Neplan Transmission ModuleDokument45 SeitenNeplan Transmission Module386Noch keine Bewertungen

- CBM Ramakrishna ResumeDokument6 SeitenCBM Ramakrishna ResumeramakrishnaNoch keine Bewertungen