Beruflich Dokumente

Kultur Dokumente

V. Hohler, A. J. Stilp and K. Weber - Hypervelocity Penetration of Tungsten Sinter-Alloy Rods Into Aluminum

Hochgeladen von

MermaczOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

V. Hohler, A. J. Stilp and K. Weber - Hypervelocity Penetration of Tungsten Sinter-Alloy Rods Into Aluminum

Hochgeladen von

MermaczCopyright:

Verfügbare Formate

Pergamon

Int. J. lmpactEngng, Vol. 17, pp. 409-418, 1995 Copyright 1995 Elsevier Science Ltd Printed in Great Britain. All rights reserved 0734-743X/95 $9.50+0.00

H Y P E R V E L O C I T Y PENETRATION OF TUNGSTEN SINTER-ALLOY RODS INTO A L U M I N U M

V. Hohler, A. J. Stilp and K. Weber

Fraunhofer-Institut ~ r Kurzzeitdynamik, Ernst-Mach-Institut, Impact Physics Division, Eckerstr. 4, 79104 Freiburg, Germany

Summary--The penetration of tungsten sinter-alloy rods having length-to-diameter ratios of L/D = 10 and 12.5 into alumina targets was investigated in the velocity range Vp = 1.25 to 3 km/s. The depth of penetration (DOP) test and the time resolved oberservation using a 600 kV flash X-ray system were applied to assess the protection efficiency of the ceramics. From DOP tests, the residual penetration into a steel backing yields the differential efficiency factor DEF and the mass efficiency factor MEF. DEF increases with vp; MEF decreases. On the other hand, DEF decre;Lses as ceramic thickness increases; MEF increases and converges to DEF for residual penetration zero. From the time resolved measurements, position and length reduction of the rod during penetration in the ceramics were obtained. The process can be described by Tate's fluid jet model in good approximation. The target resistance parameter R, defined in the modified Bernoulli equation, characterizes the ceramic performance. The average R values are 5.4, 6.1 and 4.8 GPa at impact velocities Vp= 1.7, 2.5 and 3 km/s, respectively, i.e. there is no strong dependence of R on vp. NOTATION CS D DEF DOP E lh HEL HH-RHA HV 1 L0 L MEF p PR Compression strength rod diameter differential efficiency factor depth of penetration Young modulus ceramic sheet thickness Hugoniot elastic limit high hard RHA Viekers hardness instantaneous rod length launched rod length reduced rod length at impact mass efficiency factor semi-infinite penetration in HH-RHA residual penetration in HH-RHA backing R st: sa t u v vp UTS WS Y oil/a2 8 Pc pp pa target material resistance (modified Bernoulli equation) head position of the rod in the ceramics tail position of the rod in the ceramics time penetration velocity instantaneous rod velocity impact velocity ultimate tensile strength tungsten sinter-alloy projectile material flow stress (modified Bernoulli equation) yaw and pitch angles elongation density of ceramcis density of projectile material density of steel

409

410

V. HOHLERet al. INTRODUCTION

The terminal ballistic behavior of ceramics has been the subject of many investigations over the past few years. Wilkins et al. [1, 2] did pioneering work by testing thin ceramic plates with an aluminum backing of finite thickness against armor-piercing (AP) projectiles of small L/D-ratio. Later on, the use of ceramics in heavy armor against rod-shaped penetrators became more and more of interest. One of the basic questions has been how to characterize the performance of brittle materials. Holder and Stilp [3] observed long rods during the penetration of glass with the flash X-ray technique. Based on the material flow of the projectile, which was comparable to that in ductile materials, they proposed, to apply the model of Alekseevskii [4] and of Tate [5] in a first approximation and to use the target resistance parameter R of the modified Bernoulli equation for brittle materials as well.Yaziv et al. [6] defined the differential efficiency factor DEF and the mass efficiency factor MEF. They also found out that the thickness of the backing influences the performance of ceramics. Therefore, in order to get data independent of the backing thickness, Bless et al. [7] introduced the depth of penetration test (DOP) with a semi-infinite backing. Rozenberg and Yeshurun [8] interpreted ceramic efficiency from the static and dynamic fflEL) yield strength for uniaxial strains. Stemberg [9] proposed R values to be in the order of HEL. The DOP test and the time resolved measurements became the basic test methods. The full significance of the DOP test has been mainly investigated by Woolsey et al. [10, 11], Mellgard et al. [12] and Rozenberg and Tsaliah [13]. Anderson and Morris [14] have shown that the R of alumina concluded from DOP tests is roughly independent of the total ceramic block thickness. Burkett et al. [15], Hauver et al. [16] and Yaziv and Partom [17] have applied both test methods to rod projectiles up to L/D = 20. Among other things, they found a strong influence of the cover plate and the lateral confinement on R. Ernst and Hoog [18] tried to interpret the ceramic performance with static material properties, applying dimensional analysis. Recently, computer code simulation has also been used (Anderson et al. [19]) to better understand long rod penetration in brittle materials. All this work mentioned above was done in the ordnance velocity range with the exception of the paper by Bless et al. [7]. They concluded from DOP tests up to 2.8 km/s that MEF of alumina decreases with velocity for AP bullets and behaves roughly independent of velocity for Ta rods with L/D = 5. On the other hand, Kozhushko et al. [20] found from penetration velocity measurements of "elongated copper rods" at 5- 8 km/s an R value for alumina of 26 GPa, which is about 3 to 4 times above HEL. They explained this by the fact that penetration was faster than the crack propagation wave. On the basis of theoretical considerations, Partom and Littlefield [21] postulate an increase of R with velocity in the range up to 3 km/s. Velocities above the ordnance range become more and more important for long rod penetrators. Therefore, the purpose of this paper is to study the influence of velocity upon penetration performance of tungsten sinter-alloy rods (WS) in the case of alumina targets. The velocity range covers 1.25 to 3 km/s. In addition, the thickness of the ceramic tiles and their lateral dimensions, as well as their lateral confinement, were varied. DOP tests and time resolved measurements using a 600 kV flash X-ray system were applied.

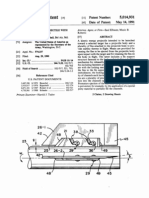

EXPERIMENTS Tests were run with WS rods at four impact velocities vp = 1.25, 1.7, 2.5 and 3 km/s. Two different WS qualities were used. The rods are cylindrical in shape with L/D-ratios of 10 and 12.5. They are launched up to 1.7 km/s by a powder gun and up to 3 km/s by a two-stage light gas gun. The original rod length Lo is reduced at higher velocities to length L by plastic deformation during acceleration. So L means the actual rod length in the moment of impact. The properties of the WS materials and the geometrical parameters of the rods are summarized in Table 1. Fig. 1 shows the DOP target arrangement used up to vp < 1.7 km/s. The total ceramic block thickness h is varied at Vp = const, by fitting different numbers of 20 mm thick A1203 files up to residual penetration pR = 0 in the semi-infinite high hard armor steel backing (HI-I-RHA, material properties s e e Table 1). The lateral dimensions of the tiles are 100, 150 and 180 mm. The ceramic block is laterally confined by 20 mm and in front by 10 mm mild steel plates. The front plate has a 30 mm hole for the rod

Penetration of tungsten-alloy rods into alumina

411

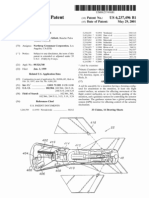

impact. A 1.5 mm rubber foil is inserted in between the front cover plate and ceramics for stress dampening. Pitch and yaw angles are ~,teasured by flash X-ray systems during impact. In the ease of observing the penetrator inside the ceramics, the lateral dimensions of the ceramics and the use of cortfinement are restricted. The available 600 kV flash X-ray system delivers pictures of acceptable qu~dity for maximal lateral tile dimensions of 100 mm. Therefore the target arrangement of Fig. 2 was used for these measurements, performed at Vp >_ 1.7 km/s. Now the ceramic block is only partly Confined because of the 50 mm window for the flash X-ray observation. The ceramic block is built of 20 mm files at 1.7 km/s and of 10 mm tiles at 2.5 and 3 km/s; one test was done with 5 mm and one with 20 mm 1tiles at 3 km/s. The measured parameters are defined in Fig. 3. Time is recorded by triggering the 180 and 600 kV systems with a short circuit trigger foil and by counting the time between the two flashe,. The moment of impact (t = 0) was determined from the 180 kV flash X-ray picture. The accuracy of the penetration time t is + 0.15 Ixs. The uncertainties ofl, s~ and SHare + 0.1 mm and + 0.2 mm, respectively. All ceramic' tiles are square in shape and plane grinded. They are glued together, to the backing, and to the confineraent with a two-component epoxy adhesive. The manufacturer of the Al203 tiles was Hoechst CeramTec, Germany. All files are produced according to the same production procedure, characterized by the trade name A1898. This guarantees a good consistency of the material properties, given in Table 1.

1801<VFLASH X-RAY U 1.5mmRUBBER I

180kV FLASH X-RAY U 1.5mmRUBBER

"

II

CERAMICS

180kVT~

I

|

EERAM,CS

I

-,.ILl

I I I

600kV I

TRIGEERFOIL 10,20ramMILD STEELCONF.

FIG. 1. DOP test arrangement applied at 1.25 and 1.7 km/s.

TRIGGERFOIL

10ramMILD STEEL CONF.

FIG. 2. Arrangement for DOP- and time resolved tests used at vp > 1.7 km/s.

Vp

f=0 L Time = f

t----- v

S~ = / / /

-o

/ / / / /

FIG. 3. Definition of parameters for time resolved measurements.

412

V. HOHLERet al. TABLE 1. PARAMETERSOF ROD PROJECTILESAND TARGETMATERIALS (*NAHM [22])

Projectile Material

WSI WS2 Steel

% [km/s]

1.25/1.7 2.5/3.0 pst

L0 [mm]

72.5 50 UTS [GPal 1.450.1

L0/D

L [mm]

72.5 49.9/49.5

pp [g/cm 3

UTS [GPa]

1.2 0.02 1.49 + 0.015

HV [GPa]

4.2 0.1 5.35 0.1

S [%]

10 1 8.8 2

1

12.5 10 HV [GPal 4.40.2 17.6 17.6

backing

HH-RHA Ceramics A1203

[g/cm 3]

7.85

p,

[g/cm3] 3.8

CS

[GPa] 4.0

HV

[GPa] 21

grain size

[trm] 6 - 12

E

[GPa] 360

HEL

[GPa] 5.3 - 7.5 *

Poisson

ratio 0.24 - 0.26

RESULTS The experimental data are summarized in Table 2. Experiments with Nos. < 2019 are DOP tests (Fig. 1). Experiments with Nos. ___7349 are DOP tests in combination with time resolved measurements (Fig. 2). Beside the test Nos., the symbols used in the diagrams are given. Since Vp in the experiments shows a certain spread sK, sa, 1, u and v have been corrected to Vp = 1.7, 2.5 and 3.0 km/s according to, e.g., sK (Vpl) = (VpI/Vp2)'SK(Vp2). No adjustment of time t was performed, u and v means average velocities with u = sr/t and v = sH/t. R has been calculated on the basis of the modified Bernoulli equation and means an average value referring to penetration time t. Y = 2 and 2.3 GPa were used for WS1 and WS2, respectively. The DOP test reveals the residual penetration PR, the semi-infinite penetration p and the differential and mass efficiency factors with DEF - (p - PR) Psi Po hc MEF = P p~ Pchc +PaPst

PR/P, DEF and MEF are plotted versus po h~/L in Figs. 4, 5 and 6. The normalization by L is needed because of the two different L/D-ratios used in the experiments. The data in these three diagrams refer to the experimental impact velocity vp, i.e., p has been corrected according to the data in Table 3. Sin~ pa/p, DEF and MEF depend only slightly on vp, the corrected data in the diagrams are also valid in good approximation at the four central velocities 1.25 kin/s, etc. The main result of Fig. 4 implies that PR/P increases with Vp. No remarkable change of the curve trace is observed dependent upon Vp. The points marked by an arrow mean extrapolation to PR/p = 0. The corresponding h~ value is some kind of semi-infinite penetration in A1203. At vp = 1.7 knds the influence of the two different confinements (see Figs. 1 and 2) and of the different lateral tile dimensions can be seen. Both confinements behave alike for lateral tile dimensions of 100 mm in the total h~ range. On the other hand, pa is a little less for lateral tile dimensions > 150 mm for p ~ / L > 3.25 (l~ > 60 ram). Therefore, two extrapolated values are given at 1.7 km/s. The time to penetrate 60 mm ceramics is in the order o f t = 65 ~ts (s. Table 2). According to Anderson and Morris [14], edge eff~ts play a role i f t > 2t*, where t* is the average time of the longitudinal and shear waves ne~:led to propagate to the lateral target edge and back to the trajectory. In the case of 100 nun lateral tile dimensions with a 10 - 20 nun confinement, t* is about 18 - 22 ~ts. So it may be concluded that for the test arrangement applied here, edge effects play a role ift > 3 t*.

Penetration of tungsten-atioy rods into alumina

413

The targets built up by 5, 10 or 20 mm thick tiles show a negligible influence of the tile thickness on PR/P at 3 km/s (see Table 2, Nos. 7839, 7843, 7844). The general tendencies of DEF dependent upon Vp and h~ are indicated in Fig. 5. For Vp = const., DEF decreases with h~ and converges at PR = 0 versus MEF, which had already been observed by Ernst and Hoog [18] in the ordnance velocity range. Furthermore DEF grows with vp. This behavior is very interesting and may be expected. However the curves become flatter at higher velocities and come closer together, i.e., fhe increase of DEF with vp is reduced at higher velocities, nearly disappears from 2.5 to 3 km/s and is strongly dependent upon 1~.

TABLE 2. LIST OF DATA

No.

2017 2018 2019 2002 2003 2004 2000 2014 2011 2012 2013 1986 1985 1984 1983 7393 7349 7394 7395 7899 7900 7901 7902 7903 7896 7905 7907 7836 7847 7848 7904 7845 7837 7840 7849 7838 7850 7839 7843 7844 7851 7852

Symbol

No. of cer. tiles of thickness

h,

lat tile dim.

vp

(xl/ct2

l~.(vp)

5

o o o o A A A A V V V V D [] D D + + + + + + + + + + + + + + x 0 + +

1o

20 mm

1 2 3 1 2 3 4 1 2 3 4 1 2 3 4 2 2 3 4

[mm]

19.8 39.6 59.8 20.2 40.1 61.1 81.4 20.0 40.0 60.0 80.0 19.9 39.5 59.6 79.0 40.6 51.0 60.0 80.7 10 20 30 50 70 10 10 10 20.5 19.9 19.6 30 30.8 40.8 41.1 40.4 62.0 69.8 82.0 81.1 80.8 101.2 100.5"

[mm]

180 180 180 100 100 100 100 150 150 150 150 180 180 180 180 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100

Ira/s]

1246 1246 1252 1705 1709 1702 1705 1717 1721 1717 1716 1710 1711 1698 1708 1711 1691 1706 1710 2552 2522 2537 2550 2516 3024 3023 2994 2984 3002 2968 3025 3000 2991 3000 2995 3037 2980 3003 2998 2995 2964 2963

['1

1.0/<1.0 1.0/<1.0 0.01<1.0 0.31<1.0 1.8/<1.0 1.51<1.0 4.8/<1.0 0.81<1.0 <0.51<1.0 0.8/<1.0 1.0/<1.0 0.3/<1.0 0.51<1.0 1.0/<1.0 1.0/<1.0 0.7/<1.0 0.8/<1.0 0.51<1.0 ~1.01<1.0 0.2/1.7 1.0/6.4 0.11<0.5 0.1/1.9 0.50.2 <2.013.1 <1.0/4.8 0.2/1.4 2.01<1.0 0.511.5 3.0/1.6 0.5/0.2 0.03.0 0.3/<1.0 0.2/<1.0 4.8/0.2 0.3/<1.0 <1.0/<1.0 <1.0/<1.0 <1.01<1.0 <1.0/0.0 <1.0/0.1 <111.5

[mm]

17.5 5.0 0.0 42.6 28.9 16.7 4.2 43.4 31.7 14.7 2.8 44.6 30.2 15.2 2.2 29.7 19.4 14.5 4.6 60.2 50.7 39.1 23.9 10.2 66.8 67.0 68.0 58.1 58.3 58.8 50.0 50.2 38.6 40.1 41.3 21.6 18.7 7.5 8.8 9.0 0 0

1 2 3 5 7 1 1 1 2 2 2 3 3 4 4 4 6 7 8 4 15 10 10

414

V. HOHLERet al.

TABLE 2. LIST OF DATA (CONTINUED)

No.

sK

[~1

7393 7349 7394 7395 7899 7900 7901 7902 7903 7907 7847 7848 7904 7845 7849 7850 7843 7844 7852 21.2 26.0 53.0 81.1 5.0 10.6 17.5 29.7 31.5 4.5 3.0 4.2 14.7 12.7 19.3 32.9 39.0 38.7 39.3

Imm]

20.5 24.4 47.6 72.4 7.8 16.4 26.3 44.9 47.2 8.9 5.9 8.2 28.6 25.0 37.6 63.1 72.2 73.4 73.9

Imm]

56.8 52.7 30.5 13.2 45.1 39.9 32.1 21.2 19.3 44.9 46.3 45.1 34.4 36.3 30.9 14.8 7.9 8.4 8.9

[m/s]

961 943 895 888 1560 1547 1503 1511 1498 1973 1967 1952 1945 1969 1948 1918 1852 1897 1881

[Oea]

5.1 5.4 6.0 5.1 5.5 5.7 6.7 6.3 6.4 4.2 4.3 4.7 4.7 4.3 4.8 5.1 5.8 5.4 4.9

TABLE4. SEMI-INFINITE PENETRATION p AND VELOCITY DEPENDENCE OF p IN THE BACKING

S E LI-~-RHA TE

vp

dp/dvp

[km/s]

WSl WSI WS2 WS2

q

-4-

[mm]

33.0 62.4 68.3 76.3

[mm]

72.5 72.5 49.9 49.5

[I0z mm/(m/s)]

6.27 6.27 2.13 1.16

1.25 1.7 2.5 3.0

~. O-

III ill

= 1.25'20/180 [] = 1.7~0/i00 o = I.~,~OAoo

B

dq.

O-

I~

[]

v : L~.~O, aso

~

+ = 3.6'10'100

<> = 3.61/ S;/lO0

= ?....5/1.0//100 =

3.d.~0/I00

~

I

+ ~L

.......

_, . . . . . . . . . . . . . . . . . . . . . . . .

...............

~=ZERO I:~KI'RATION IN ~-rr;r.~B A C K I N G

o.o

1.o

z.o

----r"

rt',_oc~c~ ~/cm*"3)

3.0

.,,.o

5.0

1~---

zo

e.o

FIG. 4. Residual penetration pR versus ceramic block thickness h~. The arrow symbols mark extrapolated values 1~ (PR = 0). 1.25 / 20 / 180 etc. means Vp = 1.25 km/s / 20 mm tile thickness / 180 mm lateral tile dimension.

Penetration of tungsten-alloy rods into alumina

415

iv

m

=._

~.

0

O ~) LX= 1.7/'~0/1,50

t'~

.~4 [] = 1.7,/~/100 l o = 1.7/zo/loo

| /

l@ = 12,5,~0/180 ' f

v = L;~exYlso = z~,,1o;loo

/ ,

+ = 3.0 16/100 <>= 3.6/5/loo

r I

= 3.0~/~, "100

o.o

1.o

z.o ~.o ~.o ~.o ~.o rhoc*hc/L (g/cm**3)

7.0

e.o

FIG. 5. Differential efficiency factor DEF versus ceramic block thickness 1~.

I

i

o I I[I

i, r

!11

= L25,9~O/t80

D = 1.~"67ioo

o = L'~?Z07100 v = 1.7,AZO/leO

= ?.~/I 0 / I 0 0 X = 3.0/~,./100 + = 3.0/10/100

!t

3.0/~/100

0.0

1.0

zo 3.0 ~.o 5.0 6.0 rhoc*he,/L (g/cm**3)

7.0

8.0

FIG. 6. Mass efficiency factor MEF versus ceramic block thickness 1~.

The MEF parameter gives the best quantitative assessment about the protection improvement of a real target using ceramics. The MEF data are plotted in Fig. 6. MEF increases with h and achieves its maximum at PR = 0. Furthermore, MEF goes down with vp for 1~ = const. So an increase of MEF at a higher velocity vp2 becomes possible only since h~ (vp2)can be thicker than 1~ (vpl), ifvp2 > Vpl. Fig. 7 shows some examples of flash X-ray pictures of the penetration process taken with the 600-kV system. No. 71394 is taken from a rod with caliber 5.8 mm, the others from rods with caliber 5 nun. For a better quantitative comparison, picture No. 7394 is reduced by a factor 5/5.8. One may see that the rods behave according to the fluid jet model. There are some discontinuities of the material flow at the interfaces beV~een the tiles. This indicates an influence of the interfaces on the process. On the other hand, such an influence on PR, SK or 1 etc. (see Table 2 and Fig. 7, Nos. 7839, 7843, 7844, 7852) cannot be observed in the tests made at 3 km/s with 5, 10 or 20 mm thick tiles. Therefore a general conclusion cannot be made that tile thickness has a negligible influence. The R data in Table 2 depend on t in the same manner at all velocities. R increases with t during early penetration, achieves a plateau and decreases slightly during late penetration. This behavior had already been observed and explained by Hauver et al. [16] at ordnance velocities. The reduction of R during early penetration occurs only in tests without a cover plate, as done here and is caused by the impact damage. The small reduction during late penetration is explained by the predestruction of the ceramics in front of the rod. The velocity dependence of R is relatively small. The average R data are 5.4, 6.1 and 4.8 GPa at

416

V. HOHLERet al.

1.7, 2.5 and 3.0 km/s. R is in the order of HEL (see Table 1, Sternberg [9]). No increase of R up to 3.0 km/s can be observed, as was expected by Partom and Littlefield [21]. The data for SK, Sa and I are plotted in Figs. 8 and 9 versus normalized time t.vp/L and normalized head position pcsg/L. The curves were calculated on the basis of Tate's model (Tale [5]), using the average R values for A1203 and Y = 2 and 2.3 GPa for WS~ and WS2, respectively. The calculation was done within the limits vp and v', where v' = (2(R-Y)pp) ~/2. Now, according to Anderson et al. [19], the R value of HH-RHA is 5 GPa. Therefore v' is calculated using the R value 5 GPa of HH-RHA at 3 km/s and the average R values 5.4 and 6.1 GPa of AI:O3 at 1.7 and 2.5 km/s, respectively. There is good agreement between experiment and calculation. Some deviations occur during late penetration. It is interesting that the simple one-dimensional model delivers a good description of the process. However this fact should not be overinterpreted. There is a need to develop improved theoretical models. Nevertheless, the R values determined from time resolved measurements can be considered to be characteristic quantities in describing the protection performance of brittle materials also. Fig. 10 shows the average rod erosion (L-I)/sK versus sg. This erosion decreases with vp and behaves according to R, i.e., the erosion increases during early penetration up to a plateau and slows down slightly during late penetration. The decrease during late penetration depends upon Vp and nearly disappears at 3 km/s.

7394

1.7 km/s

7901

2.5 km/s

7904

7843

7844

3 km/s

7852

FIG. 7. Flash X-ray pictures taken from the penetration process.

iF_':= 1.7

20 ' I00, ~.4,

~.~--2.0 G P a

1 f--

~ ~ ~ >: = 3 . 0 ' 2 0 ' I 0 0 , R - ~ . 8 , Y--~3 G P a

q

)~= a.o' "

'~- =

3.0' 16' 100 5;! loo '

- ;--c""

~.~J"~" .';,-

o i

. . 4 ......... ~ "

~ 'o.~

&5

Lo

L5

io

3.0

t'*~'lq,%

FIG. 8. Front and tail positions sK and sa of the penetrating rod versus time t. The curves are calculated according to Tate.

Penetration of tungsten-alloy rods into alumina

417

, "~.

~..~

[] +

o--3.o? 5:, too

= = = =

1.7 / 9.20,/ 100, R=~.4 -, Y = ~ 0 G P a ~/t0 ~ 100, R--~.I, Y - - ~ 3 G P a 3.0 / 2.0/ 100, R=4.8, Y=~.3 G P a 3.6 / tO'/tO0

'".. \'2",.

o.

O-

0.0

t.o

z.o 3.o 4.0 ~.o 6.0 rhoc*sK % (g ~m**3)

--

~i

7.0

8.0

FIG. 9. Residual length 1 versus head position s~:. The curves are calculated.

q

F2 ~2

~2

V2

~2 :: L T / 2 0 / I 0 0

6 4 --

= z.5,'i0/loo

t.o zo

X = 3.0/20/100 3.o ~.0

+ = 3.d/to;'too

5.o

o = 3.0/' 5 / l o 0

I

0.0

6.0

7.0

8.0

rhoc*sK %

(g 'am**3)

FIG. 10. Average rod erosion (L-l) versus head position st:.

CONCLUSIONS The protection efficiency of alumina ceramics against long rod projectiles has been investigated up to an impact velceity of 3 km/s. DOP tests and time resolved measurements were performed. It can be shown that Tate's fluid jet model also describes the penetration process above ordnance velocities in good approximation. The resistance R defined in the modified Bernoulli equation is a good parameter to characterize the protection efficiency of the ceramics. R shows no remarkable dependence on the impact velocity. Despite the good approximation achieved by Tate's model, there is a need to develop an improved description of the process, taking into account, e.g. crack propagation effects.

REFERENCES 1. M . L . Wilkins, C. F. Cline and C. A. Honodel, Fourth progress report of light armor program. Lawrence Radiation Lab. Rept. UCRL-50694 (1969). 2. M . L . Wilkins, R. L. Landingham and C. A. Honodel, Fifth progress report of light armor program. Lawrence Radiation Lab. Rept. UCRL-50980 (1971).

418

V.HOHLER et al.

3. V. Hohler and A. J. Stilp, Visualization of the penetration process of rods into glass and armor steel targets by means of flash X-ray photographs. Proc. 35th ARA Meeting, Meppen, Germany (1984). 4. V.P. Alekseevskii, Penetration of a rod into a target at high velocity. Fizika Goreniya Vzryra, 2, 99 (1966). 5. A. Tate, A theory for the deceleration of long rods after impact. J. Mech. Phys. Solids, 15, 387 (1967). 6. D. Yaziv, G. Rosenberg and Y. Partom, Differential ballistic efficiency of appliqu6 armor. Proc. 9th lnt. Symp. Ballistics, Shrivenham, UK (1986). 7. S. J. Bless, Z. Rozenberg and B. Yoon, Hypervelocity penetration of ceramics, lnt. J. lrapact Engng., 5, 165 (1987). 8. Z. Rozenberg and Y. Yeshurun, The relation between ballistic efficiency and compressiv strength of ceramic tiles. Int. J. lmpact Engng., 7, 357 (1988). 9. J. Sternberg, Material properties determining the resistance of ceramics to high velocity penetration. J. Appl. Phys., 65, 3417 (1989). 10. P. Woolsey, St. Mariano and D. Kokidko, Alternative test methodology for ballistic performance ranking of armor ceramics. Proc. 5th Annual TACOM Armor Coordinating Conference, Monterey, CA, USA (1989). 11. P. Woolsey, Ceramic materials screening by residual penetration ballistic testing. Proc. 13th lnt. Symp. Ballistics, Stockholm, Sweden (1992). 12. I. Mellgard, L. Holmberg and L. G. Olsson, An experimental method to compare the ballistic efficiencies of different ceramics against long rod projectiles. Proc. 11th lnt. Syrup. Ballistics, Brussels, Belgium (1989). 13. Z. Rozenberg and J. Tsaliah, Applying Tate's model for the interaction of long rod projectiles with ceramic targets, lnt. J. lmpact Engng., 9, 247 (1990). 14. Ch.E. Anderson and B. L. Morris, The ballistic performance of confined A1203 ceramic tiles. Int. J. ImpactEngng., 12, 167 (1991). 15. M.W. Burkett, G. E. Cort, R. B. Parker, A. D. Rollett and S. R. Skaggs, Ballistic performance evaluation of 90 wt % A1203 against a subseale kinetic energy long rod penetrator. Proc. 13th lnt. Symp. Ballistics, Stockholm, Sweden (1992). 16. G.E. Hauver, P. H. Netherwood, R. F. Benck, W. A. Gooch, W. J. Perciballi and M. S. Burkins, Variation of target resistance during long rod penetration into ceramics. Proc. 13th lnt. Syrup. Ballistics, Stockholm, Sweden (1992). 17. D. Yaziv and Y. Partom, The ballistic efficiency of thick alumina targets against long rod penetrators. Proc. 14th lnt. Syrup. Ballistics, Quebec, Canada (1993). 18. H.J. Ernst and K. Hoog, Protective power of several ceramics, correlated to some static material parameters. Proc. 13th lnt. Symp. Ballistics, Stockholm, Sweden (1992). 19. Ch.E. Anderson, V. Hohler, J. D. Walker and A. J. Stilp, Penetration of long rods into steel and glass target: Experiments and computations. Proc. 14th lnt. Symp. Ballistics, Quebec, Canada (1993). 20. A.A. Kozhushko, I. I. Rykova and A. B. Sinani, Resistance of ceramics to penetration at impact velocities above 5 km/s. J. de Physique 1V (Colloque C3, suppl, au J. de Physique III), 1, 117 (1991). 21. Y. Partom and D. L. Littlefield, Dependence of ceramic armor resistance on projectile velocity. Proc. 14th lnt. Symp. Ballistics, Quebec, Canada (1993). 22. H. Nahme, Ernst-Mach-Institut. Private communication (1994).

Das könnte Ihnen auch gefallen

- Khodadad Vahedi Et Al - Performance Optimization of A Long Rod Penetrator Penetrating Into A Semi-Infinite Target Considering Bending CharacteristicsDokument12 SeitenKhodadad Vahedi Et Al - Performance Optimization of A Long Rod Penetrator Penetrating Into A Semi-Infinite Target Considering Bending CharacteristicsMermacz0% (1)

- Planning Guidance For Response To A Nuclear Detonation-2nd Edition FINALDokument135 SeitenPlanning Guidance For Response To A Nuclear Detonation-2nd Edition FINALCathalijne ZoeteNoch keine Bewertungen

- William S. de Rosset - An Overview of Novel Penetrator TechnologyDokument43 SeitenWilliam S. de Rosset - An Overview of Novel Penetrator TechnologyMermaczNoch keine Bewertungen

- O. Andersson and J. Ottosson - High Velocity Jacketed Long Rod Projectiles Hitting Oblique Steel PlatesDokument8 SeitenO. Andersson and J. Ottosson - High Velocity Jacketed Long Rod Projectiles Hitting Oblique Steel PlatesMermaczNoch keine Bewertungen

- Harjinder S Bhatoe - Blast Injury and The NeurosurgeonDokument4 SeitenHarjinder S Bhatoe - Blast Injury and The NeurosurgeonMermaczNoch keine Bewertungen

- Michael J. Murphy Et Al - Demonstration of Enhanced Warhead Performance With More Powerful ExplosivesDokument11 SeitenMichael J. Murphy Et Al - Demonstration of Enhanced Warhead Performance With More Powerful ExplosivesMermaczNoch keine Bewertungen

- W. Lanz, W. Odermatt and G. Weihrauch - Kinetic Energy Projectiles: Development History, State of The Art, TrendsDokument8 SeitenW. Lanz, W. Odermatt and G. Weihrauch - Kinetic Energy Projectiles: Development History, State of The Art, TrendsMermaczNoch keine Bewertungen

- H.-J. Ernst, T. Wolf and W. F. Unckenbold - Protective Power of Thick Composite Layers Against Medium-Caliber Long-Rod PenetratorsDokument8 SeitenH.-J. Ernst, T. Wolf and W. F. Unckenbold - Protective Power of Thick Composite Layers Against Medium-Caliber Long-Rod PenetratorsMermaczNoch keine Bewertungen

- A.M. Diederen and J.C. Hoeneveld - Replica Scale Modelling of Long Rod Tank PenetratorsDokument10 SeitenA.M. Diederen and J.C. Hoeneveld - Replica Scale Modelling of Long Rod Tank PenetratorsMermaczNoch keine Bewertungen

- Modeling and Simulation of Shaped ChargesDokument150 SeitenModeling and Simulation of Shaped ChargesAlbet Straus100% (1)

- The B61 Family of BombsDokument3 SeitenThe B61 Family of BombsMermaczNoch keine Bewertungen

- The Preparatory Manual of ExplosivesDokument380 SeitenThe Preparatory Manual of Explosivesmighele91% (11)

- N. Heider, K. Thoma and A. Klomfass - Simulation of Geopenetrator Impact in The High Velocity RegimeDokument7 SeitenN. Heider, K. Thoma and A. Klomfass - Simulation of Geopenetrator Impact in The High Velocity RegimeMermaczNoch keine Bewertungen

- N. Heider and S. Hiermaier - Numerical Simulation of The Performance of Tandem WarheadsDokument8 SeitenN. Heider and S. Hiermaier - Numerical Simulation of The Performance of Tandem WarheadsMermaczNoch keine Bewertungen

- John Niles Et Al - Mitigating Shaped Charge Jet ImpactDokument20 SeitenJohn Niles Et Al - Mitigating Shaped Charge Jet ImpactMermaczNoch keine Bewertungen

- Nuclear Weapon Accident Response Procedures (NARP)Dokument342 SeitenNuclear Weapon Accident Response Procedures (NARP)MermaczNoch keine Bewertungen

- The Progressive - The H-Bomb Secret: How We Got It-Why We're Telling ItDokument39 SeitenThe Progressive - The H-Bomb Secret: How We Got It-Why We're Telling ItMermaczNoch keine Bewertungen

- A.B. Pittock Et Al - Chapter 1: Direct Effects of Nuclear DetonationsDokument24 SeitenA.B. Pittock Et Al - Chapter 1: Direct Effects of Nuclear DetonationsMermaczNoch keine Bewertungen

- Nuclear Fission BombDokument13 SeitenNuclear Fission BombMermaczNoch keine Bewertungen

- Ameer G. Mikhail - Kinetic Energy Projectile With Impact-Ejected FinsDokument7 SeitenAmeer G. Mikhail - Kinetic Energy Projectile With Impact-Ejected FinsMermaczNoch keine Bewertungen

- Radiological Terrorism Fact SheetDokument4 SeitenRadiological Terrorism Fact SheetMermaczNoch keine Bewertungen

- H. Böck - Kernenergie Und Umwelt Graz SS 2009Dokument35 SeitenH. Böck - Kernenergie Und Umwelt Graz SS 2009MermaczNoch keine Bewertungen

- Robert Woodall and Felipe Garcia - Precision, Airborne Deployed, GPS Guided Standoff TorpedoDokument7 SeitenRobert Woodall and Felipe Garcia - Precision, Airborne Deployed, GPS Guided Standoff TorpedoMermaczNoch keine Bewertungen

- Anthony Steven Abbott - GPS Guided MunitionDokument27 SeitenAnthony Steven Abbott - GPS Guided MunitionMermaczNoch keine Bewertungen

- Jimmy M. Madderra and James G. Williams - Acceleration Actuated Kinetic Energy Penetrator RetainerDokument6 SeitenJimmy M. Madderra and James G. Williams - Acceleration Actuated Kinetic Energy Penetrator RetainerMermaczNoch keine Bewertungen

- H.G. Berentsen - Marine ProjectileDokument6 SeitenH.G. Berentsen - Marine ProjectileMermaczNoch keine Bewertungen

- Klaus-Dieter Pahnke Et Al - Projectile For Combatting Actively and Passively Reacting ArmorDokument9 SeitenKlaus-Dieter Pahnke Et Al - Projectile For Combatting Actively and Passively Reacting ArmorMermaczNoch keine Bewertungen

- Udo Sabranski - Impact ProjectileDokument6 SeitenUdo Sabranski - Impact ProjectileMermaczNoch keine Bewertungen

- Jeffrey A. Brown Et Al - Aerodynamically Stabilized Projectile System For Use Against Underwater ObjectsDokument10 SeitenJeffrey A. Brown Et Al - Aerodynamically Stabilized Projectile System For Use Against Underwater ObjectsMermaczNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- PMDC Motor Guide: Everything You Need to KnowDokument7 SeitenPMDC Motor Guide: Everything You Need to KnowJesse Jones Seraspe100% (1)

- Control Cables PDFDokument28 SeitenControl Cables PDFPandurang NalawadeNoch keine Bewertungen

- TH407 Parts PDFDokument2 SeitenTH407 Parts PDFEric Tweneboah KoduaNoch keine Bewertungen

- Nissan Design Specification (NDS) : (Contents)Dokument6 SeitenNissan Design Specification (NDS) : (Contents)Maryana cNoch keine Bewertungen

- Honda PCX150 Service Manual PDFDokument436 SeitenHonda PCX150 Service Manual PDFjuanchoakorn71% (7)

- Manual Volvo XC90 2005Dokument17 SeitenManual Volvo XC90 2005Diego Alejandro QuinteroNoch keine Bewertungen

- Fixed Free Fixed Free Plate PDFDokument7 SeitenFixed Free Fixed Free Plate PDFbeenaNoch keine Bewertungen

- LK Ign, ElectricalDokument193 SeitenLK Ign, ElectricalPIKO MOBNoch keine Bewertungen

- FINNPOWER P Series Manual PDFDokument33 SeitenFINNPOWER P Series Manual PDFMaulanna Ibrohiim50% (2)

- Postgrad Courses PDFDokument36 SeitenPostgrad Courses PDFShah Wali UllahNoch keine Bewertungen

- Rolled Alloy ElectrodesDokument12 SeitenRolled Alloy ElectrodesradenmuhaiminNoch keine Bewertungen

- 2022.08.08 Fabrication and Installation Steel StructureDokument21 Seiten2022.08.08 Fabrication and Installation Steel StructureArifian NugrohoNoch keine Bewertungen

- FiatDokument10 SeitenFiatrgi178100% (1)

- PROSIS Part Information: 8/3/2011 1020038 20060 EC700B LC Volvo 10001-212/100 Cylinder Block 8279230Dokument3 SeitenPROSIS Part Information: 8/3/2011 1020038 20060 EC700B LC Volvo 10001-212/100 Cylinder Block 8279230Power MobileNoch keine Bewertungen

- SGL PT Brochure Graphite Block Heat ExchangersDokument16 SeitenSGL PT Brochure Graphite Block Heat ExchangersdardocapoNoch keine Bewertungen

- LUBCON High Performance H1 Food Grade LubricantsDokument9 SeitenLUBCON High Performance H1 Food Grade LubricantsNokiabhre WijayaNoch keine Bewertungen

- TM 9-707 (1943)Dokument451 SeitenTM 9-707 (1943)degardin lucNoch keine Bewertungen

- Mercedes-Benz Tractor HeadDokument9 SeitenMercedes-Benz Tractor HeadRudi KurniawanNoch keine Bewertungen

- Depressurisation - A Practical GuideDokument20 SeitenDepressurisation - A Practical GuideAhmad Firman Masudi100% (2)

- Stability Analysis of Columns With Variable Cross-Sections 1st Two Pages Placed LastDokument12 SeitenStability Analysis of Columns With Variable Cross-Sections 1st Two Pages Placed LastIntishar RahmanNoch keine Bewertungen

- Nia Audina Sitanggang CBR Temperature and Heat BMH J 17-18Dokument9 SeitenNia Audina Sitanggang CBR Temperature and Heat BMH J 17-18NIA AUDINA SITANGGANGNoch keine Bewertungen

- Catalog284 004Dokument1 SeiteCatalog284 004Miltongrimi GrimilNoch keine Bewertungen

- Errata Sheet For Fundamentals of Thermodynamics: Claus Borgnakke and Richard E. SonntagDokument3 SeitenErrata Sheet For Fundamentals of Thermodynamics: Claus Borgnakke and Richard E. SonntagNot my documentsNoch keine Bewertungen

- A Mechanical Engineer S Handbook by ONGC PDFDokument303 SeitenA Mechanical Engineer S Handbook by ONGC PDFshujad77Noch keine Bewertungen

- Bujii Opel BenzinaDokument2 SeitenBujii Opel BenzinaCata Stefan0% (1)

- Error Codes PDFDokument22 SeitenError Codes PDFcristian93% (15)

- Steel and Cast Iron Bar Compression ProblemDokument26 SeitenSteel and Cast Iron Bar Compression ProblemLarete PaoloNoch keine Bewertungen

- 2019 - Uniflair Room Cooling BrochureDokument92 Seiten2019 - Uniflair Room Cooling BrochureJeff100% (2)

- Thermal Breakage and Impact Strength of Tempered GlassDokument7 SeitenThermal Breakage and Impact Strength of Tempered GlassMartinBalanagNoch keine Bewertungen

- Gear BoxDokument14 SeitenGear Boxarackalfrancis0% (1)