Beruflich Dokumente

Kultur Dokumente

Anex 1

Hochgeladen von

rotatic_engineerOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Anex 1

Hochgeladen von

rotatic_engineerCopyright:

Verfügbare Formate

TCE CONSULTING ENGINEERS LIMITED

R0-1997-03-31

REV. NO.

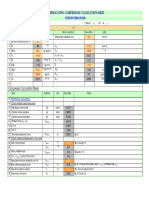

PROCESS DATA SHEET FOR VESSEL REV. GENERAL NO.

ITEM NUMBER QUANTITY CAPACITY (NOMINAL) SERVICE DESIGN CODE LOCATION 322-T-441 A/B 2 45 KL (Water Capacity) LIQUID NH3 STORAGE ASME SEC-VIII DIV. 1 INDOOR / OUTDOOR SHELL FLUID SPECIFIC GRAVITY VISCOSITY VAPOUR PRESSURE (AT 30 DEG.C.) kg/cm2(a) cP Liquid NH3 0.58 11.89

SH

1 OF 1

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 51 52 53 54 REV NO.

TCE.M4-CH-T-PDS-

FLUID PROPERTIES AT OPERATING TEMP.

N9

DESIGN DATA

SHELL OPERATING TEMPERATURE DESIGN TEMPERATURE DESIGN PRESS. INSIDE DIAMETER LENGTH HEAD TYPE- TOP - BOTTOM CORROSION ALLOWANCE SUPPORT INSULATION - REQUIRED - PURPOSE AGITATOR mm kg/cm2(a) mm mm

o o

N10 N2 N3 N11 N4

AMBIENT

N12 N8 N13 N5 N6 N7

C C

OPERATING PRESS.AT 32 DEG.C.kg/cm2(g) 12.7 KG/CM2 (a) 23.55 kg/cm2(a) 3000 7250 DISHED END DISHED END 3 MM SADDLE YES / NO PERS. PROTEC./CONSER. YES / NO

3.0 m

(-) 33 TO 55

N1

7.25 m

NOTES : 3) This vessel shall be designed, fabricated, manufactured, inspected by Third Party & Testing as per the requirement of "The Static & Mobile Pressure Vessels Rules"(SMPV Rules) .This vessel shall be approved by CCoE Nagpur

MATERIAL OF CONSTRUCTION

SHELL JACKET COIL INTERNALS GASKET AGITATOR BAFFLES COIL DIP PIPES

LOW TEMPERATURE CARBON STEEL

and obtaining approval of CCoE Nagpur and inspection by competent third party shall be in the scope of vessel vendor 5) A Test & Inspection certificate issued by manufacturer of the vessel shall be furnished to CCoE, Nagpur.This shall be duly countersigned by an Inspector, authorised by CCoE, Nagpur that the vessel meets with the requirements of the code approved by CCoE, Nagpur .

NA NA

LOW TEMPERATURE CARBON STEEL

PTFE ENVELOPED CAF

ACCESSORIES BY TANK VENDOR

YES / NO YES / NO YES / NO YES / NO N14 N13 N12 N11 N10 N9 N8 N7 N6 N5 N4 N3 N2 N1 NOZZ. NO. 25 50 50 500 25 25 25 25 25 HOLD HOLD HOLD 50 50 SIZE CLIENT 1 1 1 1 1 1 1 2 1 1 1 1 1 1 QTY.

NITROGEN INLET (DURING COMMISSIONING)

SPARE SPARE MANHOLE TEMPERATURE INDICATOR LEVEL GAUGE

LEVEL INDICATION TRANSMITTER LEVEL INDICATION TRANSMITTER

SPECIAL REQUIREMENTS

RADIOGRAPHY STRESS RELIEF BUFFING OTHER NOTES : 1) Sizes and instrument nozzles are under hold pending instrument finalization. 2) All liquid level gauging devices shall be as per "SMPV RULES" 100% AS PER CODE NA NA

PRESSURE TRANSMITTER PRESSURE GAUGE PRESSURE SAFETY VALVE (PSV) PRESSURE SAFETY VALVE (PSV) AMMONIA IN

AMMONIA OUTLET (TO NH3 COMPRESSOR)

SERVICE

NOZZLE SCHEDULE

: P0

Sd/-SPP 31.8.05 Sd/-MB 31.8.05

R0

Sd/-SPP 11.5.06 Sd/-VAK 11.5.06

PPD. BY :Sd/- SPP CKD. BY:Sd/-MB DATE :31.08.05

TCE JOB NO.

: NUCLEAR FUEL COMPLEX

PPD. BY/DATE : CKD. BY/DATE :

TCE-4246A

PROJECT : NZOSP, PALAYAKAYAL PDS NO. : TCE-4246A-CH-T-PDS-322T441

R1

TCE CONSULTING ENGINEERS LIMITED

R0-1997-03-31

REV. NO.

PROCESS DATA SHEET FOR VESSEL REV. GENERAL NO.

ITEM NUMBER QUANTITY CAPACITY (WORKING) SERVICE DESIGN CODE LOCATION 322-T-442 A/B 2 35 KL

NH4OH SOLUTION STORAGE

SH

1 OF 1

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 51 52 53 54 REV NO.

TCE.M4-CH-T-PDS-

ASME SEC-VIII DIV. 1 INDOOR / OUTDOOR

FLUID PROPERTIES AT OPERATING TEMP.

SHELL FLUID SPECIFIC GRAVITY VISCOSITY cP VAPOUR PRESSURE AT 30oC kg/cm2(a) 35% NH4OH 0.85 - 0.94 0.3 0.75

N1 N10 N3

N7

N4

N5 N6 N9 N8 N11

2.75 m

DESIGN DATA

SHELL OPERATING TEMPERATURE DESIGN TEMPERATURE OPERATING PRESS. DESIGN PRESS. INSIDE DIAMETER LENGTH HEAD TYPE - TOP - BOTTOM CORROSION ALLOWANCE INSULATION - PURPOSE mm - REQUIRED kg/cm2(g) kg/cm2(g) mm mm

o o

N2

7.00 m

N12

C C

AMBIENT 70 ATM. 10 2750 7000 DISHED END DISHED END 1 MM YES / NO PERS. PROTEC./ CONSER.

MATERIAL OF CONSTRUCTION

SHELL JACKET COIL INTERNALS GASKET AGITATOR BAFFLES COIL DIP PIPES SS 304L PTFE ENVELOPED CAF YES / NO YES / NO YES / NO YES / NO N13 N12 N11 N10 N9 N8 N7 N6 N5 N4 N3 N2 N1 NOZZ. NO. : R0

Sd/- SPP 11.05.06 Sd/-VAK 11.05.06

SS 304L NA NA

# indicates as per code

* indicates minimum for piping

ACCESSORIES BY TANK VENDOR

25 50 50 25 50 50 500 50 50 25 25 80 80 x 40 SIZE CLIENT

1 1 1 1 1 1 1 1 1 2 1 1 1 QTY.

SAMPLING POINT DRAIN RECIRCULATION INLET NITROGEN BLANKETING SPARE PVRV SHELL MANHOLE SPARE PG LEVEL INDICATOR TRANSMITTER TEMPERATURE INDICATOR AMMONIUM HYDROXIDE OUTLET AMMONIUM HYDROXIDE INLET SERVICE

SPECIAL REQUIREMENTS

RADIOGRAPHY STRESS RELIEF BUFFING OTHER NOTES : 1) Sizes and instrument nozzles are under hold pending instrument finalization. 100% AS PER CODE NA NA

NOZZLE SCHEDULE

P0

Sd/- SPP 31.08.05 Sd/- MB 31.08.05

PPD. BY :SPP CKD. BY:MB DATE :31.08.05

TCE JOB NO.

: NUCLEAR FUEL COMPLEX

PPD. BY/DATE : CKD. BY/DATE :

TCE-4246A

PROJECT : NZOSP, PALAYAKAYAL PDS NO. : TCE-4246A-CH-T-PDS-322T442

R1

TCE CONSULTING ENGINEERS LIMITED

R0-1997-03-31

REV. NO.

PROCESS DATA SHEET FOR VESSEL REV. GENERAL NO.

ITEM NUMBER QUANTITY CAPACITY (NOMINAL) SERVICE DESIGN CODE LOCATION 322-T-445 1 5 KL

VENT TANK FOR AMMONIA

SH

1 OF 1

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 51 52 53 54 REV NO.

TCE.M4-CH-T-PDS-

ASME SEC-VIII DIV. 1 INDOOR / OUTDOOR SHELL

FLUID PROPERTIES AT OPERATING TEMP.

FLUID SPECIFIC GRAVITY VISCOSITY VAPOUR PRESSURE (AT 30 DEG.C.) cP kg/cm2(a)

AMMONIUM HYDROXIDE SOLUTION

1 -

DESIGN DATA

SHELL OPERATING TEMPERATURE DESIGN TEMPERATURE DESIGN PRESS. INSIDE DIAMETER LENGTH HEAD TYPE- TOP - BOTTOM CORROSION ALLOWANCE SUPPORT INSULATION - REQUIRED - PURPOSE AGITATOR mm kg/cm2(a) mm mm

o o

N2

AMBIENT ATM, LIQUID FULL 1500 3500 DISHED END DISHED END 3 MM SADDLE YES / NO

N3

N8

N1 N6 N7

C C

OPERATING PRESS.AT 32 DEG.C.kg/cm2(g)

1.5 m

65

N4 N5

3.5 m

PERS. PROTEC./CONSER. YES / NO

MATERIAL OF CONSTRUCTION

SHELL

LOW TEMPERATURE CARBON STEEL

JACKET COIL INTERNALS

NA NA

LOW TEMPERATURE CARBON STEEL

GASKET AGITATOR BAFFLES COIL DIP PIPES

PTFE ENVELOPED CAF

ACCESSORIES BY TANK VENDOR

YES / NO YES / NO YES / NO YES / NO

SPECIAL REQUIREMENTS

RADIOGRAPHY STRESS RELIEF BUFFING OTHER NOTES : 1) Sizes and instrument nozzles are under hold pending instrument finalization. NA AS PER CODE NA NA N8 N7 N6 N5 N4 N3 N2 N1 NOZZ. NO. : R0 PPD. BY :Sd/- SPP CKD. BY:Sd/-VAK DATE :18.06.07 50 50 50 50 25 500 50 HOLD SIZE CLIENT 1 1 1 1 1 1 1 1 QTY.

SPARE SPARE

SPARE DRAIN SAMPLING POINT MANHOLE PROCESS WATER INLET AMMONIA INLET SERVICE

NOZZLE SCHEDULE

TCE JOB NO.

: NUCLEAR FUEL COMPLEX

PPD. BY/DATE : CKD. BY/DATE :

TCE-4246A

PROJECT : NZOSP, PALAYAKAYAL PDS NO. : TCE-4246A-CH-T-PDS-322T441

R0

ISSUE NO. R5

TCE CONSULTING ENGINEERS LIMITED

ENQ.SPEC.NO. TCE.4246-CH-K-PDS-001 DATA SHEET A

SECTION : D

LIQUID AMMONIA COMPRESSORS

SHEET :

OF 6

1. DESIGNATION : COMPRESSORS FOR LIQUID AMMONIA TANKER UNLOADING 2. NUMBER REQUIRED : 2 NOS (1W+1S)

19.2 FOR INTER-COOLER, AFTER-COOLER AND OIL-COOLER : WATER

20. COOLING WATER QUALITY : AS PER TACO-GYIN SPECS.

3. TAG NUMBERS : 322--K-441 A/B 21. COOLING WATER INLET 4. LOCATION : OUTDOOR GENERAL 5. OPERATION : INTERMITTENT ~ 1 1/2 hrs. for loading 10 MT Bullet 6. TYPE OF DRIVE : FLAMEPRROF ELECTRIC MOTOR 7. APPLICABLE STANDARDS : API 618/ API 619 TEMPERATURE :** 32

0

C

0

22. MAXIMUM COOLING WATER OUTLET TEMPERATURE : ** 37 23. COOLING WATER PRESSURE AT DESIGN DATA (CONTD.) AT INLET : ** 2.5 Kg/ cm 2 (g) C

24. MAXIMUM COOLING WATER PRESSURE DROP IN THE COMPRESSOR, INTER-COOLER, AFTER-COOLER AND OIL- COOLER : * Kg/ cm 2

8. 9. 10. TYPE : RECIPROCATINGHORIZONTAL NON-LUBRICATED 11. FLUID TO BE COMPRESSED : LIQUID AMMONIA VAPOR 12. CAPACITY (FAD) : * M3/Hr ( Note 4 ) DESIGN DATA 13. MASS FLOW RATE : * Kg/Hr ( Note 4 ) 14. PROPERTIES OF GAS/ GAS COMPOSITION : LIQUID AMMONIA VAPORS 15. SUCTION PRESS. :2.25 ~11.7Kg/cm (g)

0 2

25. COMPRESSOR FRAME LUBRICATION : * SPLASH/ PRESSURISED 26. TYPE OF CAPACITY CONTROL : * BY SPEED VARIATION/ AT CONSTANT SPEED 27. METHOD OF CAPACITY CONTROL AT CONSTANT SPEED : * DUAL TYPE CONTROL / MOVABLE INLET GUIDE VANES / 28. 29.

DUAL TYPE CONTROLS

16. SUCTION TEMPERATURE - MINIMUM / MAXIMUM : (-) 33 / 55 C 17. DISCHARGE PRESSURE : 15 Kg/ cm 2 (g) 18. MAXIMUM COMPRESSOR SPEED : * RPM 19. COOLING MEDIUM : * WATER 19.1 FOR COMPRESSOR:* WATER/ NOTE-1 REV.NO. DATE REV. BY

FILE NAME : DA10701R5.DOC

30. ADJUSTABLE RANGE FOR PRESSURE SWITCHES : * Kg/ cm 2

31. EXPECTED SETTING OF PRESSURE SWITCHES FOR : * 31.1 AUTO LOAD-UNLOAD REGULATION : (a) LOAD : * (b) UNLOAD : * Kg/ cm 2 (g) Kg/ cm 2 (g)

PPD. BY: SPP CHD. BY: VAK DATE : 29.06.07

JOB NO. TCE. 4246 A

CLIENT: NUCLEAR FUEL COMPLEX

PROJECT: NZOSP

TCE FORM NO. 330 R1

ISSUE NO. R5

TCE CONSULTING ENGINEERS LIMITED

ENQ.SPEC.NO. TCE. 4246-CH-K-PDS-001 DUAL TYPE CONTROLS (CONTD.) DATA SHEET A

SECTION : D

LIQUID AMMONIA COMPRESSORS

~2 ~1 Kg/ cm (g) Kg/ cm (g)

2 2 2

SHEET : 2

OF 6

31.2 AUTO START-STOP REGULATION: (a) START : * (b) STOP : *

44. IMPELLERS : CAST ALUMINIUM ASTM B 26, ALLOY C 355/ CAST SS 410/ CAST SS ASTM A 747, TYPE CB7 Cu-1 OR CB7 Cu-2/ FORGED SS 403/ MATERIALS OF CONSTRUCTION FOR CENTRIFUGAL COMPRESSORS (CONTD.)

31.3 VERY LOW RECEIVER PRESSURE ALARM : * Kg/ cm (g) Kg/ cm 2 (g)

31.4 HIGH RECEIVER PRESSURE ALARM : *

45. BLADES : PLATE STEEL AISI 4130-4140/ AISI 4320-4340/ 46. GUIDE VANES : CI ASTM A 48 OR A 278, CL 30/ CAST STEEL ASTM A 216, GR WCB/ CAST SS ASTM A 743/744 OR A 351, GR CA15, CF3, CF3M, CF8, CF8M/

32. NUMBER OF STEPS FOR LOAD UNLOAD REGULATION : * 2 / 3 / 4 / 33. 34. CYLINDER AND CYLINDER LINER : * CI

MATERIALS OF CONSTRUCTION FOR RECIPROCATING COMPRESSORS

35. PISTON RINGS : * CI

47. SHAFT : FORGED STEEL AISI 10401050 OR ASTM A 470, CL 7/FORGED SS ASTM A 336, GR F6/ 48. COVERS AND HUBS : FORGED STEEL

36. VALVE SEATS : * EN 8A FORGED 37. VALVE PLATES : * 38. VALVE STOPS : * 39. VALVE SPRINGS : *

AISI TYPE 3140/ PLATE STEEL ASTM A 543/ FORGED SS AISI TYPE 403 OR 410 /

49. CASING : 40. PISTON : * CI MATERIALS OF CONSTRUCTION FOR SCREW COMPRESSORS

CI IS 210 OR ASTM A 278 CL

40/ FABRICATED STEEL ASTM A 353/ CAST STEEL ASTM A 216 GR WCB NORMALIZED / CAST SS ASTM A 743 AND 744 CA6-NM/

41. CRANK SHAFT, CONNECTING ROD AND PISTON ROD : * EN 8A

42. CASING : CI IS 210 OR ASTM A 48 OR

MATERIALS OF CONST. FOR CENTRIFUGAL COMPRESSORS

50. ROTOR BODY : CI ASTM A 395/ FORGED STEEL AISI 1030-1045/ CAST ALUMINIUM ASTM B 26 ALLOY 355 OR C 355/ 51. SHAFT : FORGED STEEL AISI 1030-1035/ FORGED SS ASTM A151 TYPE 410 SS /

A 278 / CAST STEEL ASTM A 216 GR WCB NORMALIZED/

43. DIFFUSER : CI ASTM A 536,GR 60-4018/ CAST ALUMINIUM ASTM B 26, ALLOY 355.0 /

REV.NO. DATE REV. BY

FILE NAME : DA10701R5.DOC

PPD. BY: SPP CHD. BY: VAK DATE : 29.06.07

JOB NO. TCE. 4246 A

CLIENT: NUCLEAR FUEL COMPLEX

PROJECT NZOSP

TCE FORM NO. 330 R1

ISSUE NO. R5

TCE CONSULTING ENGINEERS LIMITED

ENQ.SPEC.NO. TCE. 4246A-CH-K-PDS001 DATA SHEET A

SECTION : D

LIQUID AMMONIA COMPRESSORS

SHEET :

3 OF 6

52. INTAKE FILTER TYPE : * PAPER/ OIL WETTED/ CLOTH/ OIL BATH/ COMBINED DRY AND WET 52.1 MATERIAL OF CONSTRUCTION : CASING : * MS/ ALUMINIUM 53. SILENCER REQUIRED : * YES 54. DRIVE PULLEYS WITH V-BELT AND BELT GUARDS REQUIRED : * YES INTER-COOLERS / AFTER-COOLERS / OIL-COOLERS DESIGN DATA

69. DESIGNATION : * INTER-COOLERS/ AFTER-COOLERS FOR 70. TAG NUMBERS FOR INTER-COOLERS : LATER 71. AFTER-COOLERS REQUIRED : *NO NUMBER : 72. TAG NUMBERS FOR AFTER-COOLERS : LATER 73. CAPACITY OF : 73.1 INTER-COOLERS : * 73.2 AFTER-COOLERS : * M3 / Hr M3 / Hr

FOR BELT DRIVEN COMPRESSORS 55. COUPLINGS AND COUPLING GUARDS REQUIRED : YES ( non sparking material) COMPRESSOR ACCESSORIES

74. TYPE : *HORIZONTAL/ VERTICAL SHELL AND TUBE TYPE WITH REMOVABLE TUBE BUNDLES/ 75. TYPE OF FLOW : COUNTER-CURRENT 76. OPERATING PRESSURE FOR AFTERCOOLERS * 76.1 GAS SIDE :* 76.2 WATER SIDE : * COOLERS * 77.1 AIR/ GAS SIDE : * 77.2 WATER SIDE : * Kg/ cm 2(g) Kg/ cm 2(g)

0

56. SLIDE RAILS FOR MOTOR REQUIRED: *YES 57. CONTROL CABINET REQUIRED : 58. IMPULSE TUBING : * STAINLESS STEEL YES

Kg/ cm 2 (g) Kg/ cm 2 (g)

59. MOTOR BY : COMPRESSOR BIDDER

77. DESIGN PRESSURE FOR AFTER-

60. STARTER BY : COMPRESSOR BIDDER

61. 62. 63. 64. 65. 66. 67. 68. REV.NO. DATE REV. BY PPD. BY: SPP CHD. BY: VAK DATE : 29.06.07

78. MAXIMUM ACCEPTABLE OUTLET GAS TEMPERATURE : * C

79. ALLOWABLE PRESSURE DROP OF AIR/ GAS THROUGH AFTER-COOLER : 0.2 Kg/ cm 2 80. DESIGN CODE : ASME SEC. VIII DIV. 1 AND TEMA 81. CORROSION ALLOWANCE : JOB NO. TCE. 4246a PROJECT: NZOSP * mm

CLIENT: NUCLEAR FUEL COMPLEX

FILE NAME : DA10701R5.DOC

TCE FORM NO.330 R1

ISSUE NO. R5

TCE CONSULTING ENGINEERS LIMITED

ENQ.SPEC.NO. TCE4246-CH-K-PDS-001 INTER-COOLERS/AFTERCOOLERS/ OIL-COOLERS M O C 82. SHELL : * DATA SHEET A

SECTION : D

LIQUID AMMONIA COMPRESSORS

SHEET :

OF 6

90. DESIGNATION : RECEIVERS FOR

83. TUBES : *

91. NUMBER REQUIRED :1 92. TAG NUMBERS :

84. TUBE SHEETS : * CS

93. TYPE : *HORIZONTAL/ VERTICAL/ CYLINDRICAL WITH WELDED DISHED

85. TUBE SUPPORT PLATES : * CS

ENDS 94. OPERATING PRESSURE : *

86. 87. MOISTURE AND OIL SEPARATOR WITH AUTO DRAIN TRAP TO BE PROVIDED WITH EACH INTERCOOLER AND AFTER-COOLER TO

RECEIVER DESIGN DATA

Kg/ cm 2 (g) 95. DESIGN PRESSURE : * Kg/ cm 2 (g) C

3

96. DESIGN TEMPERATURE : * 97. NOMINAL VOLUME : * 98. DIMENSIONS : 98.1 HEIGHT TAN TO TAN : * 98.2 DIAMETER : * 99. APPLICABLE CODE : IS 2825/ M

INTER-COOLERS / AFTER-COOLERS ACCESSORIES

DISCHARGE MOISTURE AND OIL TO DRAIN 87.1 TYPE OF MOISTURE AND OIL SEPARATOR : CENTRIFUGAL/ DEMISTER PAD/ BAFFLE 87.2 TYPE OF AUTO DRAIN TRAP : INVERTED BUCKET / BALL FLOAT / SOLENOID OPERATED / ELECTRONIC LEVEL CONTROLLED 88. MATERIAL OF CONSTRUCTION OF MOISTURE AND OIL SEPARATOR 88.1 BODY/ SHELL : CS

mm mm

100. CORROSION ALLOWANCE :

1.6 mm

101. SHELL AND DISHED END MATERIAL : IS 2002/ IS 2062 102. INTERNAL PAINTING : BLACK BITUMINOUS / 103. INSULATION : 104. 105. SUPPORT LEGS/ LUGS/ SKIRT RECEIVER ACCESSORIES REQUIRED : 106. MANHOLE WITH COVER FOR INSPECTION AND CLEANING REQUIRED : 107. 108. YES YES NO

88.2 89. MATERIAL OF CONSTRUCTION OF AUTO DRAIN TRAP 89.1 BODY : 89.2 TRIM : CI IS 210/ SS SS/ PPD. BY: SPP CHD. BY:VAK DATE : 29.06.07

REV.NO. DATE REV. BY

JOB NO. TCE. 4246 A

CLIENT: NUCLEAR FUEL COMPLEX

PROJECT: NZOSP

ISSUE NO. R5

TCE CONSULTING ENGINEERS LIMITED

ENQ.SPEC.NO. TCE. 4246-CH-K-PDS-001 DATA SHEET A

SECTION : D

LIQUID AMMONIA COMPRESSORS

SHEET :

OF 6

109. ALL THE VALVES, SPECIALITIES SPARES AND MAINTENANCE TOOLS AND TACKLES INSTRUMENTS AND ACCESSORIES AS PER ENCLOSED P&I D TCE.4246- 300-PI-8651 : REQUIRED 110. COUNTER FLANGES FOR ALL THE MISCELLANEOUS CONNECTIONS AT BATTERY LIMITS WITH NUTS, STUDS, BOLTS, GASKETS AND WASHERS REQUIRED : 110.1 FLANGES : YES YES

123. REFER TCE.M4-907 124. ESSENTIAL SPARES 124.1 OIL FILTERS 124.2 ALL KINDS AND SIZES OF GASKETS 124.3 ALL KINDS AND SIZES OF O-RINGS 124.4 WEAR RINGS 124.5 OIL SEALS 124.6 124.7 124.8 124.9 124.10 125. AS PER TCE.M4-904 AND / OR TCE.M4-85-01 AND TCE.M4-185-65 OR TESTS AND INSPECTION

111. FOUNDATION BOLTS FOR ALL THE EQUIPMENT REQUIRED : YES

112. ERECTION BY CONTRACTOR :YES/NO 113. ERECTION SUPERVISION BY CONTRACTOR : 114. 115. PRIMER : RED OXIDE/ EPOXY 115.1 NUMBER OF COATS : PAINTING 115.2 DRY FILM THICKNESS : 116. FINISH PAINT : SYNTHETIC ENAMEL/ EPOXY/ 116.1. NUMBER OF COATS : 116.2 DRY FILM THICKNESS : 117. MOTORS : TCE.M4-203-01 AND/ OR PERFORMANCE GUARANTEES COMPANION SPECIFICATIONS TCE.M4-203-02 118. TURBINE : TCE.M4-133-01/ 04 / YES

TCE.M4-186-01, 02, 04, 05, 06, 08, 09, 12 AND 26 (NOTE 2)

126. PERFORMANCE TEST AT SITE REQUIRED : YES

127. APPLICABLE STANDARDS : IS 5456 / API 618 / API 617 / API 672 / API 619 / IS 11780 / 128. 129. 130. CAPACITY OF EACH COMPRESSOR : * (+) ( ) M3/Hr Kg/ cm2 (g)

131. DISCHARGE PRESSURE : * (+) ( )

119. PIPING MATERIAL SPECIFICATIONS : TCE. 120. INSTRUMENTATION AND CONTROL TCE.M4-107-IC-01 121. CONTROL CABINET : TCE.M4-219-01 122. CABLES : TCE.M4-208-01

132. POWER CONSUMPTION : * (+) ( ) KW

133. TEMPERATURE OF AIR AT OUTLET OF AFTER COOLER : * 134. COOLING WATER FLOW RATE : * M3/Hr CLIENT: NUCLEAR FUEL COMPLEX C

REV.NO. DATE REV. BY

FILE NAME : DA10701R5.DOC

PPD. BY: SSP CHD. BY: VAK DATE : 29.06.07

JOB NO. TCE. 4246 A

PROJECT: NZOSP.

TCE FORM NO. 330 R1

ISSUE NO. R5

TCE.M4-107-01 ENQ.SPEC.NO. TCE. 4246-CH-K-PDS-001

PERFORMNCE GUARANTEES (CONTD.)

TCE CONSULTING ENGINEERS LIMITED

DATA SHEET A LIQUID AMMONIA COMPRESSORS COST LOADING AND PENALTY

SECTION : D

SHEET :

6 OF 6

135. COOLING WATER OUTLET TEMPERARURE : 37

2

139. POWER CONSUMPTION : C Rs. * / KW / M 3/Hr

136. COOLING WATER PRESSURE DROP : 0.25 137. 138. 143. BEARINGS Kg/ cm (g)

140. COOLING WATER CONSUMPTION : Rs. * 141. 142.

LIST OF SUB-VENDORS FOR BOUGHT-OUT AND CRITICAL ITEMS 1. 2.

144. MOTORS 145. TURBINE 146. ENGINE 147. COUPLINGS 148. V- BELTS 149. VALVES & SPECIALITIES 150. AUTO DRAIN TRAPS 151. VIBRATION DAMPENING PADS 152. CONTROL PANEL AND INSTRUMENTS : REFER 153. MCC 154. 155. 156.

NOTES FOR COMPRESSORS UPTO MOTOR RATING OF 7.5 KW, BIDDER MAY OFFER AIR COOLED COMPRESSOR AS AN ALTERNATIVE TO WATER COOLED COMPRESSOR.

FOLLOWING ADDITIONAL TESTS INDICATED AS B IN TCE.M4-186-01,02, 04, 05, 06, 08, 09, 12 AND 26 SHALL ALSO BE CARRIED OUT WHEN TCE.M4-186-01, 02, 04, 05, 06, 08, 09, 12 AND 26 ARE APPLICABLE 3.. * DENOTES BIDDER TO SPECIFY / CONFIRM. 4. BASIS FOR SIZING : 10 MT LIQUID AMMONIA BULLET TO BE LOADED IN 1-1.5 HOURS. TIME INCLUDES THE VAPOR RECOVERY FROM ROAD TANKER. 5. ** TO BE CONFIRMED DURING DETAILED ENGG.. 6. MOTOR SHALL BE FLAME POOF TEFC , CONFORMING TO GAS GROUP IIA/B, IS 2148, IP 55,CLASS F.

REV.NO. DATE REV. BY

FILE NAME : DA10701R5.DOC

PPD. BY: SPP CHD. BY: VAK DATE :

JOB NO. TCE. 4246 A

CLIENT: NUCLEAR FUEL COMPLEX

PROJECT: NZOSP

TCE FORM NO. 330 R1

SPECIFICATION NO.

TCE CONSULTING ENGINEERS LIMITED

DATA SHEET ANALOG SIGNAL ISOLATORS/ MULTIPLIERS

SECTION D SHEET 1 OF 1

TCE-4246A-C-300-005

Make Input signal Output signal No. of outputs Quantity Mounting Power Supply Type of isolation Accuracy Stability

: : : : : : : : : :

Bidder to state 4-20 mA DC from process transmitter 4-20 mA DC 2 nos. As per P&ID ( for all Analog signals) DIN rail mounted in Marshalling cabinets 24 V DC Transformer Isolated (Preferable)

0.1% of calibrated span including combined effect of linearity, hysterisis and repeatability

Calibration shall hold within specified accuracy for a min. period of 1 year

REV. NO. DATE REV. BY

P0

PPD. BY:DMG CKD. BY:SPA DATE: 17.12.07

JOB NO. TCE 4246A

CLIENT: NUCLEAR FUEL COMPLEX

PROJECT : NZOSP, PALAYAKAYAL TCE FORM 330 R1

SPEC NO.

TCE CONSULTING ENGINEERS LIMITED CONTENTS

SECTION : CONTENTS

TCE-4246A-C-300-005

SHEET 1 OF 3

SECTION C (TECHNICAL SPECIFICATIONS)

SECTION C1 C2 C3 C4 SPECIFICATION NO. TCE-4246A-C300-005 TEC-4246A-950 TCE-4246A-951 TCE.4246A 952 TCE-4246A-C300-005 ISSUE NO. R1 R1 R0 RO TITLE CRITERIA FOR ELIGIBILITY FOR EVALUATION OF TENDER DOCUMENT PROJECT INFORMATION GENERAL PROJECT INFORMATION ELECTRICAL DOCUMENT & DRAWING SUBMISSION & DISTRIBUTION SCHEDULE SCOPE AND GENERAL SPECIFIC TECHNICAL REQUIREMENTS FOR LIQUID AMMONIA AND 35% AMMONIUM HYDROXIDE STORAGE AND TRANSFER SYSTEM EQUIPMENT, SYSTEM AND SERVICE TO BE PROVIDED BY CONTRACTOR. SYSTEM DESCRIPTION AND VARIOUS DETAILS FOR LIQUID AMMONIA AND 35% AMMONIUM HYDROXIDE STORAGE AND TRANSFER SYSTEM DATASHEET FOR LIQUID AMMONIA STORAGE VESSEL / BULLET DATASHEET FOR AMMONIUM HYDROXIDE SOLUTION STORAGE VESSEL / BULLET DATASHEET FOR LIQUID AMMONIA VENT TANK DATASHEET FOR STATIC MIXER R0 P0 R5 R4 R0 R4 R0 R0 R1 DATASHEET FOR EXCESS FLOW CHECK VALVES DATASHEET FOR AMMONIA COMPRESSOR DATASHEET-FLOW ELEMENT DATASHEET-TEMPERATURE INDICATOR DATASHEET-DIFFERENTIAL PRESSURE TRANSMITTERS DATASHEET-ANALOG SIGNAL ISOLATORS/ MULTIPLIERS DATASHEET-DIGITAL PANEL METERS DATASHEET-CONTROL PANEL 1 1 6 3 2 2 1 1 2

ISSUE R0

NO OF PAGES 1 3 2 2

C5

R1

11

C6

TCE-4246A-C300-05 TCE-4246A-CHT-PDS-322T441 TCE-4246A-CHT-PDS-322T442 TCE-4246A-CHT-PDS-322T445 TCE-4246A-CHSM-PDS322SM101 TCE-4246A-CHX-PDS-001 TCE.4246A-CHK-PDS-001 TCE.M4-604-09 TCE.4246A-109TI-04 TCE.M4-601-06 TCE.4246A-C300-005 TCE.4246A-C300-005 TCE.M4-109UCP-54

R1

12

C6 C6 C6 C6 C6 C6 C6 C6 C6 C6 C6 C6

R1 R1 R0

1 1 1

TCE FORM NO. 329 R3

SPEC NO.

TCE CONSULTING ENGINEERS LIMITED CONTENTS

SECTION : CONTENTS

TCE-4246A-C-300-005

SHEET 2 OF 3

SECTION C (TECHNICAL SPECIFICATIONS)

SECTION C6 C6 SPECIFICATION NO. TCE.M4-607-05 TCE.M4-109-CV MECHANICAL C7 C7 C7 C7 C7 C7 C7 C8 TCE.M4-203-01 TCE.M4-208-01 TCE-M4-208-11 C9 TCE.M4-134-01 TCE.M4-134-06 TCE.M4-185-01 TCE.M4-186-01 TCE.M4-186-04 TCE.M4-186-05 TCE.M4-186-08 R1 R1 R3 R2 R2 R2 R2 R8 R7 R3 TCE.M4-107-01 TCE-4246A-300LS-001 TCE-4246A-C300-002 TCE-M4-102-01 TCE-M4-102-43 TCE-M4-102-34 TCE-M4-103-99 R6 R2 R0 R3 R3 R3 R3 WRITE-UP FOR AMMONIA COMPRESSOR PIPING MATERIAL SPECIFICATION (SA1,CR, CA, CB1, CB2) PAINTING SPECIFICATION WELDED UNFIRED PRESSURE VESSELS EARTHING CLEAT GUSSETS FOR NOZZLES VALVES AND SPECIALITIES GENERAL REQUIREMENTS. GENERAL REQUIREMENTS IN ELECTRICAL INDUCTION MOTOR CABLES CABLING ACCESSORIES, CABLE TRAYS, CONDUITS & PIPES GENERAL REQUIREMENTS IN MECHANICAL WELDING SPECIFICATION FOR CHEMICAL AND INDUSTRIAL PLANT PIPING SYSTEMS FABRICATION, ERECTION AND TESTING OF PIPING SYSTEMS FOR CHEMICAL AND INDUSTRIAL PLANTS. INFORMATION TO VENDOR ON QUALITY PLANS & GENERAL INSPECTION REQUIREMENTS SHOP INSPECTION REQUIREMENTS FOR UNFIRED PRESSURE VESSELS SHOP INSPECTION REQUIREMENTS FOR VALVES METALLIC. SHOP INSPECTION REQUIREMENTS FOR PIPES AND PIPE FITTINGS - METALLIC. SHOP INSPECTION REQUIREMENTS FOR ROTATING MACHINES MECHANICAL. 23 13 3 1 1 1 1 5 6 6 10 18 2 10 1 1 4 ISSUE NO. R2 R0 TITLE DATASHEET-PRESSURE/VACUUM RELIEF DATASHEET-CONTROL VALVES NO OF PAGES 2 2

ISSUE R0

TCE FORM NO. 329 R3

SPEC NO.

TCE CONSULTING ENGINEERS LIMITED CONTENTS

SECTION : CONTENTS

TCE-4246A-C-300-005

SHEET 3 OF 3

SECTION C (TECHNICAL SPECIFICATIONS)

SECTION C-10 TCE.M4-903 TCE.M4-904 TCE.4246A -905 TCE.M4-906 TCE.M4-907 TCE.M4-908 TCE.M4-914 TCE.M4-915 TCE.M4-916 TCE.M4-917 R3 R7 R1 R6 R5 R4 R5 R4 R4 R0 SPECIFICATION NO. ISSUE NO. TITLE GENERAL TERMS, REQUIREMENTS CONDITIONS AND 8 8 2 6 3 1 3 3 1 10 NO OF PAGES

DRAWINGS, ENGINEERING DOCUMENTS & INSTRUCTION MANUALS SHOP INSPECTION AND TESTS GUARANTEE AND PATENT RIGHTS PACKING, MARKING AND TRANSPORT INSTRUCTIONS FOR EQUIPMENT SPARES AND MAINTENANCE TOOLS & TACKLES TRAINING OF PURCHASERS PERSONNEL PROGRESS SCHEDULE AND REPORTS PERFORMANCE TESTS AT SITE RATING AND NAME PLATES SAFETY CONDITIONS FOR UNDERTAKING SITE WORK ENCLOSURES LIST OF DRAWINGS/DOCUMENT

TCE.4246A-300PI-8650 TCE.4246A-322PI-8725 TCE.4246A322-GA-8595 TCE.4246A-322GA-8600

R0 R0 R0 R0

LEGEND AND SYMBOLS P & I DIAGRAM FOR LIQUID AMMONIA STORAGE & TRANSFER GENERAL ARRANGEMENT FOR LIQUID AMMONIA STORAGE & TRANSFER GENERAL ARRANGEMENT FOR AMMONIUM HYDROXIDE STORAGE & TRANSFER

1 1 1 1

ISSUE R0

TCE FORM NO. 329 R3

SPEC NO.

TCE CONSULTING ENGINEERS LIMITED CRITERIA OF ELIGIBILITY FOR TECHNICAL EVALUATION OF THE BIDS

SECTION: C1 SH 1 OF 1

TCE- 4246A-C300-005

1. CRITERIA OF ELIGIBILITY FOR TECHNICAL EVALUATION OF THE BIDS 1.1 Experience of Contractor in similar works / Past Performance For the purpose of this clause similar work means the works of work of one or more types of the system / subsystems alongwith its components, accessories & equipment required as per this tender and including all allied works such as instrumentation, electrical and piping to make the system complete and including erection & commissioning at site. The contractor should have the proven technical, commercial and financial capability in terms of having executed turnkey jobs of this nature as required in the tender document. Bidder shall have satisfactory performance of the works carried out. Bidder shall provide a reference list of previous clients for whom similar work has been carried out and the value of the jobs. Bidder shall to provide letters from them for satisfactory performance, workmanship and delivery of items / system & completion schedules. 1.2 Design, Manufacturing & Quality Control Facilities Bidder to furnish the details of existing manufacturing (plant and machinery), infrastructural & quality control facilities available with the bidder. Bidder shall submit the organisation chart and his technical, supervisory & managerial establishment and the technical & managerial staff, CAD / CAM facilities that will be deployed for this project.

1.3 1.3.1

Financial Stability Turnover : Average annual financial turnover during last 3 years ending 31st March of the previous financial year. The contractor shall submit TDS certificates or audited balance sheets showing receipts from contracts, profit and loss etc in support of his claim.

ISSUE R1

TCE FORM 329 R3

SPEC. NO.

TCE CONSULTING ENGINEERS LIMITED DATA SHEET

SECTION D

TCE.4356A-C-300-005

DIGITAL PANEL METERS

SHEET 1 OF 1

Type Mounting size Digit height Enclosure Protection Input Range Engg. Units

: : : : : : : :

Microprocessor based Front facia of panels 24 mm (H) x 48 mm (W) 12 mm User Configurable (Universal) 4-20 mA DC from transmitters User configurable kg/ cm2 for pressure

0

C for temperature

Metres for level. Ampere, Voltage ( User Configurable) Relay Outputs : 1 changeover (For each high and low alarms, adjustable over 100% range) Contact Rating Power Supply Accuracy Display Quantity Tests : : : : : : 2A, 230 V AC 24 VDC 0.2 % of full scale 4 digit LED display As per P&ID ( for all Analog signals) Calibration & Performance tests HV test Type test certificate for protection class DRAWINGS/ DOCUMENTS 1. 2. Vendor shall submit catalogue & data sheet for review & comments by Purchaser/ Consultant. Vendor shall submit Instruction Manual for Records.

TEST CERTIFICATES 1. 2. Vendor shall submit all routine Test certificates for Purchaser/ Consultants review. Vendor shall submit type test certificates for protection class.

NOTES 1.

DATE REV. BY

Bidder shall indicate all applicable codes and standards.

PPD. BY:DMG CKD. BY:SPA DATE: 17.12.07 JOB NO. TCE 4246A PROJECT: NZOSP, PALAYAKAYAL CLIENT: NUCLEAR FUEL COMPLEX

REV. NO.

TCE FORM 330 R1

SPEC NO. TITLE

TCE CONSULTING ENGINEERS LTD. DOCUMENT & DRAWING SUBMISSION & DISTRIBUTION SCHEDULE

SECTION : C4 SHEET 1 OF 2

TCE.4246A - 952

OF

The Vendor / Contractor shall submit and distribute to the PURCHASER / OWNER and CONSULTANT / ENGINEER the following number of copies of the required documents and drawings mentioned in the tender.

Sl. No. 1. Description Vendor / Contractor Owner Engineer

General Correspondence from Vendor / Contractor a) b) Commercial Technical S S Ori.+ 1 Ori. + 1 3 (*) 3 (*)

2.

General Correspondence from : a) b) TCE NFC Ori. Ori. S 2 S 3 S 3 (*) 3 (*)

3.

Vendor / Contractor Manufacturing, fabrication, delivery and erection schedule Manufacturing Test Reports Operating, Maintenance and Erection Manuals a) b) Preliminary Final

4. 5.

Ori. + 3

S S

4 6

3 (*) 3 (*)

6.

Vendor / Contractor Drawings / Documents a) b) c) First submission and subsequent revisions As-Built As-Built (on CD) (Soft Copy) S S S S 6 R+6 3 5 6 3 (*) 3 4 (*)

7.

Draft & Final Reports

(*) : Legend :

One copy to TCE Site Office. n -- Number of Copies required. S -- Source, Ori. -- Original, R -- Reproducible

ISSUE R0

TCE FORM 329 R3

SPEC NO. TITLE

TCE CONSULTING ENGINEERS LTD. DOCUMENT & DRAWING SUBMISSION & DISTRIBUTION SCHEDULE

SECTION : C4 SHEET 2 OF 2

TCE.4246A - 952

OF

DETAILS FOR CORRESPONDENCE 1. Postal Address : Nuclear Fuel Complex Department of Atomic Energy, ECIL Post, Hyderabad 500 062, Andhra Pradesh, India. Attn : Mr. B.Laxminarayana Project Director (NZOSP) Telephone (040) 2718 4337 / -- 2718 4971 (thro office) (040) -- 2713 5019

Fax E-mail ID

bln@nfc.ernet.in

2.

Postal Address : TCE Consulting Engineers Ltd. Raj Plaza, 2nd Floor, L. B. S. Marg, Vikhroli (West), Mumbai 400 083. Attn : Mr. V.A.Kunte Project Manager Telephone Fax E-mail ID (022) 6 647 2111 (022) 6 647 2000

vakunte@tce.co.in

ISSUE R0

TCE FORM 329 R3

SPEC.NO. TCE.M4-107-01

TCE CONSULTING ENGINEERS LIMITED

SECTION: WRITE-UP SHEET 1 OF 10

AIR / GAS COMPRESSORS

1.0

SCOPE This specification covers the general design, materials, construction features, manufacture, shop inspection and testing at manufacturers works, delivery at site, handling at site, erection, testing, commissioning, performance testing and handing over of Air / Gas Compressors and Accessories.

2.0 2.1

CODES AND STANDARDS The design, materials, construction, manufacture, inspection, testing and performance of the air/ gas compressors and accessories shall comply with all currently applicable statutes, regulations and safety codes in the locality where the equipment is to be installed. The equipment shall also conform to the latest applicable Indian or equivalent standards. Other international standards are also acceptable, if these are established to be equal or superior to the listed standards. Nothing in this specification shall be construed to relieve the CONTRACTOR of this responsibility. The following are some of the important codes and standards relevant to this specification. API 617 API 618 API 619 API 672 Centrifugal Compressors for Petroleum, Chemical, and Gas Service Industry Services Reciprocating Compressors for Petroleum, Chemical, and Gas Industry Services Rotary Type Positive Displacement Compressors Petroleum, Chemical, and Gas Industry Services for

2.2

Packaged, Integrally Geared Centrifugal Air Compressors for Petroleum, Chemical, and Gas Industry Services

ASME SEC. Boiler and Pressure Vessel Code VIII DIV.1 TEMA IS 2825 IS 5456 IS 6206 IS 7938 IS 11780 Standards of the Tubular Exchanger Manufacturers Association Code for Unfired Pressure Vessels Code of Practice for Testing of Positive Displacement Type Air Compressors and Exhausters Guide for Selection, Installation and Maintenance of Air Compressor Plants with Operating Pressures up to 10 bars Air Receivers for Compressed Air Installation Code for Selection and Testing of Rotary Screw Air Compressors (Oil Flooded)

ISSUE R6

FILENAME : M410701R6.DOC TCE FORM NO. 329 R3

SPEC.NO. TCE.M4-107-01

TCE CONSULTING ENGINEERS LIMITED

SECTION: WRITE-UP SHEET 2 OF 10

AIR / GAS COMPRESSORS

IS 13124 3.0

Reciprocating Gas Compressors - Technical Supply Conditions

DESIGN AND CONSTRUCTION FEATURES The compressor shall be of reciprocating or centrifugal or screw type as specified in data sheet A.

3.1 3.1.1

RECIPROCATING COMPRESSORS Frame The frame shall be a single casting and robust in construction. It shall be provided with sufficiently large and easily removable inspection doors so that the bearings and other parts are readily accessible for checking and adjustments. Inspection doors shall be dust-proof and oil-tight.

3.1.2 Cylinder The cylinder shall be made of cast iron or stainless steel or as specified in data sheet A. The cylinder heads and barrels shall be provided with cooling water jackets. The design of jackets shall be such that low air discharge temperature and minimum carbon formation are ensured. The water jackets shall be so constructed that the flow of water is uniform throughout the cooling surface and no stagnant water pockets are formed. The walls of the cylinder shall have sufficient thickness suitable for maximum working pressure and temperature and shall be suitable for reboring. It shall be provided with liberally sized valve openings and stream-lined passages. The internal surface of the cylinder shall be highly polished to reduce wear of the piston rings. 3.1.3 Piston and Piston Rod The piston shall be of such a design and construction that the piston rings exert equal pressure at all points of the cylinder bore. The piston rod shall be designed to take up the full thrust acting on the piston. The piston rings for non- lubricated type compressor shall be of self lubricating type. Piston speed shall be maximum 300 M/Min for large capacity compressors and 350 M/Min for small capacity compressors. 3.1.4 Cross Head The cross head shall be of solid box type with the faces ground to work closely with the groove of the guides. The cross head pin shall be case hardened and ground.

ISSUE R6

FILENAME : M410701R6.DOC TCE FORM NO. 329 R3

SPEC.NO. TCE.M4-107-01

TCE CONSULTING ENGINEERS LIMITED

SECTION: WRITE-UP SHEET 3 OF 10

AIR / GAS COMPRESSORS

3.1.5 Connecting Rod and Crank Shaft The connecting rod shall be of I cross-section providing adequate strength and rigidity. The crank shaft shall be adequately designed so as to ensure smooth running, without vibrations. It shall be accurately finished to size and shall have sufficient length so as to be fitted to main bearing and flywheel. 3.1.6 Flywheel The flywheel shall be designed such that it is well balanced and is of sufficient weight to give an even turning moment. The wheel shall be of robust construction. The spokes shall have oval cross-section and the boss shall have split construction such that the wheel runs true with the shaft. The flywheel shall be suitable for type of power transmission i.e. flat belt, V-belt, direct coupling etc. between the driver and compressor. 3.1.7 Main Bearings The main bearings shall be of robust construction assuring long bearing life and shall have sufficiently large diameter and adequate length. The bearing at the crank pin end of connecting rod shall be fitted with bronze lined with best quality white metal. The bearing at the cross head end shall be fitted with a bushing made of bronze. The bearings shall be made in halves and shall have forced feed lubrication. 3.1.8 Valves The valves shall have straight and uniform lift and maximum effective area so as to ensure low air velocity and minimum valve clearance. The valve plate discs shall be heat treated, tempered and ground and the valve seat shall be case hardened. The valve springs shall be capable of effecting quick opening and closing and shall also provide the required cushioning effect. The valve design shall be such that the valve can be easily removed for checking and maintenance. 3.1.9 Lubrication (a) Frame Lubrication Frame lubrication for small compressors with motor rating upto 55 kW shall be of splash type. The pressurised i.e. forced feed system shall be used for compressors with higher motor rating. In case of force feed lubrication, the oil pump shall be either driven by crank shaft of the

ISSUE R6

FILENAME : M410701R6.DOC TCE FORM NO. 329 R3

SPEC.NO. TCE.M4-107-01

TCE CONSULTING ENGINEERS LIMITED

SECTION: WRITE-UP SHEET 4 OF 10

AIR / GAS COMPRESSORS

compressor or shall be separately driven. The pump shall draw the oil from the adequately sized oil well. (b) Cylinder Lubrication For lubricated type of compressors, multi plunger pump or metering pump shall be used for cylinder lubrication. In case of non-lubricated type air compressors, a wiper ring shall be provided such that the crank case oil is not carried to the cylinder along with the piston rod. 3.2 CENTRIFUGAL COMPRESSORS

3.2.1 Casing Casing shall be either horizontally split or vertically split type made of cast iron for moderate pressure applications, cast steel for high pressure applications or as specified in data sheet A. The thickness of casing shall be suitable for maximum working and test pressures and shall have a corrosion allowance of at least 3 mm. 3.2.2 Impellers Impellers shall be open, semi-open or closed type consisting of disk, hub and blades. The blades shall be either radial or backward leaning type only. The material of construction shall be as specified in data sheet A. The design shall be such as to produce low operating stress levels giving high mechanical integrity. 3.2.3 Gears The gears shall be of high speed precision helical type designed as per AGMA standards. The bull gear shall be directly connected to the driver by a low speed coupling. The bull gear may be integrally forged with its shaft. In case bull gear is forged separately, same shall be assembled with an interference fit on its shaft. The pinion shall be integrally forged with its shaft. It shall be hardened and precision ground to AGMA 13 quality of AGMA 2000-A88 for longer life. 3.2.4 Bearings and Seals The bearings used for pinion and impeller shall be such that high stability and low vibrations are achieved. Tapered - land thrust bearings shall be provided for rotor assembly. Bearing shoes shall be pressure lubricated and steel babbited. Bearings shall be comparatively insensitive to load changes and

ISSUE R6

FILENAME : M410701R6.DOC TCE FORM NO. 329 R3

SPEC.NO. TCE.M4-107-01

TCE CONSULTING ENGINEERS LIMITED

SECTION: WRITE-UP SHEET 5 OF 10

AIR / GAS COMPRESSORS

variations in oil supply pressure. Hydrostatic squeeze film bearings are also acceptable. The bull gear shall be supported by horizontally split sleeve journal bearings and thrust shall be absorbed in either direction by thrust bearings. To prevent any oil vapour contamination and to ensure oil-free air, mechanical type air and oil seals shall be provided on the pinion shaft. 3.2.5 Rotor Assembly Rotor assembly shall consist of pinion shaft to which impellers are attached. The shaft shall be of forged carbon steel or stainless steel or as specified in data sheet A. A thrust collar shall be provided on pinion shaft. 3.3 SCREW COMPRESSORS

3.3.1 Casing Casing shall be of barrel type made of cast iron or fabricated steel for moderate pressure applications, cast steel or stainless steel for high pressure applications or as specified in data sheet A. For water injected applications the casing shall be of stainless steel or as specified in data sheet A. Casing shall have built-in air passages either as cast or machined. 3.3.2 Rotors Rotors shall be of asymmetric profile. The material of construction of rotors shall be as specified in data sheet A. The rotors shall be dynamically balanced before and after mounting timing gears and thrust collars. The rotors shall be ultrasonically tested. For non-lubricated screw compressors rotors shall be lined with PTFE. 3.3.3 Gears Gear pair shall be used to step up speed of the compressor. Helical gear hardened to minimum 55 RC shall be used. Gear shall be shrink fit on drive shaft and shall mesh with pinion mounted on extended portion of male rotor. Gears shall be designed as per AGMA standards. 3.3.4 Bearings The rotors shall be carried in heavy duty ball and roller bearings to take radial and axial loads or journal bearings with thin babbitt metal lining.

ISSUE R6

FILENAME : M410701R6.DOC TCE FORM NO. 329 R3

SPEC.NO. TCE.M4-107-01

TCE CONSULTING ENGINEERS LIMITED

SECTION: WRITE-UP SHEET 6 OF 10

AIR / GAS COMPRESSORS

3.3.5 Air- Oil Separator In case of lubricated screw compressors, high efficiency air-oil separation system shall be provided to ensure removal of oil. 4.0 ACCESSORIES Accessories such as intake filter, silencer, inter-coolers, after -coolers, oilcoolers, receivers, control cabinet etc. shall be supplied to make the system complete in all respects. 4.1 INTAKE FILTER The intake filter shall be generally as per IS 6206. The type of intake filter shall be as specified in data sheet A. The filter shall be designed to retain particles of one (1) micron and above with ninety-seven (97) percent efficiency. In case of cloth filter, the filter element may be of nylon, polypropylene or woollen cloth attached to the wire netting. 4.2 INTER-COOLERS For multi stage compressors, inter-coolers shall be provided. These shall be of shell and tube type, with removable tube bundles. The tubes shall have sufficient thickness to withstand the operating pressure and shall be carefully expanded into the tube sheets. Capacity of inter-coolers shall be twenty (20) percent more than the compressor capacity or as specified in data sheet A. Design pressure shall be twenty-five (25) percent more than the working pressure or as specified in data sheet A. The material of construction and design shall be as specified in data sheet A. 4.3 AFTER-COOLERS AND OIL-COOLERS The construction features, design etc. shall be as per inter-coolers described above. Capacity of after-coolers and oil-coolers shall be twenty (20) percent more than the compressor capacity or as specified in data sheet A. Design pressure shall be twenty-five (25) percent more than the working pressure or as specified in data sheet A. 4.4 RECEIVERS Receivers shall generally conform to IS 7938. Receivers shall be provided with two (2) suitably sized safety valves to relieve the full compressor discharge capacity individually and shall be set at a pressure 1.25 times the operating

ISSUE R6

FILENAME : M410701R6.DOC TCE FORM NO. 329 R3

SPEC.NO. TCE.M4-107-01

TCE CONSULTING ENGINEERS LIMITED

SECTION: WRITE-UP SHEET 7 OF 10

AIR / GAS COMPRESSORS

pressure. The material of construction and design shall be as specified in data sheet A. 5.0 MOTOR RATING Motor shall be of suitable rating considering compressor power requirements. Motor rating shall be calculated as follows : (a) If compressor shaft input power requirement is 100 KW and above, Motor rating in KW shall be = 1.10 (b)

SKW

t

If compressor shaft input power requirement is less than 100 KW, Motor rating in KW shall be = 1.12

SKW

t

Where, SKW = Shaft Power at selected speed in KW t = Efficiency of transmission 6.0 CAPACITY CONTROL Capacity control shall be achieved either by speed variation or at constant speed as specified in data sheet A. In case where capacity control is to be achieved at constant speed, following methods are generally available. Data sheet A shall be referred for method to be actually employed. (a) (b) (c) (d) (e) (f) (g) 6.1 Automatic start-stop of the compressor Automatic load-unload of the compressor Throttling of suction valve By-passing air or gas from delivery to suction inlet Increasing clearance volume by a clearance pocket Variable filling using a by-pass valve. Movable inlet guide vanes.

DUAL TYPE CONTROL Capacity control by start-stop and load-unload of compressors is also known as dual type control, and same is described below.

6.1.1 The dual type control system shall permit operation of each compressor in either of the following two regulations:

ISSUE R6

FILENAME : M410701R6.DOC TCE FORM NO. 329 R3

SPEC.NO. TCE.M4-107-01

TCE CONSULTING ENGINEERS LIMITED

SECTION: WRITE-UP SHEET 8 OF 10

AIR / GAS COMPRESSORS

(a) (b)

Continuous Run-Load-Unload Regulation. Automatic Start-Stop Regulation.

6.1.2 Under continuous Run-Load-Unload Regulation, the drive motor shall run continuously while the compressor shall be loaded at pre-set (adjustable) cut-in pressure as the receiver pressure falls and unloaded at a higher pre-set (adjustable) cut-out pressure, as the receiver pressure rises. With automatic Start-Stop Regulation, the drive motor shall automatically start at pre-set (adjustable) cut-in pressure as the receiver pressure falls and automatically stop at a pre-set (adjustable) higher cut-out pressure as the receiver pressure rises. 6.1.3 With either system, the compressor shall always be unloaded when the drive motor starts. The unloaders shall keep the compressor unloaded till the drive motor comes to full speed. 6.1.4 Each compressor shall be provided with one selector switch having three positions marked AUTO-OFF-ON for the following functions: (a) (b) OFF AUTO (c) ON Stops the motor. Keeps the compressor(s) in load / unload mode as selected by master selector switch. Starts the motor of the compressor in strart-stop regulation as selected by master selector switch. For manual start up by push buttons with load / unload regulation.

6.1.5 Two (2) Compressors Operation A master selector switch common to both the compressors shall be provided having two positions marked AB and BA. When the master selector switch is in position ABand the individual compressor control switches are in AUTO position, compressor A shall have continuous run-load-unload regulation and compressor B shall have auto start-stop regulation. In the other position of the master selector switch BA, compressor B shall have continuous run-load-unload regulation while compressor A shall have startstop regulation. 6.1.6 Three (3) Compressors Operation A master selector switch common for three (3) compressors shall be provided having three (3) positions marked AB/C, BC/A and CA/B. When the individual compressor control switch is in AUTO position and the master selector switch is in position AB/C, compressors A and B shall have continuous run-load-unload regulation and compressors C shall have auto

ISSUE R6

FILENAME : M410701R6.DOC TCE FORM NO. 329 R3

SPEC.NO. TCE.M4-107-01

TCE CONSULTING ENGINEERS LIMITED

SECTION: WRITE-UP SHEET 9 OF 10

AIR / GAS COMPRESSORS

start-stop regulation. Similarly with master selector switch in position BC/A, compressors B and C shall have continuous run-load-unload regulation and compressor A shall have auto start-stop regulation. With master selector in position CA/B, compressors C and A shall have the continuous run-loadunload regulation while compressor B shall have auto start-stop regulation. 6.1.7 Four (4) Compressors Operation A master selector switch common for four (4) compressors shall be provided having four (4) positions marked AB/C, BC/D, CD/A, DA/B. When the individual compressor control switches are in AUTO position and the master selector switch is in position AB/C, compressors A and B shall have continuous run-load-unload regulation and compressor C shall have auto start-stop regulation. Similarly with master selector switch in position BC/D, compressors B and C shall have continuous run-load-unload regulations and compressor D shall have auto start-stop regulation. With master selector in position CD/A compressors C and D shall have continuous run-loadunload regulation while compressor A shall have auto start-stop regulation. With master selector in position DA/B compressors D and A shall have the continuous run-load-unload regulation while compressor B shall have auto start-stop regulation. Fourth compressor not indicated in the selector position shall be on manual control. 6.2 Two pressure switches shall be provided to monitor receiver pressure for each compressor, one for load-unload control and the other for start-stop control considering two (2) steps regulation for load-unload mode. In case number of steps are more as indicated in data sheet A, number of pressure switches provided shall be sufficient to meet the requirement. Pressure switches with alarm initiating contacts shall be provided for the receiver high and low pressures. The dual control units shall be complete with pressure switches, solenoid valves, control air tubing, air filter (if required) and other accessories as required for the afore-mentioned operations. For centrifugal compressors anti-surge control shall also be provided to protect compressor from surging. One potential free contact shall be made available for each compressor for remote alarm under trip condition and a common contact for compressor auto start.

6.3

6.4

6.5

6.6

ISSUE R6

FILENAME : M410701R6.DOC TCE FORM NO. 329 R3

SPEC.NO. TCE.M4-107-01

TCE CONSULTING ENGINEERS LIMITED

SECTION: WRITE-UP SHEET 10 OF 10

AIR / GAS COMPRESSORS

6.7

Green and red lamps shall be provided to indicate motor running and stop conditions respectively. Motors shall be provided with motor winding over-heat sensors and bearing temperature sensors for alarm indication and to trip the motor. For compressors driven with turbine, the required turbine control and instrumentation shall be provided. For air / gas compressors, depending on the hazardous area classification, motors and instrument enclosures shall be explosion-proof certified for the specific area. NOISE AND VIBRATIONS Noise level produced by any rotating equipment individually or collectively shall not exceed 85 dB(A) measured at a distance of 1.5 metres from the source in any direction. The overall vibration level shall be as per zones A and B of ISO 10816-1. Vibration dampening pads if required, shall be provided. PERFORMANCE GUARANTEES Performance parameters to be guaranteed by the CONTRACTOR and tolerances permitted shall be as indicated in section C and / or data sheet A. BIDDER shall confirm acceptance of these by indicating values in data sheet B. Compressor or any portion thereof is liable for rejection, if it fails to give any of the guaranteed performance parameters.

6.8

6.9

6.10

7.0 7.1

7.2 8.0

ISSUE R6

FILENAME : M410701R6.DOC TCE FORM NO. 329 R3

SPEC.NO. TCE.M4-107-01

TCE CONSULTING ENGINEERS LIMITED

SECTION: WRITE-UP SHEET 1 OF 2

AIR / GAS COMPRESSORS

DATA SHEET C DATA TO BE FURNISHED BY THE CONTRACTOR AFTER THE AWARD OF CONTRACT 1. List of drawings and documents to be submitted for review, approval and information with scheduled submission dates Quality Assurance Plan (QAP) Calculations for compressor capacity, drive motor rating, selection of speed reducers and couplings. Torsional vibration analysis for centrifugal and screw compressors Thermal design calculations for inter-coolers, after-coolers and oil-coolers Detailed P&I diagram showing clearly the scope of supply of equipment, piping with line sizes and material specifications, valves, specialities, instrumentation and control and all the accessories. All equipment, lines, valves, specialities and instruments shall be tagged as per the PURCHASERs procedure to be given to the successful BIDDER. All terminal points shall be clearly identified. All design data and other information furnished in data sheets A and B shall be covered either in this drawing or other relevant drawings or documents mentioned below. Detailed equipment list and bill of materials of all items in the CONTRACTORs scope Sub-vendor list for all bought-out items Mechanical design calculations for inter-coolers, after-coolers, oil-coolers, moisture and oil separator and receivers Characteristic curves of compressors. For centrifugal compressors, in addition to curves for operating conditions, characteristic curves shall be submitted considering minimum and maximum ambient temperature, minimum and maximum humidity and minimum and maximum frequency conditions Dimensioned to-scale equipment layout drawing showing all equipment, accessories, relevant external dimensions, location and elevation of terminal points, details of piping and electrical connections to be made by the PURCHASER, clearances required for erection, dismantling, operation and maintenance

2. 3.

4. 5.

6.

7. 8.

9.

10.

ISSUE R4

FILENAME : M410701R6.DOC TCE FORM NO. 329 R3

SPEC.NO. TCE.M4-107-01

TCE CONSULTING ENGINEERS LIMITED

SECTION: WRITE-UP SHEET 2 OF 2

AIR / GAS COMPRESSORS

DATA SHEET C (CONTD.) 11. Dimensioned cross-section drawings of compressors and other proprietary items with part list and materials of construction Detailed fabrication drawings of all fabricated equipment like inter-coolers, after-coolers, air receivers etc. Line designation schedule for all lines in the CONTRACTORS scope List of valves, specialities and instruments in the CONTRACTORS scope with tag numbers, type, makes, pressure ratings, materials of construction and ranges for instruments etc. Manufacturers drawings, data sheets and catalogues for valves, specialities and instruments etc. Dimensioned to-scale piping layout drawing for piping in the CONTRACTORs scope with allowable forces and moments on the piping nozzles and displacement of the nozzles Overall foundation plan, base frame drawing for each equipment, static and dynamic loads on each of the anchor bolts and dimensional details of pockets and anchor bolts Motor drawings Electrical control wiring diagrams with all interlocks Control philosophy, interlock description and logic diagrams Dimensional to-scale general arrangement and section drawings of MCC and instrument control panel with complete bill of materials List of alarms and trip settngs Erection, start-up, operation and maintenance manual complete with lubrication schedule etc.

12.

13. 14.

15.

16.

17.

18. 19. 20. 21.

22. 23.

ISSUE R4

FILENAME : M410701R6.DOC TCE FORM NO. 329 R3

R0 2002-09-30

TCE CONSULTING ENGINEERS LIMITED

PROCESS DATA SHEET FOR STATIC MIXER

RE V. NO.

SECTION SHEET 1 OF 1

mm mm mm FIXED / REMOVABLE

GENERAL

ITEM TAG NO. QUANTITY SERVICE DESIGN CODE BIDDER / VENDOR MODEL NO. LOCATION DUTY

CONSTRUCTION DATA TATA CONSULTING ENGINEER

INSIDE PIPE DIAMETER SCHEDULE / THICKNESS LENGTH FLANGE TOFLANGE MIXING ELEMENTS NO.OF ELEMENTS POSITION JACKET DESIGN TEMP.: PIPE/JACKET DESIGN PRESS.: PIPE/JACKET HYDROTEST PRESS PIPE/ JACKET CORROSION ALLOWANCE : PIPE / JACKET SURFACE TREATMENT & PAINTING

REV. NO.

TCE.M4-CH-X-PDS-440

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12.

1 2 3

322-SM-101 A/B 02 Nos. Liquid. Ammonia & DM Water

ASME SEC.VIII DIV. 1, ANSI B16.5

OUTDOOR / INDOOR INTERMIT. / CONT. 12hr/day

FILENAME : PDS440.DOC

7 8 9

HORIZONTAL/VERTICAL YES / NO 0 0C C kg/cm2(g) kg/cm2(g) kg/cm2(g) 3 mm REFER NOTE 5 kg/cm2(g) mm

PHYSICAL PROPERTIES

1 1

FLUID NAME PHASE : GAS/LIQ./SOLID DENSITY kg/m3 cP &%

Ammonia Liquid 580 NA LIQ. NH3 200 12.7 AMB

DM water Liquid 1000 1 NA DM Water 370 2.5 AMB 100

13. 14. 15. 16. 17. 18. 19. 20. 21. 22. 23. 24. 1 4 1 6

MATERIAL OF CONSTRUCTION

HOUSING INTERNALS CLADDING / LINING Low Temp. Carbon Steel Low Temp. Carbon Steel CS CS CS

VISCOSITY P SOLIDS : SIZE P FLUID NAME

PERFORMANCE DATA

kg/cm2 kg/cm2 % FLOWRATE, kg/hr PRESSURE, kg/cm2g TEMPERATURE,0C

FLANGES BOLTS & NUTS GASKETS SUPPORTS NOZZLES JACKET

ACTUAL PRESSURE DROP ALLOWABLE PRESSURE DROP DEGREE OF HOMOGENEITY MEASURED PARAMETER FOR DEGREE OF HOMOGENEITY PURPOSE OF MIXING

NOZZLE SCHEDULE (REFER NOTE 4)

SIZE NB INLET OUTLET SIDE NOZZLE JACKET INLET JACKET OUTLET VENT DRAIN 40 40 40 RATING # FACING FINISH

25. 26. 27. 28. 29. 30. 31. 32. 33. 34. 35. 36. 37. 4 0

COMPOSITION / TEMPERATURE / DENSITY BLENDING / SUSPENDING SOLIDS/ DISSOLVING / HEAT TRANSFER/GAS DISP.

ACCESSORIES BY VENDOR

LIFTING LUGS COMPANION FLANGES, NUTS,BOLTS & GASKETS EARTHING BOSS INSULATION WEIGHT OF STATIC MIXER : 1) EMPTY 2) OPERATING 3) FULL OF WATER kgs. kgs. kgs. YES / NO AS PER PIPING SPEC. / NA YES / NO YES / NO

INSPECTION & TESTS (REF.NOTE 3, 6)

HYDROTEST HOMOGENEITY TEST PRESSURE DROP TEST MATERIAL TEST CERTIFICATE SPARK TEST ( NOTE 8 ) YES / NO YES / NO YES / NO YES / NO NA mm * mm * mm

38. 39.

40. 41. 42. 43. 44. 45.

OVERALL SPACE REQUIREMENTS : NOTES : 1) - INDICATES BIDDER TO SPECIFY. 2) NA - INDICATES NOT APPLICABLE. 3) - ALL TEST INSTRUMENTS SHALL BE TRACEABLE TO NATIONAL STANDARDS. 4) REFER ATTACHED PIPING MATERIAL SPECIFICATIONS 5) REFER ATTACHED SPECS. FOR SURFACE TREATMENT & PAINTING 6) REFER ATTACHED SPECS FOR SHOP INSPECTION REQUIREMENTS 7) DIRECTION OF FLUID FLOW TO BE MARKED ON DRAWINGS & EQUIPMENT BY BIDDER. 8) SPARK TEST TO BE PERFORMED FOR LINED ITEMS. PPD.BY: CKDBY: DATE: SPP VAK TCE JOB NO. TCE-4246A

REV. NO PPD. BY / DATE CKD.BY / DATE

CLIENT : NUCLEAR FUEL COMPLEX PROJECT :NZOSP, PALAYAKAYAL PDS NO. :TCE-4246A-CH-SM-PDS-322SM101

R0

SPEC NO. TITLE

TCE CONSULTING ENGINEERS LTD. PROJECT INFORMATION GENERAL

SECTION : C2 SHEET 1 OF 3

TCE.4246A - 950

1. 2. 3. 4.

Owner / Purchaser Consultant / Engineer Project Title Location

Nuclear Fuel Complex, Hyderabad. TCE Consulting Engineers Ltd., Mumbai New Zirconium Oxide & Sponge Project (NZOSP) Palayakayal, Pazhayakayal Post, Tuticorin Tiruchendur highway, Srivaikundam Taluk, Tuticorin District, Tuticorin 628 152 Tamil Nadu (+) 5 m above Mean Sea Level ( MSL )

5. 6.0 6.1

Altitude Transport Railway Nearest Railway Station

Tuticorin (Broad Gauge) The site is located at Pazhayakayal Post, Tuticorin Tiruchendur highway, and is approx. 17 km south of Tuticorin. Madurai Tuticorin

6.2

Road

6.3 6.4 7.0

Air Port Sea Port Ambient Air Temperatures

a) Maximum dry bulb temp. b) Minimum dry bulb temp. c) Average Minimum d) Average Maximum e) Design wet bulb temp. for cooling tower 8.0 Design Ambient Temperature for electrical equipment

38.2 Deg. C (in the month of May) 19.5 Deg. C (in the month of January) 24.5 Deg. C 32.3 Deg. C 26.5 Deg. C 45 Deg. C

PROJECT INFORMATION GENERAL 4246A_950_R1.doc

21.01.2005

ISSUE R2

TCE FORM 329 R3

SPEC NO. TITLE

TCE CONSULTING ENGINEERS LTD. PROJECT INFORMATION GENERAL

SECTION : C2 SHEET 2 OF 3

TCE.4246A - 950

9.0

Rainfall 500 mm 909 mm 149.1 mm / hr 75 mm / hr. Major portion from October to December

a) Annual Average b) Peak Annual Rainfall c) Maximum Intensity d) Design Intensity e) Period of rainfall 10.0 Relative Humidity

a) Maximum b) Minimum c) Average 11.0 Wind Data

80 % 40 % 60 %

a) Basic Wind Speed b) Wind Direction 12.0 Seismic Data

55 m / sec as per IS : 875 ( Part 3 ) - 1987 Predominantly from North, North-East, West and East

a) Zone 13.0 14.0 15.0 Climate Longitude Latitude

Zone II as per IS : 1893 - 2002 Coastal and highly corrosive 780 7 E (approx.) 80 42 N (approx.)

PROJECT INFORMATION GENERAL 4246A_950_R1.doc

21.01.2005

ISSUE R2

TCE FORM 329 R3

SPEC NO. TITLE

TCE CONSULTING ENGINEERS LTD. PROJECT INFORMATION GENERAL

SECTION : C2 SHEET 3 OF 3

TCE.4246A - 950

PROJECT SITE OFFICE DETAILS :

NUCLEAR FUEL COMPLEX -- NZOSP TUTICORIN-TIRUCHENDUR HIGHWAY, PAZHAYAKAYAL POST, SRIVAIKUNDAM TALUK, TUTICORIN- 628 152 ATTN : EXECUTIVE ENGINEER

PHONE (O) TELEFAX

: :

04630-276200 04630- 276111

PROJECT INFORMATION GENERAL 4246A_950_R1.doc

21.01.2005

ISSUE R2

TCE FORM 329 R3

SPEC NO. TITLE

TCE CONSULTING ENGINEERS LTD.

SECTION: C3

TCE-4246A - 951

PROJECT INFORMATION - ELECTRICAL

SHEET 1 OF 2

OF

1.0

SUPPLY & DISTRIBUTION

1.1 1.2 1.3 1.4

Primary Power Supply from Grid Class IV Primary Distribution Voltage Secondary Distribution Voltage Stand by emergency power supply - class III UPS POWER SUPPLY FOR CRITICAL MOTORS CLASS II AUXILIARY POWER SUPPY Lighting fixtures, space heaters, 1-phase motors, 1-phase receptacles -- CLASS III / IV Control Supply

110 kV, 3-Phase , 50 Hz, Solidly grounded 11 kV, 3-Phase, 50 Hz, Solidly grounded 415V, 3-Phase, 4-WIRE, 50 Hz, Solidly grounded 415 V DG Supply

1.5 2.0 2.1

415 V , 3-Phase, AC, 50 Hz

230 V, 1-phase, 50 Hz, AC

2.2

( a ) For substation control and protection CLASS I ( b ) For Instrumentation and Control - Process & utilities- CLASS II ( c ) For MCC control CLASS IV / III 3.0 3.1

110 V DC, 2 WIRE. 230 V AC, 1-phase Through UPS 230 V , 1-phase, AC

VOLTAGE & FREQUENCY VARIATION : This shall be as follows : AC SUPPLY VOLTAGE VARIATION: FREQUENCY VARIATION COMBINED VOLTAGE & FREQUENCY VARIATION (+) / (-) 10% (+) / (-) 5% (+) / (-) 10%

ISSUE R0

PROJECT INFORMATION-ELECTRICAL.doc21.12.2004

TCE FORM 329 R3

SPEC NO. TITLE

TCE CONSULTING ENGINEERS LTD.

SECTION: C3

TCE-4246A - 951

PROJECT INFORMATION - ELECTRICAL

SHEET 2 OF 2

OF

3.2

DC SUPPLY VOLTAGE VARIATION

(+) / (-) 10%

4.0

Each of the above supplies will be made available at one Terminal Point. Vendor shall provide for further distribution of supply. If any other supply is desired by the Vendor, he shall provide for all the necessary hardware to derive this supply from the Control Supply provided by the Purchaser.

ISSUE R0

PROJECT INFORMATION-ELECTRICAL.doc21.12.2004

TCE FORM 329 R3

SPEC NO.

TCE CONSULTING ENGINEERS LIMITED SCOPE AND GENERAL REQUIREMENTS OF THE TENDER

SECTION: C5

SH. 1 OF 11

TCE- 4246A C300-005

1. SCOPE

1.1 The scope includes the design, preparation of detailed drawings, fabrication, testing, inspection, supply, transportation to site, unloading, safe storage and handling at site, erection, testing & commissioning of the Liquid Ammonia & 35% Ammonium Hydroxide solution Storage & Transfer System and Accessories as given below: LIQUID AMMONIA & 35% AMMONIUM HYDROXIDE STORAGE & TRANSFER SYSTEM AND ACCESSORIES SOLUTION

1.1.1

SR. No.

Equipment

Quantity

Details

Liquid Ammonia & 35% Ammonium Hydroxide solution Storage & Transfer System and Accessories

1 Liquid Storage Bullets Ammonia vessels / 02 Nos. Detailed scope & specifications are given in section C6 Technical Specifications of Liquid Ammonia & 35% Ammonium Hydroxide solution Storage & Transfer System

35% Ammonium Hydroxide solution 02 Nos. Storage vessels/Bullets Ammonia vent vessel 1 No.

3 4 5

Ammonia Compressors 02 Nos. Online Mixer 02 Nos.

Instrumentation

For Safe operation For Ammonia of Ammonia Compressor system Compressor only system. Detailed scope As per battery limits given in Specific shown in TCE.4246A- Electrical 322-PI-8725 R0 issue requirements of section C-6

Electrical

ISSUE R1 TCE FORM 329 R3

SPEC NO.

TCE CONSULTING ENGINEERS LIMITED SCOPE AND GENERAL REQUIREMENTS OF THE TENDER

SECTION: C5

SH. 2 OF 11

TCE- 4246A C300-005

1.2

This specification covers the requirements of design, preparation of detailed drawings, supply of materials & accessories, fabrication, manufacture, testing, inspection at Vendors / Sub-Vendors works, packing, forwarding, transportation and delivery at site, safe storage at site, transport to the site of installation, Installation / erection, mechanical completion, testing at site, precommissioning, commissioning of the Liquid Ammonia & 35% Ammonium Hydroxide solution Storage & Transfer System and Accessories alongwith its associated sub-systems and accessories complete in all respects, performance testing at site, supply of necessary documentation / calculations / drawings, manuals etc. for comments / approval by purchaser / consultant, supply of as-built documents / drawings described in various sections of this specification. It is not the intent to specify completely herein all details of design and construction of equipment or materials to be supplied or of services to be rendered. However, the equipment, materials and services shall conform in all respects to high standards of engineering design, workmanship and be capable of performing in continuous commercial operation in a manner acceptable to PURCHASER who will interpret the meaning of drawings and specifications and shall have the power to reject any work or materials which in his judgement are not in full accordance therewith. The scope of work under this contract shall also cover following : a) Supply of equipment and accessories as specified. b) Unloading, Safe storage of equipment supplied by CONTRACTOR & Unloading & Safe Storage of equipment and free-issue items wherever required, supplied by PURCHASER. c) Taking over the equipment from PURCHASER'S storage / unloading area for equipment and free-issue items supplied by PURCHASER. d) Transfer of material / equipment to CONTRACTOR'S storage area. e) Maintaining equipment during storage and installation in safe custody. f) Installation of equipment and carrying out wiring, cabling and earthing to complete the liquid ammonia & 35% ammonium hydroxide solution storage & transfer system as detailed under the technical requirements of the enclosed sections.

1.3

1.4

g) Installation of equipment at site requiring material handling including hoisting facilities. h) i) Testing and commissioning of the equipment within CONTRACTOR'S scope for PURCHASER'S satisfaction. Providing 'As-Built Drawings' and draft and final Operation & Maintenance manuals.

ISSUE R1 TCE FORM 329 R3

SPEC NO.

TCE CONSULTING ENGINEERS LIMITED SCOPE AND GENERAL REQUIREMENTS OF THE TENDER

j)

SECTION: C5

SH. 3 OF 11

TCE- 4246A C300-005

Obtaining all the clearances/ approvals from external agencies such as CCOE etc.

k) Providing with foundation drawings so as to enable the purchaser to take up with civil contractor. However minor civil works shall be in the scope of the vendor. l) Supply of essential spares.

2. INSTRUCTION TO BIDDERS

2.1 Bidders shall completely familiarise themselves with the scope of work involved & the job completion schedule. Any clarification required shall be sought from PURCHASER / CONSULTANT, prior to quoting for the Bid. Bidder shall ensure that the bids are complete & are prepared in the specified form. Incomplete bids are liable for rejection. Deviation, if any, shall be listed in Section-D; Schedule of Deviations (from Technical Specifications & General conditions). Except for these deviations, it is assumed that BIDDER shall comply with all requirements of the specifications. Any deviation sought at later date will not be entertained. While quoting the prices, BIDDER shall quote separately for supply including all taxes, duties & levies considered and separately for erection, testing & commissioning including all taxes, duties & levies considered. Bidder shall quote firm price which will be kept firm throughout the duration of the contract. The price schedule shall be strictly as per Section E of this specification. The make of components shall be as per the List of approved sub-vendors of Section C and / or subject to PURCHASER / CONSULTANT approval. In case, sub-vendors are not mentioned for some items, bidders shall identify the sub-vendor considered for these items and mention in the technical bid documents. In all cases, after placement of the order, the main contractor / main vendor shall submit the list of sub-vendors to Purchaser / Consultant for comments / approval and the order shall be placed onto sub-vendors only approved by Purchaser / Consultant. PURCHASER can add / delete items included in scope of work. Unit rates for different items shall prevail under such eventuality. Bidder may provide a separate addendum to our price schedule format and submit the unpriced format of the addendum with the technical bid (SectionD) and priced portion of the addendum with the priced bid (Section-E). Description of items offered against such additional unit rates considered by

ISSUE R1 TCE FORM 329 R3

2.2

2.3

2.4 2.5 2.6

2.7 2.8

SPEC NO.

TCE CONSULTING ENGINEERS LIMITED SCOPE AND GENERAL REQUIREMENTS OF THE TENDER

SECTION: C5

SH. 4 OF 11

TCE- 4246A C300-005

the bidder shall be mentioned in Section D of the bid (unpriced portion) and the rates / prices quoted shall be included in Section E (priced portion of the bid). Purchaser / Consultant shall review these points from technical and commercial considerations and discuss, if required with the bidders at the time of technical bid evaluation. The bid shall be evaluated on lump sum basis including the spares.

2.9

PURCHASERS RIGHT: The PURCHASER does not bind himself to accept the lowest or any Bid and reserves the right to accept or reject any Bid or a portion thereof without assigning any reason thereof.

2.10

ACKNOWLEDGEMENT OF ENQUIRY: BIDDER shall acknowledge the receipt of enquiry and within two (2) days advise whether he will be quoting or not. If the BIDDER is not quoting, all enclosures to this enquiry must be returned promptly to the issuing authority with REGRET letter. All specifications and documents enclosed are PURCHASERs property and are to be used only for the purpose of this enquiry and any order which may result from it.

2.11

DELIVERY: Tenderers should note that no tender will be considered by Purchaser unless the Tenderer can meet the delivery schedule specified by the Purchaser. All equipments / machinery / plant / components covered by this tender document should be supplied on or before 24 Weeks or as specified in the tender document from the date of receipt of LOI. The prices quoted by the tenderer should include all charges involved for direct and safe delivery of the items by Road to the Project site of the Purchaser. If a tenderer so desires, separate lumpsum charges for transportation and safe delivery to the Purchasers site at Palayakayal could be furnished. Purchaser will neither undertake responsibility for transit insurance nor pay for it separately. No other, delivery term will be accepted by the Purchaser. The installation and commissioning of the Liquid Ammonia & 35% Ammonium Hydroxide solution Storage & Transfer System shall be carried out within 8 weeks from the date of intimation of site readiness. The vendor will depute personnel to site and carry out joint inspection of site to confirm site readiness.

ISSUE R1 TCE FORM 329 R3

SPEC NO.

TCE CONSULTING ENGINEERS LIMITED SCOPE AND GENERAL REQUIREMENTS OF THE TENDER

SECTION: C5

SH. 5 OF 11

TCE- 4246A C300-005

2.12

The OWNER reserves the right to :

2.12.1 Increase / decrease the quantities of equipment involved in scope of supply of CONTRACTOR. 2.12.2 The item rates for supply & installation in Section-E shall be applicable for: any increase / decrease in quantities without any ceiling on variation. 2.12.3 Splitting of the order for individual sub-systems / package systems mentioned in the tender. 2.12.4 Calculating the extra price / price reduction on account of any variation. 2.12.5 The prices for new items shall be negotiable. 2.12.6 All site test reports in a specified format maintained by the CONTRACTOR, duly approved by the CONSULTANT / PURCHASER shall be handed over to the PURCHASER/CONSULTANT after completion of job, as per Vendor Distribution Schedule enclosed. 2.12.7 In overall planning of installation work, it shall be the responsibility of CONTRACTOR to minimise wastage of materials and consumables. 2.12.8 The Contractor shall supply all the required documentation / drawings as mentioned in document no. TCE.4246A-952 / R0 enclosed as a part of this tender.

3. GENERAL REQUIREMENTS

3.1 The following definitions shall cover the scope of work and as such the quoted prices shall be based on the same considerations. Payment claims arising out of wrong understanding shall not be entertained or paid for. Supply, Installation, Testing & Commissioning: The items are enlisted below in and Section E 'Schedule of Prices' enclosed in this specification. Following works are envisaged for these items under the head of Supply and Installation, Testing and commissioning. 3.1.1.1 SUPPLY: This shall include supply of equipment including packing / forwarding, transport and insurance charges complete with all fittings and accessories which form integral part of the equipment for installation purpose to ensure satisfactory commercial operation and timely delivery of the equipment to site. The place of supply shall be Zirconium Complex at Palayakayal near Tuticorin, Tamilnadu. Manufacturing, inspection & Testing at vendor's / subvendors works of equipment, accessories and items, shall conform to relevant standards and meet statutory approvals.

3.1.1

ISSUE R1 TCE FORM 329 R3

SPEC NO.

TCE CONSULTING ENGINEERS LIMITED SCOPE AND GENERAL REQUIREMENTS OF THE TENDER

SECTION: C5

SH. 6 OF 11

TCE- 4246A C300-005

3.1.1.2

INSTALLATION, TESTING & COMMISSIONING: This shall cover: a) Unloading, handling, storage of equipment, transportation of equipment from CONTRACTOR'S and from PURCHASER'S stores to their proposed locations. Installation of equipment as per Manufacturer's guidelines or specification drawings and / or relevant Indian Standards, Codes of Practice, including supply of materials / fittings / accessories as are necessary for the completion of the installation in all respects, and Testing and commissioning of the equipment as per manufacturer's guidelines, Indian Standards, Codes of practices etc. The PURCHASER / CONSULTANT may ask for such additional tests at site as in his opinion are necessary for determining that the works comply with the specification. The CONTRACTOR shall be responsible for carrying out the same at no extra cost to the PURCHASER. d) e) Preparation of 'AS BUILT' Drawings The VENDOR shall arrange following at his own cost. i. Adequate quantum of welding electrodes including special electrodes and welding units required for erection. ii. All consumable items viz. kerosene oil, cotton wool, emery paper etc. iii. All erection tools and tackles, cranes, hoisting equipment, etc as required. iv. All skilled, semi-skilled and unskilled labour required for erection. Any facility, as required, for the labour force such as accommodation, transport, medical facility, insurance etc. v. First fill of lubricants and grease etc. vi. Chemical cleaning operation for Liquid Ammonia & 35% Ammonium Hydroxide solution Storage & Transfer System and piping. vii. Commissioning the Liquid Ammonia & 35% Ammonium Hydroxide solution Storage & Transfer System and accessories and handing over to PURCHASER.

b)

c)

3.2

CODES AND STANDARDS: All equipment, supply, installation, testing and commissioning shall comply with the requirements of SMPV Rule, latest editions of Indian Standards and Codes of Practices. Where these standards are in conflict with the stipulations of this specification, this specification shall govern.

ISSUE R1 TCE FORM 329 R3

SPEC NO.

TCE CONSULTING ENGINEERS LIMITED SCOPE AND GENERAL REQUIREMENTS OF THE TENDER

SECTION: C5

SH. 7 OF 11

TCE- 4246A C300-005

3.3

3.3.1

DRAWINGS: All engineering documents & drawings, construction purpose drawings, cable schedules for execution of contract works, Operation & Maintenance manuals etc. will be prepared & furnished by the Contractor for review, comments, approval by PURCHASER / CONSULTANT. The drawings attached with this specification, are for the general guidance of the BIDDER. The CONSULTANT / PURCHASER may also issue further drawings and sketches if considered necessary during execution of the work. TESTING AND COMMISSIONING: The performance and commissioning tests shall be carried out as per Section-C of this specification. It is the responsibility of the Contractor to arrange for required test equipment and instruments for such purpose. The PURCHASER may ask for such additional tests on site, as in his opinion are necessary to determine that the work comply with the specifications, of manufacturer's instruction or IS code of Installation. The CONTRACTOR shall be responsible and bear the cost of such additional tests. All routine tests shall be conducted in the presence of PURCHASER / ENGINEER on all equipment as per relevant IS standards. Typical type tests certificate for all equipment of equivalent ratings shall be submitted for scrutiny / approval by PURCHASER / CONSULTANT. All commissioning tests shall be carried out in the presence of PURCHASER'S representative and approval for the same shall be obtained before commissioning the installations. All instruments and accessories required for testing and commissioning of the items specified shall be provided by the CONTRACTOR at no extra cost for the duration of Performance Test. All instruments used for Testing and Commissioning shall have valid calibration certificates, traceable to National / International Standards of repute. All instruments used for testing at vendors / sub-vendors works or at site shall have valid calibration certificates, traceable to national / international standards of repute. The calibration certificates shall be presented to PURCHASERS / CONSULTANTS representative. MAINTENANCE REQUIREMENTS: In order to carry out preventive maintenance, it should be possible to readily

ISSUE R1 TCE FORM 329 R3

3.3.2

3.4 3.4.1

3.4.2

3.4.3 3.4.4 3.4.5

3.4.6

3.4.7

3.4.8

3.5 3.5.1

SPEC NO.

TCE CONSULTING ENGINEERS LIMITED SCOPE AND GENERAL REQUIREMENTS OF THE TENDER

SECTION: C5

SH. 8 OF 11

TCE- 4246A C300-005