Beruflich Dokumente

Kultur Dokumente

Lab Report Vibration

Hochgeladen von

interdex_006Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lab Report Vibration

Hochgeladen von

interdex_006Copyright:

Verfügbare Formate

1.

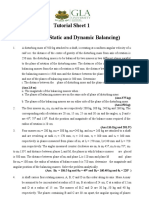

0 LEARNING OUTCOME: At the end of this experiment, the student should be able to, 1) to find natural frequency for the system Wn = 2f = 2(0.1639) = 1.0298 rps 2) to identify the properties of spring used in the system (wn)2 = k1 + k2 + k3 + k4 + / m1 + m2 + m3 + m4 (1.0298rps)2 = 4k / (1.0+1.0+1.4+1.1) K = 1.193 N/m

2.0

INTRODUCTION Balancing of rotating equipment is a very important aspect in the design of any mechanical system that involves a rotating shaft. Rotating systems are rarely perfectly balanced ; the degree of balance required depends upon size and location of the unbalances and the speed of operation. Unbalance is generally caused by an unbalanced mass, located at some eccentricity, spinning about the center of rotation at a constant frequency

3.0

SAFETY No hand touching the machine while still in operation

4.0

THEORY: The total force unbalanced is the sum of all of unbalance forces. The total moment unbalanced is the sum of all of the unbalance forces operating at different locations along the axis rotation. Static balancing refers to a procedure that adds or subtracts mass at some eccentricity to balance the vector forces. Dynamic balancing refers to a procedure that adds or subtracts mass at some eccentricity and location along the axis of rotation to balance the unbalance moments. Free vibration is initiated by disturbing the system from its static equilibrium position by imparting the mass some displacement u (0) and velocity u(0) at time t=0. Un damped free vibration: The governing equation for undamped free vibration is mu + ku = 0 Where, m= mass , u = acceleration, K= stiffness, u = displacement. Model Math: Fm + FL = 0 mx + (K1 + K2 + K3 + K4)x = 0

5.0

APPARATUS Balancing Apparatus and steel ruler Balancing machines consist of horizontal square frame that was hanging at their own positions using a spring. This machine also has rotating system which is operating by motor and belt. The rotation system consist one spindle that is supported by bearing at end of shaft. It is has four discs such as discs A, B, C and D. Where the distance between each discs is a same (6 inches) and has same radius position which is 3, 4, 5, and 6 inches respectively.

6.0 6.1

PROCEDURE: Observed the system weather it is balanced or otherwise without load and mass once the motor is switched on.

6.2 6.3 6.4 6.5

The motor is switched off The load 1.0kg weight on 4 inches radius at 00 is fixed on discs B. The load 1.4kg weight on 4 inches radius at 1200 is fixed on discs C Fit the load 1.0kg and 1.1 kg weights at 2200 and 2700 on discs A and D. Start the both side of discs with 6 inch.

6.6

Change the mass position of both discs. Change the both discs position untill the dynamic balancing is formed

6.7 6.8

Record the mass position of the mass in the result table. Use the Mr polygon diagram to calculate the X value. And the load 1.1 kg is placed at X distance.

7.0

RESULT: The position of the load radius for load 1.0kg weight discs A is 3 radius The position of the load radius for load 1.1kg weight at disc D is 4 radius

8.0

DISCUSSION AND CONCLUSION: Select plane A as a reference plane.

ROTATION PLANE A B C D

MASS , M (KG) 1.0 1.0 1.4 1.1

RADIUS, r (INCH) 3 5 4 4

Mr (KG INCH) 3.0 5.0 5.6 4.4

DISTANCE, L (INCH) 6 6 6 0

MRL (KG INCH2) 18 30 33.6 0

Draw the Mr polygon diagram. Compare the experiment results with the result from drawing method

Period of oscillation = 6.1 second F = 1/6.1 = 0.1639Hz Natural frequency, Wn = 2(0.1639) = 1.0298 rps

Das könnte Ihnen auch gefallen

- METTL PERSONALITY TEST REVEALS INDIVIDUAL STRENGTHSDokument6 SeitenMETTL PERSONALITY TEST REVEALS INDIVIDUAL STRENGTHSVijeesh MNoch keine Bewertungen

- Problem On Equation of Motion For Damped Free VibrationDokument4 SeitenProblem On Equation of Motion For Damped Free VibrationKristine Ann Reclosado100% (1)

- CH-10 Plane Motion of Rigid Bodies 2Dokument13 SeitenCH-10 Plane Motion of Rigid Bodies 2Anshuman SinghNoch keine Bewertungen

- Verify Conservation of Linear MomentumDokument8 SeitenVerify Conservation of Linear MomentumAlex YoungNoch keine Bewertungen

- AssignDokument10 SeitenAssignkakaNoch keine Bewertungen

- Mechanical VibrationsDokument57 SeitenMechanical VibrationsHari Tej AvvaruNoch keine Bewertungen

- Question Bank (Unit I) Cs6402-Design and Analysis of Algorithms Part - ADokument12 SeitenQuestion Bank (Unit I) Cs6402-Design and Analysis of Algorithms Part - Aviju001Noch keine Bewertungen

- Code: Kdm2-1 Title: Basic of Balancing 1.0 Learning Outcome at The End of This Experiment, The Student Should Be Able ToDokument5 SeitenCode: Kdm2-1 Title: Basic of Balancing 1.0 Learning Outcome at The End of This Experiment, The Student Should Be Able ToMohd Irman100% (1)

- Machine Dynamics Lab ManualDokument18 SeitenMachine Dynamics Lab ManualRishi ShuklaNoch keine Bewertungen

- Sr. No. Practical 1: Static and Dynamic Balancing of Rotating MassesDokument21 SeitenSr. No. Practical 1: Static and Dynamic Balancing of Rotating MassesFa CaNoch keine Bewertungen

- Lab Session No 10: Learning ObjectiveDokument18 SeitenLab Session No 10: Learning ObjectiveMuhammad AbdullahNoch keine Bewertungen

- Static & Dynamic Balancing: I-IntroductionDokument10 SeitenStatic & Dynamic Balancing: I-Introductionboud3Noch keine Bewertungen

- ME 354A Vibration Problems and SolutionsDokument4 SeitenME 354A Vibration Problems and SolutionsAkhilNoch keine Bewertungen

- Exp 6 Melita 06Dokument14 SeitenExp 6 Melita 06jumanneshambiNoch keine Bewertungen

- Assignment-1 Vibrations 2017Dokument3 SeitenAssignment-1 Vibrations 2017Arpit Sharma0% (1)

- Lab Report 1-Engineering StaticsDokument5 SeitenLab Report 1-Engineering StaticsAndhika UtamaNoch keine Bewertungen

- Hydraulic RamDokument16 SeitenHydraulic RamAbdul HameedNoch keine Bewertungen

- 5 Study of Ballistic PendulumDokument8 Seiten5 Study of Ballistic PendulumMathaven Rajoo0% (2)

- Rotational Inertia: Ma T MG FDokument8 SeitenRotational Inertia: Ma T MG FharpreetNoch keine Bewertungen

- Mechanics L8Dokument39 SeitenMechanics L8Charlie LaiNoch keine Bewertungen

- Tutorial Sheet 1Dokument3 SeitenTutorial Sheet 1Shashank SrivastavaNoch keine Bewertungen

- рисунки PDFDokument18 Seitenрисунки PDFLeo KutsNoch keine Bewertungen

- Static and Dynamic Balancing: Experiment#2Dokument4 SeitenStatic and Dynamic Balancing: Experiment#2Maqbool Khan100% (1)

- Lab Report On Inertia WheelDokument4 SeitenLab Report On Inertia WheelAngela Leong Feng Ping100% (4)

- Static & Dynamic BalancingDokument5 SeitenStatic & Dynamic BalancingSchöberl ErichNoch keine Bewertungen

- SHM of a tethered trolley experimentDokument2 SeitenSHM of a tethered trolley experimentMaria MirahNoch keine Bewertungen

- UTHM Mechanical Engineering document on rotor balancingDokument46 SeitenUTHM Mechanical Engineering document on rotor balancinghamryNoch keine Bewertungen

- Mass Moment of Inertia of FlywheelDokument8 SeitenMass Moment of Inertia of Flywheelabdulaziz67% (3)

- Mechanical Vibration Kme - 057: Frequency Calculation Equivalent SystemDokument14 SeitenMechanical Vibration Kme - 057: Frequency Calculation Equivalent Systemprashant uttamNoch keine Bewertungen

- M.tech Kinematics Dynamics Lab RecDokument20 SeitenM.tech Kinematics Dynamics Lab Recmevitsn6Noch keine Bewertungen

- ME-346 Lab SheetDokument17 SeitenME-346 Lab SheetZayed KhanNoch keine Bewertungen

- Dynamics LabDokument14 SeitenDynamics LabDhiraj ThakurNoch keine Bewertungen

- NCERT Solutions for Class 11 Physics Chapter 7 System of ParticlesDokument32 SeitenNCERT Solutions for Class 11 Physics Chapter 7 System of Particleserfgtrgv vfvvvNoch keine Bewertungen

- Three Cylinder Engine Turning Moment Diagram AnalysisDokument57 SeitenThree Cylinder Engine Turning Moment Diagram AnalysisRasikaPereraNoch keine Bewertungen

- Structural Analysis LabDokument29 SeitenStructural Analysis Labsamiee_meNoch keine Bewertungen

- Engineering Vibrations LectureDokument25 SeitenEngineering Vibrations LectureRoy Vincent Villasfer100% (1)

- Tom 8Dokument7 SeitenTom 8Om TandelNoch keine Bewertungen

- Measure Spring Constant and Natural FrequencyDokument15 SeitenMeasure Spring Constant and Natural FrequencyCma WeyhNoch keine Bewertungen

- Dyn Labrep1Dokument10 SeitenDyn Labrep1Vivin MathewNoch keine Bewertungen

- Tutorial Chapter 3Dokument2 SeitenTutorial Chapter 3hanaNoch keine Bewertungen

- LabDokument14 SeitenLabJeff KwhNoch keine Bewertungen

- Gnitc/Set/Dme Kinematics&Dynamics LabDokument32 SeitenGnitc/Set/Dme Kinematics&Dynamics LabdivyanshNoch keine Bewertungen

- Chapter 17Dokument89 SeitenChapter 17thulf100% (2)

- HiwotDokument16 SeitenHiwotFiker FikerwessenuNoch keine Bewertungen

- ME2307 Lab ManualDokument14 SeitenME2307 Lab ManualAnirudhan RaviNoch keine Bewertungen

- Rotational Inertia FixDokument7 SeitenRotational Inertia FixAndi Rafika Dwi RachmaNoch keine Bewertungen

- Part-A: Homework No.4 PHY101: MechanicsDokument2 SeitenPart-A: Homework No.4 PHY101: Mechanicsprabhat_007Noch keine Bewertungen

- 14-Experiment 11Dokument3 Seiten14-Experiment 11ZuhdiismailNoch keine Bewertungen

- (A) Energy of The Cylinder at Point ADokument25 Seiten(A) Energy of The Cylinder at Point AGaurav ShekharNoch keine Bewertungen

- Applied Mechanics Lab - PGBDDFDokument41 SeitenApplied Mechanics Lab - PGBDDFyahska1305Noch keine Bewertungen

- ROTATING MASSES BALANCINGDokument25 SeitenROTATING MASSES BALANCINGEngineering DesignNoch keine Bewertungen

- Rolling On An Inclined PlaneDokument10 SeitenRolling On An Inclined PlaneRichard Puni75% (4)

- Return to CEMB Beginning 1: Understanding Unbalance and Its EffectsDokument27 SeitenReturn to CEMB Beginning 1: Understanding Unbalance and Its EffectsRaphael LemosNoch keine Bewertungen

- Multiple Choice Mechanics ExamDokument5 SeitenMultiple Choice Mechanics ExamAvnish GargNoch keine Bewertungen

- CHPT 07Dokument14 SeitenCHPT 07sambarta.sanyalNoch keine Bewertungen

- Solid Mechanics Balancing Tutorial - Balancing of Rotating BodiesDokument0 SeitenSolid Mechanics Balancing Tutorial - Balancing of Rotating BodiesIman SatriaNoch keine Bewertungen

- Sem 2 PHYS TUT BOOK 2017Dokument76 SeitenSem 2 PHYS TUT BOOK 2017Cynthia ValerianaNoch keine Bewertungen

- Physics 211 Experiment # 10 Measurement of Moment of Inertia ObjectiveDokument7 SeitenPhysics 211 Experiment # 10 Measurement of Moment of Inertia ObjectiveKhabi NadaNoch keine Bewertungen

- Module 1Dokument17 SeitenModule 1robejr2013Noch keine Bewertungen

- Rotational Equilibrium and Rotational Dynamics StudentDokument13 SeitenRotational Equilibrium and Rotational Dynamics StudentMark PaulNoch keine Bewertungen

- Eng Sample Paper 2 With Ans 1299Dokument12 SeitenEng Sample Paper 2 With Ans 1299Mikky TripathiNoch keine Bewertungen

- Dissertation Que Pensez Vous de La ModeDokument5 SeitenDissertation Que Pensez Vous de La ModeCollegePapersForSaleCanada100% (1)

- Forging Sustainable Change at Tata Steel: by T.V. Narendran and Amit GaneriwallaDokument9 SeitenForging Sustainable Change at Tata Steel: by T.V. Narendran and Amit GaneriwallaAnkit BansalNoch keine Bewertungen

- Module 1 SDG Q2Dokument21 SeitenModule 1 SDG Q2araymundoNoch keine Bewertungen

- Bac Sample 1Dokument2 SeitenBac Sample 1Kouam AbdelkaderNoch keine Bewertungen

- Risk Management Plan - Philippine-Specific AnnexDokument2 SeitenRisk Management Plan - Philippine-Specific Annexultimate_2226252Noch keine Bewertungen

- Promoting Self Esteem: Presented by Shilpa Hotakar MSC Nursing Dept of Psychiatric NursingDokument23 SeitenPromoting Self Esteem: Presented by Shilpa Hotakar MSC Nursing Dept of Psychiatric NursingShilpa Vhatkar0% (1)

- LDC LP No. 06 DTD 8th January 2024Dokument12 SeitenLDC LP No. 06 DTD 8th January 2024Shubhajit ChakrabortyNoch keine Bewertungen

- Intro To Remote Sensing Test QuestionsDokument3 SeitenIntro To Remote Sensing Test QuestionsdannyNoch keine Bewertungen

- Numerical Differentiation and Integration: By: Habtamu GaromaDokument53 SeitenNumerical Differentiation and Integration: By: Habtamu GaromaAmiin HirphoNoch keine Bewertungen

- FIRST-TERM FORM TEST (2020/21) Form Two Integrated Science: Instructions Multiple-Choice Answer SheetDokument14 SeitenFIRST-TERM FORM TEST (2020/21) Form Two Integrated Science: Instructions Multiple-Choice Answer SheetYuki LiNoch keine Bewertungen

- Chapter 7 Project Cost ManagementDokument48 SeitenChapter 7 Project Cost Managementafifah suyadiNoch keine Bewertungen

- Clark, THE STEADY-STATE PERFORMANCE OF A SOLAR STILLDokument7 SeitenClark, THE STEADY-STATE PERFORMANCE OF A SOLAR STILLsama aldabaghNoch keine Bewertungen

- Angular Dispersion and Dispersive PowerDokument6 SeitenAngular Dispersion and Dispersive PowerShivkant SinghNoch keine Bewertungen

- Advanced Pranic Healing Pranic CrystalDokument6 SeitenAdvanced Pranic Healing Pranic CrystalbombeiromaxNoch keine Bewertungen

- Bsce Quarantine Reviewer Diagnostic Exams PDFDokument27 SeitenBsce Quarantine Reviewer Diagnostic Exams PDFLaurence CervoNoch keine Bewertungen

- General FileDokument15 SeitenGeneral FileMayega BrianNoch keine Bewertungen

- SCB Chemical Solutions - HAZOPDokument20 SeitenSCB Chemical Solutions - HAZOPGuillyNoch keine Bewertungen

- Proof of Performance Mobilith SHC 1500 Zahnradkupplung in Kohleminen EngDokument1 SeiteProof of Performance Mobilith SHC 1500 Zahnradkupplung in Kohleminen EngLaurent GuyotNoch keine Bewertungen

- Head Boy and Girl Final Application FormDokument5 SeitenHead Boy and Girl Final Application FormboobooNoch keine Bewertungen

- 11.1 - Skill Acquisition: Assessment Statement Notes 11.1.1Dokument3 Seiten11.1 - Skill Acquisition: Assessment Statement Notes 11.1.1Alamedin SabitNoch keine Bewertungen

- Calamansi-Aloe Vera-Malunggay Organicantibacterial Hand SanitizerDokument7 SeitenCalamansi-Aloe Vera-Malunggay Organicantibacterial Hand SanitizerELIZABETH MABIDA100% (2)

- Refractory Installation Qualification ChecklistDokument3 SeitenRefractory Installation Qualification ChecklistSUNIL RAJPUTNoch keine Bewertungen

- SCSS1 Midterm Exam OutlineDokument5 SeitenSCSS1 Midterm Exam OutlineRezy ElegueNoch keine Bewertungen

- Mvc2 ManualDokument49 SeitenMvc2 ManualMICHELLE ALEXANDRA SOTOMAYOR MONTECINOSNoch keine Bewertungen

- Problem Solution and Cause EffectDokument20 SeitenProblem Solution and Cause EffectJhona NaragNoch keine Bewertungen

- ProjectDokument13 SeitenProjectFE3056 NAGARAJ.SNoch keine Bewertungen

- THC 6 Final Module 2Dokument142 SeitenTHC 6 Final Module 2Arvie Tejada100% (1)