Beruflich Dokumente

Kultur Dokumente

Safe Use of Work Platforms

Hochgeladen von

Francis Enriquez TanOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Safe Use of Work Platforms

Hochgeladen von

Francis Enriquez TanCopyright:

Verfügbare Formate

Safe Use of Work Platforms/ Trestles

This information sheet is produced for employers, employees and anyone who works at a height using work platforms or trestles. Its purpose is to inform you of some of the key issues required by the Work at Height regulations in relation to work platforms. It also tells you what you need to do to comply with the regulations. The work at height regulations set out the basic principles for safe work at height. The Regulations apply to all work at height using a work platform i.e scaffold, trestle, gangway, where there is a risk of a fall liable to cause personal injury. The regulations replace all the earlier regulations about working at height. Prior to the Work at Height Regulations the 2 meter rule existed. This is no longer the case and all work platforms must meet the requirements of the new regulations. What is a working platform? The work at height regulations define a working platform as any platform used as a place of work or as a means of access to or egress from a place of work, including any scaffold, suspended scaffold, cradle, mobile platform, trestle, gangway, gantry and stairway that is so used. As you can see the definition does include trestles and therefore this equipment is subject to requirements placed on working platforms by the new regulations. What is work at height? Work at height is work in any place, including a place at, above or below ground level, where a person could be injured if they fell from that place. Access and egress to a place of work can also be work at height. Examples of work activities that are classified as working at height: working on trestles working on a flat roof erecting falsework or formwork working on a ladder working at ground level adjacent to an excavation working on formwork within an excavation working near or adjacent to fragile materials As an employer, what do the Work at Height Regulations mean to me? The Work at Height Regulations requires employers to ensure that: all work at height is properly planned and organised a risk assessment is carried out for all work conducted at height appropriate work equipment is selected and used people working at a height are competent

Information Sheet

equipment used for work at height is properly inspected and maintained risks from fragile surfaces are properly controlled the risks associated with the equipment during erection, maintenance and dismantling of such equipment are taken into account. What is a risk assessment? A risk assessment is a careful examination of what could cause harm to people as a result of a work activity. It allows you to take the necessary precautions to prevent the harm occurring. In considering the necessary precautions the general principles of prevention must be taken into account. The work at height regulations are based on a risk assessment approach. When considering work at height, a risk assessment should be carried out in order to identify what the hazard is and the degree of risk present. How do I do a risk assessment? There are five steps to a risk assessment: 1. Look at the hazards. 2. Decide who might be harmed and how. 3. Evaluate the risks and decide whether the existing precautions are adequate or whether more should be done. 4. Record your findings. 5. Review your assessment. What do I need to consider if I am doing a risk assessment? If you are doing a risk assessment you need to consider the following: the work activity the equipment to be used the duration of the work the location of the work activity i.e. presence of hazards such as open excavation, underground services overhead power lines etc the working environment, e.g. weather conditions, lighting condition and stability of existing work surfaces physical capabilities of the workers e.g. vertigo suffers What is required when planning to do work at height? Any work at height needs to be planned in advance of the work activity. Careful consideration should be given to the selection and use of the work equipment so that a safe system of work is adopted. This safe system of work needs to take account of; any supervision of workers that may be necessary, e.g. work equipment selected lower down the hierarchy of control, such as fall arrest equipment, will require a high level of supervision; any weather conditions that workers may be exposed to, e.g. carrying out work on a sloped roof in icy or rainy conditions; any emergency or rescue procedures that may be required, e.g. if persons fall while using a fall arrest system. It is not acceptable to

rely on the emergency services. It needs to be covered in the risk assessment and planned prior to the start of the work activity. The user of fall arrest equipment and sufficient numbers of persons must have received adequate training in the use of the equipment and this includes immediate rescue procedures. For example, how will an unconscious person be rescued, after falling into a net? How will a person be rescued after falling in a fall arrest harness? You may need to consider the use of a mobile elevating work platform, or tower to undertake the rescue. What do I need to consider when selecting equipment for working at height? When selecting work equipment for use at height, the following need to be taken into account: the working environment: What are the ground conditions, are there space constraints, are other people working in the same area, will members of public be affected? the duration and frequency of use: Is the work activity of short duration, is it repetitive? emergency and rescue procedures: Can a timely evacuation and/or rescue be instigated? the task to be carried out: Does it require the use of both hands? Is it light duty? the risk, including the distance and consequences of any potential fall: Can a fall from the work equipment occur? If so, does this have the potential to cause injury? in the case of access and egress, what is the distance to be travelled? any other additional risks posed by the installation, use, dismantling or removal of the work equipment. the dimensions of the work equipment, to ensure a safe working area and safe passage the potential loadings of persons, equipment and materials is it appropriate for the nature of the work to be undertaken? The type of work equipment required should be selected in conjunction with the risk assessment in accordance with the hierarchy of control What do I have to do about falls below 2 metres? There has always been a duty to use a safe system of work and to prevent people from falling from any height. Under the construction regulations all falls were required to be prevented. For falls under 2 m a risk assessment determines what precautions are taken, while for over 2 m, the use of guardrails and working platforms (or other similar equipment) to prevent falls were required. Traditionally this meant that while using trestles for block work, plastering or access, that guardrails and toe boards were not required. This is no longer the case. The work at height regulations require the risk of a fall to be prevented wherever a fall is liable to cause personal injury. This means that for any

height where there is a risk of a fall causing personal injury then measures should be taken to prevent injury. The old division between low and high falls has gone. The duty is to prevent falls. There are almost as many low-fall injuries as high-fall injuries and low falls cause many serious injuries. The work at height regulations requires you to take a sensible risk-based approach to preventing falls. Where it is reasonably practicable to take precautions to prevent a fall, steps should be taken to do so. However, it is essential that a sensible and pragmatic approach is taken when addressing low falls, so precautions should only be taken when the scope and duration of the work presents a risk of injury. If the risk is trivial and it is not reasonably practical to take other precautions, then no action needs to be taken apart from training and instruction. What are the requirements for using working platforms/trestles? In considering whether a platform is suitable for work at height, employers need to ensure that it is: of sufficient dimensions to allow safe passage and safe use of equipment and materials; free from trip hazards or gaps through which persons or materials could fall; fitted with toeboards and handrails; kept clean and tidy, e.g. do not allow mortor and debris to build up on platforms; not loaded so as to give rise to a risk of collapse or to any deformation that could affect its safe use. This is particularly relevant in relation to blockwork loaded on trestles; erected on firm level ground to ensure equipment remains stable during use. Is it necessary to inspect working platforms? Work equipment, including working platforms at any height, including trestles must be inspected before use where the safety of the equipment depends on how it was erected or assembled. The purpose of such an inspection is to identify whether the equipment is fit for its purpose, has been properly assembled or installed, and can be used safely. Work equipment exposed to conditions causing deterioration that is liable to result in danger must be inspected at regular intervals, and also where any exceptional circumstances have occurred that are liable to jeopardise the safety of the equipment. These inspections are important in ensuring that the equipment can continue to be used safely and that any deterioration is detected and remedied before it results in unacceptable risks. A competent person should determine the nature, frequency and extent of any inspection, taking account of such factors as the type of equipment, how and where it is used, and the likelihood of deterioration. Periods between inspections should be chosen on the basis of risk assessment and should be reviewed in the light of experience.

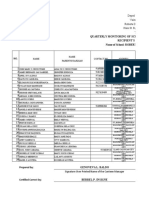

What is included in a report of inspection? A report of inspection should include: 1. The name and address of the person for whom the inspection was carried out. 2. The location of the work equipment inspected. 3. A description of the work equipment inspected. 4. The date and time of the inspection. 5. Details of any matter identified that could give rise to a risk to the safety or health of any employee. 6. Details of any action taken as a result of any matter identified in paragraph 7. Details of any further action considered necessary. 8. The name and position of the person making the report. Training Employee training is a key element to safe work platforms/trestles on site is employee training. Where appropriate, employee fs should be adequately trained in relation to erection, use and dismantling of work platforms. Employees should be aware of the safe systems of work when working at height and they should understand the principles of fall prevention. Supervision A lack of adequate site supervision can lead to unsafe work platforms being used on site. A strict checking and monitoring regime is needed on site. This regime should form part of the employee training and be reviewed on an ongoing basis.

Das könnte Ihnen auch gefallen

- Scaffolds Scaffolding Work General GuideDokument18 SeitenScaffolds Scaffolding Work General GuideSanjoy ChowdhuryNoch keine Bewertungen

- Play It SAFE: Working AT HeightDokument20 SeitenPlay It SAFE: Working AT Heightandi permanaNoch keine Bewertungen

- SWMS Scaffold FixedDokument11 SeitenSWMS Scaffold FixedEdha AliNoch keine Bewertungen

- 112 D HSE Bulletin Safe Working at HeightDokument1 Seite112 D HSE Bulletin Safe Working at HeightOws AnishNoch keine Bewertungen

- Working at Heights GuidelineDokument13 SeitenWorking at Heights GuidelineKwang Sun100% (1)

- Completed Example of A Risk Assessment - Example 1Dokument3 SeitenCompleted Example of A Risk Assessment - Example 1Rahil Tasawar0% (1)

- Scaffolding Written ReportDokument21 SeitenScaffolding Written ReportJenie Marie Nitoral100% (1)

- Scaffolding Safety: Erection of Mobile ScaffoldingDokument18 SeitenScaffolding Safety: Erection of Mobile Scaffoldingmuzica muzNoch keine Bewertungen

- HSA MEWPs GuidanceDokument20 SeitenHSA MEWPs GuidancemadmossyNoch keine Bewertungen

- Scaffold Ladder Safety 1569604009Dokument128 SeitenScaffold Ladder Safety 1569604009eerrddeemmNoch keine Bewertungen

- Concrete Preparation GeneralDokument14 SeitenConcrete Preparation GeneralTahar Berrachedi100% (1)

- Erection Manual Loyal Trade King 730Dokument14 SeitenErection Manual Loyal Trade King 730grandeNoch keine Bewertungen

- 7 Scaffolding SafetyDokument15 Seiten7 Scaffolding SafetyMithlesh SinghNoch keine Bewertungen

- Safe Work Procedure, Gem MaintenanceDokument46 SeitenSafe Work Procedure, Gem MaintenanceAsif Khanzada100% (1)

- Job Safety Analysis: Required References Jsa ReviewDokument3 SeitenJob Safety Analysis: Required References Jsa Reviewaioudi100% (2)

- Crane Lift Work PlatformDokument13 SeitenCrane Lift Work PlatformsheqarayzanNoch keine Bewertungen

- Scaffolding-Fixed and Mobile: Safety Operating ProceduresDokument1 SeiteScaffolding-Fixed and Mobile: Safety Operating Proceduresmohammed muzammilNoch keine Bewertungen

- Working at Heights ProcedureDokument16 SeitenWorking at Heights ProcedureHendrias Ari SujarwoNoch keine Bewertungen

- JSA Erection & Dismantling of ScaffoldingDokument3 SeitenJSA Erection & Dismantling of ScaffoldingMc Evans MagallanesNoch keine Bewertungen

- Scaffolding JSADokument10 SeitenScaffolding JSAlabaimathuatqn2000Noch keine Bewertungen

- GL 28 Material Loading PlatformDokument1 SeiteGL 28 Material Loading Platformtp101267Noch keine Bewertungen

- Suspended Scaffold Pre-Operation Inspection Checklist: Project InformationDokument4 SeitenSuspended Scaffold Pre-Operation Inspection Checklist: Project InformationMartine OtienoNoch keine Bewertungen

- Sample Swms Heights Mobile ScaffoldDokument7 SeitenSample Swms Heights Mobile ScaffoldAnonymous BzGb2fnfENoch keine Bewertungen

- SWP Working Safely at Height Version 2.01Dokument7 SeitenSWP Working Safely at Height Version 2.01marvinNoch keine Bewertungen

- SOP For Drill PressDokument1 SeiteSOP For Drill Press5am. exeNoch keine Bewertungen

- Best Practice Guidelines For Working at Height in New ZealandDokument25 SeitenBest Practice Guidelines For Working at Height in New ZealandPerwez21Noch keine Bewertungen

- WAH Final PresentationDokument72 SeitenWAH Final PresentationS RNoch keine Bewertungen

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Dokument3 SeitenKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNoch keine Bewertungen

- Elevating Work Platforms USADokument61 SeitenElevating Work Platforms USAdorpetNoch keine Bewertungen

- Design Scaffold Instruction REV3Dokument9 SeitenDesign Scaffold Instruction REV3le huy100% (1)

- Fall ProtectionDokument23 SeitenFall Protectionanwarhas05Noch keine Bewertungen

- SWP 025 Mechanical Lifts and Suspended LoadsDokument3 SeitenSWP 025 Mechanical Lifts and Suspended Loadsknabpsho100% (1)

- Risk Assessment Accessing Tower Crane For MaintenanceDokument6 SeitenRisk Assessment Accessing Tower Crane For MaintenanceSammie Williams100% (2)

- Working at Height EbookDokument14 SeitenWorking at Height EbookSubhi El Haj SalehNoch keine Bewertungen

- Sop LiftingDokument5 SeitenSop LiftingShaiful AnnuarNoch keine Bewertungen

- JSA ScaffoldingDokument2 SeitenJSA ScaffoldingHrishikesh UnnikrishnanNoch keine Bewertungen

- Lifting MaterialsDokument6 SeitenLifting MaterialsRoselyn SharronNoch keine Bewertungen

- TRA For ScaffoldingDokument3 SeitenTRA For Scaffoldingaparna_losariNoch keine Bewertungen

- Job Safety Analysis FormDokument2 SeitenJob Safety Analysis FormAbhaySngh100% (1)

- SRISE W@H Safety Training - Part 2Dokument29 SeitenSRISE W@H Safety Training - Part 2Mohammed SadruddinNoch keine Bewertungen

- Safety Management - Module2Dokument27 SeitenSafety Management - Module2Atienza ArjayNoch keine Bewertungen

- Qcs 2010 Section 11 Part 2.3.10 She Procedures - The Safe Use of CranDokument26 SeitenQcs 2010 Section 11 Part 2.3.10 She Procedures - The Safe Use of Cranbryanpastor106100% (7)

- Guide Scaffolds ScaffoldingDokument5 SeitenGuide Scaffolds ScaffoldingCoolaboo22Noch keine Bewertungen

- JSA Working in Live AreasDokument1 SeiteJSA Working in Live Areasyc safetyNoch keine Bewertungen

- Scaffold Safety GuideDokument17 SeitenScaffold Safety Guideuserr29990100% (2)

- RA Tower 0004 Dec 2011Dokument8 SeitenRA Tower 0004 Dec 2011grandeNoch keine Bewertungen

- Mobile Platform Safety RequirementDokument56 SeitenMobile Platform Safety Requirementtnsv222Noch keine Bewertungen

- Scaffolding Control & MeasuresDokument3 SeitenScaffolding Control & Measuresviswamanoj100% (1)

- Work at Heights On ConstructionDokument42 SeitenWork at Heights On ConstructionChristian100% (2)

- Working at Heights Checklist1112222333Dokument1 SeiteWorking at Heights Checklist1112222333Shojib khan100% (2)

- ScaffoldDokument8 SeitenScaffoldSAYED100% (1)

- FinalWorking at HeightDokument38 SeitenFinalWorking at HeightcrisorpilsNoch keine Bewertungen

- Practical Alternatives To Using StepladdersDokument18 SeitenPractical Alternatives To Using StepladdersBazzer1947Noch keine Bewertungen

- 16.1 Fall Protection PlanDokument11 Seiten16.1 Fall Protection PlanMelissa SmithNoch keine Bewertungen

- Wah BookletDokument17 SeitenWah BookletPrayitno Budi Cahaya SantosoNoch keine Bewertungen

- Working at HeightDokument19 SeitenWorking at Heightoky kurniawanNoch keine Bewertungen

- Working at Height: A Brief GuideDokument7 SeitenWorking at Height: A Brief Guidefredu3Noch keine Bewertungen

- Working at Height Day 2Dokument48 SeitenWorking at Height Day 2OsamaAlaasamNoch keine Bewertungen

- Working at Height Day 2Dokument46 SeitenWorking at Height Day 2OsamaAlaasam67% (3)

- Oct-Nov-WSO Newsletter-2022Dokument18 SeitenOct-Nov-WSO Newsletter-2022Francis Enriquez TanNoch keine Bewertungen

- Risk Assessment - 1106Dokument2 SeitenRisk Assessment - 1106Francis Enriquez TanNoch keine Bewertungen

- Risk Assessment - 1059Dokument3 SeitenRisk Assessment - 1059Francis Enriquez TanNoch keine Bewertungen

- Defensive DrivingDokument54 SeitenDefensive DrivingFrancis Enriquez TanNoch keine Bewertungen

- Risk Assessment For External Façade & Canopies CleaningDokument8 SeitenRisk Assessment For External Façade & Canopies CleaningFrancis Enriquez Tan100% (1)

- Cleaning Window Risk AssessmentDokument3 SeitenCleaning Window Risk AssessmentFrancis Enriquez TanNoch keine Bewertungen

- Method Statement For Scaffolding WorksDokument17 SeitenMethod Statement For Scaffolding WorksFrancis Enriquez TanNoch keine Bewertungen

- Daily Observation Report: Health, Safety & EnvironmentDokument3 SeitenDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNoch keine Bewertungen

- Daily Observation Report: Health, Safety & EnvironmentDokument3 SeitenDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNoch keine Bewertungen

- 2021 - 10 - 04 - Ddab-Hse-Dor-Contraco - JJJDokument3 Seiten2021 - 10 - 04 - Ddab-Hse-Dor-Contraco - JJJFrancis Enriquez TanNoch keine Bewertungen

- 2021-10-02 - Ddab-Hse-Dor-Contraco - RBLDokument3 Seiten2021-10-02 - Ddab-Hse-Dor-Contraco - RBLFrancis Enriquez TanNoch keine Bewertungen

- Daily Observation Report: Health, Safety & EnvironmentDokument3 SeitenDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNoch keine Bewertungen

- Guideline For Plans SubmissionDokument7 SeitenGuideline For Plans SubmissionPrathamesh ShevaleNoch keine Bewertungen

- 2021-10-02 - Ddab-Hse-Dor-Contraco - RBLDokument3 Seiten2021-10-02 - Ddab-Hse-Dor-Contraco - RBLFrancis Enriquez TanNoch keine Bewertungen

- 2021.10.2 - Ddab-Hse-Dor-Contraco - MDDokument2 Seiten2021.10.2 - Ddab-Hse-Dor-Contraco - MDFrancis Enriquez Tan100% (1)

- Daily Observation Report: Health, Safety & EnvironmentDokument3 SeitenDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNoch keine Bewertungen

- 2021.10.2 - Ddab-Hse-Dor-Contraco - JJJDokument3 Seiten2021.10.2 - Ddab-Hse-Dor-Contraco - JJJFrancis Enriquez TanNoch keine Bewertungen

- 2021.10.02 - Ddab-Hse-Dor-Contraco - RFMDokument2 Seiten2021.10.02 - Ddab-Hse-Dor-Contraco - RFMFrancis Enriquez TanNoch keine Bewertungen

- 2021.10.02 - Ddab-Hse-Dor-Contraco - VNDokument2 Seiten2021.10.02 - Ddab-Hse-Dor-Contraco - VNFrancis Enriquez TanNoch keine Bewertungen

- Daily Observation Report: Health, Safety & EnvironmentDokument3 SeitenDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNoch keine Bewertungen

- 2021.10.02 - Ddab-Hse-Dor-Contraco - MNLDokument3 Seiten2021.10.02 - Ddab-Hse-Dor-Contraco - MNLFrancis Enriquez TanNoch keine Bewertungen

- Daily Observation Report: Health, Safety & EnvironmentDokument3 SeitenDaily Observation Report: Health, Safety & EnvironmentFrancis Enriquez TanNoch keine Bewertungen

- 2021.10.02 - Ddab-Hse-Dor-Contraco - AmpDokument2 Seiten2021.10.02 - Ddab-Hse-Dor-Contraco - AmpFrancis Enriquez TanNoch keine Bewertungen

- Ev01 - Hse Induction Attendance SheetDokument5 SeitenEv01 - Hse Induction Attendance SheetFrancis Enriquez TanNoch keine Bewertungen

- Assignment Nos. 3 - Scaffolding Risk AssessmentDokument11 SeitenAssignment Nos. 3 - Scaffolding Risk AssessmentFrancis Enriquez Tan100% (1)

- Ev05 - Safety Task Analysis Reduction - Star Card in Different LanguageDokument3 SeitenEv05 - Safety Task Analysis Reduction - Star Card in Different LanguageFrancis Enriquez TanNoch keine Bewertungen

- Additional Guidance Unit 1Dokument5 SeitenAdditional Guidance Unit 1Francis Enriquez TanNoch keine Bewertungen

- Ev04 - Behavioral Based Safety Training SlidesDokument21 SeitenEv04 - Behavioral Based Safety Training SlidesFrancis Enriquez TanNoch keine Bewertungen

- Ev02 - Brief Program For New Work at Height CampaignDokument2 SeitenEv02 - Brief Program For New Work at Height CampaignFrancis Enriquez TanNoch keine Bewertungen

- Heat IndexDokument2 SeitenHeat IndexFrancis Enriquez TanNoch keine Bewertungen

- MalariaDokument170 SeitenMalariatummalapalli venkateswara rao100% (4)

- Adverse Events Associated With Melatonin For The Treatment of Primary or Secondary Sleep Disorders: A Systematic ReviewDokument20 SeitenAdverse Events Associated With Melatonin For The Treatment of Primary or Secondary Sleep Disorders: A Systematic ReviewZach Segmuel MiñanoNoch keine Bewertungen

- Pengaruh Aplikasi Pyraclostrobin Terhadap Serangan Penyebab Penyakit Bulai Pada Lima Varietas Jagung (Zea Mays)Dokument8 SeitenPengaruh Aplikasi Pyraclostrobin Terhadap Serangan Penyebab Penyakit Bulai Pada Lima Varietas Jagung (Zea Mays)Rajif S. YahyaNoch keine Bewertungen

- Adver PaperDokument10 SeitenAdver PaperDee Jay de JesusNoch keine Bewertungen

- Evaluation Tool (Competency Based) - NonescostDokument35 SeitenEvaluation Tool (Competency Based) - NonescostFroilan GuilleranNoch keine Bewertungen

- Coca Cola The Water Stewardship and Replanish Report1 2012Dokument80 SeitenCoca Cola The Water Stewardship and Replanish Report1 2012CSRmedia.ro NetworkNoch keine Bewertungen

- Applying A Feminist Lens To Indias Foreign Policy A Compendium of EssaysDokument124 SeitenApplying A Feminist Lens To Indias Foreign Policy A Compendium of EssaysRasced AliNoch keine Bewertungen

- Inventory Management NestleDokument40 SeitenInventory Management Nestlesrinivas2help883675% (4)

- Cancer - 2011 - Hajdu - A Note From History Landmarks in History of Cancer Part 2Dokument10 SeitenCancer - 2011 - Hajdu - A Note From History Landmarks in History of Cancer Part 2Pilar AufrastoNoch keine Bewertungen

- K4health-The Mhealth Planning Guide Key Considerations For Integrating Mobile Technology Into Health Programs-2015!04!06Dokument49 SeitenK4health-The Mhealth Planning Guide Key Considerations For Integrating Mobile Technology Into Health Programs-2015!04!06DitaMaryaniNoch keine Bewertungen

- Ijc Heart & Vasculature: SciencedirectDokument8 SeitenIjc Heart & Vasculature: SciencedirectFerdi YuanNoch keine Bewertungen

- Rewirement With Notes The Science of Well-BeingDokument33 SeitenRewirement With Notes The Science of Well-Beingswikar AcharyaNoch keine Bewertungen

- Apply Appropriate Safety Measures While Working inDokument28 SeitenApply Appropriate Safety Measures While Working inNanette A. Marañon-Sansano100% (5)

- Appendix - F2 - RAPDokument156 SeitenAppendix - F2 - RAPMecha MartiniNoch keine Bewertungen

- ENA - TS - 41-37 - Part - 3 CBDokument40 SeitenENA - TS - 41-37 - Part - 3 CBRodolfo DelgadoNoch keine Bewertungen

- PDokument3 SeitenPPamela GuevaraNoch keine Bewertungen

- Sps PPR CleaningDokument5 SeitenSps PPR CleaningManutençãoTI TechNoch keine Bewertungen

- Ethiopia - Design Gudeline Final - OromiaDokument71 SeitenEthiopia - Design Gudeline Final - OromiaEphrem Gizachew100% (15)

- VACCP Template Checklist - SafetyCultureDokument7 SeitenVACCP Template Checklist - SafetyCulturepattysaborio520Noch keine Bewertungen

- Public Health Community Health Nursing: Goal: To Enable EveryDokument10 SeitenPublic Health Community Health Nursing: Goal: To Enable Everyjamie carpioNoch keine Bewertungen

- Patient Monitor PC-5000 User Manual PDFDokument85 SeitenPatient Monitor PC-5000 User Manual PDFdanniel9090100% (1)

- EQ11151903A ThyssenKrupp Full and Public ContractDokument130 SeitenEQ11151903A ThyssenKrupp Full and Public Contractmozhi selvamNoch keine Bewertungen

- School Canteen Feeding Program 2019 2020 K 6 1Dokument20 SeitenSchool Canteen Feeding Program 2019 2020 K 6 1MaryRoseTrinidadNoch keine Bewertungen

- No Sweat - Chapter 2: Escape The Vicious Cycle of FailureDokument27 SeitenNo Sweat - Chapter 2: Escape The Vicious Cycle of FailureAMACOM, Publishing Division of the American Management AssociationNoch keine Bewertungen

- User's Manual: M200A Syringe PumpDokument44 SeitenUser's Manual: M200A Syringe PumpGandavaa Enkhee50% (4)

- Biphasic and Polyphasic SleepDokument6 SeitenBiphasic and Polyphasic SleepalNoch keine Bewertungen

- Medical Supplies - English VocabularyDokument4 SeitenMedical Supplies - English Vocabularyfatimageraldinep2564Noch keine Bewertungen

- Medihuanna Brand GuidelinesDokument71 SeitenMedihuanna Brand GuidelinespuskickNoch keine Bewertungen

- FLOWSERVE 350-LNN 71569074-EDokument56 SeitenFLOWSERVE 350-LNN 71569074-Eroyert80100% (1)

- Barangay Peace and Order and Public Safety PlanDokument3 SeitenBarangay Peace and Order and Public Safety PlanPeter Fritz Boholst100% (1)