Beruflich Dokumente

Kultur Dokumente

Ultrasonic Ceramic Sensors (Ultrasonic Ceramic Transducers) U/H/S/Q

Hochgeladen von

garunanaras1992Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ultrasonic Ceramic Sensors (Ultrasonic Ceramic Transducers) U/H/S/Q

Hochgeladen von

garunanaras1992Copyright:

Verfügbare Formate

Ultrasonic Ceramic Sensors

Ultrasonic Ceramic Sensors (Ultrasonic Ceramic Transducers)

Type:

U/H/S/Q

Ultrasonic Ceramic Sensor consisting of a disc type/a bimorph type piezoelectric ceramic vibrator is a sensor for transmitting and receiving ultrasonic wave in the air.

s Features

q q q q q

High output S.P.L.: 112 dB min. (Ex. EFRTUB40K5) High sensitivity: 45 dB min. (Ex. EFRRUB40K5) Excellent temperature and humidity durability Small in size Applicable to multi-function remote control system because of its wide bandwidth

s Recommended Applications

Ultrasonic wave transmitter and receiver for; q Proximity switch for burglar alarm system, parking meter and automatic door opener q Remote control equipment for such as air conditioner and garage door opener

s Explanation of Part Numbers

1 2 3 4 5 6 7 8 9 10 11

Design No.

Nominal Product Code EFR Ultrasonic Ceramic Sensors R T Applications For reception use For transmission use U H Type Standard Type Compact Type Temperature Stable Type Enclosed Type Construction of Element B Bimorph Type Frequency 25K 40K 25 kHz 40 kHz

S Q

Design, Specifications are subject to change without notice.

Ask factory for technical specifications before purchase and/or use.

Whenever a doubt about safety arises from this product, please inform us immediately for technical consultation without fail.

EF72

Ultrasonic Ceramic Sensors

s Ratings and Characteristics

Type Part No. Item Nominal Frequency Sensitivity Sound Pressure Level Bandwidth Application Maximum Input Voltage Operating Temperature Range (Vrms) (C) Type Part No. Item Nominal Frequency Sensitivity Sound Pressure Level Bandwidth Application Maximum Input Voltage Operating Temperature Range (Vrms) (C) Type Part No. Item Nominal Frequency Sensitivity Sound Pressure Level Bandwidth Application Maximum Input Voltage Operating Temperature Range

V 0 dB=1 V/Pa VV 0 dB=2105 Pa

Ask factory for technical specifications before purchase and/or use.

Standard Type EFRRUB40K5 40.0 45 min. 4.0 min. Receiver EFRTUB40K5 40.0 112 min. 4.0 min. Transmitter 20 EFRRUB25K5 25.0 45 min. 2.5 min. Receiver 20 to 60 Compact Type EFRRHB40K5 40.0 47 min. 4.0 min. Receiver 20 to 60 Enclosed Type EFRRQB40K5 40.0 55 min. 1.0 min. Receiver EFRTQB40K5 40.0 105 min. 1.0 min. Transmitter 20 20 to 60 EFRTHB40K5 40.0 110 min. 4.0 min. Transmitter 20 Temperature Stable Type EFRRSB40K5 40.0 50 min. 4.0 min. Receiver 40 to 100 EFRTSB40K5 40.0 105 min. 4.0 min. Transmitter 20 EFRTUB25K5 25.0 105 min. 2.5 min. Transmitter 20

(kHz) (dB) (dB)

V

VV

(kHz)

(kHz) (dB) (dB)

V

VV

(kHz)

(kHz) (dB) (dB)

V

VV

(kHz)

(Vrms) (C)

Design, Specifications are subject to change without notice.

Whenever a doubt about safety arises from this product, please inform us immediately for technical consultation without fail.

EF73

Ultrasonic Ceramic Sensors

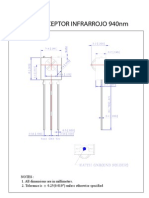

s Dimensions in mm (not to scale)

Type U Standard Type

f

Type H Compact Type

f

Type S TemperatureStable Type

f

Type Q Enclosed Type

f

13.0 0.5

10.0 0.5

13.0 0.5

10.0 1.5

Screen

Screen

16.0 0.5

12.6 0.5

16.0 0.5

f

18.0 0.5 12.0 0.5 2-f 0.8 0.2 7.5 0.5

Amp.

12.0 0.5

12.0 0.5

21.0 1.0

21.0 1.0

2-f 0.8 0.1 2-f 1.2 0.1

15.6 1.0

2-f 1.2 0.1

10.0 0.5

8.0 0.5

10.0 0.5

s Test Circuits Diagram

Test Circuit Diagram for Receiver

feed back 30cm Ein Osc. Tw. UCS Rec. RL Amp. UCS Silent Box SCM Rec.

Test Circuit Diagram for Transmitter

Amp. 30 cm Osc. SCM

Silent Box

Freq. Freq. Counter Counter

RL UCS SCM Amp. Osc. Rec. Tw.

: : : : : : :

3.9 k Ultrasonic Ceramic Sensor Standard Condenser Microphone Amplifier Oscillator Recorder Tweeter

Brel Brel Brel Brel

& & & &

Kjr Kjr Kjr Kjr

4135 2606 1013 2305

UCS SCM Amp. Osc. Rec. Ein

: : : : : :

Ultrasonic Ceramic Sensor Standard Condenser Microphone Amplifier Oscilator Recorder 10 Vrms.

Brel Brel Brel Brel

& & & &

Kjr Kjr Kjr Kjr

4135 2606 1013 2305

[Sensitivity] Output voltage of the specimen shall be measured in accordance with the specified Test Circuit and the specified test conditions. The output voltage shall be expressed in decibeles (dB), where 1 V/Pa is 0 dB.

[Sound Pressure Level] Maximum sound pressure level from the specimen shall be measured in accordance with the specified Test Circuit and the specified test conditions. The output sound pressure shall be expressed in decibeles (dB), where 2 105Pa is 0 dB.

Design, Specifications are subject to change without notice.

Ask factory for technical specifications before purchase and/or use.

Whenever a doubt about safety arises from this product, please inform us immediately for technical consultation without fail.

EF74

24.5 1.0

9.5 0.5

Ultrasonic Ceramic Sensors

s Typical Characteristics

Frequency Characteristics (Sensitivity)

Type U / H

Frequency Characteristics (Sound Pressure Level)

Type U / H 40 Sensitivity (dB) 45 50 55 TypeS Output S.P.L. (dB) 115 110 105 100 TypeQ TypeS

TypeQ

35

40 Frequency (kHz)

45

35

40 Frequency (kHz)

45

EFRRUB25K

35

Output S.P.L.(dB) 40

45

50

55 115

110

105

100

95

EFRTUB25K

Sensitivity (dB)

20

25 Frequency (kHz)

30

20

25 Frequency (kHz)

30

Directivity Type U/H/S

0 dB= 41 dB

ft Le

Type Q

R ig ht

0 15 15

30 0

30

ft e L

15 30

15 30 0

R ig h t

45

45 45

45

60

-10 -20

60 60 75 75

10 20 30 40

60

75

-30 -40

75

90

0 10

30

50

30

10

90 90 0 10 30

Attenuation (dB)

50

30

10

90

Attenuation (dB)

Characteristic Change vs. Load Resistance Type U/H/S

(40 kHz)

Sensitivity (dB)

Type Q

100 k Sensitivity (dB) 30 35 40 45 50 55

10 k

1 k

30 100 k 35 10 k 40 45 50 55

3.9 k

3.9 k 1 k

35

40 Frequency (kHz)

45

35

40 Frequency (kHz)

45

Design, Specifications are subject to change without notice.

Ask factory for technical specifications before purchase and/or use.

Whenever a doubt about safety arises from this product, please inform us immediately for technical consultation without fail.

EF75

Ultrasonic Ceramic Sensors

Application Notes

Because the Ultrasonic Sensors are designed for use in the air, they can not be used under the water or others liquid. 1. Design Engineering Notes 1. Application of DC voltage DC voltage shall not be applied to the Ultrasonic Sensors because insulation resistance may deteriorate. 2. Maximum Input Voltage The Ultrasonic Sensors shall not be operated beyond the specified Maximum Input Voltage in the catalog or the specifications. 3. Characteristics change owing to load impedance Center frequency and sensitivity change in accordance with load impedance. Therefore, the load characteristics chart shall be taken into consideration in designing circuit. 4. In the Design of Transmitting Circuits It shall be noted that the impedance of the device is as low as 500 (approximately) at the resonance frequency. 2. Mounting Notes 1. Installation It is recommended to hold the Ultrasonic Sensors by means of rubberV sheets or cushions for absorption of mechanical stresses such as shock and vibration.

VExcept sulfurated rubber

2. Soldering Soldering of the lead terminals shall be done at a position of 2.5 mm or more apart from bottom plain of the devices. 3. Bending force to the Terminals Abnormal bending force shall not be applied to the terminals of the Sensors, otherwise holding parts of the terminals may be easily broken, resulting in failures and damages of the devices. 4. Directivity Please be cafeful enough in deciding facing position of the sensor because of directivity. 3. Storage Notes 1. Environmental Conditions The Ultrasonic Sensors shall not be operated and/or stored under following environmental conditions; a) To be exposed directly to water or salt water. b) Under conditions of dew formation or frost. c) Under conditions of corrosive atomosphere such as hydrogen sulfide, sulfurous acid, chlorine and ammonia. 2. Long Term Storage The Ultrasonic Sensors shall not be stored under severe conditions of high temperature and high humidity. Store them indoors under 40 C max. and 75 %RH max. Use them within one year and check the solderbility before use.

Design, Specifications are subject to change without notice.

Ask factory for technical specifications before purchase and/or use.

Whenever a doubt about safety arises from this product, please inform us immediately for technical consultation without fail.

EF76

Das könnte Ihnen auch gefallen

- TC4035Dokument3 SeitenTC4035ravix4755Noch keine Bewertungen

- Is Mc1 DatasheetDokument2 SeitenIs Mc1 DatasheetReinaldo SouzaNoch keine Bewertungen

- hk3370/hk3470 Service Manual: Harman/kardon Stereo ReceiverDokument123 Seitenhk3370/hk3470 Service Manual: Harman/kardon Stereo ReceiverBotelja VinaNoch keine Bewertungen

- Sultan ManualDokument97 SeitenSultan ManualMukeshKrNoch keine Bewertungen

- Service Manual Hrman Kardon AVR 430, AVR 630Dokument126 SeitenService Manual Hrman Kardon AVR 430, AVR 630aliarro100% (1)

- Gras 40aoDokument2 SeitenGras 40aoPalazzo345Noch keine Bewertungen

- ONKYO TX910-930 Service ManualDokument31 SeitenONKYO TX910-930 Service Manuala.mateNoch keine Bewertungen

- AVR110 Service Manual: Harman/kardonDokument127 SeitenAVR110 Service Manual: Harman/kardonRicardo CachorrãoNoch keine Bewertungen

- Submersible Liquid Level Transmitters Type LS-10, LH-10: ApplicationsDokument4 SeitenSubmersible Liquid Level Transmitters Type LS-10, LH-10: ApplicationsDragos NojeaNoch keine Bewertungen

- ATK200Dokument1 SeiteATK200Ermansyah SitorusNoch keine Bewertungen

- Andrew CNT 100 RDokument2 SeitenAndrew CNT 100 RsfynksNoch keine Bewertungen

- T8200 tube optimizer user manualDokument16 SeitenT8200 tube optimizer user manualPaolo MaghacotNoch keine Bewertungen

- Level Transmitter For Corrosive Media Atm/NcDokument4 SeitenLevel Transmitter For Corrosive Media Atm/NcJoseph TaylorNoch keine Bewertungen

- A141 Sounder DatasheetDokument3 SeitenA141 Sounder Datasheetbieniu24Noch keine Bewertungen

- Vital Components and Functions of an Electrical SubstationDokument20 SeitenVital Components and Functions of an Electrical Substationsanju0156100% (1)

- 60w SubwoferDokument3 Seiten60w Subwoferghimpe--Noch keine Bewertungen

- 50 W VHF Low-Profi Le Antenna HV 3012Dokument4 Seiten50 W VHF Low-Profi Le Antenna HV 3012nounouNoch keine Bewertungen

- User Guide: E2003, Shure IncorporatedDokument8 SeitenUser Guide: E2003, Shure IncorporatedElpidio StorolliNoch keine Bewertungen

- High-Performance Submersible Pressure Transmitter For Level Measurement Model LH-20Dokument6 SeitenHigh-Performance Submersible Pressure Transmitter For Level Measurement Model LH-20behnamatgNoch keine Bewertungen

- Iraudamp 11Dokument35 SeitenIraudamp 11Bin LowenNoch keine Bewertungen

- Service Manual: Harman/kardon A/V Dolby Digital ReceiverDokument87 SeitenService Manual: Harman/kardon A/V Dolby Digital ReceiverJim FordNoch keine Bewertungen

- Receptor IR TSOP4836Dokument7 SeitenReceptor IR TSOP4836damijoseNoch keine Bewertungen

- Metrel Mi 3290 Earth AnalyserDokument4 SeitenMetrel Mi 3290 Earth AnalyserMarijan MustačNoch keine Bewertungen

- Compact NSX Lv430745Dokument4 SeitenCompact NSX Lv430745yannrodrigues97Noch keine Bewertungen

- RC 1976 03Dokument66 SeitenRC 1976 03Jan PranNoch keine Bewertungen

- Ka Band Antenna 6m SaleDokument18 SeitenKa Band Antenna 6m SaleWahid ZubediNoch keine Bewertungen

- Amplituner Technics SA-EX310Dokument45 SeitenAmplituner Technics SA-EX310Terry MorleyNoch keine Bewertungen

- Konka Kp2107astn SMDokument14 SeitenKonka Kp2107astn SMrhozel2010Noch keine Bewertungen

- Ultralow Noise Bifet Op Amp Ad743: MV P-P, 0.1 HZ To 10 HZDokument12 SeitenUltralow Noise Bifet Op Amp Ad743: MV P-P, 0.1 HZ To 10 HZRicardo Teixeira de AbreuNoch keine Bewertungen

- Electromagnetic Buzzers Pin Terminal SD Series: Conformity To Rohs DirectiveDokument4 SeitenElectromagnetic Buzzers Pin Terminal SD Series: Conformity To Rohs DirectiveYugi Abdul LathifNoch keine Bewertungen

- Product Data Sheet: Circuit Breaker Compact Nsx100F, 36 Ka at 415 Vac, Micrologic 4.2 Vigi Trip Unit 100 A, 4 Poles 4DDokument3 SeitenProduct Data Sheet: Circuit Breaker Compact Nsx100F, 36 Ka at 415 Vac, Micrologic 4.2 Vigi Trip Unit 100 A, 4 Poles 4Daditya agasiNoch keine Bewertungen

- RCB600 :: ROAL Living EnergyDokument10 SeitenRCB600 :: ROAL Living EnergyroalscribdNoch keine Bewertungen

- LED IR 940nm (RX)Dokument7 SeitenLED IR 940nm (RX)fcruzyNoch keine Bewertungen

- Pressure Transmitter For Level Measurement Atm/NDokument4 SeitenPressure Transmitter For Level Measurement Atm/NJoseph TaylorNoch keine Bewertungen

- Re-Entrant Paging Horn Speakers: Acoustic ModelingDokument4 SeitenRe-Entrant Paging Horn Speakers: Acoustic ModelingelshoubryNoch keine Bewertungen

- TM 241A ManualDokument59 SeitenTM 241A ManualoeterrelNoch keine Bewertungen

- Standard Microphone Test Object: OSC AMP RECDokument1 SeiteStandard Microphone Test Object: OSC AMP RECCarlos AlexandreNoch keine Bewertungen

- ILER-40 SSB QRP Transceiver Assembly ManualDokument38 SeitenILER-40 SSB QRP Transceiver Assembly Manualmail5452Noch keine Bewertungen

- VISHAY Standard Avalanche Sinterglass Diodes 1N5059-1N5062Dokument5 SeitenVISHAY Standard Avalanche Sinterglass Diodes 1N5059-1N5062AndersonBachNoch keine Bewertungen

- JBL PSW-D110/DPS-10 powered subwoofer service manualDokument28 SeitenJBL PSW-D110/DPS-10 powered subwoofer service manualJose Luis Moran ChinchayNoch keine Bewertungen

- CP 060 en PenningvacDokument8 SeitenCP 060 en PenningvacMayur ChauhanNoch keine Bewertungen

- AVR-65 Specs and FeaturesDokument81 SeitenAVR-65 Specs and FeaturesneonestNoch keine Bewertungen

- Harman Kardon Avr7000Dokument163 SeitenHarman Kardon Avr7000videosonNoch keine Bewertungen

- Affordable 40PH Array MicrophoneDokument2 SeitenAffordable 40PH Array MicrophoneDino SilvaNoch keine Bewertungen

- BP104 Data SheetsDokument5 SeitenBP104 Data SheetssegalignoNoch keine Bewertungen

- Compact NSX Lv431630Dokument3 SeitenCompact NSX Lv431630intescolimauNoch keine Bewertungen

- 3017C-SIP9: SANYO Electric Co.,Ltd. Semiconductor Bussiness HeadquartersDokument5 Seiten3017C-SIP9: SANYO Electric Co.,Ltd. Semiconductor Bussiness HeadquartersHumberto Trujillo OrtizNoch keine Bewertungen

- C3704Dokument2 SeitenC3704Ardillah PrawiraNoch keine Bewertungen

- FIN21 Three Phase Parallel Filters: Electric CharacteristicsDokument3 SeitenFIN21 Three Phase Parallel Filters: Electric CharacteristicsTeo GonzalezNoch keine Bewertungen

- ComPact NSX - LV430630Dokument3 SeitenComPact NSX - LV430630Ahmad Sayyiddur RamadhanNoch keine Bewertungen

- ComPact NSX - LV4296358Dokument3 SeitenComPact NSX - LV4296358rezaprindaNoch keine Bewertungen

- RCB600 :: ROAL Living EnergyDokument10 SeitenRCB600 :: ROAL Living EnergyroalscribdNoch keine Bewertungen

- Timers, Time, Switches, Hour Meters & Supply MonitorsDokument24 SeitenTimers, Time, Switches, Hour Meters & Supply MonitorsnogeshwarNoch keine Bewertungen

- 933Dokument13 Seiten933Fernando Lopez DiazNoch keine Bewertungen

- Pioneer sx1300 sx2300 (ET)Dokument23 SeitenPioneer sx1300 sx2300 (ET)alecs_irgNoch keine Bewertungen

- VR Amplifier Guide - Features and Specifications of Top VR ModelsDokument12 SeitenVR Amplifier Guide - Features and Specifications of Top VR ModelsChristopher A ArcherNoch keine Bewertungen

- The Technician's Radio Receiver Handbook: Wireless and Telecommunication TechnologyVon EverandThe Technician's Radio Receiver Handbook: Wireless and Telecommunication TechnologyNoch keine Bewertungen

- Build Your Own Low-Power Transmitters: Projects for the Electronics ExperimenterVon EverandBuild Your Own Low-Power Transmitters: Projects for the Electronics ExperimenterBewertung: 5 von 5 Sternen5/5 (4)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsVon EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNoch keine Bewertungen

- Synthesizers A Brief IntroductionDokument60 SeitenSynthesizers A Brief IntroductionAyoub AmriNoch keine Bewertungen

- Vibration Sensors CatalogDokument17 SeitenVibration Sensors CatalogBATIAR2D2Noch keine Bewertungen

- Technote #Cm1 Vibcode: Correct Handling With The Vibcode TransducerDokument3 SeitenTechnote #Cm1 Vibcode: Correct Handling With The Vibcode TransducerJHON ANGEL VARGAS HUAHUASONCCONoch keine Bewertungen

- gp340 BrochureDokument2 Seitengp340 Brochuresayed bialNoch keine Bewertungen

- Eurocell Panel Vertical Polarization Half-Power Beam WidthDokument2 SeitenEurocell Panel Vertical Polarization Half-Power Beam WidthFerhat SayinNoch keine Bewertungen

- Smartotdr Ds Fop Nse AeDokument4 SeitenSmartotdr Ds Fop Nse AemoneyminderNoch keine Bewertungen

- Multiple Complaints Against Pittsburg - Kansas - Police Chief Brent Narges and Pittsburg - Kansas - Police Officer Larry Warner Dated September 4th, 2019Dokument16 SeitenMultiple Complaints Against Pittsburg - Kansas - Police Chief Brent Narges and Pittsburg - Kansas - Police Officer Larry Warner Dated September 4th, 2019Conflict GateNoch keine Bewertungen

- Wavetek 184 Service ID13489Dokument13 SeitenWavetek 184 Service ID13489Demartino MicheleNoch keine Bewertungen

- Bird Manual de UsoDokument52 SeitenBird Manual de UsojozeolmosNoch keine Bewertungen

- AE Testing Fundamentals, Equipment, ApplicationsDokument30 SeitenAE Testing Fundamentals, Equipment, ApplicationsFernando Piñal MoctezumaNoch keine Bewertungen

- DR DG 10 Mo NRZDokument6 SeitenDR DG 10 Mo NRZGilbertoLageNoch keine Bewertungen

- Nepal Power Transmission Line DataDokument28 SeitenNepal Power Transmission Line DataMuzammil SayedNoch keine Bewertungen

- Centrimaster GT1 Technical Catalogue 2002 11 ENGDokument62 SeitenCentrimaster GT1 Technical Catalogue 2002 11 ENGCarlos PintoNoch keine Bewertungen

- M002 069 3 - Mobi PackDokument12 SeitenM002 069 3 - Mobi PackAnonymous OFwyjaMyNoch keine Bewertungen

- Chapter 1 Introduction To Communication SystemsDokument16 SeitenChapter 1 Introduction To Communication SystemsMelz WiggieNoch keine Bewertungen

- Test Equipment Solutions DatasheetDokument5 SeitenTest Equipment Solutions DatasheetmagicecstaticNoch keine Bewertungen

- Hearing: Frequency and Volume Gizmo Student Exploration GuideDokument8 SeitenHearing: Frequency and Volume Gizmo Student Exploration GuideDifficultiesNoch keine Bewertungen

- 2519 - Solved Problems For MCDokument4 Seiten2519 - Solved Problems For MCNihal GuptaNoch keine Bewertungen

- Gps RF Front-End Considerations: Component Selection GuideDokument102 SeitenGps RF Front-End Considerations: Component Selection GuideaslamNoch keine Bewertungen

- Power Your Signal: Antenna SpecificationsDokument3 SeitenPower Your Signal: Antenna SpecificationsAntonNoch keine Bewertungen

- Adu451604 PDFDokument2 SeitenAdu451604 PDFAnnBlissNoch keine Bewertungen

- أسئلة دورات تجميعDokument131 Seitenأسئلة دورات تجميعRashed Abu AlsondosNoch keine Bewertungen

- Le3 VT23Dokument110 SeitenLe3 VT23John DanielNoch keine Bewertungen

- IBPS Technical Officer Model Questions Electronics and Communication Paper IIDokument2 SeitenIBPS Technical Officer Model Questions Electronics and Communication Paper IIVijay PrakashNoch keine Bewertungen

- Manual Honeywell Opticki KalbloviDokument13 SeitenManual Honeywell Opticki KalbloviKovačević DarkoNoch keine Bewertungen

- ANT-A264521R2-2548 DatasheetDokument2 SeitenANT-A264521R2-2548 DatasheetDavid NigraNoch keine Bewertungen

- Li9Yc (ST) 11Y 4X2X0.15 GN: Leoni Special Cables GMBHDokument2 SeitenLi9Yc (ST) 11Y 4X2X0.15 GN: Leoni Special Cables GMBHLeodoletaNoch keine Bewertungen

- CQ 12 December 1945Dokument56 SeitenCQ 12 December 1945Сергей БезразличныйNoch keine Bewertungen

- Hexport Dual-Band Antenna: Hpa-65F-Buu-H2 Data SheetDokument7 SeitenHexport Dual-Band Antenna: Hpa-65F-Buu-H2 Data Sheetpandavision76100% (1)