Beruflich Dokumente

Kultur Dokumente

British Plastics & Rubber

Hochgeladen von

EcodekCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

British Plastics & Rubber

Hochgeladen von

EcodekCopyright:

Verfügbare Formate

composites

Success on an Ol for UK-based Com

The Olympic decking is a solid decking board that gives a lot of benefits ov

lympic scale

mposites Company

ver hollow composite decking

>

Vannplastic Limited, based in Saltney, Wales, is a UK small business enjoying an Olympicsized success story after being chosen to supply 3900 m2 (approx 110 tonnes) of its Ecodek composite decking for use in the VIP area of level 02 of the Olympic Stadium. The British-made wood polymer composite was chosen due to its ecological and sustainability credentials which fit in with the ethos for the 2012 Games. Together with the specifiers, Vannplastic designed a bespoke decking profile to meet stadia design regulations that allowed for drainage, but stopped litter falling through the gaps and therefore becoming a fire hazard. According to the company, the decking had to undergo stringent testing for slip resistance, load testing and burn resistance before it could get approval for use on the stadium. The Olympic Delivery Authority (ODA), the public body responsible for developing and building the new venues and infrastructure

Over 100 tonnes worth

Credit London 2012

for the Games and thei so impressed with the p their CEO, John Armitt, factory for a tour and p

h of Ecodek decking on the right hand side of the stadium in this picture

r use after 2012, was product that they sent down to the Ecodek presentation.

Leanne Taylor caught up with Alex Collins, Director of Vannplastic Ltd, to discover more about the project and what it means for the company as a UK small business. >

BP&R: As a small business, what does it mean to you to be awarded a contract to supply the Olympic games with your composite decking material? AC: Being approved as a supplier to the Olympic Stadium has given us even more credibility with large construction companies and architects alike. The ODAs flooring specification for the stadium was far in-excess of any standards we have had to meet in the past and as such, we had to subject our composite decking to some very rigorous testing procedures. All the testing was done on our standard Ecodek decking product and it passed with flying colours. Passing these stringent tests has given us and our customers even more faith in the qualities of our product. >

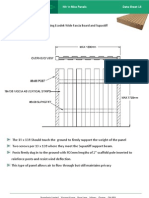

The bespoke decking profile has been designed to meet stadia regulations that allowed for drainage but stopped litter falling through the gaps

BP&R: How long was the process from initial specification to the completed project? AC: We were first contacted by the Stadiums specifiers in May 2009. We then had to get the product approved for visual appearance and price. The physical and slip testing started in July 2009, followed by factory inspections and audits from the ODA and its approved contractors. The profile design (mildly modified from the standard Ecodek deck board to include an overlap) was approved early 2010. After this, we had to write up installation guidelines and approve fasteners etc. The actual product did not commence supply until winter 2010. All 110 tonnes of Ecodek were then taken over a very short period of about eight weeks. BP&R: Can you explain more about composite decking, what its benefits are and how it measures up against traditional decking? AC: We never suggest the composite decking is there to replace wood, rather that it is an alternative, in the same way that stone or slabs would be. Good quality composite >

Alex Collins with John A

click to view advertisers page opens in new window

Armitt, CEO of the ODA at the Ecodek factory

decking offers many advantages over timber, the most obvious ones being reduced maintenance, no painting or staining, improved slip resistance, 95 percent recycled and 100 percent recyclable, smarter appearance, no splinters, available in custom lengths and in a range of colours. BP&R: How big an opportunity for UK businesses is having the Olympic games held in London? AC: I suspect that it is a fantastic opportunity for business based in the south of England, but the further North you go, the less of an opportunity it seems to have been. We are one of the very few companies in Wales to benefit from the games so far, and I feel thats a shame for the Welsh economy as a whole. BP&R: Were you up against a lot of competition to supply the material for the stadium? AC: Initially, I naively thought that we would easily get the contract due to the lack of other UK manufacturers of composite decking. I was soon put right on that and told that the country of manufacture was immaterial. In the end we were competing

against four or five othe manufacturers from all

BP&R: Can you explain up of the decking and particular materials ar

AC: Ecodek has full FSC and is made up from re fibres and recycled HDP ingredients are the pigm additives that improve s resistance, durability an absorption. Ecodek is a that gives a lot of bene composite decking. We fibres as these give bett properties, improved ap reduced fade when com based composite produ content is HDPE; we us very tough, has good lo resistance, excellent scr readily available in recyc BP&R: At the end its l recyclable?

AC: Yes, its 100 percen fully sustainable constru

click to view advertisers page opens in new window

er decking over Europe.

n the material maked why these re used?

C & PEFC certification eclaimed hardwood PE. The other ment system and strength, UV nd reduce moisture solid decking board fits over hollow e only use hardwood ter mechanical ppearance and mpared to softwood ucts. Our polymer e this polymer as it is ow temperature impact ew retention and is a cled form.

even buy off-cuts and scrap back. However, because we make to custom lengths for no extra charge, there is always minimal waste on site and the customer is not paying for material that would end up as off-cuts.

Alex Collins

BP&R: Is the Olympic decking being used for any other applications? AC: The Olympic profile has now been relabeled as our Stadia profile, as the overlapping profile of the board prevents flammable media from falling through the gaps and building up in any enclosed areas underneath. This was required in order to meet the ODAs fire safety requirements. It is not a profile that we run often, as you can imagine, there arent that many stadiums being built, but it is also available for other projects where an overlapping board is required.

ife, is the decking

t recyclable making it a uction material. We

www.ecodek.co.uk

Das könnte Ihnen auch gefallen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Directions To EcodekDokument1 SeiteDirections To EcodekEcodekNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Ecodek - WPC DeckingDokument3 SeitenEcodek - WPC DeckingEcodekNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Ecodek PEFC CertificateDokument1 SeiteEcodek PEFC CertificateEcodekNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Data Sheet 19 - Anti Slip Price ListDokument1 SeiteData Sheet 19 - Anti Slip Price ListEcodekNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Ecodek FSC CertificateDokument1 SeiteEcodek FSC CertificateEcodekNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Data Sheet 13 - Hit 'N Miss PanelsDokument1 SeiteData Sheet 13 - Hit 'N Miss PanelsEcodekNoch keine Bewertungen

- Data Sheet 14 - Step Construction GuideDokument2 SeitenData Sheet 14 - Step Construction GuideEcodekNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Data Sheet 18 - Installing Ecodek On A Flat RoofDokument1 SeiteData Sheet 18 - Installing Ecodek On A Flat RoofEcodekNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Data Sheet 11 - Post Fixing GuideDokument1 SeiteData Sheet 11 - Post Fixing GuideEcodekNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Data Sheet 3 - Ecodek WarrantyDokument1 SeiteData Sheet 3 - Ecodek WarrantyEcodekNoch keine Bewertungen

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- Data Sheet 10 - Balcony Screw Fitting GuideDokument1 SeiteData Sheet 10 - Balcony Screw Fitting GuideEcodekNoch keine Bewertungen

- Data Sheet 7 - Ecodek Slip Test ResultsDokument1 SeiteData Sheet 7 - Ecodek Slip Test ResultsEcodekNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Data Sheet 6 - Material SafetyDokument1 SeiteData Sheet 6 - Material SafetyEcodekNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Data Sheet 5 - Handrail AssemblyDokument1 SeiteData Sheet 5 - Handrail AssemblyEcodekNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Data Sheet 2 - Ecodek Technical DataDokument4 SeitenData Sheet 2 - Ecodek Technical DataEcodekNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Data Sheet 1 - Quick Installation GuideDokument1 SeiteData Sheet 1 - Quick Installation GuideEcodekNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Ecodek 2011 NewsletterDokument4 SeitenEcodek 2011 NewsletterEcodekNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Data Sheet 9 - Product RangeDokument1 SeiteData Sheet 9 - Product RangeEcodekNoch keine Bewertungen

- Ferrous Materials Metallurgy I: Contents: STD - Jisf 2008 V.1Dokument30 SeitenFerrous Materials Metallurgy I: Contents: STD - Jisf 2008 V.1monkey1929Noch keine Bewertungen

- Jaypee Cement Project ReportDokument29 SeitenJaypee Cement Project ReportPurnendu MishraNoch keine Bewertungen

- Expoband H45Dokument3 SeitenExpoband H45Balasubramanian AnanthNoch keine Bewertungen

- Plywood Used in So Many Different Ways: Eaturing Lywood in UildingsDokument23 SeitenPlywood Used in So Many Different Ways: Eaturing Lywood in Uildingspilapil_jNoch keine Bewertungen

- Deaerators: Technical BackgroundDokument8 SeitenDeaerators: Technical Backgroundกี๋ แต่งงามNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Z&s Finishing CottonDokument12 SeitenZ&s Finishing Cottonguven440% (1)

- Productivity RateDokument12 SeitenProductivity RateZubair Mohammed98% (41)

- Csi Eifs Foamglas BasfDokument11 SeitenCsi Eifs Foamglas BasfLloyd R. PonceNoch keine Bewertungen

- A Review On The Driving Performance of FRP Composite PilesDokument11 SeitenA Review On The Driving Performance of FRP Composite PilesrajeevjayanathNoch keine Bewertungen

- Design of RCC FoundationsDokument10 SeitenDesign of RCC FoundationsARVIND VAISHNAVNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Bo Bergman Knifemaking PDFDokument154 SeitenBo Bergman Knifemaking PDFFrancisco Bustos-González75% (4)

- Painting Specification for Aegean Refinery ProjectDokument18 SeitenPainting Specification for Aegean Refinery Projectraluca_19735597Noch keine Bewertungen

- Construction hydro techniques and dam evolutionDokument47 SeitenConstruction hydro techniques and dam evolutionGaftoi Daniel AndreiNoch keine Bewertungen

- 609 - Sanitary Sewer SystemDokument5 Seiten609 - Sanitary Sewer SystemkagdishNoch keine Bewertungen

- Sliding Wear Performance of A413 Alloy Reinforced with IntermetallicsDokument8 SeitenSliding Wear Performance of A413 Alloy Reinforced with IntermetallicsirajfarjiNoch keine Bewertungen

- Use of Silicon Carbide in Induction in Induction FurnaceDokument2 SeitenUse of Silicon Carbide in Induction in Induction FurnacemkraijadaNoch keine Bewertungen

- Axminster 15 - Hand Tools - p448-p516Dokument69 SeitenAxminster 15 - Hand Tools - p448-p516Pierre799esNoch keine Bewertungen

- SSS - Volume 1 of 2 (Part 2 of 3)Dokument231 SeitenSSS - Volume 1 of 2 (Part 2 of 3)kokueiNoch keine Bewertungen

- Evaluation of Tribological Behaviour of LM13 - Silicon Carbide Composite Under Ambient & Elevated TemperatureDokument7 SeitenEvaluation of Tribological Behaviour of LM13 - Silicon Carbide Composite Under Ambient & Elevated TemperatureijsretNoch keine Bewertungen

- Characterization of Recycled Aggregate ConcreteDokument10 SeitenCharacterization of Recycled Aggregate ConcreteKrittiya KaewmaneeNoch keine Bewertungen

- Detailed Estimate For 2.0 X 2.0m Box Cell Culvert.: Total 42 NosDokument90 SeitenDetailed Estimate For 2.0 X 2.0m Box Cell Culvert.: Total 42 Nosnandini50% (2)

- Surface Preparation For Carbon SteelDokument2 SeitenSurface Preparation For Carbon Steelgovimano100% (1)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Kluber Equivalencia CompresoresDokument3 SeitenKluber Equivalencia CompresorescarlosNoch keine Bewertungen

- Method Statement For PLASTERINGDokument6 SeitenMethod Statement For PLASTERINGVinodh Palanichamy100% (1)

- Cold Hot Working AnnealingDokument40 SeitenCold Hot Working AnnealingBaljeet KaurNoch keine Bewertungen

- Bamboo Leaf Ash As Supplementary Cementitious MaterialDokument8 SeitenBamboo Leaf Ash As Supplementary Cementitious MaterialAJER JOURNALNoch keine Bewertungen

- Case Study SCCDokument2 SeitenCase Study SCCSatrio HerbirowoNoch keine Bewertungen

- EfflorescenceDokument2 SeitenEfflorescenceMihaiu AdrianNoch keine Bewertungen

- Thermowood CladdingDokument2 SeitenThermowood CladdingРома ЦвирчакNoch keine Bewertungen

- Pictorial Surface Preparation Standards For Painting Steel Surfaces - MHG PaintsDokument24 SeitenPictorial Surface Preparation Standards For Painting Steel Surfaces - MHG PaintsBellana SirishNoch keine Bewertungen