Beruflich Dokumente

Kultur Dokumente

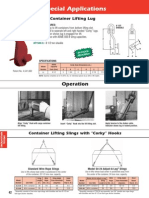

51 Caldwell Rig Master Catalog

Hochgeladen von

Thomas StempienOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

51 Caldwell Rig Master Catalog

Hochgeladen von

Thomas StempienCopyright:

Verfügbare Formate

Care & Use

Rig-Master Rigging Attachments have been designed for specific tasks to withstand the particular forces imposed. A summary of guidelines for installation, inspection, maintenance, repair, safe operation, and operator training of these attachments follow:

INSTALLATION Below/Hook Lifters shall be assembled and installed in accordance with the manufacturers instructions, unless other specific arrangements have been approved in writing by manufacturer. Check for specific maintenance and installation procedures in accordance with manufacturers instructions. OPERATOR TRAINING Lifters shall be operated in accordance with manufacturers operating instructions, and by personnel who have received instructions described in the Operating Practices section of these guidelines. Training shall also include instruction regarding: 1. Details of the lifting cycle. 2. Application of the lifter to the load including (according to the manufacturers instructions) adjustments to the lifter, if any, to adapt it to various sizes and kinds of loads. 3. Instruction in any special operations or precautions that may be required. 4. Recognition of proper load configuration. For example, preferred operation requires an orderly pattern of stacking. 5. Before assuming responsibility for using the lifter, an operator shall demonstrate his understanding of the lifting procedure to the instructor. The instructor should record, for your personnel evaluation, notes of operators demonstrated ability. INSPECTION The lifter shall be visually inspected by or under the direction of an appointed person on a daily or weekly schedule depending on the nature of the lifter and the severity of the service. Details to look for include but are not limited to: 1. Structural deformation. 2. Cracks in the structural frame, welds, hoist hook attachment points, mechanically operating parts, any attached slings, clevises and hooks. 3. Malfunctions during operation of a mechanically operating lifter. 4. Loose covers, fasteners and stops. 5. Faulty operation of automatic hold and release mechanisms. 6. Wear of hoist hooking points, load supporting clevises, pins, slings, linkages and mechanical parts. 7. Missing nameplates and markings. Contact Caldwell for replacements. MAINTENANCE AND REPAIRS 1. A preventive maintenance program should be established for each lifter by a qualified person based on recommendations made by its manufacturer. 2. A qualified person should have responsibility for repairs. Dated records and details of repairs and parts replacement should be carefully maintained by a qualified person, and copies kept in your possession. 3. Replacement parts shall be at least equivalent to the original manufacturers specifications. 4. Keep products clean of dirt and debris to ensure proper and safe operation. 5. Oil pins and moving parts as required. OPERATING PRACTICES DOS 1. The operator shall have received, read and understood the manufacturers operating instructions. 2. The operator shall watch carefully that the lifter is performing properly during the lifting procedure. 3. The operator shall be familiar with the standard crane directing hand signals. 4. The operator shall respond to signals from an appointed person only. However, stop signals from anyone shall be obeyed. 5. The operator shall notify a designated person when he considers a load to be unsafe. 6. The operator shall observe the lifter before using. A defect observed shall be examined by a qualified person to determine if it is a hazard. DONTS 1. The operator shall not operate a malfunctioning lifter or one with an out of service tag attached. 2. The operator shall not use the lifter for any purpose(s) other than those designated by the manufacturers operating instructions. 3. The operator shall not use a lifter when the capacity, weight or safety markings are missing or are no longer legible. 4. No one shall make alterations or modifications to lifters without consulting the manufacturer. 5. No one shall obscure or paint over the manufacturers capacity, weight, or safety markings. 6. Loads shall not be lifted higher than necessary or be left suspended unattended. 7. The lifter shall not lift a load that is not properly balanced for safe lifting. HANDLING THE LOAD 1. The lifter shall not be loaded in excess of its rated load. 2. The combined weight of the lifter and load shall not exceed the rated load of the crane or hoist. 3. The lifter shall be applied to the load in accordance with the manufacturers recommended operating procedure. 4. Lifter ropes and chains shall not be kinked, and multiple part lines shall not be twisted about each other. 5. The lifter shall not touch obstructions during load movement. 6. The lifter shall not be loaded with loose material that might fall during movement. 7. The operator or other personnel shall not place themselves or any part of their bodies beneath suspended loads. 8. The load or lifter shall not be slid on the floor or other surface. 9. The lifter shall not be used for loads for which it is not designed. 10. If suspended loads are moved manually, they shall be pushed, not pulled. 11. A preliminary lift of a few inches shall be made to establish that the load is stable. 12. All loads shall be accelerated and decelerated smoothly.

Modifications to your lifting equipment without prior approval from The Caldwell Group, Inc. will void your warranty. Refer to ASME B30.20 regarding the liability of repaired or modified lifters.

51

CARE & USE

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- To Be African or Not To Be: An Autoethnographic Content Analysis of The Works of Dr. Asa Grant Hilliard, III (Nana Baffour Amankwatia, II) - by Qiana M. CuttsDokument283 SeitenTo Be African or Not To Be: An Autoethnographic Content Analysis of The Works of Dr. Asa Grant Hilliard, III (Nana Baffour Amankwatia, II) - by Qiana M. Cutts☥ The Drop Squad Public Library ☥100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- PTW QuestionareDokument63 SeitenPTW QuestionareIshtiaq Ahmad100% (2)

- Lift Truc CatalogDokument24 SeitenLift Truc CatalogThomas StempienNoch keine Bewertungen

- Latihan Soal Recount Text HotsDokument3 SeitenLatihan Soal Recount Text HotsDevinta ArdyNoch keine Bewertungen

- Release emotions with simple questionsDokument10 SeitenRelease emotions with simple questionsDubravko ThorNoch keine Bewertungen

- Model MPP CatalogDokument1 SeiteModel MPP CatalogThomas StempienNoch keine Bewertungen

- 47 Caldwell Rig Master CatalogDokument1 Seite47 Caldwell Rig Master CatalogThomas StempienNoch keine Bewertungen

- Drum Handling SlingsDokument1 SeiteDrum Handling SlingsThomas StempienNoch keine Bewertungen

- 45 Caldwell Rig Master CatalogDokument1 Seite45 Caldwell Rig Master CatalogThomas StempienNoch keine Bewertungen

- 50 Caldwell Rig Master CatalogDokument1 Seite50 Caldwell Rig Master CatalogThomas StempienNoch keine Bewertungen

- 7 Caldwell Rig Master CatalogDokument1 Seite7 Caldwell Rig Master CatalogThomas StempienNoch keine Bewertungen

- 9 Caldwell Rig Master CatalogDokument1 Seite9 Caldwell Rig Master CatalogThomas StempienNoch keine Bewertungen

- 8 Caldwell Rig Master CatalogDokument1 Seite8 Caldwell Rig Master CatalogThomas StempienNoch keine Bewertungen

- 4 Caldwell Rig Master CatalogDokument1 Seite4 Caldwell Rig Master CatalogThomas StempienNoch keine Bewertungen

- 5 Caldwell Rig Master CatalogDokument1 Seite5 Caldwell Rig Master CatalogThomas StempienNoch keine Bewertungen

- 44 Caldwell Rig Master CatalogDokument1 Seite44 Caldwell Rig Master CatalogThomas StempienNoch keine Bewertungen

- Model F CatalogDokument1 SeiteModel F CatalogThomas StempienNoch keine Bewertungen

- 52 Caldwell Rig Master CatalogDokument1 Seite52 Caldwell Rig Master CatalogThomas StempienNoch keine Bewertungen

- 49 Caldwell Rig Master CatalogDokument1 Seite49 Caldwell Rig Master CatalogThomas StempienNoch keine Bewertungen

- 48 Caldwell Rig Master CatalogDokument1 Seite48 Caldwell Rig Master CatalogThomas StempienNoch keine Bewertungen

- 40 Caldwell Rig Master CatalogDokument1 Seite40 Caldwell Rig Master CatalogThomas StempienNoch keine Bewertungen

- Model A o CatalogDokument1 SeiteModel A o CatalogThomas StempienNoch keine Bewertungen

- 41 Caldwell Rig Master CatalogDokument1 Seite41 Caldwell Rig Master CatalogThomas StempienNoch keine Bewertungen

- 3 Caldwell Rig Master CatalogDokument1 Seite3 Caldwell Rig Master CatalogThomas StempienNoch keine Bewertungen

- 46 Caldwell Rig Master CatalogDokument1 Seite46 Caldwell Rig Master CatalogThomas StempienNoch keine Bewertungen

- 42 Caldwell Rig Master CatalogDokument1 Seite42 Caldwell Rig Master CatalogThomas StempienNoch keine Bewertungen

- 39 Caldwell Rig Master CatalogDokument1 Seite39 Caldwell Rig Master CatalogThomas StempienNoch keine Bewertungen

- 38 Caldwell Rig Master CatalogDokument1 Seite38 Caldwell Rig Master CatalogThomas StempienNoch keine Bewertungen

- 37 Caldwell Rig Master CatalogDokument1 Seite37 Caldwell Rig Master CatalogThomas StempienNoch keine Bewertungen

- 36 Caldwell Rig Master CatalogDokument1 Seite36 Caldwell Rig Master CatalogThomas StempienNoch keine Bewertungen

- 35 Caldwell Rig Master CatalogDokument1 Seite35 Caldwell Rig Master CatalogThomas StempienNoch keine Bewertungen

- 33 Caldwell Rig Master CatalogDokument1 Seite33 Caldwell Rig Master CatalogThomas StempienNoch keine Bewertungen

- 34 Caldwell Rig Master CatalogDokument1 Seite34 Caldwell Rig Master CatalogThomas StempienNoch keine Bewertungen

- 1st ClassDokument18 Seiten1st Classchitl.23bi14075Noch keine Bewertungen

- Upper Six 2013 STPM Physics 2 Trial ExamDokument11 SeitenUpper Six 2013 STPM Physics 2 Trial ExamOw Yu Zen100% (2)

- Estimating PSCC for Electrical InstallationsDokument2 SeitenEstimating PSCC for Electrical InstallationsgmuitaNoch keine Bewertungen

- X32 Digital Mixer: Quick Start GuideDokument28 SeitenX32 Digital Mixer: Quick Start GuideJordán AstudilloNoch keine Bewertungen

- Biology 11th Edition Mader Test BankDokument25 SeitenBiology 11th Edition Mader Test BankAnthonyWeaveracey100% (44)

- PublicReviewDraft2742 (1) (002)Dokument75 SeitenPublicReviewDraft2742 (1) (002)dhruv.encontrolsNoch keine Bewertungen

- Curriculum Vitae: Name: Bhupal Shrestha Address: Kamalamai Municipality-12, Sindhuli, Nepal. Email: ObjectiveDokument1 SeiteCurriculum Vitae: Name: Bhupal Shrestha Address: Kamalamai Municipality-12, Sindhuli, Nepal. Email: Objectivebhupal shresthaNoch keine Bewertungen

- Female and Male Hacker Conferences Attendees: Their Autism-Spectrum Quotient (AQ) Scores and Self-Reported Adulthood ExperiencesDokument25 SeitenFemale and Male Hacker Conferences Attendees: Their Autism-Spectrum Quotient (AQ) Scores and Self-Reported Adulthood Experiencesanon_9874302Noch keine Bewertungen

- Inbound 8511313797200267098Dokument10 SeitenInbound 8511313797200267098phan42Noch keine Bewertungen

- Single-phase half-bridge inverter modes and componentsDokument18 SeitenSingle-phase half-bridge inverter modes and components03 Anton P JacksonNoch keine Bewertungen

- School readiness assessmentDokument10 SeitenSchool readiness assessmentJave Gene De AquinoNoch keine Bewertungen

- Working Capital Management (2015)Dokument62 SeitenWorking Capital Management (2015)AJNoch keine Bewertungen

- CANAVAN' and VESCOVI - 2004 - CMJ X SJ Evaluation of Power Prediction Equations Peak Vertical Jumping Power in WomenDokument6 SeitenCANAVAN' and VESCOVI - 2004 - CMJ X SJ Evaluation of Power Prediction Equations Peak Vertical Jumping Power in WomenIsmenia HelenaNoch keine Bewertungen

- Enbrighten Scoring Rubric - Five ScoresDokument1 SeiteEnbrighten Scoring Rubric - Five Scoresapi-256301743Noch keine Bewertungen

- 2017 Grade 9 Math Challenge OralsDokument3 Seiten2017 Grade 9 Math Challenge OralsGracy Mae PanganibanNoch keine Bewertungen

- Demo TeachingDokument22 SeitenDemo TeachingCrissy Alison NonNoch keine Bewertungen

- Learn R For Applied StatisticsDokument457 SeitenLearn R For Applied StatisticsyasortyNoch keine Bewertungen

- Booklet English 2016Dokument17 SeitenBooklet English 2016Noranita ZakariaNoch keine Bewertungen

- Repair Max II Pump 310894lDokument20 SeitenRepair Max II Pump 310894lAndreina FajardoNoch keine Bewertungen

- Armitage Tutorial for Cyber Attack ManagementDokument54 SeitenArmitage Tutorial for Cyber Attack Managementworkmumbai3870Noch keine Bewertungen

- AESCSF Framework Overview 2020-21Dokument30 SeitenAESCSF Framework Overview 2020-21Sandeep SinghNoch keine Bewertungen

- 11.trouble Shooting For TMDokument9 Seiten11.trouble Shooting For TMfrezgi birhanuNoch keine Bewertungen

- Atomic Structure - One Shot by Sakshi Mam #BounceBackDokument231 SeitenAtomic Structure - One Shot by Sakshi Mam #BounceBackchansiray7870Noch keine Bewertungen

- Manage a micro business with BSB30315Dokument3 SeitenManage a micro business with BSB30315Theo A W JacksonNoch keine Bewertungen

- Disk Electrostatic Automatic Coating System - OTSON - DM - OTS - 5000!3!0Dokument16 SeitenDisk Electrostatic Automatic Coating System - OTSON - DM - OTS - 5000!3!0otsontek9227Noch keine Bewertungen

- Academic Language Use in Academic WritingDokument15 SeitenAcademic Language Use in Academic WritingDir Kim FelicianoNoch keine Bewertungen