Beruflich Dokumente

Kultur Dokumente

HB 31.1FR06

Hochgeladen von

hebieOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

HB 31.1FR06

Hochgeladen von

hebieCopyright:

Verfügbare Formate

Synthesis of an Alkyl Halide

Herbert Magboo Tolentino

Institute of Chemistry, University of the Philippines, Diliman, Quezon City 1101 Philippines Institute of Biology, College of Science, University of the Philippines, Diliman, Quezon City 1101 Philippines

ABSTRACT The experiment focuses on the synthesis of an Alkyl Halide (Tert-Butyl Chloride) from an alcohol (Tert-butyl Alcohol) and understanding the mechanism of nucleophilic substitution. The alkyl halide was formed by using concentrated HCl that provided the halide to displace the hydroxyl group in the alcohol. The obtained amount of alkyl halide synthesized from a 10-ml alcohol was 5 ml or a 43% yield which is quite small. The result was affected by different determinate and indeterminate errors.

Introduction Alkyl halides are compounds with a halogen atom bonded to a saturated, sp3hybridized carbon atom thus forming a tetrahedral shape. The C-X bond is polar, and alkyl halides can therefore behave as electrophiles[1]. Due to electronegativity differences between the carbon and halogen atoms, the covalent bond between these atoms is polarized, with the carbon atom becoming slightly positive and the halogen atom partially negative. Halogen atoms increase in size and decrease in electronegativity when going down a family in the periodic table thus, the bond length between carbon and halogen becomes longer and less polar as the halogen atom changes from fluorine to iodine [2]. Alkyl halides are used as cleaning solvents, Freon and pesticides. It is one of the common products of modern industry. The experiment aims to synthesize an alkyl halide, specifically tert-butyl chloride from an alcohol, tert-butyl alcohol. It also aims to understand the mechanisms behind the reactions behind the synthesis. Experimental Detail Ten millilitres of tert-butyl alcohol and 20 ml of cold concentrated HCl was placed in a dry separatory funnel. The concentrated needed 1

was cold in order to increase the yield of the alkyl halide since the reactions between the alcohol and the acid are very fast. Slowing the reaction renders a more complete reaction [1]. The mixture was then swirled with care and internal pressure being relieved from time to time.

Figure 1. Proper holding and venting of separatory funnel

The mixture was allowed to stand for 20 minutes undisturbed and was then separated (3-5 ml 6 M NaCl solution can facilitate separation). The aqueous layer determined by the dissolution of the water drops was discarded and the organic layer was transferred into a dry flask containing NaHCO3 in order to remove excess hydrogen ions in the organic layer. It was then swirled and decanted into another flask. The filtrate was dried out of the remaining water and unreacted alcohol by using anhydrous CaCl2. The mixture was again decanted into a 25 ml round bottom

flask. The addition of boiling chips was no longer required by the instructor and was purified by simple distillation. The boiling chips prevent the violent boiling of a liquid being heated. They provide sharp or rough surfaces on which small bubbles of vapour can form, promoting smooth boiling .

Figure 2. Simple Distillation Setup

The pure tert-butyl chloride was transferred to a 10-ml graduated cylinder and placed in an ice bath. The fraction that boiled at 49-52 C was collected. Only the fraction at this temperature range was considered since the boiling point of tert-butyl chloride is 50.7 C and anything outside may not be tert-butyl chloride. Results and Discussion Based from the data gathered, the obtained amount of purified tert-butyl chloride showed a 43.07% yield. Some physical characteristics were also observed. Table 1. Some Tert-butyl chloride properties Color Colorless Solubility in Water Boiling Point 50.7 C Molecular Weight 92.57 g/mol Density 0.84 g/ml Treatment of alcohols with HCl typically undergo a necleophilic substitution reaction to form alkyl halides [3]. Displacement of the hydroxyl ion takes place in this kind of acidic medium. For a tertiary alcohol, concentrated HCl is one of the appropriate hydrogen-halides and these alcohols generally proceed through the SN1 (Substitution Nucleophilic 1) mechanism. SN1 is a multi-step 2

process, specifically a three-step process which starts with the alcohol protonation which will form a leaving group, followed by cleavage of the C-O bond which allows the loss of the leaving group, a neutral water molecule, to give off a carbocation intermediate. This is the rate determining step (bond breaking is endothermic). The last step is the attack of the nucleophilic chloride ion on the electrophilic carbocation creates the new bond [4]. The percent yield obtained was relatively little which might have been caused by different errors. Handling of the reagents could have not been proper wherein some of the reagents might have spilled when they were transferred to different containers. Some of the purified tert-butyl chloride might have evaporated even before the volume was recorded. Another possible source of error is the improper use of cold concentrated HCl. Not using cold HCl would inhibit the completeness of the reaction, thus yielding less alkyl halide. Conclusion A 43% yield is not relatively efficient since the product (tert-butyl chloride) obtained is small. But the aim of synthesising an alkyl halide, being able to perform the procedures properly and understanding the mechanisms behind the process were achieved. Even though it gave a small yield, the goal of synthesising an alkyl halide is successful. References McMurry, J. (1984). Organic Chemistry. United States of America: Wadsworth.

[2] [1]

http://www.cliffsnotes.com/study_guide/Introd uction-to-Alkyl-Halides.topicArticleId23297,articleId-23251.html

[3]

http://www.mhhe.com/physsci/chemistry/care y/student/olc/ch04prepare.html

[4]

http://www.mhhe.com/physsci/chemistry/care y/student/olc/graphics/carey04oc/ref/ch04nucle. html#1

Appendix SIMPLE DISTILLATION PREPARATION: y Prepare distillation setup above. Make sure that the water flows into the bottom of the condensers cooling jacket ad out from the top and a thermometer bulb is placed just below the side arm of the distillation head. Choose a round-bottom flask of appropriate volume. It must be big enough so that the sample fills 1/2 2/3 of its volume. Use water or oil bath to regulate the temperature. Place sample inside the flask. Add 2-3 pieces of boiling chips. Into the flask. Turn water supply on and check water flow through the condenser. Check that all ground glass joints fit well. Slowly heat the sample to a gentle boil. Record the boiling point. The vapours and condensate will pass through the side arm and into the condenser, where most of the vapour will condense into liquid and will finally drip from the adapter into the receiving flask. Adjust flame so that the distillation occurs at a rate of 2 drops per second. Discard the first 1 mL of distillate and collect the fraction that distils at a constant temperature. Do not distill to dryness. Remove heat source when sample starts to boil.

y y y y

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Beration of LightDokument7 SeitenBeration of LightAnonymous i71HvPXNoch keine Bewertungen

- Yr 6 Maths G-6 E P-I PDFDokument168 SeitenYr 6 Maths G-6 E P-I PDFdina171279Noch keine Bewertungen

- MCAT Uhs Past Paper (2008-2016)Dokument180 SeitenMCAT Uhs Past Paper (2008-2016)Abdullah SheikhNoch keine Bewertungen

- Hillside College of Engineering Department of Civil EngineeringDokument2 SeitenHillside College of Engineering Department of Civil EngineeringRamsharan DhakalNoch keine Bewertungen

- Full Test Bank For Understanding Pathophysiology 6Th Edition by Huether PDF Docx Full Chapter ChapterDokument36 SeitenFull Test Bank For Understanding Pathophysiology 6Th Edition by Huether PDF Docx Full Chapter Chapterexequycheluract6oi100% (9)

- Technical Support Engineer - Home AssignmentDokument5 SeitenTechnical Support Engineer - Home AssignmentRahul KohliNoch keine Bewertungen

- Design and Implementation of Audio Transceiver Using Infrared Laser For Audio Signal DetectionDokument4 SeitenDesign and Implementation of Audio Transceiver Using Infrared Laser For Audio Signal DetectionGoitom HaileNoch keine Bewertungen

- Transmission Line TowersDokument3 SeitenTransmission Line TowersSoumik Dandapat100% (2)

- Regnet Research Paper SeriesDokument7 SeitenRegnet Research Paper Seriesnqdpuhxgf100% (1)

- Kou2003 PDFDokument6 SeitenKou2003 PDFGe EffgenNoch keine Bewertungen

- Evaluating Capital ProjectsDokument254 SeitenEvaluating Capital Projectsariff_sodriNoch keine Bewertungen

- Analytic Geometry Parabola ProblemsDokument14 SeitenAnalytic Geometry Parabola ProblemsOjit QuizonNoch keine Bewertungen

- Introduction To Chaos: The Damped, Driven, Nonlinear PendulumDokument14 SeitenIntroduction To Chaos: The Damped, Driven, Nonlinear PendulumKikkuNoch keine Bewertungen

- Fatigue Life Prediction - An Overview - ScienceDirect TopicsDokument14 SeitenFatigue Life Prediction - An Overview - ScienceDirect TopicsMohamed AlaaElDinNoch keine Bewertungen

- OL ICT First Term Kengalla Maha Vidyalaya English Medium Grade 11 MCQ Paper 2019Dokument5 SeitenOL ICT First Term Kengalla Maha Vidyalaya English Medium Grade 11 MCQ Paper 2019mazhus123Noch keine Bewertungen

- Inserting Images - ShareLaTeX, Online LaTeX EditorDokument11 SeitenInserting Images - ShareLaTeX, Online LaTeX EditorAviraj3892Noch keine Bewertungen

- Mha Mca Cet SyllabusDokument20 SeitenMha Mca Cet Syllabusm kumarNoch keine Bewertungen

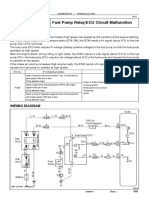

- DTC P1200 Fuel Pump Relay/ECU Circuit MalfunctionDokument4 SeitenDTC P1200 Fuel Pump Relay/ECU Circuit MalfunctiononealNoch keine Bewertungen

- Pseudocode Is A Technique Used To Describe The Distinct Steps of An Algorithm in ADokument3 SeitenPseudocode Is A Technique Used To Describe The Distinct Steps of An Algorithm in AChristian Doson EstilloreNoch keine Bewertungen

- Ordered Groups and Infinite Permutation Groups PDFDokument252 SeitenOrdered Groups and Infinite Permutation Groups PDFmc180401877Noch keine Bewertungen

- Linear Algebra Cheat SheetDokument2 SeitenLinear Algebra Cheat SheetBrian WilliamsonNoch keine Bewertungen

- Rsa Netwitness Logs and Packets: Server, Dac and San HW SpecificationsDokument10 SeitenRsa Netwitness Logs and Packets: Server, Dac and San HW SpecificationsfunyiroemberNoch keine Bewertungen

- 8051 Serial CommunicationDokument35 Seiten8051 Serial CommunicationSanthosh CricketNoch keine Bewertungen

- 1.basic Electrical Engineering Lecture Part-1Dokument17 Seiten1.basic Electrical Engineering Lecture Part-1jimvalenciaNoch keine Bewertungen

- Regression Analysis AssignmentDokument8 SeitenRegression Analysis Assignmentضیاء گل مروت100% (1)

- Theories and Methods of Two Way Slab Design-5-8-2017Dokument3 SeitenTheories and Methods of Two Way Slab Design-5-8-2017amerta 4320Noch keine Bewertungen

- Adjectives 4Dokument34 SeitenAdjectives 4Delia Bolasoc100% (1)

- LAB 7 - Getting Started With Google BigQueryDokument10 SeitenLAB 7 - Getting Started With Google BigQueryRama VNoch keine Bewertungen

- SMO Senior 2017Dokument6 SeitenSMO Senior 2017Kanchit SaehoNoch keine Bewertungen

- 4.uses of Metals - 1-32 For StudentsDokument13 Seiten4.uses of Metals - 1-32 For StudentsnergisalihpasaogluNoch keine Bewertungen