Beruflich Dokumente

Kultur Dokumente

Serving The Motorized Units That Built The Alcan Highway

Hochgeladen von

Steven HowellOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Serving The Motorized Units That Built The Alcan Highway

Hochgeladen von

Steven HowellCopyright:

Verfügbare Formate

SERVICING THE THAT BUILT THE

By Harold McKeever

, N YORK 3600 EW

r [EDMONTON 1215-iv

.LOW/ER POST 151 LIARD RIVER WHITEHORSE TESLIN

8.. 1

-'22

172.

EMPERATURES that went down to 76 below zeroa 1,500 mile highway to build through almost impenetrable forestand nothing to live in but tents, or quickly constructed huts. That gives some idea of the terrific job facing the Army and Civilian contractors, in building the Alcan Highwaya military road over which a stream of men and munitions is now flowing to smash the Japs. It's a story of high courage, engineering skill, and the adaptation of ingenious mechanical ability to automotive service problemsproblems that had to be solved with the help of lathe, welder and other shop equipment with which good mechanics make new parts out of old ones. Some day the Alcan Highway may be the world's most interesting road for touristsa road dotted with hotels, resorts, camps, service stations and hot dog stands. Today, however, it is strictly a military highway, and, at that, a very arduous one to travel. Consider, for example, that the round trip from Chicago to Fairbanks is 8,000 miles and you have some picture of the distance, while the highway itself is 1,500 miles from the end of the farthermost rail line in

(Left) The author beside one of the sgin posts on the Akan Highway (Right) An unusually straight streteh of the great highway

At first over ten thousand engineer troops lived in hastily erected tent ramps. Later tent. were winterised or replaced by warm insulated huts

Snow is windrowed along the outer shoulder as a safety aid

Northwestern Canada up to Fort Nelson and White Horse, and on into Fairbanks, Alaska. Yes, the same general methods that keep cars and trucks running in your own home town were used to keep tractors, bulldozers and other road making equipment in operating condition, but

it couldn't have been done without that vital something that inspires men to win against all odds. Take for example a night in November with the temperature down to zero and buck private grease monkeys working through the night in bitter cold with lanterns, to lubricate service trucks bare-

handed in half open pitsand nary a grumble or gripe. Consider also a bunch of lonesome boys in the Northwoodsten thousand of them from the engineering regimentsmany of whom hadn't seen a woman in seven months. And the story of Alcan also brings the memory of a fine young Captain who

took pity on the author of this article and kept him over night in his tent at a point five hundred miles up the highway when there was no other place to sleep. "Look," said the Captain, revealing a thumbed radiogram which said: "Congratulations on a job well done." But what it left unsaid was how this Captain

This "Caterpillar" track-type tractor hauls a trailer-load of supplies over on unfinished pioneer road

Fleets of dozers widened the pioneer cut by side-casting trees, roots and humus to the clearing edges. This Is a Caterpillar diesel with LeTourneau angledozer.

../1

maasss."e.

31 could spend the period of spring isolation, getting set to build road at the earliest moment of summer. Tons of machinery parts were flown north, by bush flyers who set snowshoed planes down on frozen lakes. Similar drama was enacted at the other entry points. Up in Alaska one contractor flew fifteen hundred men into the interior to get going. How They Went At the Job The first idea in planning actual construction was this: The U. S. Army regiments would build a rough pioneer "tote road," and civilian contractors would come in and build a wide parallel highway of a more permanent character. That's the way work was started at the southern end. But in a few weeks all hands saw the necessity for joining forces and "working like hell" on the best possible single road. Actually, the Army pioneered about 85 per cent of the road, and the contractor outfits followed in their wake, widening, straightening, cutting down steep hills and strengthening the roadway with gravel. Contractors pioneered four stretches amounting to about 200 miles of excellent highway. Some of their work matched the Army's for speed, resourcefulness and war-spirit. When it came to actual construction the American bulldozer was king. Bulldozers and choppers felled probably ten million trees, to clear a 60 to 100 foot patch through the dense forest. First a bulldozer operator attacked the woods along a line of trees which the surveyors had tagged with red rags. With his sharp 'dozer blade he severed shallow side roots (northern trees have no big tap roots) then pushed the trees over, clearing a narrow path a few hundred feet ahead. Next came a half dozen more tractors, which scraped trees, roots and forest humus to one side like piles

Diesel tractor with blade grader, grading section of the highway

and his boys had felled trees, hewn logs and thrown a 200-foot trestle across an icy, turbulent river in three days and nightsall accomplished through an ingenious scheme and with meager equipment, yet without getting a single man "dunked." World's Biggest Roadbuilding Fleet The interesting fact about Alcan's construction is that no new tricks were used. Just time-tried American roadbuilding methods, employing standard models of American tractors, bulldozers, scrapers, power shovels, air compressors and trucks. Aided by fifty-five American and Canadian contractors under the U. S. Public Roads Administration, the Army "ganged up" on the job, blazing trail simultaneously from many working fronts, with the biggest fleet of roadbuilding equipment in history. Back in the States, long before the 1942 spring 30

thaw, the vast, intricate job of planning supply lines and strategy and assembling and shipping equipment, camp supplies and troops had been organized and gotten under waya dramatic chapter as yet practically untold. The wilderness was invaded from three working basesat the southern end; at midpoint via Skagway and the narrow-gauge rail line over the mountains to Whitehorse; and into the Alaskan end through the port of Valdez. Knowing that time was the essence, the first U. S. Corps of Engineer troops entered the southern end a month before the scheduled time of the awful bottomless spring thaw that hits the north country. In this month, working and living out in the blizzards at 25 to 40 below, our soldiers scattered great quantities of equipment and supplies along through the woods to Fort Nelson, establishing base camps where the men

Cheeking the bulldozer hydraulic control on one of the heavy unite

of giant matches, leaving the full width clearing in their wake. Then along came the big hauling scrapers, and soon a semblance of a road took form. Graders put on the remaining touches, aided by quantities of gravel shoveled and sledded and dumped onto the roadbed to cover the muck.

Supplies Always a Problem

Throughout all this melee were the supply movements. Supply-lining, here as in the African campaign, was a problem of staggering difficulty and immensity. Even ahead of the first bulldozer floundered pack horses laden with paraphernalia for advance camps, and detachments of pontoon troops lugging boats and trestle panels for fashioning temporary floating bridges. So fast did the advance construction crews build at times, the surveyors often had trouble keeping out ahead. One surveyor told me, "We worked in one shift until we dropped, whereas the advance construction crew worked in two 11serv

t7 jjy

Small tractors were very handy around the tamp. This is an International with a Bueyrus-Erie dozer

A bridge like this was all in the days work

Combination gas, oil and grease truck

icing one of E. W. Elliott :2, Co.'s shovels

hours shifts. It got so we didn't dare pitch our tents near where the road was coming through, for fear the big electrically lighted tractors would crash in on us in the dark." This surveyor, by the way, revealed something of the complete isolation and vastness of the British Columbia wilderness by telling how he and his party had paddled canoes 236 miles along winding streams to get to their task, seeing only three cabins in the whole distance. Needless to say, this spectacular job involved many problems of automotive service and maintenance. Cold starting and crankcase dilution were serious problems, and motors were often kept running sometimes weeks at a time because of the difficulty of starting. Cold weather also played its tricks on metal parts, snapping off wheel spindles made of steel that gave no trouble in ordinary climates. Then there was lubrication failure, frozen and locked brake drums from passage through half-frozen fords, and all of the miscellaneous troubles that 33

"gang-up" on men and machine when temperatures drop. Take for example the welding of five hundred truck springs just an indication of the rough going and the arduousness of the job. Some five thousand motorized units were in use. The Army's equipment was

"Repair itrebuild itmanufacture it, if necessary!" in the slogan in Okra Construction Co.'s shop on Mean Highway. Here at the left Is a sprocket for a crusher drive which wan restored by welding broken and worn teeth. At the right is a home-made companion sprocket, rut from 1in. steel plate; it will be finished by inserting a splined bob, made from a 4-Inch-thick piece of

Motor

Service

July, 1943

35

Dowell Construction Co.'. Mean repair shop was also a "factory" for war-scarce part.. This fellow is threading a boltone of hundreds made from bar stock. Heads were forged on in the blacksmith shop

largely new, but that used by the contractors consisted of all makes and ages of used machinery, overhauled for the purpose. Often there were mechanical casualties, for this was no sissy job, and the Army considered the sacrifice of hundreds of machines a small price to pay for refinishing a road by winter. Tractors rolled down banks, truck frames buckled, axle housings were smashed riding ruts, and motor failures laid up many machines, but the vast majority were kept moving by the work of the men who operated the portable repair shops. Each regiment was responsible for the upkeep of its outfit, and most repairing was done right where the machines

broke down, using tool kits with which the regiment was equipped. Timber Aframes and tripods for lifting out engines or raising tractors for track repairs were a common sight along the road, and each regiment had a heavyduty wrecking truck, while additional hoisting equipment was constructed by setting up timber A-frames on front bumpers. In spite of an AA-2 priority rating, there was often a shortage of parts, but the order was to keep all units going as long as possible, the junking of units for spare parts being permitted only as a last resort. Convertible welding trailers were available, and welders who built up worn surfaces and restored broken parts were star performers. Small regiment repair shops worked wonders, rebuilding, converting, and making parts that could not be otherwise obtained. The size of the contractor equipment outlay is indicated by the fact that one management firm alone had over 1,400 major pieces of rolling equipment. In addition to their own outfits, this outfit was supplied with a great quantity of machinery transferred from CCC camps of the western states. Among these were 300 tractors equipped with scrapers, bulldozers or trailbuilders, 1,000 trucks, 125 air compressors with drilling accessories, 55 power shovels, 200 electric light plants, 65 portable repair shops, mixers, rollers, pumps, trailers and other equipment. The contractors also had the ad vantage of having many experienced operators, and they also had more elaborate central repair shops at their project headquarters. Typical of the well-equipped (but never large enough) repair aand machine shops was that of Okes Construction Company at Fort St. John. It included one 12 in. and two 16 in. lathes, a large and a smalldrill press, a surface grinder,

(Continued on page 82)

CHAMPION

SPARK PLUGS

The Champion Spark Plug Company is an independent company in the generally accepted business sense of that word. But in another and very real sense, our company is mutually interdependent with literally hundreds of other businesses. In the direct conduct of our business we are continually purchasing raw materials, M, supplies and services from a large number of companies. In our turn we sell to distributors and jobbers who perform indispensable sales functions for us. They, in their turn, distribute to the retailer whose business is directly with the public. In this cycle which so typifies the American free enterprise system, both large and small business are equally involved.

To Save Gasoline keep Spark Plugs Clean!

The simple facts are, all businesses, whether large or small, are interdependent. Recognition of this fact makes for harmony that spells maximum production at lowest cost and equable profits. It makes for mutually advantageous distribution of work and responsibility and above all, mutual respect and esteem upon which all long-term business relationships and successes are squarely based.

For Personal Security For National Security

BUY WAR BONDS and STAMPS

Motor Service

Barrett

Using Generator with Magnet Charger

Question: "I operate a magneto service station in connection with my tractor repairing. I received one of your magneto books, written by Jack Beater. "I have an Eisemann coil tester, a test bench built by American Bosch, and a Cowie Charger. I'm well satisfied with my equipment, and I'm using a storage battery with the charger. "In the booklet I received from you I see where a car generator works very satisfactorily. I would like some more definite instructions on how to make such a hook-up, the type of generator to use, wiring instructions, etc." Grant Chapman, Brook, Ind.

the field is grounded, and in that case the external wire would go from the F to the G post of the generator. The switch is not absolutely essential, but could be included, since when you shut down the motor that drives the generator, the current will automatically stop anyhow, and there is no battery in the circuit to discharge. Mr. Beater's book suggests approximately 18 amperes at 18 volts, and you could check this by inserting an ammeter at the place where the switch is shown and putting a voltmeter across the magneto charger terminals. A little higher voltage or greater current would do no harm, and a little less would merely make the charger slightly weaker.

LIMITATION ORDER L-270 SAYS YOU CAN BUY

BARRETT BRAKE NOW EQUIPMENT SERVICED

BARRETT DRAKE DRUM LATHE

BARRETT BRAKE SHOE DRUM GAUGES

I

.7.. . ,..... 2.12111 : l'... , ..... ,... ., ....,

A LIMITED NUMBER Of 'THESE

BARRETT

T OOLS

Answer: In Mr. Beater's book he suggests that a 6-volt generator of fairly large capacity be used. Possibly you can pick up one which was designed to be used with a voltage and current regulator, and in the sketch we have indicated such

MAGNET CHARGER <SWITCH

The Alcan highway

(Continued from page 34)

ARE AVAILABLE FOR. QUICK DELIVERIES

ruling, we will be pemitted to

N

GROUND CONNECTION ON GENERATOR FRAME

Circuit of generator and magnet charger

a generator. Of course, the regulator will not be needed, and the wire that ordinarily went from the Field post up to the Regulator, will be connected to generator frame. That is, it will be grounded. This is assuming the circuits are as shown. In some cases the internal connection of

large planer, milling machine, shaper, seven piston pin grinders, seven piston grinders, drum lathe, three portable electric welders (gas driven), electric-driven shop welder, four acetylene outfits, two steam cleaners, modern electrical test bench, portable hoist, armature lathe, two forges, greasing equipment to handle eight vehicles at once, and a 50 kw A.C. light plant. The shop was run on a 24-hour-a-day basis, and handled hundreds of novel repair and part making jobs. Yes, the Alcan Highway is finished, although it is just the start of one route from America to Tokyo. But the spirit which carried this job to completion is the same spirit that will finish the bigger job of restoring to America the safety of that freedom she so much cherishes.

(Photos courtesy Cater pillar Tractor Co. and of "Road & Streets." Harold McKeever i3 Associate Editor of this publication.)

Under a recent govern otter for sale to brake service shops, a limited number of the famous Barrett Brake Dokters, drum lathes, gauges, hone sets and reliners. Since our production is restricted, deliveries will be made according to priority received with order.

, .1!A k ,,,i. Mky,IR,I .,,,,, ,TA 2jk_s du.' YOUR Onxtes BRAKE SERVICE ACCESSORIES -- sM BARRETT... r ditiS ' ''''... 1'ho,""" b'4 c.,E,b0IC.,UI10,- h. HORSESHOE PLIERS stole 'N'nidert'ltt .11:'11,9:a.. R rro+e 'C"..osIselsto,ot eSHIMT.OCK

t'

PIINCH,,0112, 10,01,:S \ High quality vulacnized shim stock non-compressible.

,th,o,slle:torlIns 1, 1)1 '''I11y ,...cloastoble to ,

FRO

Co, co, shos peomg sondlof boloy cuttes Own 80110 EitaSe aws

'''.--:' BLEEDER MAD GRINDING WHEELS "jiffy" washers i:,..ob

p , no, os le en o n '41 lo mi .L7._..4 N: o: s /1 tifo1re's'yTtels"Nod'pett . '-'\...-. -1 '/Y

FIL

17Xe7elorsida.9ieertemk

CASS AVENUE AT 21st STREET * ST. LOUIS, MISSOURI

Sippor.o.c

Net

Das könnte Ihnen auch gefallen

- (Food) Apple Pie Recipe 2Dokument7 Seiten(Food) Apple Pie Recipe 2Steven HowellNoch keine Bewertungen

- Loving and Leaving: Sex Differences in Romantic Attachments 1Dokument15 SeitenLoving and Leaving: Sex Differences in Romantic Attachments 1Steven HowellNoch keine Bewertungen

- GE Electron Tubes Essential Characteristics WWDokument231 SeitenGE Electron Tubes Essential Characteristics WWSteven HowellNoch keine Bewertungen

- 50 Easy Things: That Will Actually Improve Your PostureDokument33 Seiten50 Easy Things: That Will Actually Improve Your PostureSteven HowellNoch keine Bewertungen

- Eu AtionsDokument1 SeiteEu AtionsSteven HowellNoch keine Bewertungen

- Does A Helping Hand Put Others at Risk - Affirmative Action, Police Departments, and Crime (2000) by John Richard Lott JRDokument39 SeitenDoes A Helping Hand Put Others at Risk - Affirmative Action, Police Departments, and Crime (2000) by John Richard Lott JRSteven HowellNoch keine Bewertungen

- 2011 Summer Academic Calendar: Maymester (Part of Term 0)Dokument2 Seiten2011 Summer Academic Calendar: Maymester (Part of Term 0)Steven HowellNoch keine Bewertungen

- Bis 1001 - Programming For Iphone, Ipod Touch, and Ipad DevicesDokument12 SeitenBis 1001 - Programming For Iphone, Ipod Touch, and Ipad DevicesSteven HowellNoch keine Bewertungen

- BIS 4523/6523 - Programming For Mobile DevicesDokument15 SeitenBIS 4523/6523 - Programming For Mobile DevicesSteven HowellNoch keine Bewertungen

- PDM: Rev:C ReleasedDokument2 SeitenPDM: Rev:C ReleasedSteven HowellNoch keine Bewertungen

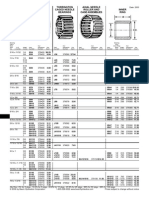

- Q36 Torrington Torrington Axial Needle Full Complement Caged Needle Roller and Inner Needle Bearings Bearings Cage Assemblies RingDokument1 SeiteQ36 Torrington Torrington Axial Needle Full Complement Caged Needle Roller and Inner Needle Bearings Bearings Cage Assemblies RingSteven HowellNoch keine Bewertungen

- Ad Remake PrevDokument18 SeitenAd Remake PrevSteven HowellNoch keine Bewertungen

- Silvertone 1485Dokument1 SeiteSilvertone 1485dodNoch keine Bewertungen

- Naca Report 49Dokument50 SeitenNaca Report 49Steven HowellNoch keine Bewertungen

- Grishchuk EPL5 2011 2Dokument10 SeitenGrishchuk EPL5 2011 2Steven HowellNoch keine Bewertungen

- (4HP40G1) - CAT PUMP: M&S Service Co. Inc. 1 March 2006Dokument3 Seiten(4HP40G1) - CAT PUMP: M&S Service Co. Inc. 1 March 2006Steven HowellNoch keine Bewertungen

- Fourier Transform PropertiesDokument1 SeiteFourier Transform PropertiesSteven HowellNoch keine Bewertungen

- Fourier Transform PairsDokument1 SeiteFourier Transform PairsSteven HowellNoch keine Bewertungen

- 06 Chapter 1Dokument55 Seiten06 Chapter 1Steven HowellNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 10 ĐỀ HSG ANH 9 + FILE NGHE + KEYDokument86 Seiten10 ĐỀ HSG ANH 9 + FILE NGHE + KEYHa TrangNoch keine Bewertungen

- Music in Chishti SufismDokument17 SeitenMusic in Chishti SufismkhadijaNoch keine Bewertungen

- Carollo Motion To StayDokument7 SeitenCarollo Motion To Stayal_crespoNoch keine Bewertungen

- Price Build UpsDokument22 SeitenPrice Build UpsFirasAlnaimiNoch keine Bewertungen

- Faith in GenesisDokument5 SeitenFaith in Genesischris iyaNoch keine Bewertungen

- History of Anthropology in India by Dr. Abhik GhoshDokument50 SeitenHistory of Anthropology in India by Dr. Abhik GhoshVishal hingeNoch keine Bewertungen

- Gyges RingDokument1 SeiteGyges RingCYRINE HALILINoch keine Bewertungen

- Housing Project Process GuideDokument52 SeitenHousing Project Process GuideLelethu NgwenaNoch keine Bewertungen

- Test Beca Week 6de8Dokument3 SeitenTest Beca Week 6de8Ninoshka EstradaNoch keine Bewertungen

- Bromelia in Bolivia Key Chiquitania PDFDokument10 SeitenBromelia in Bolivia Key Chiquitania PDFthrashingoNoch keine Bewertungen

- Configuring Srewquid Proxy ServerDokument4 SeitenConfiguring Srewquid Proxy ServerPendekar BlankNoch keine Bewertungen

- The Kurdistan Worker's Party (PKK) in London-Countering Overseas Terrorist Financing andDokument28 SeitenThe Kurdistan Worker's Party (PKK) in London-Countering Overseas Terrorist Financing andrıdvan bahadırNoch keine Bewertungen

- Week 5 6 Diass 3.0Dokument7 SeitenWeek 5 6 Diass 3.0Jonathan ReyesNoch keine Bewertungen

- Rolando Solar's Erroneous Contention: The Evidence OnDokument6 SeitenRolando Solar's Erroneous Contention: The Evidence OnLuis LopezNoch keine Bewertungen

- Basic Tax EnvironmentDokument8 SeitenBasic Tax EnvironmentPeregrin TookNoch keine Bewertungen

- Applicability of ESIC On CompaniesDokument5 SeitenApplicability of ESIC On CompaniesKunalKumarNoch keine Bewertungen

- Career Oriented ProfileDokument3 SeitenCareer Oriented ProfileSami Ullah NisarNoch keine Bewertungen

- University of Lagos: Akoka Yaba School of Postgraduate Studies PART TIME 2017/2018 SESSIONDokument5 SeitenUniversity of Lagos: Akoka Yaba School of Postgraduate Studies PART TIME 2017/2018 SESSIONDavid OparindeNoch keine Bewertungen

- Army Aviation Digest - Jan 1994Dokument56 SeitenArmy Aviation Digest - Jan 1994Aviation/Space History Library100% (1)

- Cover LetterDokument1 SeiteCover Letterapi-254784300Noch keine Bewertungen

- Malayalam International TransliterationDokument89 SeitenMalayalam International TransliterationSASHMIRA MENONNoch keine Bewertungen

- Classification and Use of LandDokument5 SeitenClassification and Use of LandShereenNoch keine Bewertungen

- Bishal BharatiDokument13 SeitenBishal Bharatibishal bharatiNoch keine Bewertungen

- File:///d - /... SER/Desktop/LABOR LAW/Cases/G.R. No. 196036, October 23, 2013 - ELIZABETH M..TXT (8/24/2020 9:55:51 PM)Dokument6 SeitenFile:///d - /... SER/Desktop/LABOR LAW/Cases/G.R. No. 196036, October 23, 2013 - ELIZABETH M..TXT (8/24/2020 9:55:51 PM)Russ TuazonNoch keine Bewertungen

- Who Am I NowDokument7 SeitenWho Am I Nowapi-300966994Noch keine Bewertungen

- ЛексикологіяDokument2 SeitenЛексикологіяQwerty1488 No nameNoch keine Bewertungen

- John Carroll University Magazine Winter 2008Dokument69 SeitenJohn Carroll University Magazine Winter 2008johncarrolluniversityNoch keine Bewertungen

- 01 - Quality Improvement in The Modern Business Environment - Montgomery Ch01Dokument75 Seiten01 - Quality Improvement in The Modern Business Environment - Montgomery Ch01Ollyvia Faliani MuchlisNoch keine Bewertungen

- Torrens System: Principle of TsDokument11 SeitenTorrens System: Principle of TsSyasya FatehaNoch keine Bewertungen

- KALIC J - Palata Srpskih Despota U Budimu (Zograf 6, 1975)Dokument9 SeitenKALIC J - Palata Srpskih Despota U Budimu (Zograf 6, 1975)neven81Noch keine Bewertungen