Beruflich Dokumente

Kultur Dokumente

PR 2303

Hochgeladen von

Karthik SrinivasOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PR 2303

Hochgeladen von

Karthik SrinivasCopyright:

Verfügbare Formate

Reg. No.

Question Paper Code : 55571

B.E./B.Tech. DEGREE EXAMINATION, NOVEMBER/DECEMBER 2011. Fifth Semester

Production Engineering

PR 2303 ENGINEERING STATISTICS AND QUALITY CONTROL (Regulation 2008) Time : Three hours

Use of statistical table permitted. Answer ALL questions.

1. 2. 3. 4. 5. 6. 7. 8. 9. 10.

What do you understand by TYPE-II error?

Define the term Operating-Characteristic curve. What do you mean by chance causes?

Define LTPD.

Differentiate between producers risk and consumers risk. Define latent defect.

What is reliability function? What do you understand by fractional-factorial design?

11.

(a)

19

(i)

Distinguish between controllable and uncontrollable variables with examples. PART B (5 16 = 80 marks) (6)

Outline the properties of a good point estimator.

(ii)

The output voltage of a power supply is assumed to be normally distributed. Sixteen observations are taken at random on voltage as shown below : 10.3 9.3 10.0 9.9 11.6 12.0 11.2 9.58 5 0 0 6 5 0 5

What do you understand by Cp index?

19

PART A (10 2 = 20 marks)

4 19

Maximum : 100 marks

11.5 4

9.9 5

10.2 8

8.3 7

10.4 4

9.25

9.38

10.8 5

Test the hypothesis that mean voltage equals 12V against two side alternative using = 0.05. Also construct a 95% two sided confidence interval on . (10) Or (b) (i) (ii) Compare Type-I and Type-II errors.

A new purification unit is installed in a chemical process. Before its installation, a random sample yielded the following data about the percentage of impurity : X1 = 9.85 and S12 = 81.73 and n1 = 10. After installation a random sample resulted in X2 = 8.08, 2 = 78.46 and n2 = 8. S2 Can you conclude that the two variances are equal? (Use = 0.05). Also can you conclude the new purification device has reduced the mean percentage of impurity? (Use = 0.05) (10)

12.

(a)

Outline the logic for the construction of control chart for count number of defectives. Or

(b)

(i) (ii)

Why X chart and R chart are used together.

19

Or 2

Control charts for X and R are to be established to control the tensile strength of a metal part. Assume that tensile strength is normally distributed. Thirty samples of size n= 6 parts are collected over a period of time with following results Xi = 6000 (i = 1 to 30) and Ri = 150 (i = 1 to 30). Calculate the control limit. If both charts are in control and specifications on tensile strength are 200 5 . What is your conclusion about process capability? (10)

13.

(a)

(b)

19

Find a single sampling plan for which p1 = 0.01, = 0.05, p2 = 0.10 and = 0.10. Suppose that lots of N = 2000 are submitted. Draw the AOQ and find AOQL.

Draw the primary and supplementary OC curves for a double sampling plan n1 = 50, c1 = 2, n2 = 100 and c2 = 6. If the incoming lots have fraction nonconforming p = 0.05, what is probability of

4 19

(6) (6)

55571

acceptance on first sample? What is probability of final acceptance? Calculate the probability of rejection on the first sample. 14. (a) (i) (ii) Explain the product life characteristics curve and how it can be used. (8) Discuss with suitable example, how the average failure rate over the time interval is computed? Differentiate cumulative failure rate curve from failure rate curve. Or (b)

4 19

55571

(8)

An automated production system consists of three operations: turning, milling and grinding. Individual parts are transferred from one operation to the next by robot. Hence, if one machine or robot fails the process stops. (i) If the reliabilities of the robot, turning center, milling machine and grinder are 0.98, 0.94, 0.98 and 0.90 respectively, what is the reliability of the system? (ii) Suppose that two grinders are available and the system does not stop if one fails. What is the reliability of the system? An article in industrial quality control describes an experiment to investigate the effect of glass type and phosphor type on the brightness of a television tube. The response measured is the current necessary (in micro amps) to obtain a specific brightness level. The data are shown here. Analyse the data and draw conclusions. Phosphor type Glass type 1

15.

(a)

4

28 0 29 0 28 5 2

19 4

(b)

A process engineer is trying to improve the life of a cutting tool. He has run a 23 experiment using cutting speed (A), Metal hardness (B)

19

1 2 3 30 0 31 0 29 5 26 0 24 0 23 5 29 0 28 5 29 0 22 0 22 5 23 0 23 0 23 5 24 0 Or 3

and cutting angle (C) as the factors. The data from two replicates are shown here. Run (1) a b ab c ac bc ab c Replicate I Replicate II (i) (ii) 22 1 31 1 32 5 43 5 35 4 34 8 55 2 47 2 44 0 45 3 40 6 37 7 60 5 50 0 39 2 41 9

Does any of the three factors affect tool life? What combination of factor levels produces the longest tool life?

19

4

4

55571

19

4 19

Das könnte Ihnen auch gefallen

- Materials Science and Technology of Optical FabricationVon EverandMaterials Science and Technology of Optical FabricationNoch keine Bewertungen

- At345 Quality Control and Reliability EngineeringDokument3 SeitenAt345 Quality Control and Reliability EngineeringRacherla Mega RaniNoch keine Bewertungen

- Reliablity AssignmentDokument11 SeitenReliablity AssignmentSwati Gadave-Chougule100% (1)

- Advanced Manufacturing ProcessDokument2 SeitenAdvanced Manufacturing Processmukesh3021Noch keine Bewertungen

- Problemas Bono para Tercer Examen de Estadística - Verano 2012Dokument8 SeitenProblemas Bono para Tercer Examen de Estadística - Verano 2012David Meza CarbajalNoch keine Bewertungen

- Engineering Design Process - EP60042Dokument2 SeitenEngineering Design Process - EP60042Abhishek RoyNoch keine Bewertungen

- 07a81002 RoboticsandautomationDokument8 Seiten07a81002 RoboticsandautomationSharanya ThirichinapalliNoch keine Bewertungen

- Ilffiiililt Il - T Ililt Iltil - ) Il IltlDokument2 SeitenIlffiiililt Il - T Ililt Iltil - ) Il IltlStanly KurianNoch keine Bewertungen

- MBA 1st Sem Model PapersDokument18 SeitenMBA 1st Sem Model PapersRahul CharanNoch keine Bewertungen

- GGL 2205 Geo-StatisticsDokument3 SeitenGGL 2205 Geo-StatisticslucyNoch keine Bewertungen

- 1252-Transducer Engineering Question PaperDokument5 Seiten1252-Transducer Engineering Question Papermoney_kandan2004100% (1)

- EC1255 Measurements and Instrumenation May/June 2009Dokument2 SeitenEC1255 Measurements and Instrumenation May/June 2009babajohn123Noch keine Bewertungen

- rr312002 Metrology and Quality ControlDokument8 Seitenrr312002 Metrology and Quality ControlSRINIVASA RAO GANTANoch keine Bewertungen

- AE 6702 Experimental Stress Analysis, Final Year, Department of Aeronautical Engineering, Model Exam QuestionsDokument1 SeiteAE 6702 Experimental Stress Analysis, Final Year, Department of Aeronautical Engineering, Model Exam QuestionsRAJANoch keine Bewertungen

- Measurement & Control Question PaperDokument4 SeitenMeasurement & Control Question Papersanjay_kajal7942Noch keine Bewertungen

- Final Year Mech QP May 2017Dokument59 SeitenFinal Year Mech QP May 2017gauravkumar bhandariNoch keine Bewertungen

- Industrial Engineering and Quality Control MSBTEDokument5 SeitenIndustrial Engineering and Quality Control MSBTEJaydip Jadhav100% (2)

- Mste 1Dokument6 SeitenMste 1nitish naramoniNoch keine Bewertungen

- STRUCTURED/ESSAY (100 Marks) : Page 2 of 10Dokument9 SeitenSTRUCTURED/ESSAY (100 Marks) : Page 2 of 10Iskandar IbrahimNoch keine Bewertungen

- Cre Sample Exam 1Dokument10 SeitenCre Sample Exam 1Karthik Suresh100% (1)

- BTME 2nd Year AssignmentDokument15 SeitenBTME 2nd Year AssignmentshishunalNoch keine Bewertungen

- Petroleum Training Institute, Effurun: Department of General StudiesDokument2 SeitenPetroleum Training Institute, Effurun: Department of General StudiesBright AjibadeNoch keine Bewertungen

- ONGC Exam Paper-2010 For Mechanical EngineerDokument31 SeitenONGC Exam Paper-2010 For Mechanical EngineerNisha SinghNoch keine Bewertungen

- PSR 1Dokument11 SeitenPSR 1Poornima TadikondaNoch keine Bewertungen

- Assignment Booklet: BTME ProgrammeDokument20 SeitenAssignment Booklet: BTME ProgrammeSarvanKumarNoch keine Bewertungen

- Question PaperDokument28 SeitenQuestion PaperVijayakumarNoch keine Bewertungen

- Final Exam, Data Mining (CEN 871) : Name Surname: Student's IDDokument2 SeitenFinal Exam, Data Mining (CEN 871) : Name Surname: Student's IDDimitrios A. KarrasNoch keine Bewertungen

- USN X, E/ Y: Experim N MechaDokument2 SeitenUSN X, E/ Y: Experim N Mechamusic lover oldNoch keine Bewertungen

- 9EH EoC Test 2013 No SolsDokument11 Seiten9EH EoC Test 2013 No SolsDanny EtieveNoch keine Bewertungen

- Aaoc C111 515 C 2009 2Dokument3 SeitenAaoc C111 515 C 2009 2Krishnamurthy AnantharamakrishnanNoch keine Bewertungen

- Question Paper Code: X 10700Dokument4 SeitenQuestion Paper Code: X 10700Anonymous dL8dsCncNoch keine Bewertungen

- InstrumentationDokument7 SeitenInstrumentationNagaValliNoch keine Bewertungen

- 2010 Oct QMT500Dokument8 Seiten2010 Oct QMT500Nurul Hidayah IbrahimNoch keine Bewertungen

- 2017 Final ExamDokument24 Seiten2017 Final ExamBi11y 1eeNoch keine Bewertungen

- BE ElectricalDokument45 SeitenBE ElectricalOmkar SheteNoch keine Bewertungen

- Gujarat Technological University: InstructionsDokument2 SeitenGujarat Technological University: InstructionsAmit PandeyNoch keine Bewertungen

- Quality Engg.Dokument16 SeitenQuality Engg.Nilankan KumarNoch keine Bewertungen

- RR420305 Robotics PDFDokument9 SeitenRR420305 Robotics PDFSarath ChandraNoch keine Bewertungen

- Qar Makeup 17Dokument3 SeitenQar Makeup 17psychshetty439Noch keine Bewertungen

- EPD2Dokument5 SeitenEPD2XXXNoch keine Bewertungen

- EAT 227 May 2015 ExamDokument7 SeitenEAT 227 May 2015 ExamΚωνσταντινος ΕυρουNoch keine Bewertungen

- Analogue II Exams Eee 2210 Mechatronics-PrintreadyDokument4 SeitenAnalogue II Exams Eee 2210 Mechatronics-PrintreadyMike ShakespeareNoch keine Bewertungen

- ME-mit Admission FormDokument1.057 SeitenME-mit Admission FormBittu50% (2)

- SQC TestDokument10 SeitenSQC Testendu wesenNoch keine Bewertungen

- 01feb2016-Industrial Robotics,Design With Advanced Materials,Applied Mathematics,Optical Communication Technology,Advanced Data Structures and Algorithm Analysis,Mathematical Modeling,Analysis OfDokument15 Seiten01feb2016-Industrial Robotics,Design With Advanced Materials,Applied Mathematics,Optical Communication Technology,Advanced Data Structures and Algorithm Analysis,Mathematical Modeling,Analysis OfsirapuNoch keine Bewertungen

- Total No of Questions: (8) Seat No.:: RZ - P V 11 CO-) I 0/ 'N CH Gen-)Dokument2 SeitenTotal No of Questions: (8) Seat No.:: RZ - P V 11 CO-) I 0/ 'N CH Gen-)sujitppawarNoch keine Bewertungen

- BE 2008 Electronics&Telecommunication PDFDokument71 SeitenBE 2008 Electronics&Telecommunication PDFcontrasterNoch keine Bewertungen

- Improving The Reliability of Mechanical Components That Have Failed in The Field Due To Repetitive StressDokument14 SeitenImproving The Reliability of Mechanical Components That Have Failed in The Field Due To Repetitive StresshuyvuNoch keine Bewertungen

- Linear and Dig Italic Applications Jntu Model Paper WWW Student Yogi Com 100113195343 Phpapp02Dokument8 SeitenLinear and Dig Italic Applications Jntu Model Paper WWW Student Yogi Com 100113195343 Phpapp02Ranjith ReddyNoch keine Bewertungen

- Quality Concepts in DesignDokument2 SeitenQuality Concepts in DesignThulasi Raman KowsiganNoch keine Bewertungen

- Modeling of Automatic Lathe Management SystemDokument7 SeitenModeling of Automatic Lathe Management SystemaffiahmatNoch keine Bewertungen

- MEMS (MTRX BRANCH) PREVIOUS YEAR QUESTION PAPER - SearchableDokument1 SeiteMEMS (MTRX BRANCH) PREVIOUS YEAR QUESTION PAPER - SearchableAk InventerNoch keine Bewertungen

- Met304 DDM SyllabusDokument10 SeitenMet304 DDM SyllabuselsonpaulNoch keine Bewertungen

- Final Year Mechanical Question Paper MAY 2018Dokument34 SeitenFinal Year Mechanical Question Paper MAY 2018gauravkumar bhandariNoch keine Bewertungen

- Sri Siddhartha Institute of Technology, Tumkur.: Answer Any Five Full QuestionsDokument2 SeitenSri Siddhartha Institute of Technology, Tumkur.: Answer Any Five Full QuestionswhatisnameNoch keine Bewertungen

- TE1Dokument498 SeitenTE1Smith KashidNoch keine Bewertungen

- S.E. 2012 (Mechanical, Mechanical Sandwich, Automobile)Dokument2 SeitenS.E. 2012 (Mechanical, Mechanical Sandwich, Automobile)Tejas AdakNoch keine Bewertungen

- r05320204 InstrumentationDokument6 Seitenr05320204 InstrumentationMounikaManuNoch keine Bewertungen

- Design and Implementation of Portable Impedance AnalyzersVon EverandDesign and Implementation of Portable Impedance AnalyzersNoch keine Bewertungen

- User Manual Guide - AN1020-20Dokument41 SeitenUser Manual Guide - AN1020-20Jaya ChandrikaNoch keine Bewertungen

- Pro/Desktop R/C Model Plane Engine: Created By: Tim Kaltenbach Clarion County Career CenterDokument42 SeitenPro/Desktop R/C Model Plane Engine: Created By: Tim Kaltenbach Clarion County Career CenterKarthik SrinivasNoch keine Bewertungen

- Autocad SymbolsDokument8 SeitenAutocad SymbolsSenchaa100% (1)

- Tutorial: Simulate In-Cylinder Premixed Combustion Using ECFM ModelDokument35 SeitenTutorial: Simulate In-Cylinder Premixed Combustion Using ECFM ModelKarthik Srinivas100% (1)

- Proe Animations - Guide For Me170Dokument8 SeitenProe Animations - Guide For Me170Karthik SrinivasNoch keine Bewertungen

- FLUENT IC Tut 03 Direct InjectionDokument38 SeitenFLUENT IC Tut 03 Direct InjectionKarthik Srinivas100% (2)

- FLUENT IC Tut 04 PremixedDokument36 SeitenFLUENT IC Tut 04 PremixedKarthik Srinivas100% (2)

- FLUENT IC Tut 01 Hybrid ApproachDokument30 SeitenFLUENT IC Tut 01 Hybrid ApproachKarthik Srinivas100% (2)

- FLUENT IC Tut 01 Hybrid ApproachDokument30 SeitenFLUENT IC Tut 01 Hybrid ApproachKarthik Srinivas100% (2)

- FLUENT IC Tut 02 Layering ApproachDokument29 SeitenFLUENT IC Tut 02 Layering ApproachKarthik Srinivas100% (1)

- Project Feasibility ReportDokument8 SeitenProject Feasibility ReportKarthik SrinivasNoch keine Bewertungen

- Radial Ball Bearings - 316 StainlessDokument7 SeitenRadial Ball Bearings - 316 StainlessKarthik SrinivasNoch keine Bewertungen

- Friction Stir Welding Process Optimization: Experimental MethodsDokument2 SeitenFriction Stir Welding Process Optimization: Experimental MethodsKarthik SrinivasNoch keine Bewertungen

- X-Ray Diffraction For Phase IdentificationDokument2 SeitenX-Ray Diffraction For Phase IdentificationKarthik SrinivasNoch keine Bewertungen

- PC Based Remote Material Handler For Industrial Application: SynopsisDokument4 SeitenPC Based Remote Material Handler For Industrial Application: SynopsisKarthik SrinivasNoch keine Bewertungen

- Agv and Fire Fighting Vehicle: SynopsisDokument4 SeitenAgv and Fire Fighting Vehicle: SynopsisKarthik SrinivasNoch keine Bewertungen

- 6.3 Chi Squared - TestDokument7 Seiten6.3 Chi Squared - TestTahmina KhatunNoch keine Bewertungen

- Statistics and Probability MathComDokument5 SeitenStatistics and Probability MathComZaldy Roman MendozaNoch keine Bewertungen

- Statistics and ProbabilityDokument5 SeitenStatistics and ProbabilityTrisTan Dolojan0% (1)

- Analisis BivariatDokument2 SeitenAnalisis Bivariatmaitato afriansyahNoch keine Bewertungen

- Co VariateDokument30 SeitenCo Variateastari rahmaditaNoch keine Bewertungen

- Review-Validation of QSAR Models-Strategies and ImportanceDokument9 SeitenReview-Validation of QSAR Models-Strategies and Importancecarlos ArozamenaNoch keine Bewertungen

- SPSS Assignment 3 1.: Paired Samples TestDokument2 SeitenSPSS Assignment 3 1.: Paired Samples TestDaniel A Pulido RNoch keine Bewertungen

- Detection of Multiple Change Points From Clustering Individual ObservationsDokument13 SeitenDetection of Multiple Change Points From Clustering Individual ObservationsAlexandre HesslerNoch keine Bewertungen

- SNU Assignment 1Dokument3 SeitenSNU Assignment 1Deepanshu SharmaNoch keine Bewertungen

- Stats Final ExamDokument7 SeitenStats Final ExamPaul BandolaNoch keine Bewertungen

- MMS 2022-24 QP Business StatisticsDokument5 SeitenMMS 2022-24 QP Business StatisticsnimeshnarnaNoch keine Bewertungen

- T TestDokument16 SeitenT TestMohammad Abdul OhabNoch keine Bewertungen

- DAY Temperature (X) Total Sales (Y) X 2 y 2 XyDokument4 SeitenDAY Temperature (X) Total Sales (Y) X 2 y 2 Xydaniel naoeNoch keine Bewertungen

- Mar3613 Marketing Research HW 4Dokument12 SeitenMar3613 Marketing Research HW 4api-620252953Noch keine Bewertungen

- Elementary StatDokument15 SeitenElementary StatGeralyn T. FamilganNoch keine Bewertungen

- Online Shopping Sales Infographics by SlidesgoDokument6 SeitenOnline Shopping Sales Infographics by SlidesgoLohith AnjaanNoch keine Bewertungen

- Thesis With Anova TableDokument5 SeitenThesis With Anova Tablesew0m0muzyz3100% (2)

- BDA 09 Shridhti TiwariDokument12 SeitenBDA 09 Shridhti TiwariShrishti TiwariNoch keine Bewertungen

- Introduction To Item AnalysisDokument6 SeitenIntroduction To Item AnalysisGultaj BangashNoch keine Bewertungen

- Monitoreo de Perfiles: Rubén Darío Guevara GonzálezDokument17 SeitenMonitoreo de Perfiles: Rubén Darío Guevara GonzálezRoceguNoch keine Bewertungen

- 2020-3-Pen-Jit SinDokument3 Seiten2020-3-Pen-Jit SinKeertana SubramaniamNoch keine Bewertungen

- 1935510219+edwin Thungari Macpal+ Experiment2Dokument14 Seiten1935510219+edwin Thungari Macpal+ Experiment2EDWIN THUNGARINoch keine Bewertungen

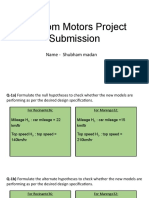

- Random Motors Project Submission: Name - Shubham MadanDokument10 SeitenRandom Motors Project Submission: Name - Shubham MadanShubham MadanNoch keine Bewertungen

- Practice of Statistics For Business and Economics 4th Edition Moore Solutions ManualDokument19 SeitenPractice of Statistics For Business and Economics 4th Edition Moore Solutions Manualkerenzavaleriehed0100% (26)

- GARCH - Tutorial and Excel SpreadsheetDokument4 SeitenGARCH - Tutorial and Excel SpreadsheetAjinkya AgrawalNoch keine Bewertungen

- Full Factorial (Minitab 1)Dokument3 SeitenFull Factorial (Minitab 1)Muhammad Fauzan Ansari Bin AzizNoch keine Bewertungen

- E 876-89-Estadistica-1Dokument17 SeitenE 876-89-Estadistica-1Mariela TurciosNoch keine Bewertungen

- Biostatistics An Applied Introduction For The Public Health Practitioner 1st Edition Bush Test BankDokument7 SeitenBiostatistics An Applied Introduction For The Public Health Practitioner 1st Edition Bush Test Bankjoanneesparzagwjxmyqont100% (37)

- Cluster SamplingDokument22 SeitenCluster Samplingrhena malahNoch keine Bewertungen

- Understanding Penalty AnalysisDokument5 SeitenUnderstanding Penalty AnalysisSushil BarabariNoch keine Bewertungen