Beruflich Dokumente

Kultur Dokumente

Alternative Low GWP MAC Refrigerants

Hochgeladen von

Cheung Wai Man StephenOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Alternative Low GWP MAC Refrigerants

Hochgeladen von

Cheung Wai Man StephenCopyright:

Verfügbare Formate

Alternative Low GWP MAC Refrigerant Blends

N. COX (a), V. MAZUR (b), D. COLBOURNE (c) (a) Earthcare Products Limited, 405 Mill Studio, Crane Mead, Ware, Herts. SG12 9PY, UK njc@earthcareproducts.co.uk (b) Department of Thermodynamics, Academy of Refrigeration, 1/3 Dvoryanskaya Street, 65082 Odessa, Ukraine (c) Re-phridge, PO Box 4745, Stratford-upon-Avon, Warwickshire CV37 1FE, UK

Abstract ECP744 is a near azeotrope which shows promising improvements in system efficiency compared to pure R744, whilst also operating at significantly lower pressures. It is considered to be particularly applicable to vehicle air conditioning equipment. The improvement in efficiency is a significant benefit, but the main commercial benefit arises from the reduced pressure (compared to R744). Since the major problem for R744 refrigeration systems is the high pressure which increases leakage despite the use of considerably more aluminium material for the equipment. The use of lower pressure ECP744 refrigerant will overcome this problem, reducing leakage and the weight of aluminium required. Furthermore, it is understood that the CO2 content of ECP744 is sufficiently diluted to overcome the US EPA toxicity objections to the use of R744 in MAC applications.

1. Introduction The EU MAC directive is unprecedented in so far as it legislated for the phase out of an environmentally damaging substance before acceptable alternatives were available on the market. Given the opportunities that this presents for not in kind technologies it is disappointing that so few alternatives are actively being considered: Flammable Options: 1. 2. 3. 4. R290 / R600a blends RE170 - DME R152A R1234yf Tetrafluorpropene

Non- flammable Options: 1. 2. R744 ECP744 - R744 / R41

What ever happened to heat driven cycles, air cycle or Stirling cycles for MAC applications?

2. Flammable Options 2.1 R290 / R600a blends Conversions of car air conditioners from fluorocarbon to hydrocarbon refrigerant commenced in Idaho, USA during 1992. Today over 10 million car air conditioners worldwide have been converted, about half of these in North America and over 20 million user years have accumulated. Almost all of these have been drop-in

conversions usually costing less than 50. Panama, Indonesia, Korea, Philippines and China also have many systems with drop-in HC MAC charges. The following now have ASHRAE designation: R436A - R290/R600a (56.0/44.0) R436B - R290/R600a (52.0/48.0)

2.2 RE170 DME Dimethylether (RE170, DME) makes a better refrigerant than R290 / R600a blends as it has no temperature glide and doesnt separate during leakage. It has been extensively adopted by the aerosol industry as the most cost effective replacement for R12 and R134A in propellant applications. There are many recognised blends containing DME, most notably: R723 - R717 / RE170 (60.0 / 40.0) R510A - RE170/R600a (88.0/12.0) R429A - RE170/R152a/R600a (60.0/10.0/30.0) R432A - R1270/RE170 (80.0/20.0) R435A - RE170/R152a (80.0/20.0) There is no evidence to suggest that any of these blends would perform better as a MAC refrigerant than DME itself.

2.3 HFC R152A It must be remembered that the GWP limit of 150 set by the EU for MAC applications was not chosen on the advice of climate scientists as a safe GWP, but to accommodate lobbying by the MAC industry to allow the use of R152A, so it seems rather churlish that none of the MAC manufacturers now wish to use it! The problem is, that at a practical level, the safety requirements for A2 refrigerants are little different to A3 refrigerants and the early adoption of R152A would have opened the door for cheaper and more efficient hydrocarbon alternatives. ASHRAE has recognised two R152A blends: R430A - R152a/R600a (76.0/24.0) R431A - R290/R152a (71.0/29.0) There is no evidence to suggest that either of these blends would perform better as a MAC refrigerant than R152A itself. However, a mixture of 82.6% HFC134A and 17.4% HFC152A is non-flammable and shows an increase in COP of 2.7% over HFC134A. It is interesting to speculate that had the MAC industry offered to adopt this blend together with a voluntary agreement to reduce leakage then perhaps the MAC directive could have been avoided altogether, but that opportunity has now passed!

2.4 HFC1234yf Tetrafluorpropene The great benefit of R1234 is that it requires relatively little fire suppressant to make it non-flammable. With the benefit of hindsight, the producers should have used fluoroketones or fluoroethers as fire suppressants but instead opted for CF3I, trifluoroiodomethane. This is used by the US Air Force as a fire suppressant and high altitude emissions have been found to be ozone depleting so its use in MAC refrigerants is not permitted. But instead of returning to the laboratory to test other fire suppressants, the producers decided that it would be easier to amend the safety regulations! Thus any benefit to be derived from the use of R1234 rather than the other flammable options is entirely dependant on the creation of a new refrigerant category A2L. There are already precedents for the manipulation of refrigeration safety standards for the commercial benefit of those lobbying

for the changes and the European Commission has to date declined to investigate, but this practice demeans not only those who engage in it, but also our industry as a whole, so perhaps on this occasion it will be stopped? In an almost surreal about face, the F Gas lobby is now complaining that environmental NGOs are showing scaremongering videos on the internet demonstrating the flammable effects of R1234. This is highly ironic, given that the F Gas lobby has been using the same tactic for over 15 years to keep hydrocarbons out of the market!

3.

Non- flammable Options

3.1 R744 Carbon Dioxide Used as a refrigerant since 1862, until the advent of halocarbons in the 1930s led to its decline, CO2 finally went out of use in the 1950s. Recent developments suggest that the time is now right for its reapplication with modern technology as a MAC refrigerant. Much of the criticism directed against R744 is unwarranted. Specifically, attempts to ban its use as a MAC refrigerant on toxicity grounds are difficult to justify, except as a trade protectionist measure. However, there are a number of legitimate concerns: The very high pressure may result in higher leakage rates The increased mass of aluminium required adds to cost and weight There is a disproportionate reduction in capacity and efficiency at very high ambient temperatures

3.2 ECP744 - R744 / R41 One approach to overcome these shortcomings is to blend R744. The R744 / R41 (fluoromethane) mixture known as ECP744 is considered to be the optimum solution. Figure 1 illustrates the phase behaviour of ECP744 in the temperature range -50C to +50C. In the temperature-concentration range of interest a temperature glide of less than 2C is observed, corresponding to near azeotropic (quasi-azeotropic) behaviour. This makes the blend attractive as a practical refrigerant. To construct a thermodynamic model of ECP744, the Peng-Robinson equation of state (EoS) was applied. The results are superimposed on Figure 1. For each set of predicted isotherms the upper line indicates the pressure of the saturated liquid (also known as the bubble-point) at the temperature, T, and the lower line indicates the pressure of the saturated vapour (also known as the dew-point). Each set of curves are isotherms for -50C, 0C, +30C, +35C and +50C. This temperature range represents the approximate limits of the anticipated operating conditions. A performance evaluation was carried out in order to determine the preferred composition and to compare its efficiency and capacity. Further considerations include maintaining as high a critical temperature as possible, minimising temperature glide and achieving the highest COP. System performance evaluations with a detailed system model were carried out at European rating conditions, which revealed the following: Both evaporating and condensing capacity increase notably as R744 composition increases. There is a notable reduction in both heating and cooling COP as R744 composition increases. Evaporating and condensing temperatures show little variation across the range of compositions, whereas discharge temperature rises slightly with higher R744 composition.

Experimental data

-28OC

Figure 1: ECP744 phase equilibria In order to evaluate the ECP744 mixture, it was compared against pure R744, since their thermodynamic characteristics are similar. Of primary interest is the COP, which was compared over a range of operating conditions (evaporator air-on temperature, and condenser air-on temperature). In particular, it was of interest to consider both sub-critical and trans-critical operation, so consideration was also given to the gas-cooler pressure. Figure 2 presents the cooling COP (for air-conditioning application) of ECP744 and pure R744 against the gas cooler pressure, since the operation is mostly above the critical point. At a gas cooler air-on temperature of 39C, it is seen that ECP744 achieves its highest COP at about 8,000 kPa, whilst pure R744 does not reach its peak CO2 until some 12,000 kPa. Furthermore, the COP of ECP744 is about 10% higher than that of the pure CO2. When the entering temperature is at 27C, the highest COP of pure R744 is 1.7 at just under 8,000 kPa, but ECP744 is still operating in sub-critical operating, achieving a COP of 2.0.

2.5 R41/R744 (subcritical) 2.0 Cooling COP (-) . CO2 1.5 R41/R744 1.0 0.5 0.0 6000 air-on = 39C CO2 air-on = 27C

8000

10000

12000

14000

16000

Gas cooler pressure (kPa)

Figure 2: COP comparison between CO2 and ECP744 over a range of pressures and temperatures Figure 3 shows the variation in cycle COP over a wide range of condenser air-on temperatures, and in transcritical mode, the ideal high side pressure, i.e., the system controller is assumed to modulate the gas cooler pressure to optimise COP. For both refrigeration and air conditioning application temperatures, ECP744 produces a notably higher COP than pure R744, both under sub-critical and transcritical operating conditions. It is also noted that as the operating conditions approach the critical point of R744, and until after the critical point of the R41/R744, there is a significantly greater difference between the COPs.

4 R41/R744 Maximum COP (-) . 3 CO2 R41/R744 2 transcritical (R41/R744) CO2 transcritical (CO2) 0 10 20 30 40 Condenser/gas cooler air-on temperature (C) air conditioning (Tair = +15C) refrigeration (Tair = 0C)

Figure 3: Comparison of maximum COP between CO2 and ECP744 under sub-critical and transcritical operation When considering the difference between the optimum gas cooler pressure of the two refrigerants the important distinction is that ECP744 requires some 3,000 kPa lower operating pressure than pure R744. A commercial benefit arises from this reduced high-side pressure, allowing a larger number of standard refrigeration components to be used, and the use of silver soldered joints with seamed mild steel pipe without incurring the penalty of the relatively high refrigerant leakage rates observed with most pure R744 systems. Figure 4 shows the ECP744 Liquid Vapour Composition data and demonstrates that any preferential permeation / leakage of the more volatile R744 would be minimal, and certainly insufficient to make the remaining charge flammable.

Figure4: ECP744 Liquid Vapour Composition data

A summary of the characteristics of ECP744 is provided in Table 1. Table 1: Characteristics of ECP744 Name Composition (molar) Molar Mass NBP (C) Critical temp (C) Freezing temp (C) Likely safety class ODP GWP (100) ECP744 50% R744, 50% R41 39.0 -84.5 37.9 -121 A1 0 46

Figure 5 shows the P H diagram for ECP744

Figure 5: ECP744 P H diagram

Figure 6 shows the comparison of evaporation heat for the ECP744 and R744

600

500

HV-HL, kJ/kg

400

R41 ECP744 R744

300

200

100 0 1 2 3 4 5

Saturation pressure, MPa Figure 6: Comparison of evaporation heat for the ECP744 and R744

Figure 7 shows the Saturation curves of the ECP744, R744, and R41

R744 R41 ECP744 bubble point line ECP744 dew point line

Pressure, MPa

0 -100

-80

-60

-40

-20

20

40

60

Temperature, OC Figure7: Saturation curves of the ECP744, R744, and R41

ECP744 is a near-azeotrope which shows promising improvements in system efficiency compared to pure R744, in both sub-critical and transcritical operations, whilst also operating at significantly lower pressures. It is considered to be particularly applicable to vehicle air conditioning equipment and it offers notable advantages over R744 for the following reasons: 1. 2. 3. At low temperatures the heat of evaporation ECP744 is app. 10% higher than R744, corresponding to the proportional gain in the COP at equal compressor power ( Fig. 6) A significant pressure decreasing in evaporator and shift of freezing point to lower temperatures (Fig. 7) The higher critical temperature of ECP744 which gives advantages at both subcritical and supercritical conditions

References 1. 2. 3. UNEP. 2006 Report of the Refrigeration, Air Conditioning and Heat Pumps Committee. United Nations Climate Change 2007:The Fourth Assessment Report of the IPCC Cox, N and Mazur V. Is CO2 The Natural Alternative To R410A Or Are There Other Options? 7th IIR Gustav Lorentzen Conference on Natural Working Fluids, Trondheim (2006) 4. Cox, N. Working Towards More Environmentally Friendly Refrigerant Blends, 12th European Conference, United Nations UNEP, Centro Studi Galileo, Associazione Tecnici del Freddo, Milan (2007) 5. Mazur V. Optimum refrigerant selection for low temperature engineering. In: Kakac S, editor. LowTemperature and Cryogenic Refrigeration. Kluwer Academic Publishers; 2003. p. 101118. 6. Lemmon, EW, Huber, ML, McLinden, MO. NIST Reference Fluid Thermodynamic and Transport Properties REFPROP. Version 8.0. National Institute of Standards and Technology, Boulder, USA. 2007. 7. ISO 817: 2007, Refrigerants Designation and Safety Classification. BSI, London. 2007. 8. Artemenko S., Mazur V. Azeotropy in the natural and synthetic refrigerant mixtures, Int. J. Refrigeration (2007), v.30, pp. 831 839 doi:10.1016/j.ijrefrig.2006.11.010 9. N. Cox, V. Mazur, D. Colbourne, The Development Of A Quasi-Azeotropic Refrigerant For Commercial PointOf-Sale Refrigeration And Vehicle Air Conditioning, 8th IIR Gustav Lorentzen Conference on Natural Working Fluids, Copenhagen, 2008 10. N. Cox, V. Mazur, D. Colbourne, New High Pressure Low GWP Refrigerant Blends, the Institute of Refrigeration, Solihull, 2008

Acknowledgement The authors would like to acknowledge Earthcare Products Ltd and the Odessa State Academy of Refrigeration in the Ukraine for the resources to complete this work.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Ongc BopDokument385 SeitenOngc BopFSTNoch keine Bewertungen

- pb3-06 510series Broc QX PDFDokument8 Seitenpb3-06 510series Broc QX PDFJaime LondoñoNoch keine Bewertungen

- Critical properties of elements and compoundsDokument2 SeitenCritical properties of elements and compoundsWulfranoSánchezNoch keine Bewertungen

- Mechanics and Thermodynamics of PropulsionDokument45 SeitenMechanics and Thermodynamics of PropulsionSrinivasan MuthuvelNoch keine Bewertungen

- Stable Versus Thermal Minimum Continuous Flow For Centrifugal PumpsDokument3 SeitenStable Versus Thermal Minimum Continuous Flow For Centrifugal PumpssatstarNoch keine Bewertungen

- FLOW SERVE InstruktionPlan52 - 53Dokument8 SeitenFLOW SERVE InstruktionPlan52 - 53Angel ManuelNoch keine Bewertungen

- Sieve Tray Rating Data Registered To: PAVAN, ZEPPELIN KG-TOWER® Version 5.0Dokument1 SeiteSieve Tray Rating Data Registered To: PAVAN, ZEPPELIN KG-TOWER® Version 5.0Pavan KumarNoch keine Bewertungen

- Uop-1 Mid Sem 2Dokument65 SeitenUop-1 Mid Sem 2ShreyaDixitNoch keine Bewertungen

- Head Losses in Pipes: NomenclatureDokument2 SeitenHead Losses in Pipes: NomenclatureAudrey Patrick KallaNoch keine Bewertungen

- Heat Recovery Steam Generator (HRSG) - Chemical EngineeringDokument3 SeitenHeat Recovery Steam Generator (HRSG) - Chemical EngineeringMahmoud RagabNoch keine Bewertungen

- Global Warming: Air Is The Name Given To Atmosphere Used inDokument15 SeitenGlobal Warming: Air Is The Name Given To Atmosphere Used insamoooonNoch keine Bewertungen

- Manual Stooper BagDokument2 SeitenManual Stooper Bagnasser saldaña quinteroNoch keine Bewertungen

- Industrial 501 KDokument8 SeitenIndustrial 501 K'Izzad AfifNoch keine Bewertungen

- Modelling of Natural Gas Sweetening and Dehydration Prior To LiquefactionDokument10 SeitenModelling of Natural Gas Sweetening and Dehydration Prior To LiquefactionAhmed ShaepNoch keine Bewertungen

- Hydraulic Machines - TurbinesDokument52 SeitenHydraulic Machines - Turbinesxyz100% (1)

- Modeling and optimization of a vortex tube for cooling applicationsDokument5 SeitenModeling and optimization of a vortex tube for cooling applicationsemir123456Noch keine Bewertungen

- Tecum Refrige Matrix Na enDokument1 SeiteTecum Refrige Matrix Na enAZERTY AZERTYNoch keine Bewertungen

- Crane FS FM463 FA463 FM466 Wafer Check Valves IOM 1020Dokument2 SeitenCrane FS FM463 FA463 FM466 Wafer Check Valves IOM 1020Septiana DamayantiNoch keine Bewertungen

- Turbine Types & Working ComparisonDokument13 SeitenTurbine Types & Working Comparisonumarmanan100% (1)

- Hydraulics: Prepared by Ajesh Kumar.T Si/FireDokument18 SeitenHydraulics: Prepared by Ajesh Kumar.T Si/FireSuriya Das100% (2)

- physics reddytubeDokument4 Seitenphysics reddytubepp2922192Noch keine Bewertungen

- BEMS Point Diagram UC PG 6Dokument1 SeiteBEMS Point Diagram UC PG 6psn_kylmNoch keine Bewertungen

- 7 E's DLL-Gas LawDokument3 Seiten7 E's DLL-Gas Lawcharish catungalNoch keine Bewertungen

- Dead Weight Pressure Gauge TestersDokument2 SeitenDead Weight Pressure Gauge Testersmhatresameer0% (1)

- CryoTiger Gas PT-30Dokument7 SeitenCryoTiger Gas PT-30Chacha ScribdNoch keine Bewertungen

- Pumps Catalog en PDFDokument36 SeitenPumps Catalog en PDFHABIB PIRZADANoch keine Bewertungen

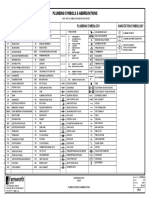

- Plumbing Symbols & AbbreviationsDokument8 SeitenPlumbing Symbols & AbbreviationsThel Cruz100% (1)

- Separation of AirDokument46 SeitenSeparation of AirbhargavNoch keine Bewertungen

- Effect of Lean Amine Temperature on Gas SweeteningDokument5 SeitenEffect of Lean Amine Temperature on Gas SweeteningYorman Zambrano SilvaNoch keine Bewertungen

- Lift PDFDokument15 SeitenLift PDFGuillermo LedezmaNoch keine Bewertungen